MX5 Berkeley to MEV Exocet projec

Discussion

Turn7 said:

Photobucket - destroying forum thread history across the web.

Bunch of twunts.

Absolutely - I have spent a few hours so far redoing the images back to the point I decided the car was becoming a kit on here (and the other forums I have been posting on) - will try and get the rest done too at some point - but it is just depressing now to see all of that information across so many forums just missing so many of their images...Bunch of twunts.

I have done this as it is a work in progress and I am still adding to the thread - but I can see why you wouldn't bother with going back and doing historical builds - it does take some time!

Thanks again for all the positive comments - as you will see from the earlier posts here, I was actually a bit unsure whether to go down the kit route or try and save this car, but I am pleased that I have done it now, as I am enjoying the build process, and I think that I will end up with a much better finished end result that if I had tried to weld up the car myself - and it is nice to have something that will be pretty unique too! I have had a look at the BRM thread too - interesting to see a possible workaround on there, although I wonder how long it will be until they get wise to that one? When I have a quiet evening again, I will try to work through and redo the early part of the thread (I have the pictures hosted on flickr - just need to sort the links)

I have made a little more progress over the weekend - I have bled up the brakes, and they all seem to work ok (it is very nice to be able to bleed all 4 brakes with the car on the ground and with the wheels in place!) - just need to p-clip the hoses into place now to make sure they are all ok for IVA.

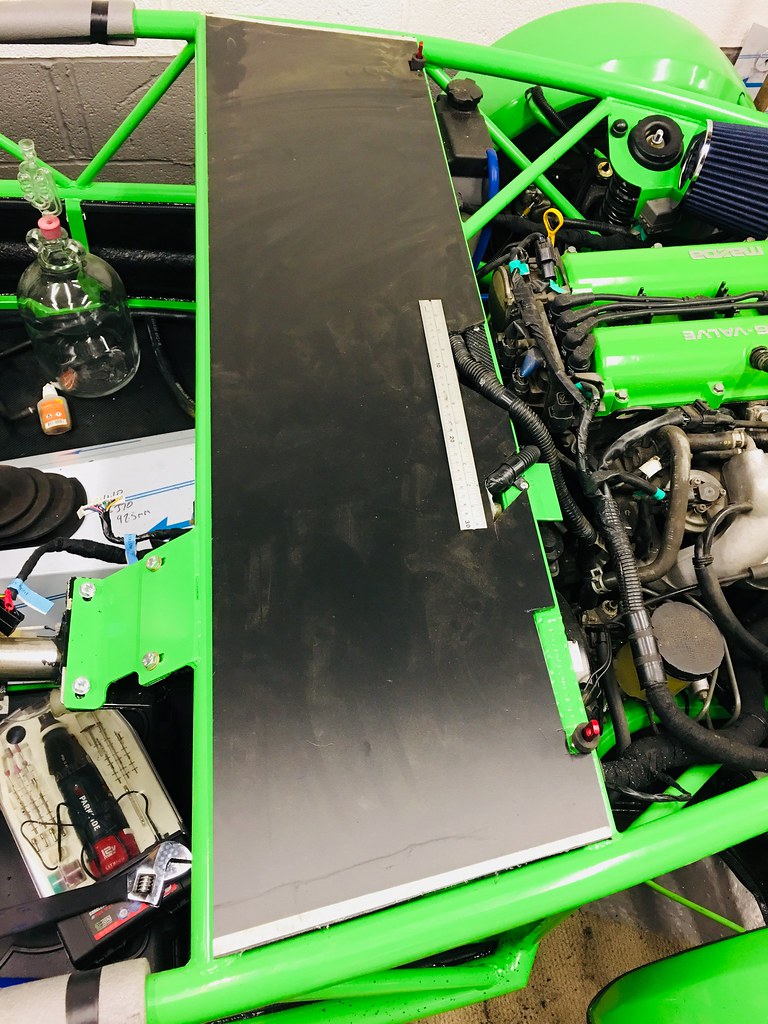

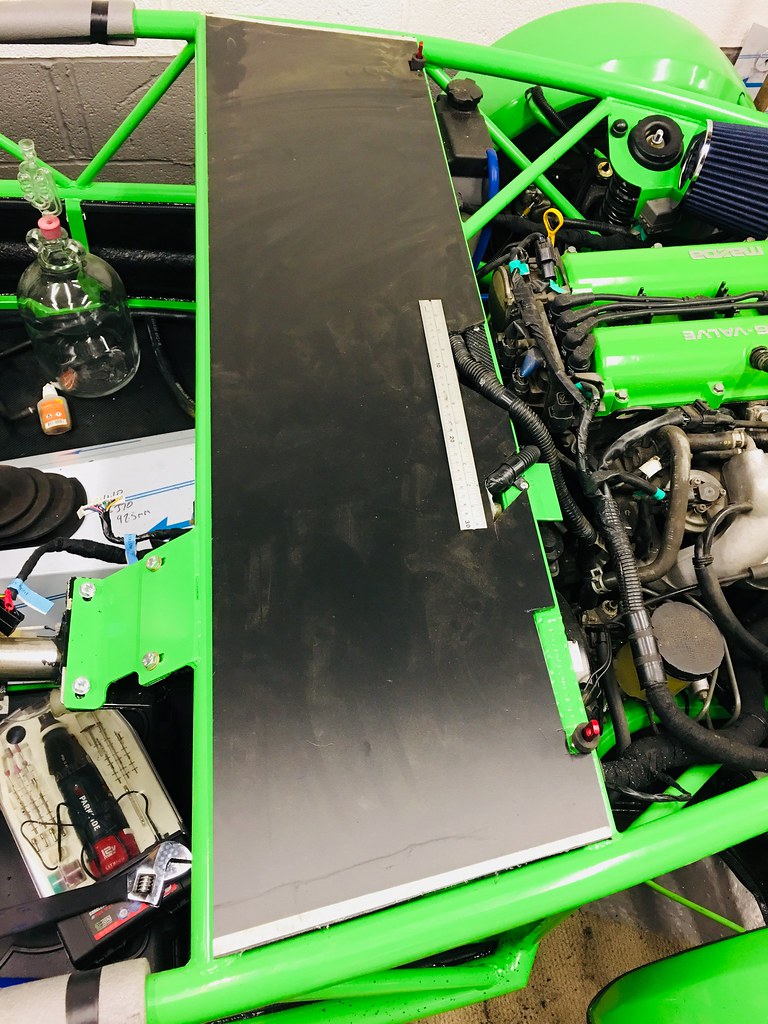

I have also taken a look at what I want to do to fit the radiator. I have the MEV brackets, but since everything else on the car is either green or black, I wasn't sure about having bare alloy on show, so I had a go with teh carbon vinyl - which I am quite pleased with, but am unsure how the heat might affect it. I think I might go with this to begin with and if it looks ropey I can always whip them off and give them a lick of paint... ( I am assuming that I may also need some edge trim to finish this off too)

radiator bracket on Flickr

radiator bracket on Flickr

I have made a little more progress over the weekend - I have bled up the brakes, and they all seem to work ok (it is very nice to be able to bleed all 4 brakes with the car on the ground and with the wheels in place!) - just need to p-clip the hoses into place now to make sure they are all ok for IVA.

I have also taken a look at what I want to do to fit the radiator. I have the MEV brackets, but since everything else on the car is either green or black, I wasn't sure about having bare alloy on show, so I had a go with teh carbon vinyl - which I am quite pleased with, but am unsure how the heat might affect it. I think I might go with this to begin with and if it looks ropey I can always whip them off and give them a lick of paint... ( I am assuming that I may also need some edge trim to finish this off too)

radiator bracket on Flickr

radiator bracket on FlickrCheers - the replicar is a nice looking thing, and the good news is (from the MEV forums), that new owners, ANC sports cars are going to be up and running soon, and are working on building an initial demo car...

Agree that real carbon would be nice - I did consider it (and am still wondering about it for the side panels!) - but it isn't cheap, and I wondered how it might fare long-term for floor panels... I do have some carbon sheet that I will certainly be using it in some places on the car!

I have not been doing as much as I would have liked over the last couple of weeks, but have got a few bits done (I have also been getting my mini prepped for a rolling road setup, which has involved swapping carbs over and tweaking some bits).

Firstly, having bought a rivnut tool, I fitted the radiator, which looks good - with the vinyl working well (we will see how that lasts once it has got hot):

Radiator fitted on Flickr

Radiator fitted on Flickr

Radiator fitted on Flickr

Radiator fitted on Flickr

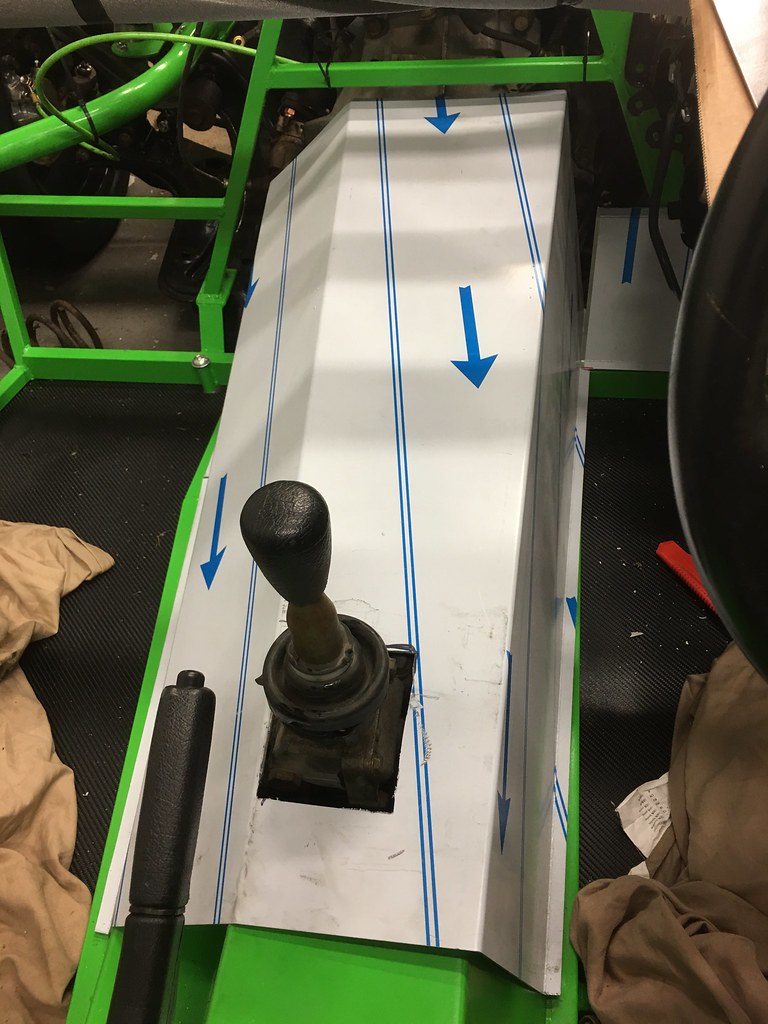

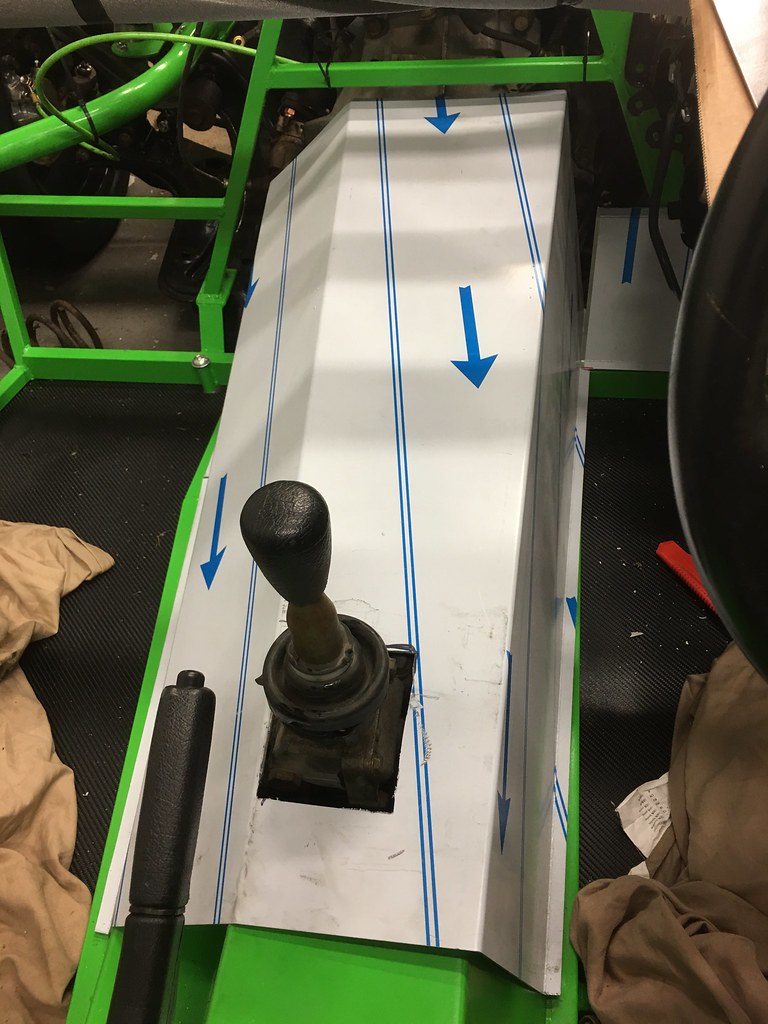

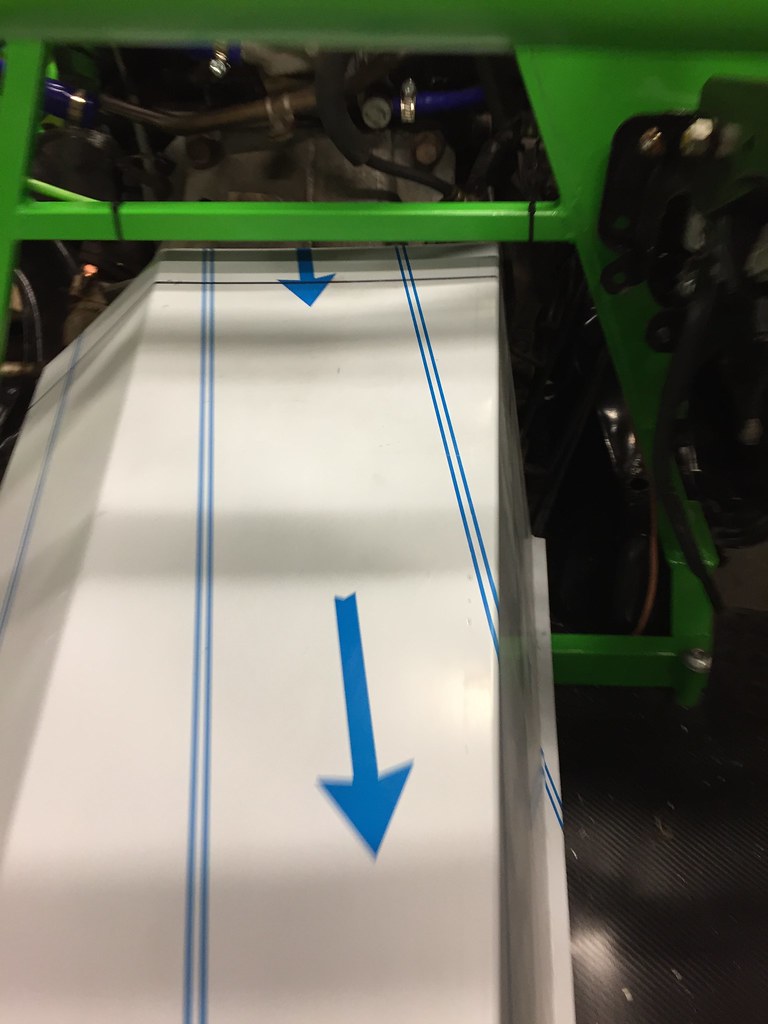

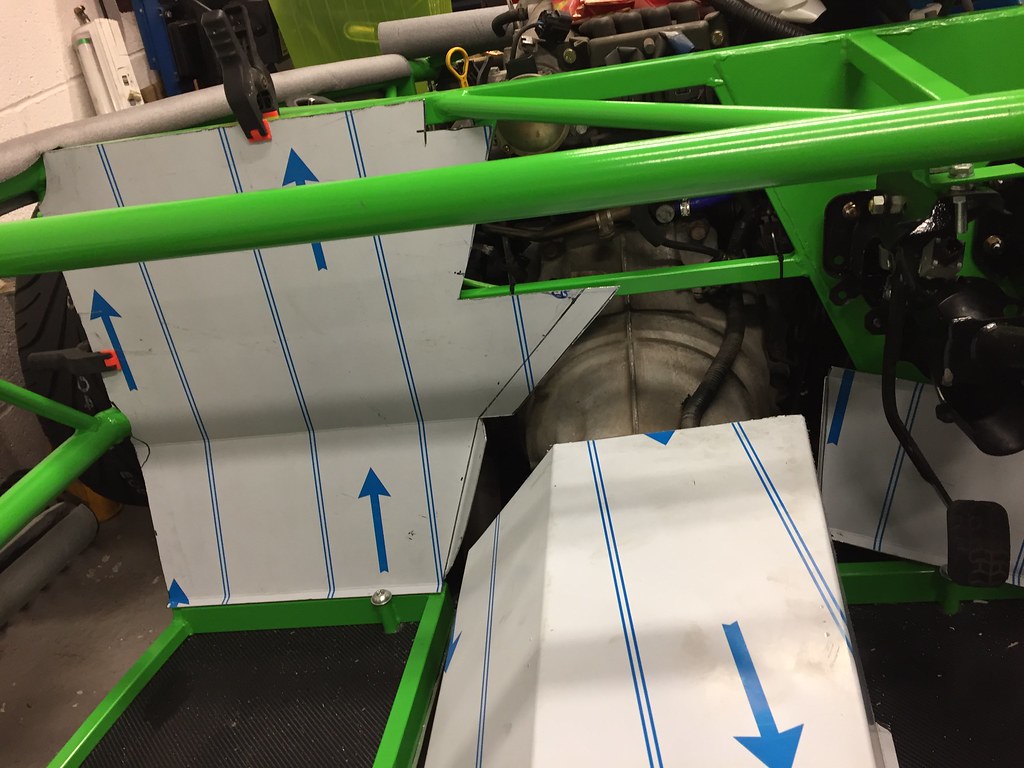

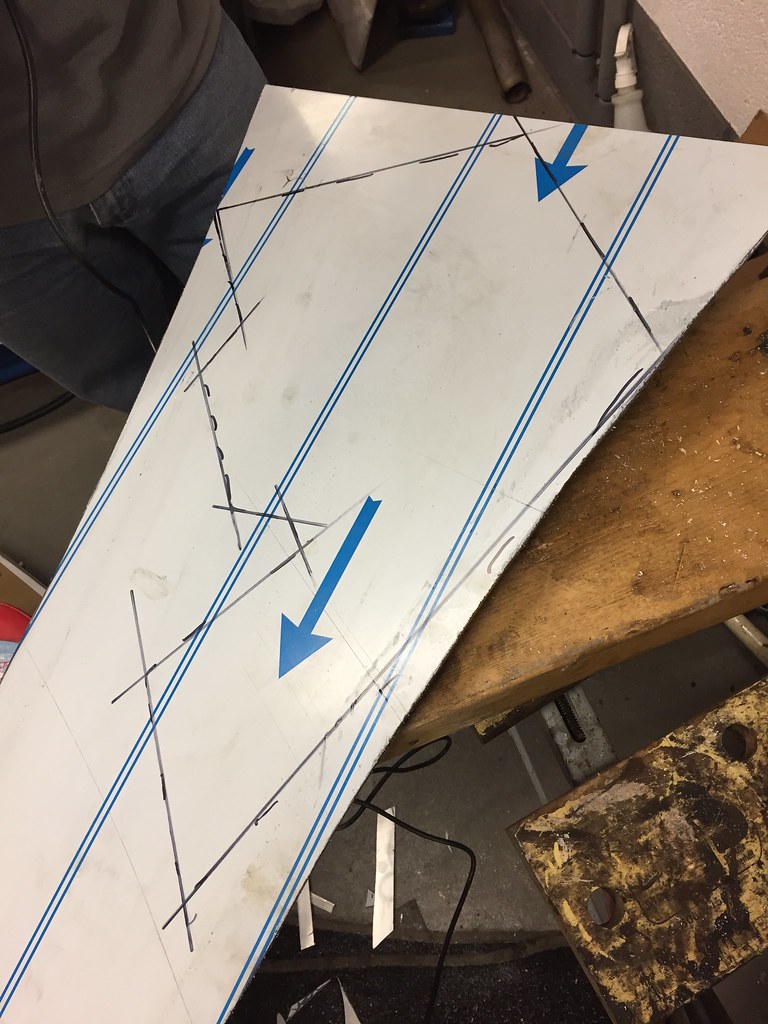

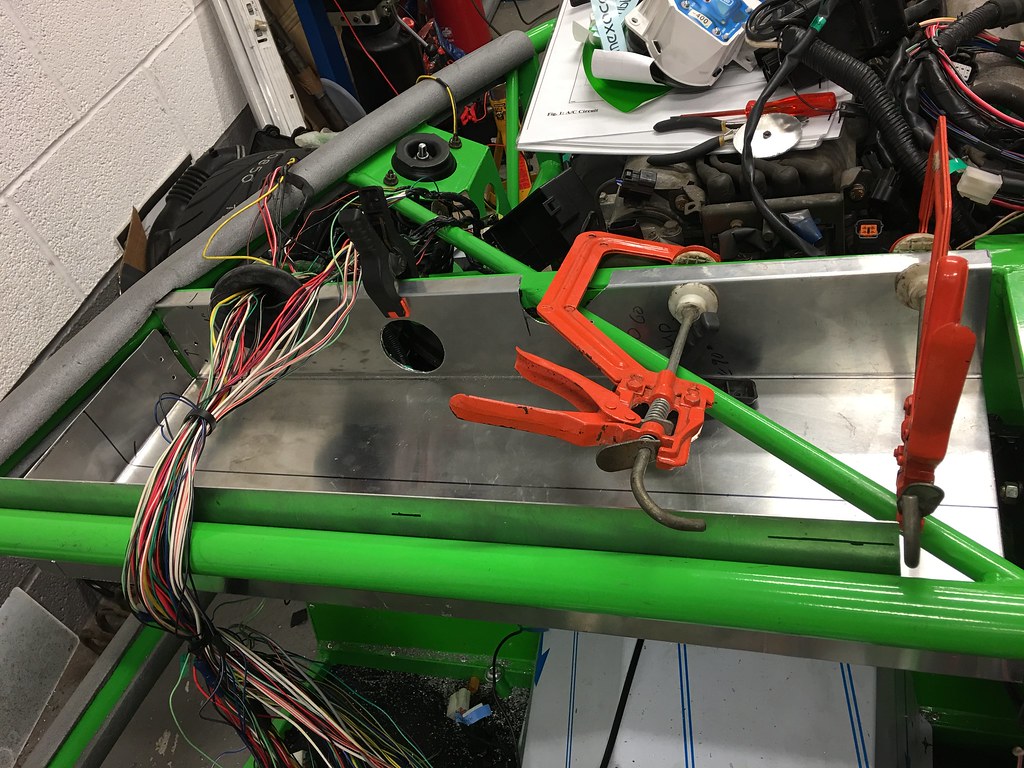

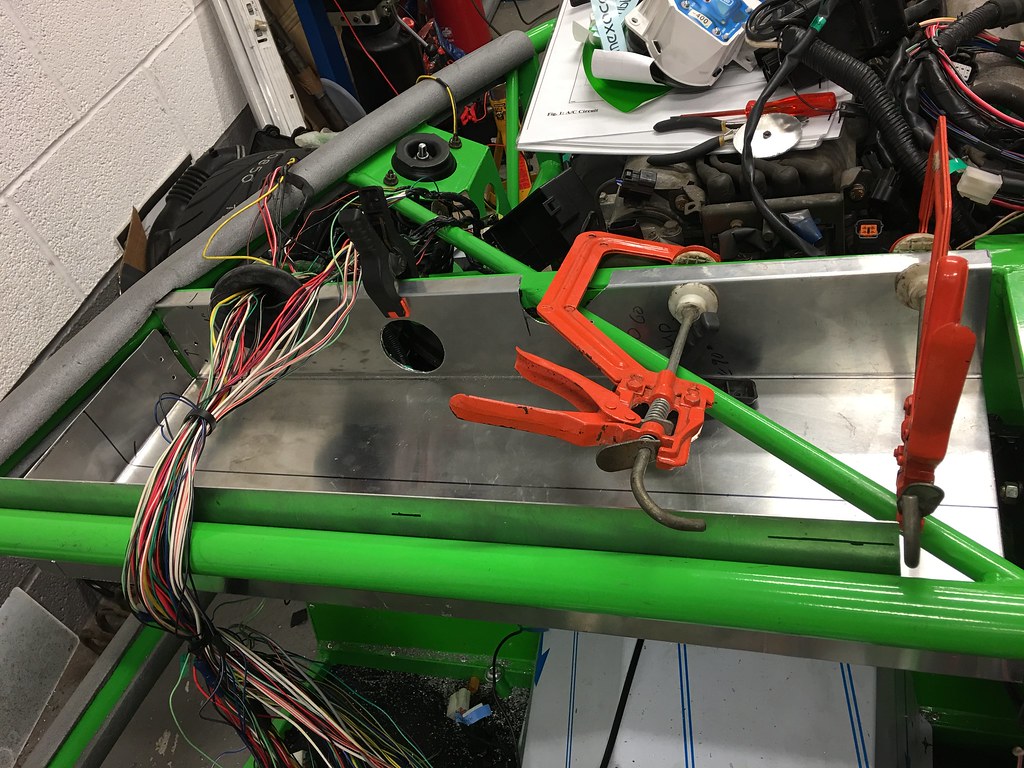

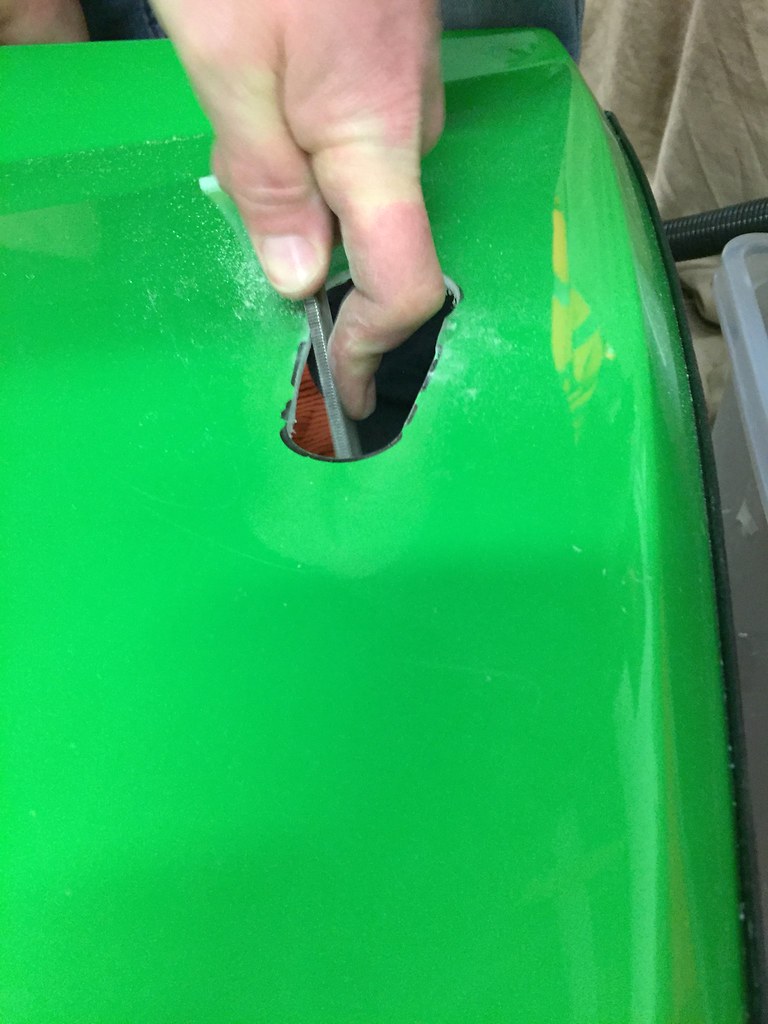

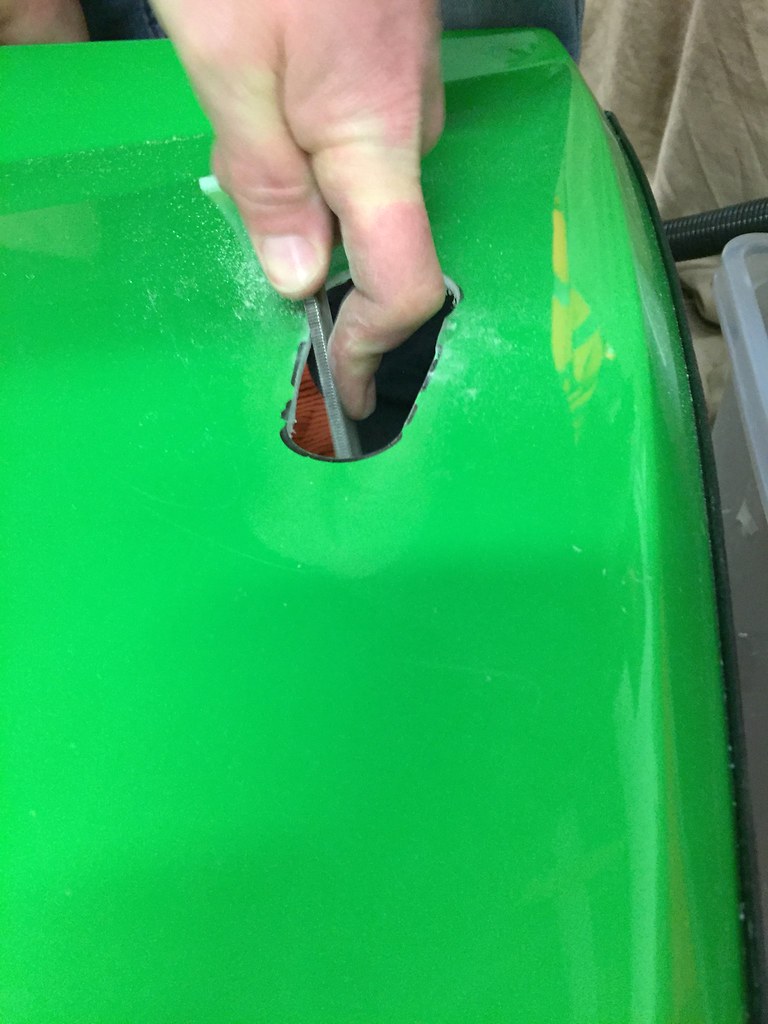

and I have been working on figuring out the 3-D puzzle that is the tunnel and bulkhead panelling! This is where the loss of history from photo bucket has really hurt, as many of the threads I looked at on here and elsewhere had great descriptions, but no pictures to be able to really visualise what was going on. I began with trying to sketch out templates for the panels that need modifying/making. having started that, I then realised that I really needed to cut the hole for the gearstick and get the tunnel in place and the front end trimmed up before I finalise my templates.

So tonights job was to do just that - and some measuring, double checking and marking was followed by a first conservative cut that was then gradually opened out to fit.

Untitled on Flickr

Untitled on Flickr

This then allowed me to put my templates into place - so I can start to refine the shapes to ensure that i get tabs in the right places to hold the front of the tunnel and also mark where the front needs a trim.

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Not masses of progress, but still moving forwards - I now need to order more aluminium sheet, as the offcuts from the floor aren't quite big enough to make the panels as I have them templated - I might even try to make the passenger side and upper panel into a single piece, will see if that will work!

Agree that real carbon would be nice - I did consider it (and am still wondering about it for the side panels!) - but it isn't cheap, and I wondered how it might fare long-term for floor panels... I do have some carbon sheet that I will certainly be using it in some places on the car!

I have not been doing as much as I would have liked over the last couple of weeks, but have got a few bits done (I have also been getting my mini prepped for a rolling road setup, which has involved swapping carbs over and tweaking some bits).

Firstly, having bought a rivnut tool, I fitted the radiator, which looks good - with the vinyl working well (we will see how that lasts once it has got hot):

Radiator fitted on Flickr

Radiator fitted on Flickr Radiator fitted on Flickr

Radiator fitted on Flickrand I have been working on figuring out the 3-D puzzle that is the tunnel and bulkhead panelling! This is where the loss of history from photo bucket has really hurt, as many of the threads I looked at on here and elsewhere had great descriptions, but no pictures to be able to really visualise what was going on. I began with trying to sketch out templates for the panels that need modifying/making. having started that, I then realised that I really needed to cut the hole for the gearstick and get the tunnel in place and the front end trimmed up before I finalise my templates.

So tonights job was to do just that - and some measuring, double checking and marking was followed by a first conservative cut that was then gradually opened out to fit.

Untitled on Flickr

Untitled on FlickrThis then allowed me to put my templates into place - so I can start to refine the shapes to ensure that i get tabs in the right places to hold the front of the tunnel and also mark where the front needs a trim.

Untitled on Flickr

Untitled on Flickr Untitled on Flickr

Untitled on FlickrNot masses of progress, but still moving forwards - I now need to order more aluminium sheet, as the offcuts from the floor aren't quite big enough to make the panels as I have them templated - I might even try to make the passenger side and upper panel into a single piece, will see if that will work!

A bit of a gap in updates here as I have been off travelling with work and busy with other things - but have got back onto making a little more progress.

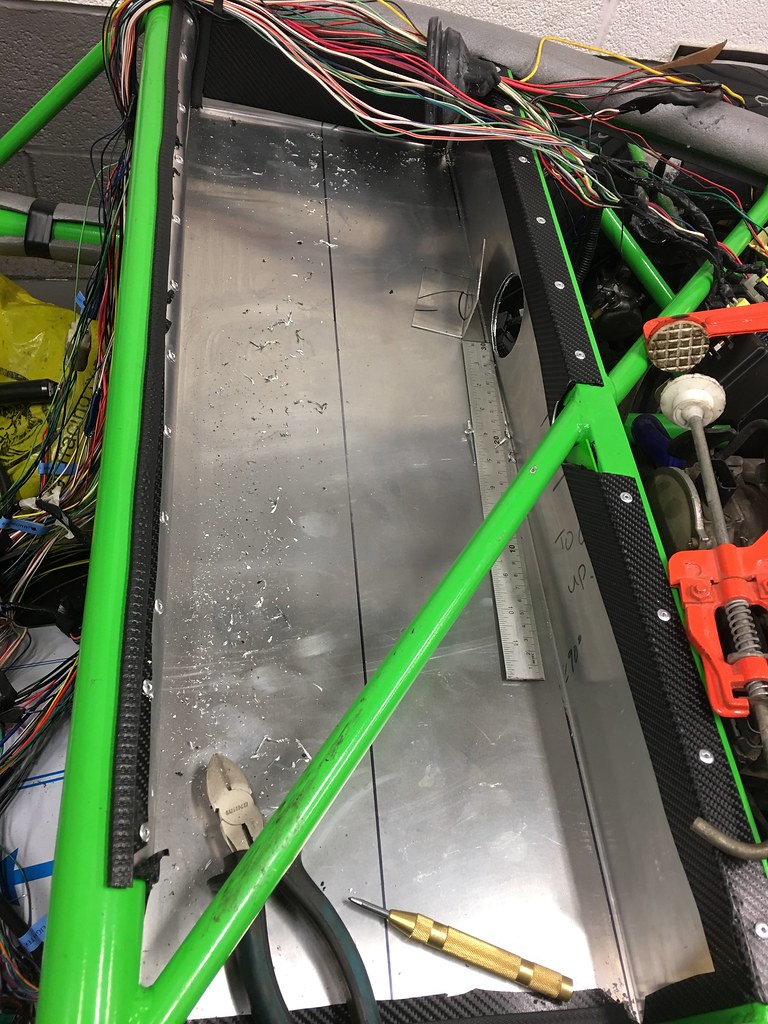

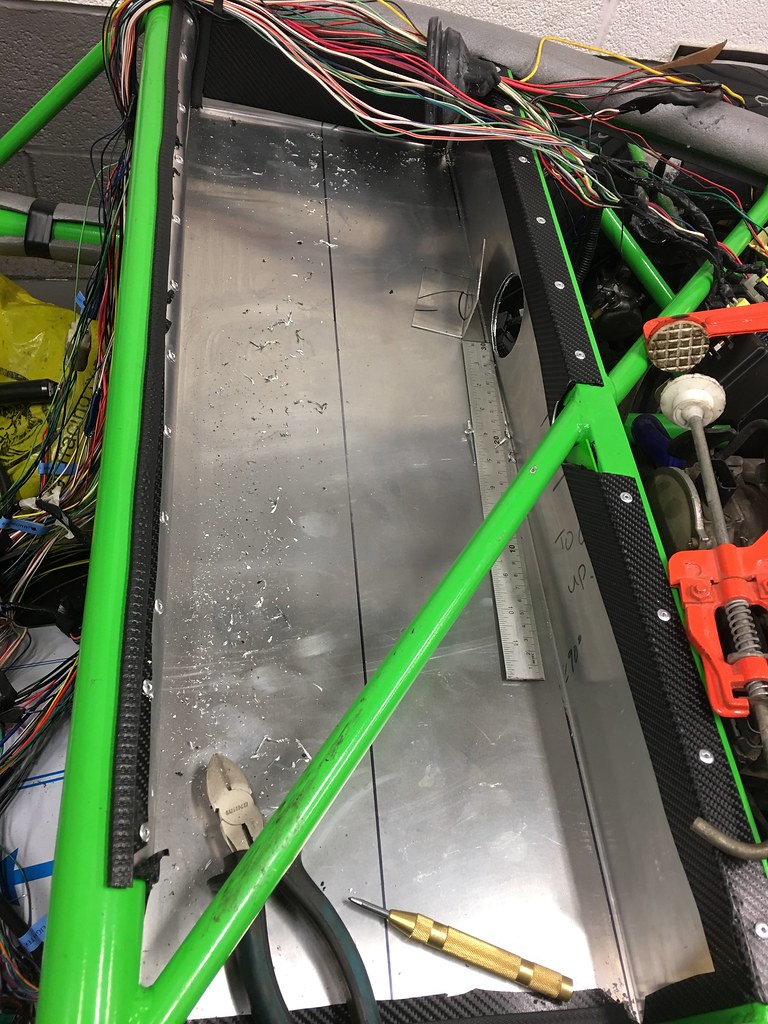

First job was to do a little more cardboard fabrication to finish the bulkhead and also work on a first draft of a wiring tray... One question on that - how deep have people made their trays, and did you feel that was right or could you have done with a bit more?

Untitled on Flickr

Untitled on Flickr

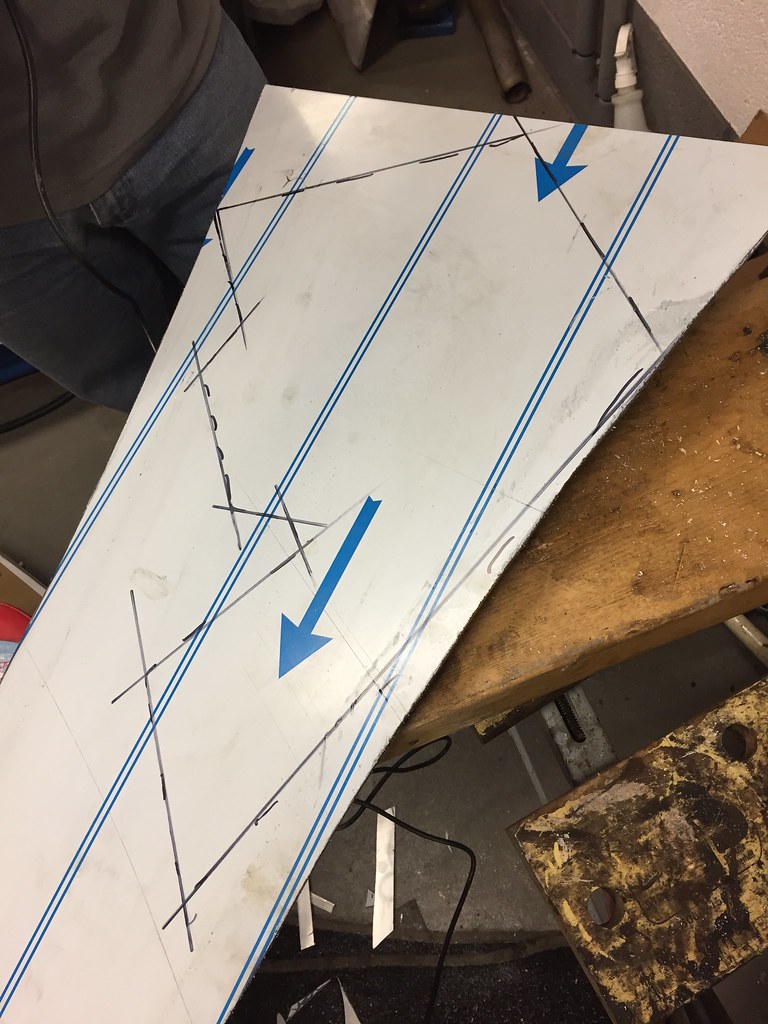

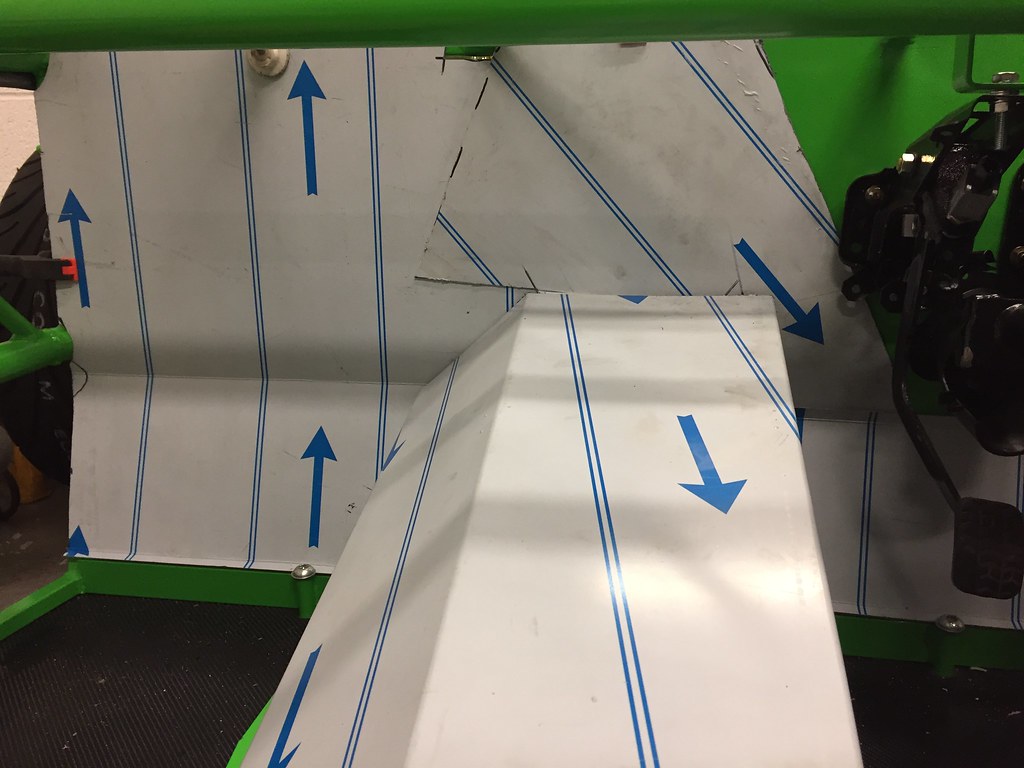

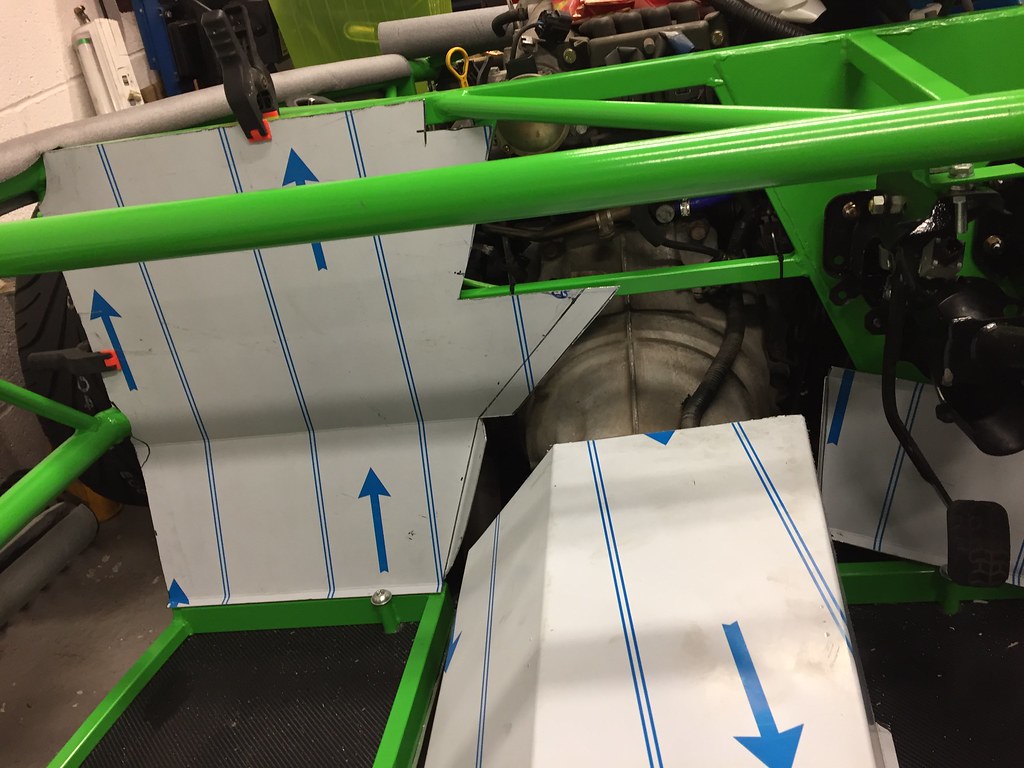

but I am not sure that cardboard will quite be suitable for the IVA man, so I marked out and trimmed off the front end of the tunnel, and then began transferring the dimensions into something a little more suitable!

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

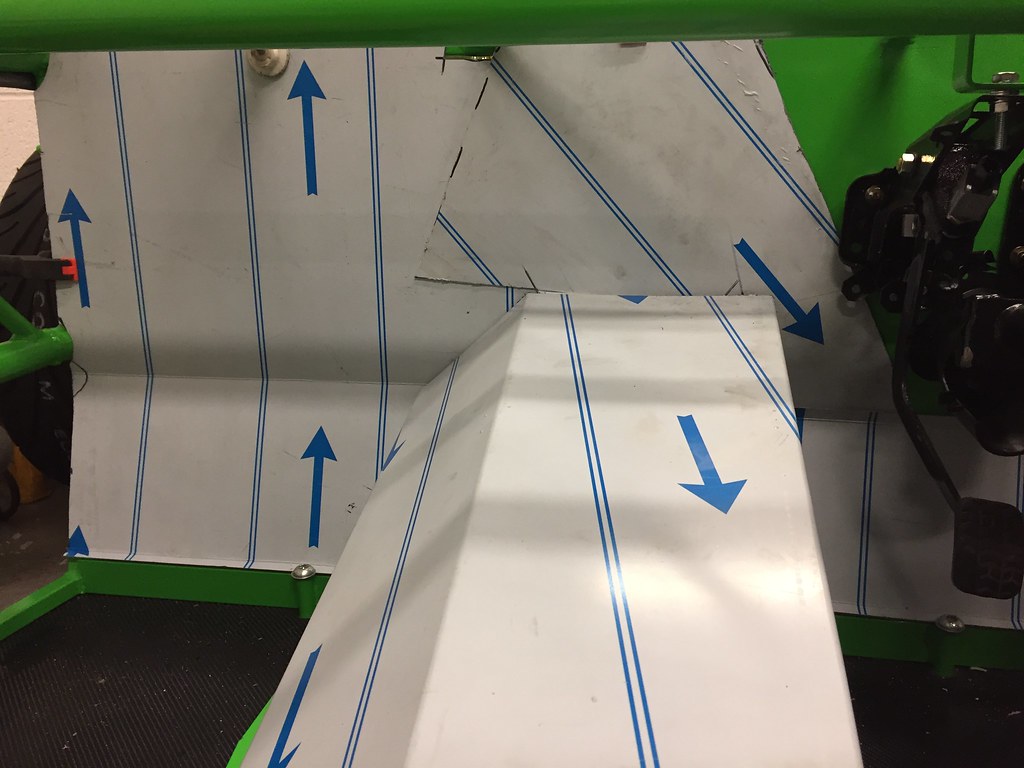

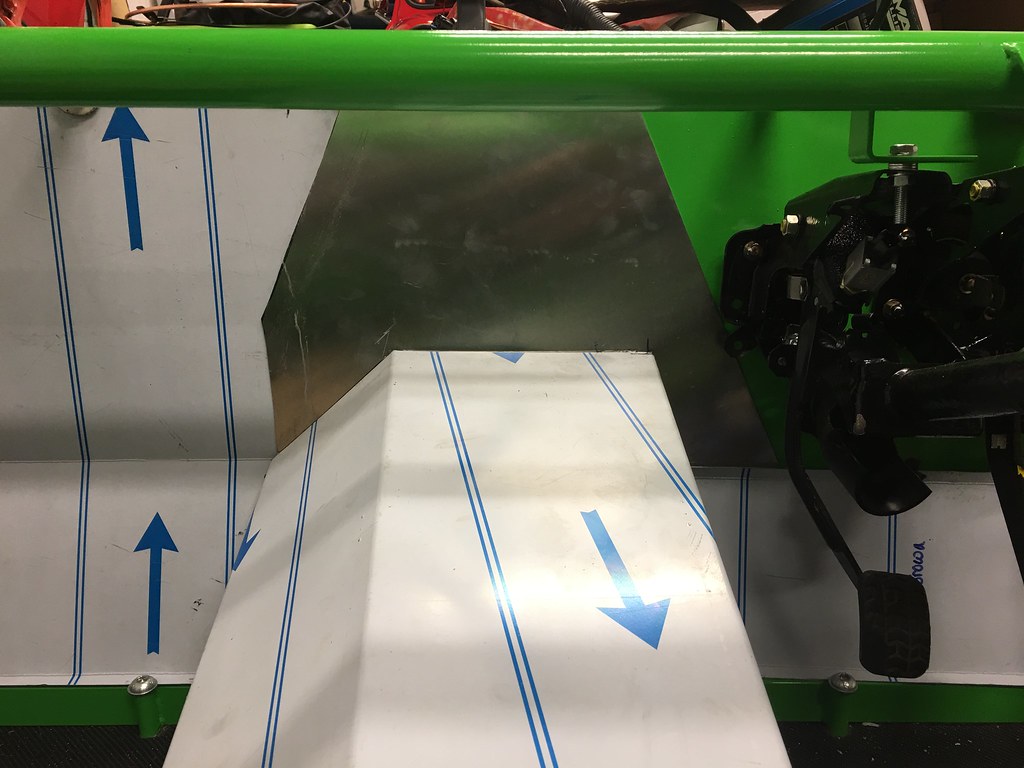

then started offering up the panels (and progressively adjusting them!) to get a decent fit:

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

which looked ok - but I wasn't keen on the pointed edge floating on the centre panel, so then had a go at remaking an improved shape to drop the join below the tunnel and neaten things up.

Untitled on Flickr

Untitled on Flickr

this version is still a work in progress as a couple of bits aren't quite straight and need a bit of tweaking - but it is looking like a good start! Having been hesitant at the start that this was going to be a very tricky 3-d jigsaw puzzle, I am very pleased with the progress to this stage - and am confident that I can get these fitted up nicely with a little adjustment (or in the worst case, making another iteration!).

So, progress has been slow, but I am still working on it, and hopefully I am now properly back on it, so will be keeping things moving along!

First job was to do a little more cardboard fabrication to finish the bulkhead and also work on a first draft of a wiring tray... One question on that - how deep have people made their trays, and did you feel that was right or could you have done with a bit more?

Untitled on Flickr

Untitled on Flickrbut I am not sure that cardboard will quite be suitable for the IVA man, so I marked out and trimmed off the front end of the tunnel, and then began transferring the dimensions into something a little more suitable!

Untitled on Flickr

Untitled on Flickr Untitled on Flickr

Untitled on Flickrthen started offering up the panels (and progressively adjusting them!) to get a decent fit:

Untitled on Flickr

Untitled on Flickr Untitled on Flickr

Untitled on Flickrwhich looked ok - but I wasn't keen on the pointed edge floating on the centre panel, so then had a go at remaking an improved shape to drop the join below the tunnel and neaten things up.

Untitled on Flickr

Untitled on Flickrthis version is still a work in progress as a couple of bits aren't quite straight and need a bit of tweaking - but it is looking like a good start! Having been hesitant at the start that this was going to be a very tricky 3-d jigsaw puzzle, I am very pleased with the progress to this stage - and am confident that I can get these fitted up nicely with a little adjustment (or in the worst case, making another iteration!).

So, progress has been slow, but I am still working on it, and hopefully I am now properly back on it, so will be keeping things moving along!

chryslerben said:

Mate, as a quick point to add to your list of things to do if you haven't already that is, might be an idea to bead roll or get a flare on those fuel line ends. Possibly even upgrade to compression fittings as straight pipe plus little clips and 3 bar of fuel ain't your fiend.

Cool build either way

Thanks for spotting this - thankfully, I have already added double flares to both ends of the copper lines to make sure that they don't escape. The lines are a nice tight fit so are well clamped and have not moved or shown signs of leakage with the fuel system pressured up. The screw-type clips I have used offer much more clamping than the squeezy-type clips on the OEM fuel lines, so I am overall fairly confident that they are ok!Cool build either way

These are certainly the kids of details that I am glad for folks to pick up and make sure I check now rather than have an issue later!

Thanks again for the encouragement - it is good to keep things moving along (albeit more slowly recently!)

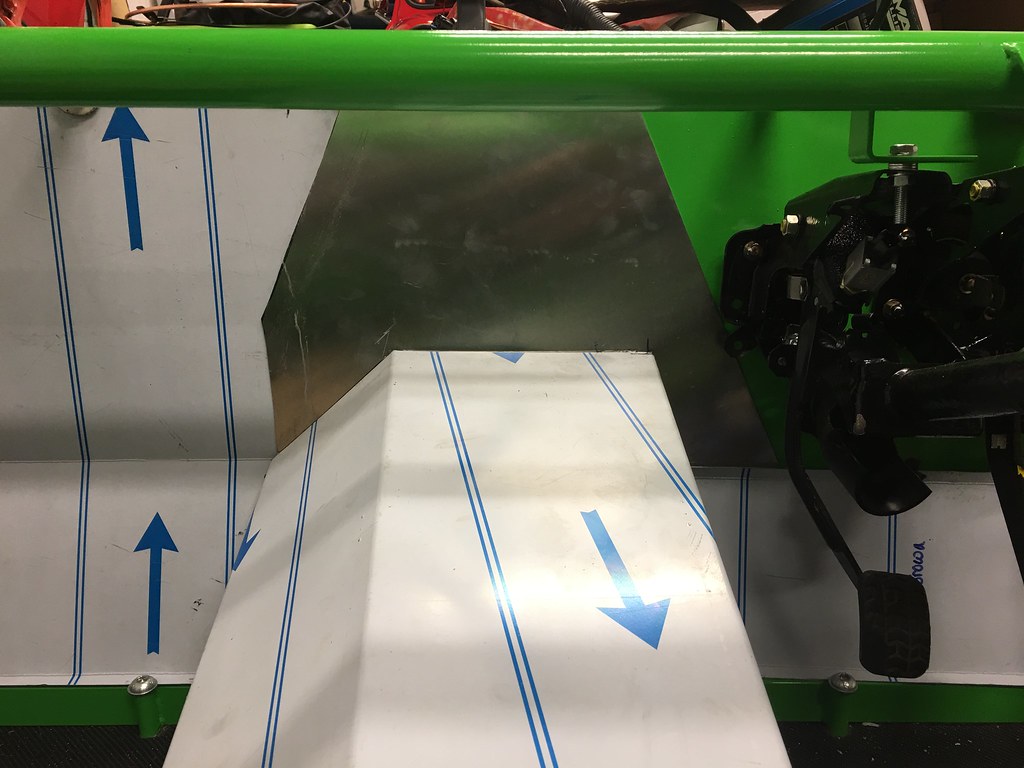

I have managed more progress though - having made up all of the panels, I then neatened them all up, and then it was time to get them all ready for fitting. Having pondered how to finish the bulkhead, I decided that I wanted them in body colour to tie in with the frame - so after some searching, I was able to find some vinyl in the correct (RAL6018) colour to match, and wrapped the panels - which match nicely.

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Then it was time to get everything lined up and drilled for riveting (and all of the holes cleaned and deburred.

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Then it was finally time to apply a generous bead of tiger seal to ensure good bonding and prevent vibration/drumming of the panels and start riveting into position.

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Overall, I am happy that it is looking pretty tidy as a finished job, especially with the tunnel in place (next job is to sort the tabs that located to the front of the tunnel and get that fitted).

Untitled on Flickr

Untitled on Flickr

And since I am making progress - I decided that I was overdue some time to play in my other toy, so headed up to Blyton with Mazda on Track for an unseasonably sunny trackday at the weekend - which was very enjoyable!

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

I have managed more progress though - having made up all of the panels, I then neatened them all up, and then it was time to get them all ready for fitting. Having pondered how to finish the bulkhead, I decided that I wanted them in body colour to tie in with the frame - so after some searching, I was able to find some vinyl in the correct (RAL6018) colour to match, and wrapped the panels - which match nicely.

Untitled on Flickr

Untitled on Flickr Untitled on Flickr

Untitled on FlickrThen it was time to get everything lined up and drilled for riveting (and all of the holes cleaned and deburred.

Untitled on Flickr

Untitled on Flickr Untitled on Flickr

Untitled on Flickr Untitled on Flickr

Untitled on FlickrThen it was finally time to apply a generous bead of tiger seal to ensure good bonding and prevent vibration/drumming of the panels and start riveting into position.

Untitled on Flickr

Untitled on Flickr Untitled on Flickr

Untitled on Flickr Untitled on Flickr

Untitled on FlickrOverall, I am happy that it is looking pretty tidy as a finished job, especially with the tunnel in place (next job is to sort the tabs that located to the front of the tunnel and get that fitted).

Untitled on Flickr

Untitled on FlickrAnd since I am making progress - I decided that I was overdue some time to play in my other toy, so headed up to Blyton with Mazda on Track for an unseasonably sunny trackday at the weekend - which was very enjoyable!

Untitled on Flickr

Untitled on Flickr Untitled on Flickr

Untitled on FlickrLong time, no update! I haven't forgotten about my build - but have in fact been busy doing various things in the garage - only some of them on the Exocet.

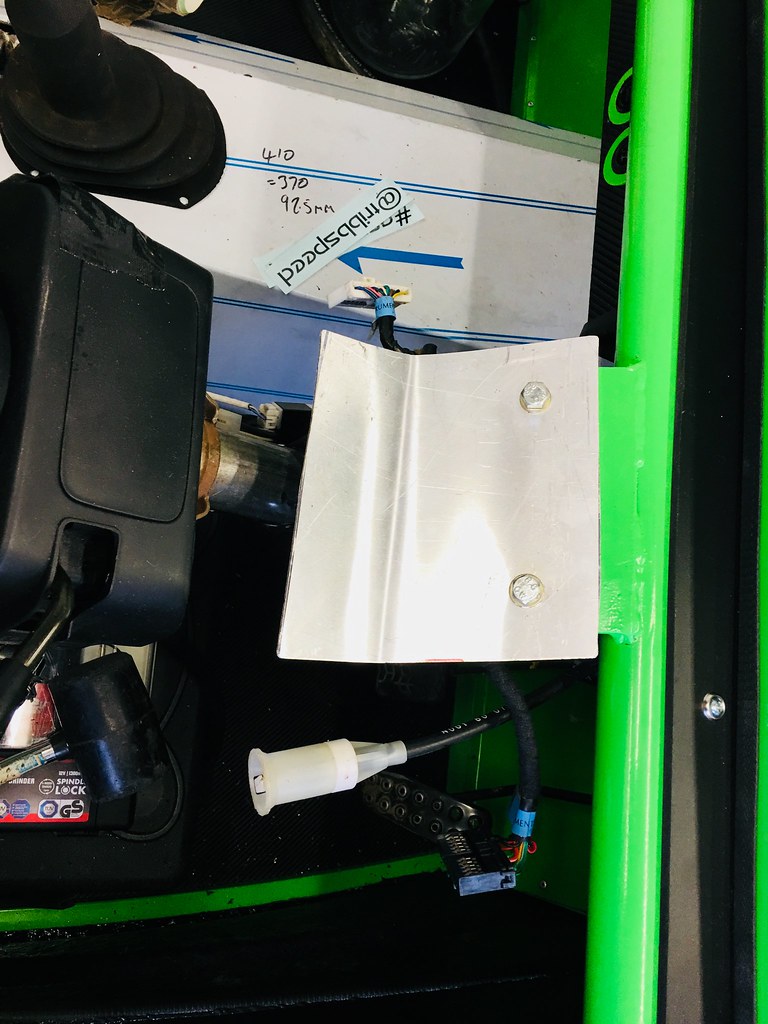

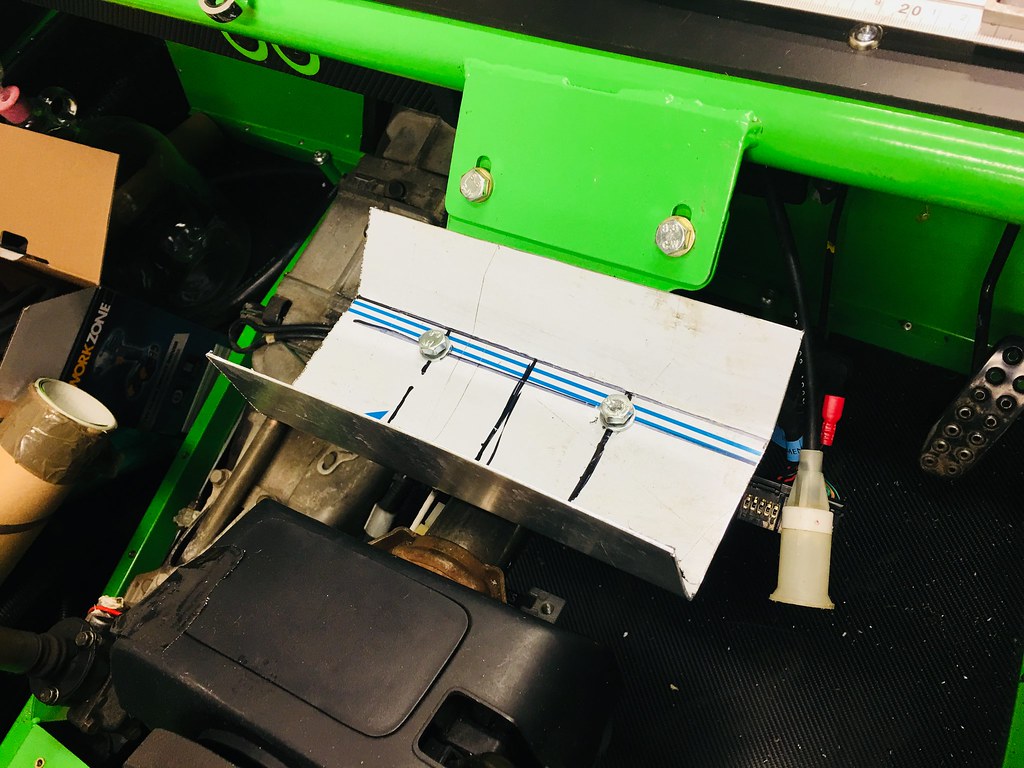

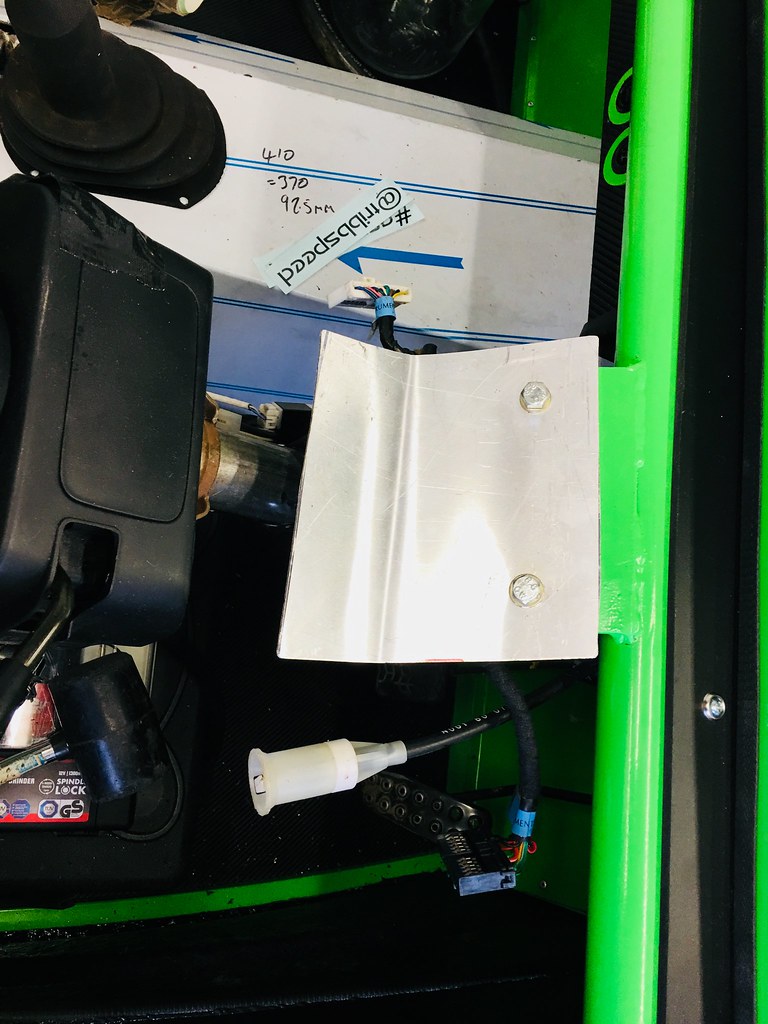

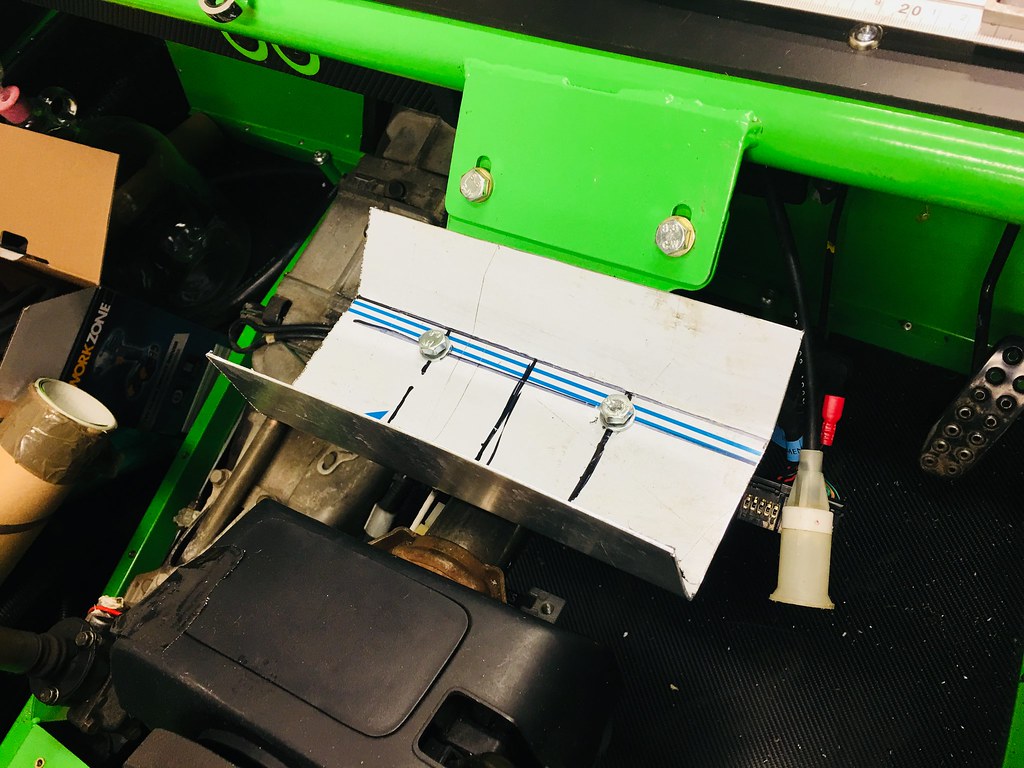

After the previous update, I had started templating a wiring tray to hold the ECU and electrics neatly - so I cut out a sheet of ally and got it folded in the workshop at work - which left me with a neat tray that just need a little adjustment to fit into place:

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Then I took a break away from the Exocet as I wanted to finally get my mini sorted and running right - this has been a very long (23 year!) build, that I finally got MOT'd in March, but needed to get setup - so took it off to Peter Burgess to get sorted on his rolling road. It was a very steady drive over with a badly set engine meaning I couldn't drive over about 35mph without serious spluttering! Having worked his magic (and had a good chat), Peter has transformed the drive - and it now has a whole 51BHP (ish!) and drives much better, pulling happily now. This meant that I could take it out for its first proper drive - and then put it to bed for winter!

Untitled on Flickr

Untitled on Flickr

video on the rollers: https://youtu.be/rBlHv9IuFvg

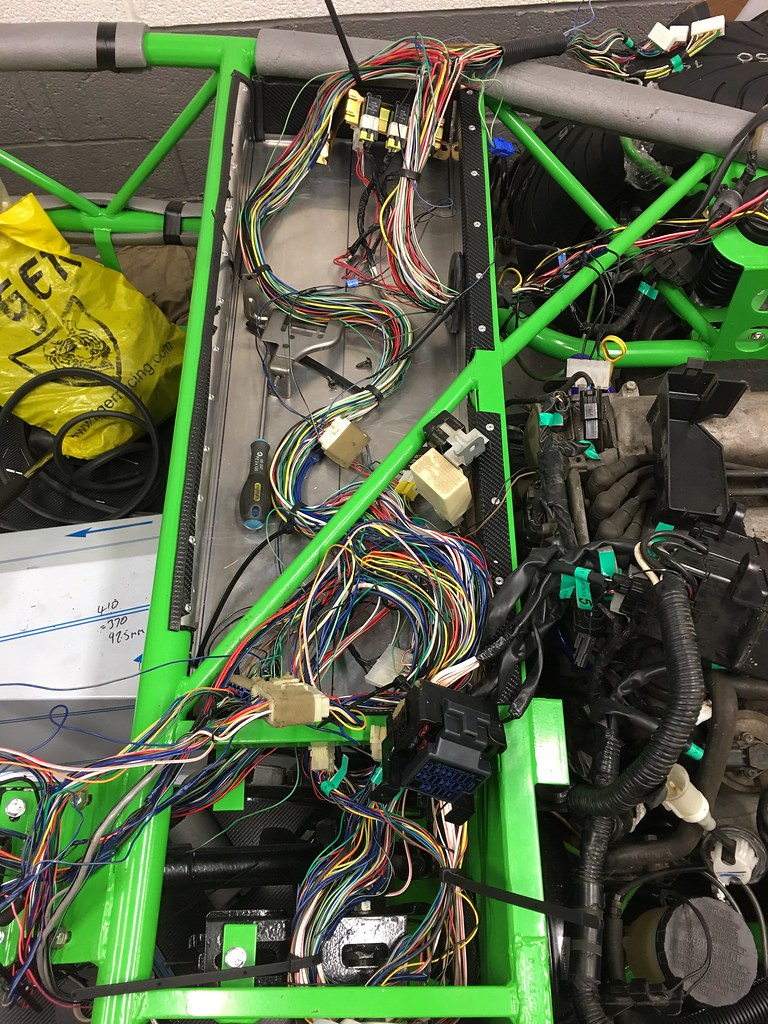

and since that, I have been starting to work on the Exocet electrics - firstly plugging the loom back into the key areas to get the engine to fire again, and then starting to strip out the unneeded wiring... so I currently have a car covered in large amounts of multi-coloured spaghetti - and lots of removed wiring!

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

So I have now removed all of the wiring that I can see is unneeded (and that I dare remove!) and the engine still fires - so that's good! Next is to re-wrap the loom and then begin getting everything refitted and neatened up. However (as ever, there is always a challenge!), my brother has caught the trackday bug and has bought himself a clio 172 cup which we need to fettle a bit - and so that has been taking up some garage time too!

After the previous update, I had started templating a wiring tray to hold the ECU and electrics neatly - so I cut out a sheet of ally and got it folded in the workshop at work - which left me with a neat tray that just need a little adjustment to fit into place:

Untitled on Flickr

Untitled on Flickr Untitled on Flickr

Untitled on Flickr Untitled on Flickr

Untitled on FlickrThen I took a break away from the Exocet as I wanted to finally get my mini sorted and running right - this has been a very long (23 year!) build, that I finally got MOT'd in March, but needed to get setup - so took it off to Peter Burgess to get sorted on his rolling road. It was a very steady drive over with a badly set engine meaning I couldn't drive over about 35mph without serious spluttering! Having worked his magic (and had a good chat), Peter has transformed the drive - and it now has a whole 51BHP (ish!) and drives much better, pulling happily now. This meant that I could take it out for its first proper drive - and then put it to bed for winter!

Untitled on Flickr

Untitled on Flickrvideo on the rollers: https://youtu.be/rBlHv9IuFvg

and since that, I have been starting to work on the Exocet electrics - firstly plugging the loom back into the key areas to get the engine to fire again, and then starting to strip out the unneeded wiring... so I currently have a car covered in large amounts of multi-coloured spaghetti - and lots of removed wiring!

Untitled on Flickr

Untitled on Flickr Untitled on Flickr

Untitled on Flickr Untitled on Flickr

Untitled on FlickrSo I have now removed all of the wiring that I can see is unneeded (and that I dare remove!) and the engine still fires - so that's good! Next is to re-wrap the loom and then begin getting everything refitted and neatened up. However (as ever, there is always a challenge!), my brother has caught the trackday bug and has bought himself a clio 172 cup which we need to fettle a bit - and so that has been taking up some garage time too!

Time for another delayed update - as the clio mentioned previously has needed rather more attention than planned - a lumpy, missing idle wasn't solved by swapping over engine sensors, and so deeper investigation was needed. It turned out that the cambelt that had been done by the previous owner had been fitted slightly out of time (the 172 uses a floating cam setup and timing (and belt replacement in general) is a pain - so we had to open it up, get it all retimed and put in a new cambelt, water pump and aux-drivebelt, which have resulted in it running much better!

Untitled on Flickr

Untitled on Flickr

So with that sorted and back out of the garage (for now - we have a full set of new springs and dampers to fit to it next!), I could get back onto the exocet.

First challenge was to check where the loom could run best and then cut holes in the bulkhead for the big wiring grommets (which required a decent holesaw!)

Untitled on Flickr

Untitled on Flickr

and then with the nearside also done, position the wiring tray and drill that too...

Untitled on Flickr

Untitled on Flickr

and with that done, it was then time to wrap and secure the wiring tray in place.

Untitled on Flickr

Untitled on Flickr

Which I think now looks quite tidy from inside (although I know I will need to sort a way to radius the lower edge rather more for IVA - I am thinking some kind of tubing stuck on might do the trick) - so the next job is to get in with routing and tidying the loom up - I have already planned and rearranged the wiring for things like the engine fusebox to move into the wiring tray, so there may be some more creative work required to make sure that it all looks neat and is routed with minimal wiring on show. (and I also need to get a knife and ruler to tidy up the edges of the wrap too!)

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on FlickrSo with that sorted and back out of the garage (for now - we have a full set of new springs and dampers to fit to it next!), I could get back onto the exocet.

First challenge was to check where the loom could run best and then cut holes in the bulkhead for the big wiring grommets (which required a decent holesaw!)

Untitled on Flickr

Untitled on Flickrand then with the nearside also done, position the wiring tray and drill that too...

Untitled on Flickr

Untitled on Flickrand with that done, it was then time to wrap and secure the wiring tray in place.

Untitled on Flickr

Untitled on FlickrWhich I think now looks quite tidy from inside (although I know I will need to sort a way to radius the lower edge rather more for IVA - I am thinking some kind of tubing stuck on might do the trick) - so the next job is to get in with routing and tidying the loom up - I have already planned and rearranged the wiring for things like the engine fusebox to move into the wiring tray, so there may be some more creative work required to make sure that it all looks neat and is routed with minimal wiring on show. (and I also need to get a knife and ruler to tidy up the edges of the wrap too!)

Untitled on Flickr

Untitled on FlickrSo I think it is new year, new update time for the Exocet, as I have been busy with lots of stuff (including lots on the clio mentioned previously - completing a full suspension refresh and exhaust replacement) - but have managed to find some time to make a little further progress.

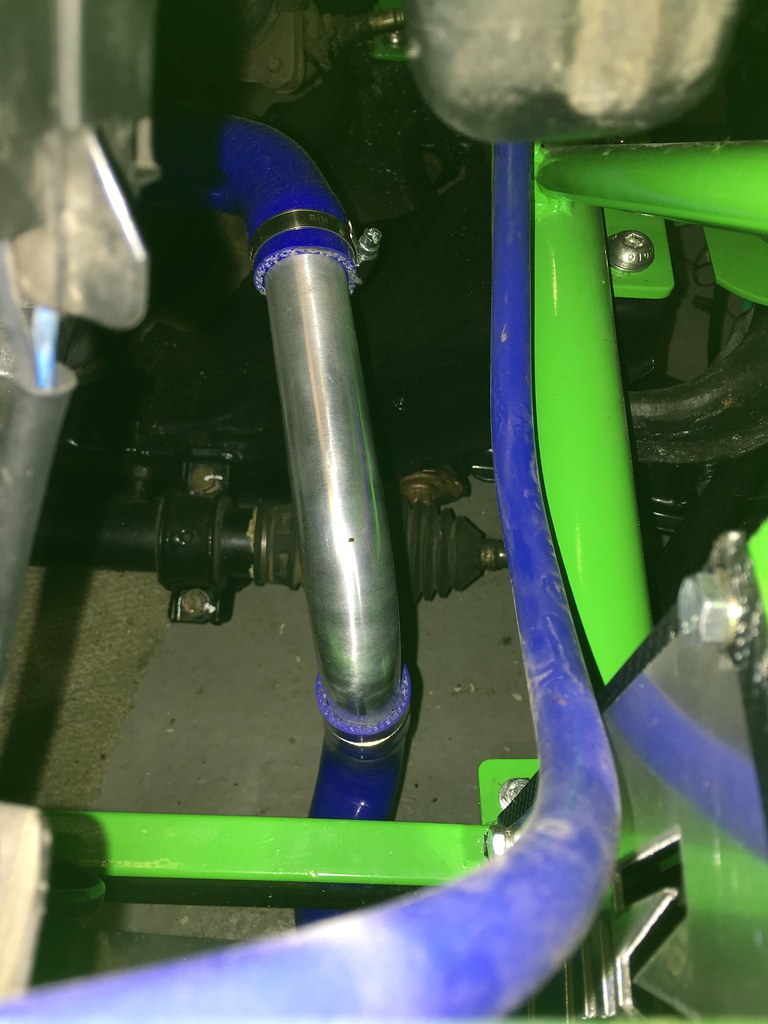

So, having fitted the wiring tray, I then started to feed the (still unwrapped) loom back into place - which left me with lots of spaghetti!

Untitled on Flickr

Untitled on Flickr

So in order to try and clean things up and look more organised in there, I started adding some conduit, which started to improve matters.

Untitled on Flickr

Untitled on Flickr

As I had to move things around in the garage to accommodate the clio on my ramp, I had to shift the nosecone (which had been suspended above my lift) - so briefly put it into place to see how it looks with the car on its wheels.

Untitled on Flickr

Untitled on Flickr

Then I started wrapping the loom (with the hope that I won't need to access the wiring, so fingers crossed the loom thinning has worked out ok!), starting in the engine bay...

Untitled on Flickr

Untitled on Flickr

Then I have started fixing things down in the wiring tray - with the ecu riveted down and the large fusebox secured to the chassis with a couple of rivnuts, and also getting some of the earth points located and bolted in, and I have started to locate the conduit also - using self adhesive cable tie bases (which will be securely riveted in place for IVA - as it seems that is required).

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

So with this at this stage, I thought I'd better check that things still work, and I am glad to report that it still turns over and fires - and now that I have the earths properly fixed actually runs without cutting out after a couple of seconds - I think that the immobiliser wasn't properly earthed as I was stripping the loom and was killing the engine as soon as it fired. The horn even works too!

I have also been busy shopping for more bits and have ordered most of the lights that I need along with hazard and foglight switches - so can get some more of the wiring completed. I will also be heading to the Autosport show in a couple of weeks, so will be on the lookout for some seats that might tie in with the car well without breaking the bank (currently thinking a pair of Corbeaus might be right), along with any other bits that take my fancy!

So, having fitted the wiring tray, I then started to feed the (still unwrapped) loom back into place - which left me with lots of spaghetti!

Untitled on Flickr

Untitled on FlickrSo in order to try and clean things up and look more organised in there, I started adding some conduit, which started to improve matters.

Untitled on Flickr

Untitled on FlickrAs I had to move things around in the garage to accommodate the clio on my ramp, I had to shift the nosecone (which had been suspended above my lift) - so briefly put it into place to see how it looks with the car on its wheels.

Untitled on Flickr

Untitled on FlickrThen I started wrapping the loom (with the hope that I won't need to access the wiring, so fingers crossed the loom thinning has worked out ok!), starting in the engine bay...

Untitled on Flickr

Untitled on FlickrThen I have started fixing things down in the wiring tray - with the ecu riveted down and the large fusebox secured to the chassis with a couple of rivnuts, and also getting some of the earth points located and bolted in, and I have started to locate the conduit also - using self adhesive cable tie bases (which will be securely riveted in place for IVA - as it seems that is required).

Untitled on Flickr

Untitled on Flickr Untitled on Flickr

Untitled on FlickrSo with this at this stage, I thought I'd better check that things still work, and I am glad to report that it still turns over and fires - and now that I have the earths properly fixed actually runs without cutting out after a couple of seconds - I think that the immobiliser wasn't properly earthed as I was stripping the loom and was killing the engine as soon as it fired. The horn even works too!

I have also been busy shopping for more bits and have ordered most of the lights that I need along with hazard and foglight switches - so can get some more of the wiring completed. I will also be heading to the Autosport show in a couple of weeks, so will be on the lookout for some seats that might tie in with the car well without breaking the bank (currently thinking a pair of Corbeaus might be right), along with any other bits that take my fancy!

Edited by browno on Thursday 4th January 14:11

Time for an update again - and some more progress (but it is certainly getting to the stage where I there are a lot of jobs to do that have less to show for a lot of time!)

First of all, I got some deliveries - including lights, so I roughly connected the wiring to test that all worked - and was pleased to see light!

Untitled on Flickr

Untitled on Flickr

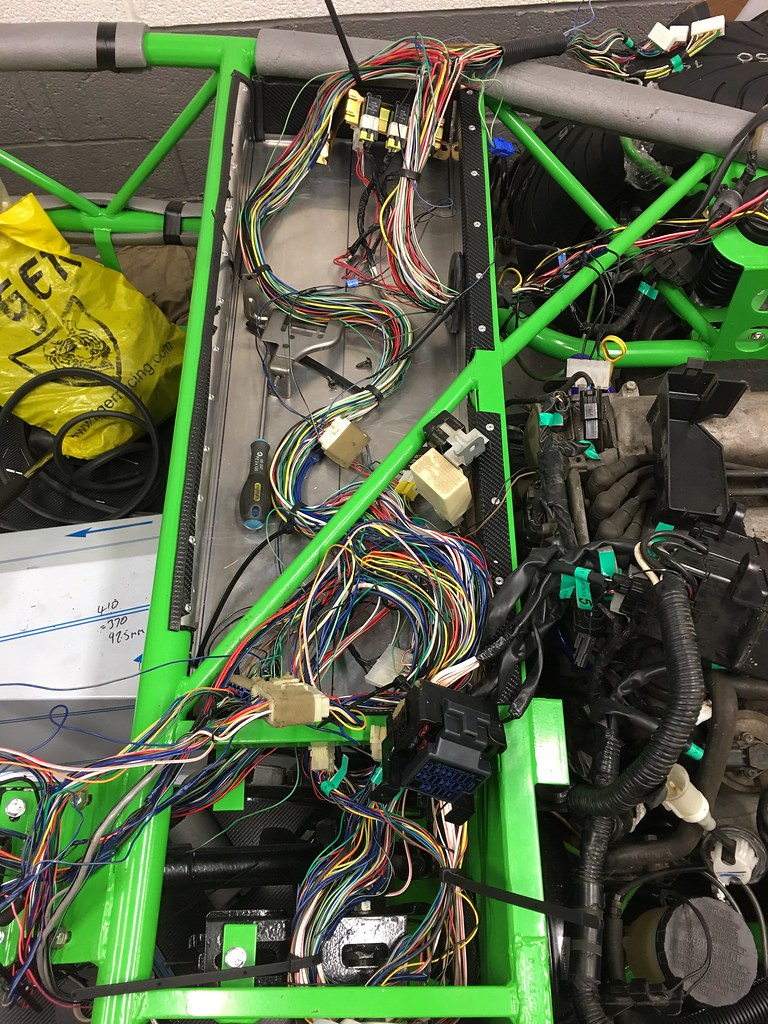

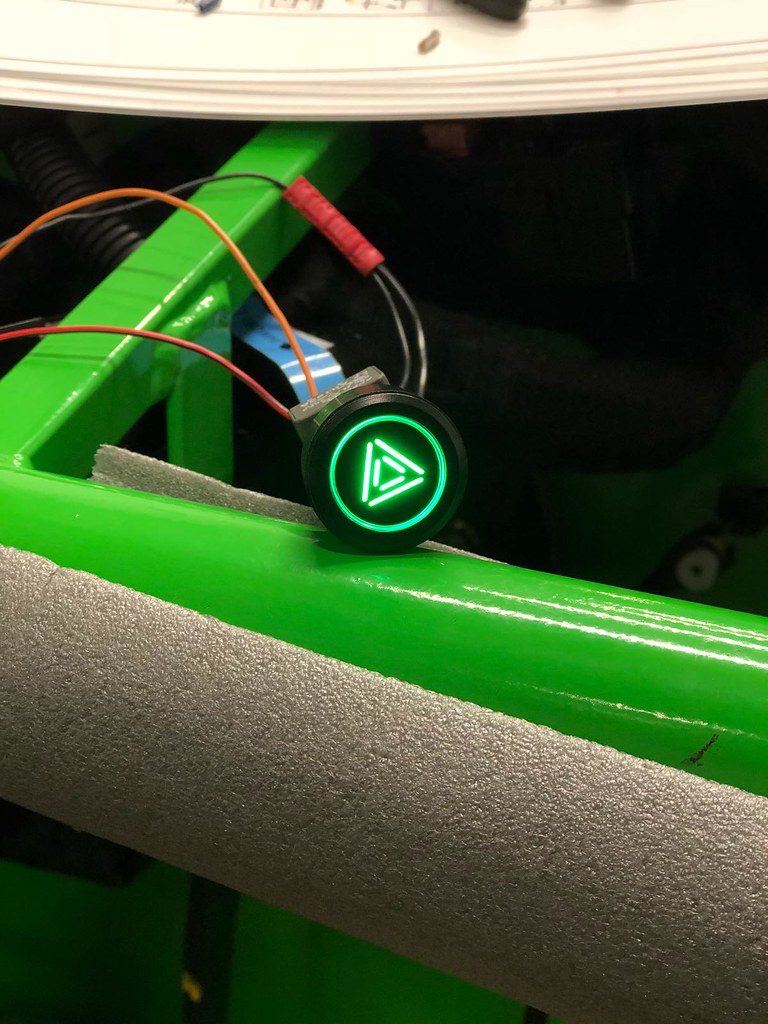

I also tried the wiring for my savage switches for the rear fog and hazard lights - which work and light up in a nicely coordinated colour...

Untitled on Flickr

Untitled on Flickr

the only significant wiring issues have been sorting the earths on the panel lights and also discovering I had a dead instrument panel - which appears to be down to a broken track on the circuit board - which I will sort - but just want to check that the track hasn't broken due to high current leaking through the panel before I do so...

Untitled on Flickr

Untitled on Flickr

I then started trying to tidy up some of the awkward bits that I hadn't got to and get some extra p-clips in some of the spots the IVA-man will be looking for - having bought myself a new drill and flexible drive to reach those tricky spots!

Untitled on Flickr

Untitled on Flickr

Handbrake cable and fuel lines

Untitled on Flickr

Untitled on Flickr

Rear braided lines

Untitled on Flickr

Untitled on Flickr

Front braided line across the bulkhead behind the engine

I then had a short break while I did a bit of work on my NC - service, replacement Lambda sensor and new front pads.

Untitled on Flickr

Untitled on Flickr

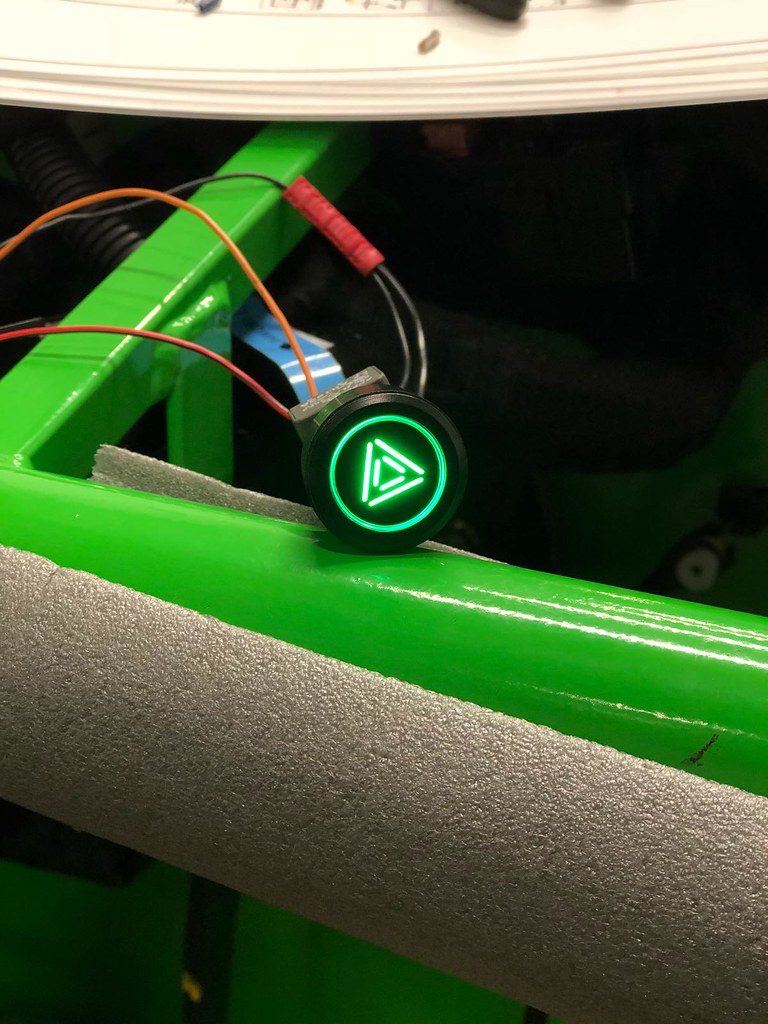

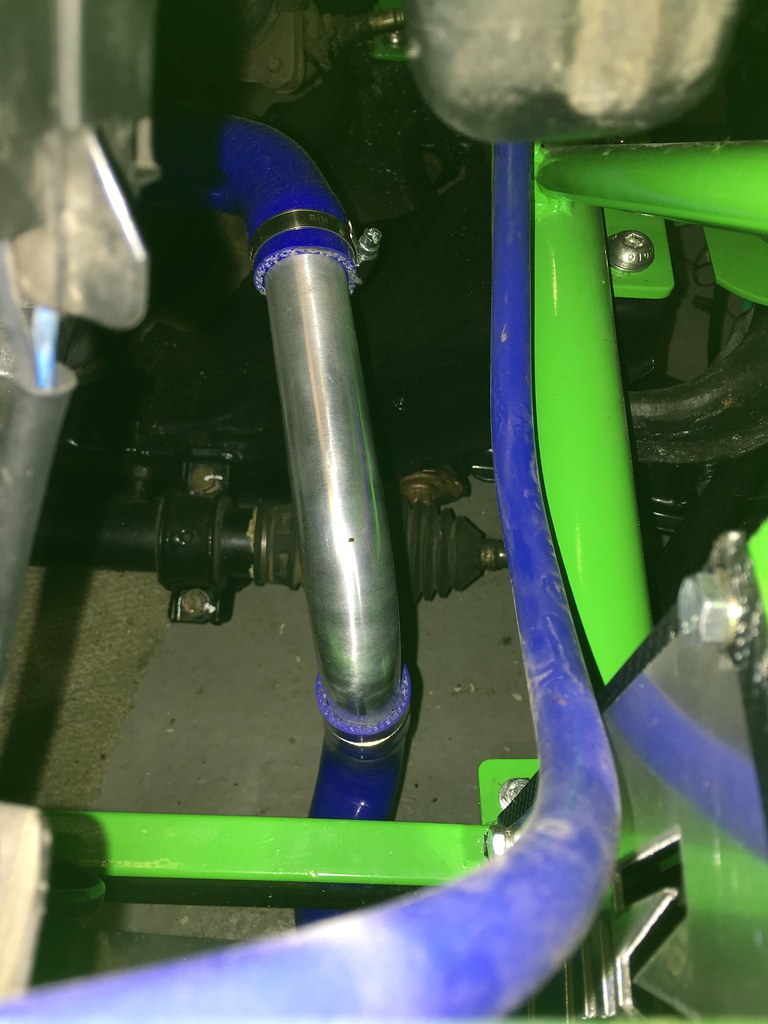

Then it was time to finally get the cooling system hooked up with a new bend in the bottom hose (which will be secured for IVA) and get some coolant into my (temporarily held) Hyundai Getz header tank....

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Next, I bolted down my fuel tank (I went for M10 bolts at each corner with Nylocs underneath - I expect this counts as secure enough for IVA) - and then tested that the rear bodywork fitted correctly.

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

I had deliberated about seats a lot and had swung between bare GRP and something more upholstered (like some corbeau/sparco buckets) but eventually settled on the lightweight approach and picked up a pair of MEV GRP seats, which I think will suit the minimalist nature of the car (and be a bit more weatherproof!)

Untitled on Flickr

Untitled on Flickr

Then the latest fun and games - I started fitting the o/s rear wing stay and as I was tapping the hole in the hub, the M8 tap snapped off flush in the hole (just about visible by the driveshaft below)

Untitled on Flickr

Untitled on Flickr

So, I had to whip off the hub and get it onto the bench - where thankfully, I was able to access the flutes in the tap and move it - and with some gentle persuasion thankfully managed to get the broken piece removed.

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

With the messing around, it meant the hole was a little mangled, so I then drilled and retapped it to M10 to ensure that I have a secure fit, and got everything rebuilt.

So that's as far as I have got for now, and the next plans are to get the wings mounted and get the lights all fitted and working as the next step towards being ready to go!

First of all, I got some deliveries - including lights, so I roughly connected the wiring to test that all worked - and was pleased to see light!

Untitled on Flickr

Untitled on FlickrI also tried the wiring for my savage switches for the rear fog and hazard lights - which work and light up in a nicely coordinated colour...

Untitled on Flickr

Untitled on Flickrthe only significant wiring issues have been sorting the earths on the panel lights and also discovering I had a dead instrument panel - which appears to be down to a broken track on the circuit board - which I will sort - but just want to check that the track hasn't broken due to high current leaking through the panel before I do so...

Untitled on Flickr

Untitled on FlickrI then started trying to tidy up some of the awkward bits that I hadn't got to and get some extra p-clips in some of the spots the IVA-man will be looking for - having bought myself a new drill and flexible drive to reach those tricky spots!

Untitled on Flickr

Untitled on FlickrHandbrake cable and fuel lines

Untitled on Flickr

Untitled on FlickrRear braided lines

Untitled on Flickr

Untitled on FlickrFront braided line across the bulkhead behind the engine

I then had a short break while I did a bit of work on my NC - service, replacement Lambda sensor and new front pads.

Untitled on Flickr

Untitled on FlickrThen it was time to finally get the cooling system hooked up with a new bend in the bottom hose (which will be secured for IVA) and get some coolant into my (temporarily held) Hyundai Getz header tank....

Untitled on Flickr

Untitled on Flickr Untitled on Flickr

Untitled on FlickrNext, I bolted down my fuel tank (I went for M10 bolts at each corner with Nylocs underneath - I expect this counts as secure enough for IVA) - and then tested that the rear bodywork fitted correctly.

Untitled on Flickr

Untitled on Flickr Untitled on Flickr

Untitled on FlickrI had deliberated about seats a lot and had swung between bare GRP and something more upholstered (like some corbeau/sparco buckets) but eventually settled on the lightweight approach and picked up a pair of MEV GRP seats, which I think will suit the minimalist nature of the car (and be a bit more weatherproof!)

Untitled on Flickr

Untitled on FlickrThen the latest fun and games - I started fitting the o/s rear wing stay and as I was tapping the hole in the hub, the M8 tap snapped off flush in the hole (just about visible by the driveshaft below)

Untitled on Flickr

Untitled on FlickrSo, I had to whip off the hub and get it onto the bench - where thankfully, I was able to access the flutes in the tap and move it - and with some gentle persuasion thankfully managed to get the broken piece removed.

Untitled on Flickr

Untitled on Flickr Untitled on Flickr

Untitled on FlickrWith the messing around, it meant the hole was a little mangled, so I then drilled and retapped it to M10 to ensure that I have a secure fit, and got everything rebuilt.

So that's as far as I have got for now, and the next plans are to get the wings mounted and get the lights all fitted and working as the next step towards being ready to go!

So, last time I was sorting out my rear wing mount, which I (eventually) got into place and so it was time to try and fit the wings...

Untitled on Flickr

Untitled on Flickr

So the first job was to mount the rear light into the wing (with some edge trim to fill in any gaps), which I thought looked like a good start.

Untitled on Flickr

Untitled on Flickr

then we could mark and drill the holes for mounting and get some tiger seal applied to fix it in place...

Untitled on Flickr

Untitled on Flickr

The only slight downside is that having put the wheel on, I had put the wing about 5-10mm too far into the stay and the tyre is catching slightly on the outside of the wing - so i need to redo the mounting again - and of course the remaining three. In the meantime, I decided to move onto other things, so I have also bought LOTS of edge trim - figuring I will need plenty for IVA, I have ordered a 50m reel (which took some finding - but I discovered Rejel do 25 and 50m reels) - which has cost me about the same as buying 20m by the metre, and means I can trim everything and more ready for the IVA man.

One thing that I had been wondering about was mounting the headlights - and I wanted to work out a mount that looked neat and tidy - so having sketched a few things up, I got some Aluminium bar machined up with a radiused end and suitable holes for mounting the lights and to bolt through to the frame - I did have to do a rethink on the dominator light threads having originally made (what I thought was) M8 thread, and realising the lights didn't fit - I then measured and rethreaded to the correct 3/8" UNF thread for my lights.

This then allowed me to test-fit, which I thought looked a good start before then painting the mounts up and fitting the lamps:

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Then I added my indicators onto the sides of the lights and started wiring as neatly as possible, and I am very happy with the result - and something that I think is a nice touch at tidying up the front end.

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

So I am happy with my progress so far - and have done a few other bits including mounting my header tank properly (if there is one thing I will change at some point, it will be to get rid of the blue hoses, and get something more in keeping with the green and black of everything else...)

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on FlickrSo the first job was to mount the rear light into the wing (with some edge trim to fill in any gaps), which I thought looked like a good start.

Untitled on Flickr

Untitled on Flickrthen we could mark and drill the holes for mounting and get some tiger seal applied to fix it in place...

Untitled on Flickr

Untitled on FlickrThe only slight downside is that having put the wheel on, I had put the wing about 5-10mm too far into the stay and the tyre is catching slightly on the outside of the wing - so i need to redo the mounting again - and of course the remaining three. In the meantime, I decided to move onto other things, so I have also bought LOTS of edge trim - figuring I will need plenty for IVA, I have ordered a 50m reel (which took some finding - but I discovered Rejel do 25 and 50m reels) - which has cost me about the same as buying 20m by the metre, and means I can trim everything and more ready for the IVA man.

One thing that I had been wondering about was mounting the headlights - and I wanted to work out a mount that looked neat and tidy - so having sketched a few things up, I got some Aluminium bar machined up with a radiused end and suitable holes for mounting the lights and to bolt through to the frame - I did have to do a rethink on the dominator light threads having originally made (what I thought was) M8 thread, and realising the lights didn't fit - I then measured and rethreaded to the correct 3/8" UNF thread for my lights.

This then allowed me to test-fit, which I thought looked a good start before then painting the mounts up and fitting the lamps:

Untitled on Flickr

Untitled on Flickr Untitled on Flickr

Untitled on FlickrThen I added my indicators onto the sides of the lights and started wiring as neatly as possible, and I am very happy with the result - and something that I think is a nice touch at tidying up the front end.

Untitled on Flickr

Untitled on Flickr Untitled on Flickr

Untitled on Flickr Untitled on Flickr

Untitled on FlickrSo I am happy with my progress so far - and have done a few other bits including mounting my header tank properly (if there is one thing I will change at some point, it will be to get rid of the blue hoses, and get something more in keeping with the green and black of everything else...)

Untitled on Flickr

Untitled on FlickrAfraid that I have been busy tinkering for the last few weeks - so am overdue another update to the thread! I have been making more progress - although I am now getting into some of the fiddly bits that are really taking quite a bit of time and thought to get right (and even then, some things are taking a couple of attempts until I am really happy that they are up to standard.

First job for this instalment was to clean out the garage (and get my brother's clio out!) then I could move the exocet forward on to my lift for the first time (and in fact the furthest it has so far moved since being on it's wheels).

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

And to go with the wings being sat in place, we also offered up the next addition - which is a pair of new g-type side panels from MEV, which I saw and thought would finish off the sides rather more neatly than the standard black plastic panelling.

Untitled on Flickr

Untitled on Flickr

The next job was then to actually drill the remaining three wings and offer them up into place:

Untitled on Flickr

Untitled on Flickr

and then tiger seal them into place with some suitable load on each wing...

Untitled on Flickr

Untitled on Flickr

Next, we carefully measured, marked, measured again and then cut out and mounted the fuel filler and fog/reverse lights in the rear tank cover.

Untitled on Flickr

Untitled on Flickr

Which meant we could then test-fit the cover onto the rear end to see how it is all going to look (I have ordered a number plate light, but think it may be too small to light the whole plate - time for some more IVA manual checking and shopping, I think).

Untitled on Flickr

Untitled on Flickr

Before the cover can be properly fitted, the pipework and wiring all needed tidying up

Untitled on Flickr

Untitled on Flickr

and then getting the fuel filter mounted - using the tank mount which also doubled up as a good earth point.

Untitled on Flickr

Untitled on Flickr

In the meantime, I have been wondering what to do about an exhaust, and after a bit of an eBay session came up with something that will at least provide me with a solution that's neater than the big standard box hanging out the back, but that isn't too expensive to replace when I eventually go turbo and might want to replace the whole system (as I currently have the less-used 475mm cat).

Untitled on Flickr

Untitled on Flickr

and with a bend and some clamps (and some highly secure cable ties) I could test fit it, and I think it looks pretty tidy.

Untitled on Flickr

Untitled on Flickr

So there is some more work to do, next major job being to get the rear cover fitted and sorted, which I hope to get onto this week.

First job for this instalment was to clean out the garage (and get my brother's clio out!) then I could move the exocet forward on to my lift for the first time (and in fact the furthest it has so far moved since being on it's wheels).

Untitled on Flickr

Untitled on Flickr Untitled on Flickr

Untitled on FlickrAnd to go with the wings being sat in place, we also offered up the next addition - which is a pair of new g-type side panels from MEV, which I saw and thought would finish off the sides rather more neatly than the standard black plastic panelling.

Untitled on Flickr

Untitled on FlickrThe next job was then to actually drill the remaining three wings and offer them up into place:

Untitled on Flickr

Untitled on Flickrand then tiger seal them into place with some suitable load on each wing...

Untitled on Flickr

Untitled on FlickrNext, we carefully measured, marked, measured again and then cut out and mounted the fuel filler and fog/reverse lights in the rear tank cover.

Untitled on Flickr

Untitled on FlickrWhich meant we could then test-fit the cover onto the rear end to see how it is all going to look (I have ordered a number plate light, but think it may be too small to light the whole plate - time for some more IVA manual checking and shopping, I think).

Untitled on Flickr

Untitled on FlickrBefore the cover can be properly fitted, the pipework and wiring all needed tidying up

Untitled on Flickr

Untitled on Flickrand then getting the fuel filter mounted - using the tank mount which also doubled up as a good earth point.

Untitled on Flickr

Untitled on FlickrIn the meantime, I have been wondering what to do about an exhaust, and after a bit of an eBay session came up with something that will at least provide me with a solution that's neater than the big standard box hanging out the back, but that isn't too expensive to replace when I eventually go turbo and might want to replace the whole system (as I currently have the less-used 475mm cat).

Untitled on Flickr

Untitled on Flickrand with a bend and some clamps (and some highly secure cable ties) I could test fit it, and I think it looks pretty tidy.

Untitled on Flickr

Untitled on FlickrSo there is some more work to do, next major job being to get the rear cover fitted and sorted, which I hope to get onto this week.

So, it has been a little while since I last updated - so here is the latest instalment in my build!

The first job from last time was to get a number plate light fitted - which started out with some careful marking and positioning...

Untitled on Flickr

Untitled on Flickr

and got the lights in the cover all connected up and tested:

Untitled on Flickr

Untitled on Flickr

so I could then secure the rear cover into place (the silver screws have since been replaced with some nice black allen-head bolts and countersink washers)

Untitled on Flickr

Untitled on Flickr

then I fitted the side repeaters into the cycle wings and wired those in

Untitled on Flickr

Untitled on Flickr

Next were some painting jobs to get out of the way:

Priming and painting the cam cover:

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

and a coat of black gloss over the backs of my GRP seats to finish them off

Untitled on Flickr

Untitled on Flickr

Fitted my fog and reverse light switches (with rings due to a *slight* error with the initial drill placement).

Untitled on Flickr

Untitled on Flickr

Next was a bit of cardboard templating and cutting out the rear bulkhead ready to be fitted:

Untitled on Flickr

Untitled on Flickr

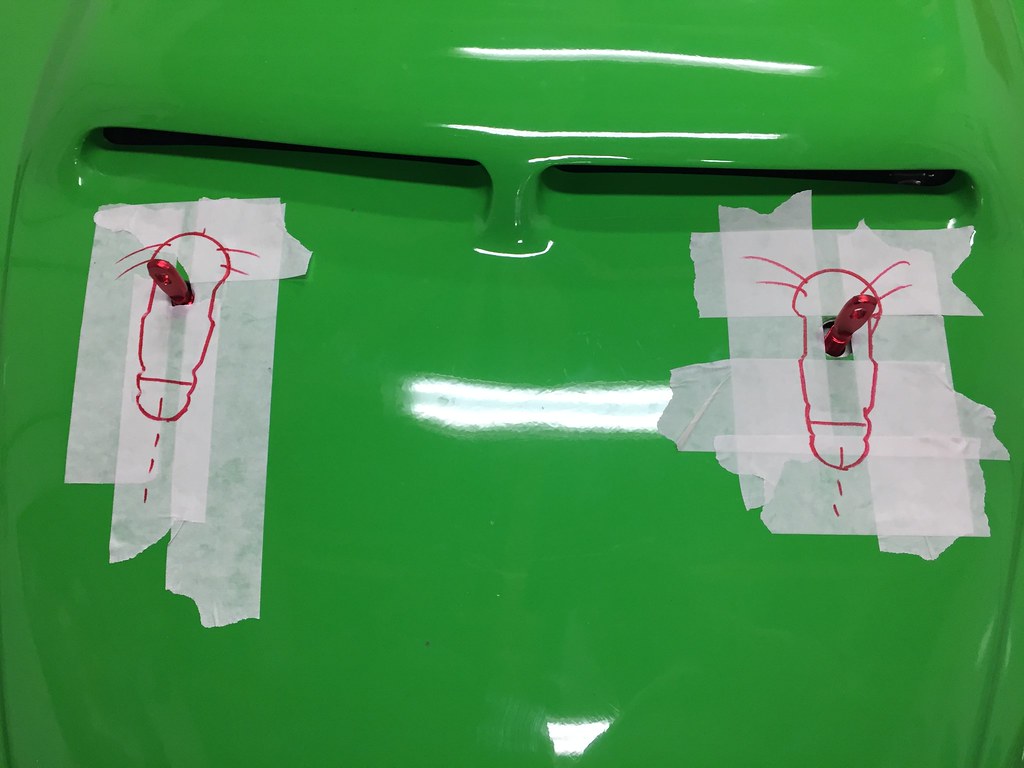

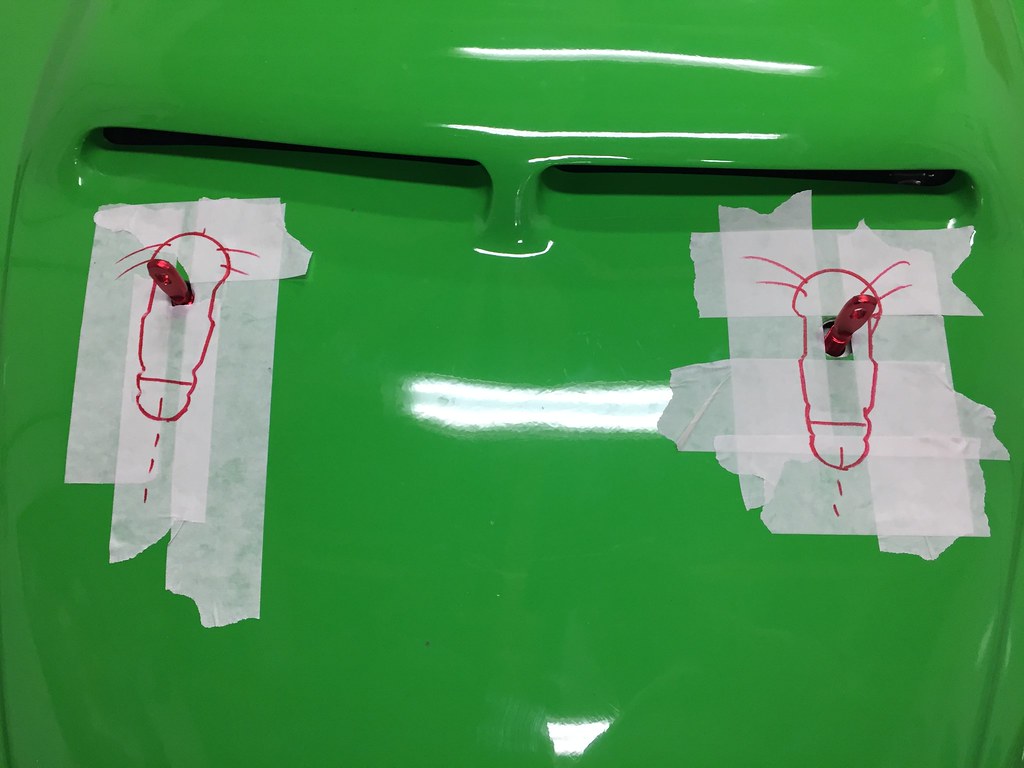

and then the bit I hadn't been looking forward to - fitting the nose. Unfortunately, even with the radiator moved as far back as possible (the fan housing is hard against the frame) and the inside of the bonnet contacting the radiator, there is still a gap of about 20mm between the back edge of the bonnet and the top bulkhead rail - which is a shame, but something I can't see a way around without further modification - so I will address the gap somehow instead.

Nervously cutting out the openings for the aero catches:

Untitled on Flickr

Untitled on Flickr

and fitting them

Untitled on Flickr

Untitled on Flickr

and bonnet fitted (but with a noticeable gap)

Untitled on Flickr

Untitled on Flickr

finally, I have added a couple of push-button pins onto the front end to secure that - and everything is nice and secure.

Untitled on Flickr

Untitled on Flickr

I have tonight started to trim up my side panels ready to fit them up - so hopefully I can get them and my seats all fitted up very shortly. I am pleased with how it is coming together and am managing to tick off some of the jobs that I wasn't looking forward to as well!

The first job from last time was to get a number plate light fitted - which started out with some careful marking and positioning...

Untitled on Flickr

Untitled on Flickrand got the lights in the cover all connected up and tested:

Untitled on Flickr

Untitled on Flickrso I could then secure the rear cover into place (the silver screws have since been replaced with some nice black allen-head bolts and countersink washers)

Untitled on Flickr

Untitled on Flickrthen I fitted the side repeaters into the cycle wings and wired those in

Untitled on Flickr

Untitled on FlickrNext were some painting jobs to get out of the way:

Priming and painting the cam cover:

Untitled on Flickr

Untitled on Flickr Untitled on Flickr

Untitled on Flickrand a coat of black gloss over the backs of my GRP seats to finish them off

Untitled on Flickr

Untitled on FlickrFitted my fog and reverse light switches (with rings due to a *slight* error with the initial drill placement).

Untitled on Flickr

Untitled on FlickrNext was a bit of cardboard templating and cutting out the rear bulkhead ready to be fitted:

Untitled on Flickr

Untitled on Flickrand then the bit I hadn't been looking forward to - fitting the nose. Unfortunately, even with the radiator moved as far back as possible (the fan housing is hard against the frame) and the inside of the bonnet contacting the radiator, there is still a gap of about 20mm between the back edge of the bonnet and the top bulkhead rail - which is a shame, but something I can't see a way around without further modification - so I will address the gap somehow instead.

Nervously cutting out the openings for the aero catches:

Untitled on Flickr

Untitled on Flickrand fitting them

Untitled on Flickr

Untitled on Flickrand bonnet fitted (but with a noticeable gap)

Untitled on Flickr

Untitled on Flickrfinally, I have added a couple of push-button pins onto the front end to secure that - and everything is nice and secure.

Untitled on Flickr

Untitled on FlickrI have tonight started to trim up my side panels ready to fit them up - so hopefully I can get them and my seats all fitted up very shortly. I am pleased with how it is coming together and am managing to tick off some of the jobs that I wasn't looking forward to as well!

Edited by browno on Thursday 29th March 00:08

It has been a few weeks, so it's time for another update!

First job was to fix my rear bulkhead with a combination of a good bead of tiger seal and some rivets - as seen here in progress...

Untitled on Flickr

Untitled on Flickr

Next up (after some trimming and double checking fitment!) was to fit my side panels, which I secured using LOTS of tiger seal! I used a full tube across the bottoms which was then allowed to go off (and a further bead added on the inside and outside of the bottom edge to fill out the space), and then 2/3rds of a tube for the top edges. I added edge trim along the bottom, front and rear edges after fitting, and along the top edges (glued on), before then securing the top with a (mostly) neat bead along the top edge.

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

I then added a bit of identification...

Untitled on Flickr

Untitled on Flickr

I have then been doing a whole series of smaller jobs (changing the oil and filter, torquing bolts and sorting a blow in the exhaust), which aren't so photogenic!

I have also bought a battery box, which is positioned ready to be bolted in, but I have been diverted by trying to get my seats in and fitted up. I had sold my donor seat runners along with the seats, so needed to buy a set of runners, which turned out to be mk2 runners, so needed a little tweaking to allow them to fit. Having fitted the runners and edge trimmed the seats, I spent some time playing with position and adjustments, I got the drill out and made the necessary holes which have allowed me to test fit my seats. I now need to get some shorter bolts to final fix them, and to cut out the holes for the harnesses (which I have the lower eye bolts prepped for).

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Next jobs are to fit the battery box and then I am into final prep for IVA, where I plan to take it for a pre-check at a mate's garage with MOT bay, so we can check brakes, lights and emissions. I think that I am going to be ready to submit my paperwork very soon to get it ready for the road!

First job was to fix my rear bulkhead with a combination of a good bead of tiger seal and some rivets - as seen here in progress...

Untitled on Flickr

Untitled on FlickrNext up (after some trimming and double checking fitment!) was to fit my side panels, which I secured using LOTS of tiger seal! I used a full tube across the bottoms which was then allowed to go off (and a further bead added on the inside and outside of the bottom edge to fill out the space), and then 2/3rds of a tube for the top edges. I added edge trim along the bottom, front and rear edges after fitting, and along the top edges (glued on), before then securing the top with a (mostly) neat bead along the top edge.

Untitled on Flickr

Untitled on Flickr Untitled on Flickr

Untitled on Flickr Untitled on Flickr

Untitled on Flickr Untitled on Flickr

Untitled on FlickrI then added a bit of identification...

Untitled on Flickr

Untitled on FlickrI have then been doing a whole series of smaller jobs (changing the oil and filter, torquing bolts and sorting a blow in the exhaust), which aren't so photogenic!

I have also bought a battery box, which is positioned ready to be bolted in, but I have been diverted by trying to get my seats in and fitted up. I had sold my donor seat runners along with the seats, so needed to buy a set of runners, which turned out to be mk2 runners, so needed a little tweaking to allow them to fit. Having fitted the runners and edge trimmed the seats, I spent some time playing with position and adjustments, I got the drill out and made the necessary holes which have allowed me to test fit my seats. I now need to get some shorter bolts to final fix them, and to cut out the holes for the harnesses (which I have the lower eye bolts prepped for).

Untitled on Flickr

Untitled on Flickr Untitled on Flickr

Untitled on FlickrNext jobs are to fit the battery box and then I am into final prep for IVA, where I plan to take it for a pre-check at a mate's garage with MOT bay, so we can check brakes, lights and emissions. I think that I am going to be ready to submit my paperwork very soon to get it ready for the road!

It has been a while again, so it's time for another update...

So, after last time, I carefully considered the placement and shape of the harness holes before taking the plunge and chopping into the seats, which I then finished with edge trim.

[ Untitled on Flickr

Untitled on Flickr

Next on the list was to tidy up the gap between the bonnet and the dash rail, so I used the now redundant black side panel material to make up a lid that covers the top of the tray and neatens up the rear edge (which I have since finished with some wide edge trim).

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Next up was fitting the instrument binnacle, which took a few goes to get a bracket that worked:

Untitled on Flickr

Untitled on Flickr

Version 1

Untitled on Flickr

Untitled on Flickr

Version 2... Finally version 4 did the trick fixing on the front tabs and with an additional bracket from the rear of the housing to the dash top rail - so with the original MX5 instrument cluster stuck into the MEV GRP housing, I could fix it into place.

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Untitled on Flickr

Then, I have added some infill panels on each side to help with edges for IVA - again using some of the plastic side panel material, just cable tied into place.

Untitled on Flickr

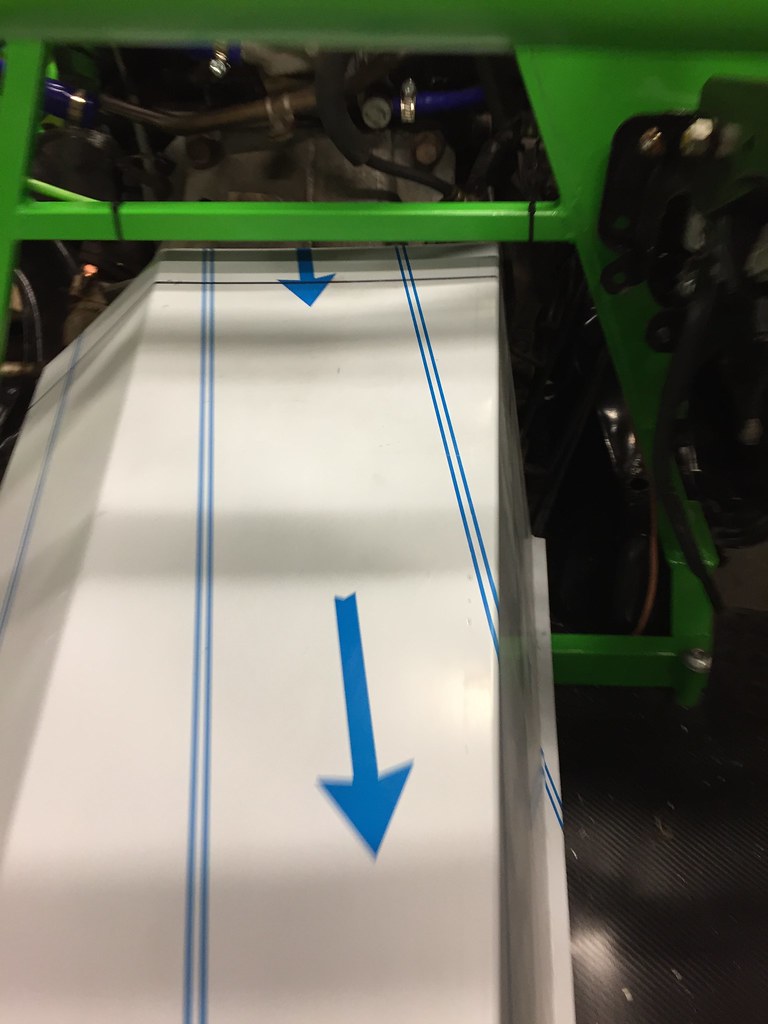

I have also done a whole load more smaller jobs - mounting the back box, wrapping and fitting the transmission tunnel and starting to work through all the edges that need trimming for IVA.

On that note, I now have a deadline - with the IVA test now booked in for June 20th, so I have a self-imposed deadline to work to, which I think is do-able, as long as I can get it up to my mate's garage for a pre-check of brakes, lights and emissions, just to be sure, but there is certainly going to be a need for some serious garage time for the next week or so!

So, after last time, I carefully considered the placement and shape of the harness holes before taking the plunge and chopping into the seats, which I then finished with edge trim.

[

Untitled on Flickr

Untitled on FlickrNext on the list was to tidy up the gap between the bonnet and the dash rail, so I used the now redundant black side panel material to make up a lid that covers the top of the tray and neatens up the rear edge (which I have since finished with some wide edge trim).

Untitled on Flickr

Untitled on Flickr Untitled on Flickr

Untitled on FlickrNext up was fitting the instrument binnacle, which took a few goes to get a bracket that worked:

Untitled on Flickr

Untitled on FlickrVersion 1

Untitled on Flickr

Untitled on FlickrVersion 2... Finally version 4 did the trick fixing on the front tabs and with an additional bracket from the rear of the housing to the dash top rail - so with the original MX5 instrument cluster stuck into the MEV GRP housing, I could fix it into place.

Untitled on Flickr

Untitled on Flickr Untitled on Flickr

Untitled on FlickrThen, I have added some infill panels on each side to help with edges for IVA - again using some of the plastic side panel material, just cable tied into place.

Untitled on Flickr

I have also done a whole load more smaller jobs - mounting the back box, wrapping and fitting the transmission tunnel and starting to work through all the edges that need trimming for IVA.

On that note, I now have a deadline - with the IVA test now booked in for June 20th, so I have a self-imposed deadline to work to, which I think is do-able, as long as I can get it up to my mate's garage for a pre-check of brakes, lights and emissions, just to be sure, but there is certainly going to be a need for some serious garage time for the next week or so!

Thanks guys - good to know this is of interest! Will definitely watch the cable ties (I imagine many of them might fall off post-IVA anyway!)

Exciting news today! I managed to get my replacement used injector shipped and here Friday night, so fitted that and the front is all leak free when I have had it running a good while.

So, with some trepidation, this afternoon, I borrowed some trade plates and headed out - to get fuel and then to check brakes, lights and emissions at my mate’s MOT garage...

First challenge was after about 1/2 mile, I had a rotational squeak from the nsr - which i thought as possibly the wing stay contacting the CV - but there were no marks... so i carried carefully on.

I got the the nearest filling station and began filling... and carried on, for quite some time - until I got fed up at about 35 litres (plus at least 5 already in the tank) - and discovered there was a drip from below...

So I carefully drove it up to the garage - and whipped off the rear cover to discover the filler hose clip had come slightly adrift at the tank end - which was soon solved with no more dripping.

Next it was lights - which needed a tweak but look ok, then brakes - which was mostly ok - the foot brake worked ok (and were noted by my mate as being quite sharp) - but the handbrake was not working at all on the ns...

Emissions check failed first time on lambda (at 1.05) but dropped in after holding 3000rpm for a few minutes to get it nice and hot. The CO and HC were essentially zero meaning the cat is working properly at least!

So with that done, I went for a little run round the block (and covered 20 miles!) - impressions so far are that it certainly draws some attention! It also drives very well - apart from the nsr squeak - with the brakes working well and steering feeling good - the wheel even being well centred despite setting the alignment by eye only (it will be getting a full corner weight and align after IVA). It also feels like it pulls well - although I was going relatively steady to get everything settled.

Once home, I have had a look over and spotted the brake problem. One of the pad fitting shims has slipped on the nsr and was trapped between pad and disc. As a result, it was holding the piston off - meaning that was adjusted too far out for the handbrake mechanism to engage. With the shim removed (I have a new fitting kit reserved for Tuesday collection), I have proven that the handbrake now adjusts and operates - so I think all is well.

The only other problem was the diff drain plug had rattled loose, meaning it had dropped about 100ml of fluid - so I sorted that and topped up.

Overall I am very happy that it is going to be sorted and ready for Wednesday!

Exciting news today! I managed to get my replacement used injector shipped and here Friday night, so fitted that and the front is all leak free when I have had it running a good while.

So, with some trepidation, this afternoon, I borrowed some trade plates and headed out - to get fuel and then to check brakes, lights and emissions at my mate’s MOT garage...

First challenge was after about 1/2 mile, I had a rotational squeak from the nsr - which i thought as possibly the wing stay contacting the CV - but there were no marks... so i carried carefully on.

I got the the nearest filling station and began filling... and carried on, for quite some time - until I got fed up at about 35 litres (plus at least 5 already in the tank) - and discovered there was a drip from below...

So I carefully drove it up to the garage - and whipped off the rear cover to discover the filler hose clip had come slightly adrift at the tank end - which was soon solved with no more dripping.

Next it was lights - which needed a tweak but look ok, then brakes - which was mostly ok - the foot brake worked ok (and were noted by my mate as being quite sharp) - but the handbrake was not working at all on the ns...

Emissions check failed first time on lambda (at 1.05) but dropped in after holding 3000rpm for a few minutes to get it nice and hot. The CO and HC were essentially zero meaning the cat is working properly at least!

So with that done, I went for a little run round the block (and covered 20 miles!) - impressions so far are that it certainly draws some attention! It also drives very well - apart from the nsr squeak - with the brakes working well and steering feeling good - the wheel even being well centred despite setting the alignment by eye only (it will be getting a full corner weight and align after IVA). It also feels like it pulls well - although I was going relatively steady to get everything settled.

Once home, I have had a look over and spotted the brake problem. One of the pad fitting shims has slipped on the nsr and was trapped between pad and disc. As a result, it was holding the piston off - meaning that was adjusted too far out for the handbrake mechanism to engage. With the shim removed (I have a new fitting kit reserved for Tuesday collection), I have proven that the handbrake now adjusts and operates - so I think all is well.

The only other problem was the diff drain plug had rattled loose, meaning it had dropped about 100ml of fluid - so I sorted that and topped up.

Overall I am very happy that it is going to be sorted and ready for Wednesday!

Thanks again for the comments guys - guess I probably should update you all on how I've got on with the IVA.. but first (to keep you in suspense), I probably should get you up to date with some more pics and updates on the hours I've been spending in the garage over the last fortnight!

A bit of branding!

Untitled on Flickr

Untitled on Flickr

Wing mirrors fitted on the top tubes

Untitled on Flickr

Untitled on Flickr

Cable tie bases glued around the grille opening and black grille mesh fitted

Untitled on Flickr

Untitled on Flickr

IMG_8955 on Flickr

IMG_8955 on Flickr

IMG_8953 on Flickr

IMG_8953 on Flickr

When we got it out of the garage, my brother took some nice pics (which show how good an iPhone can be in a decent photographer's hands!), which are quite good:

IMG_6732 on Flickr

IMG_6732 on Flickr

IMG_7178 on Flickr

IMG_7178 on Flickr

Untitled on Flickr

Untitled on Flickr

A quick snap when I took it up for emissions/brakes check:

Untitled on Flickr

Untitled on Flickr

Since then I have had a busy couple of nights, adding even more edging (I bought a 50m roll of edge trim, and probably used about 30-35m of it!), nut covers on everything (with judiscious use of the hot glue gun to hold them in place, thanks to Mazda's liking of an 11mm bolt), wrapped the back section of the exhaust and sorted out my rear brakes so the handbrake worked.

Then we get to this morning, where we loaded my mate Steve's Landy with half the contents of my garage (so we had the ability to fix pretty much anything!) and all of my paperwork in a nice big folder. Then we headed from home over to the test centre. We were lucky with the traffic and got there about 20 minutes early.

IMG_9097 on Flickr

IMG_9097 on Flickr

Untitled on Flickr

Untitled on Flickr

So after a brief photo break, we were greeted by out tester who said he was looking forward to testing his first and last Exocet - it transpired that due to DVSA rearrangements, he was due to take voluntary redundancy and this was his last test - he even said that due to the changes, and a limited number of trained testers that it was likely that if I failed, I would need to go to Manchester for retest.

So the test began with pulling the car into the test lane where the speedo was checked and deemed to be bang on, so that was good. Next was to pull forward a little for the emissions test - where I had my first worry of the day! I knew the polutants were fine, but when we checked, had seen the lambda was at the top end of the MOT range - and it was the same today. With a limit of 1.03, the first test failed at 1.031, but a second test (with me holding the revs steady at 3000 - the top of the window to get everything stable between) saw the second result squeak in at 1.030! At this point, my mate was looking anxious, and thinking we were failing at the first hurdle - but we carried on!

Next was the check of edges and projections - which was interesting to watch, with our tester clearly having a thorough eye, and a system that he had used on many vehicles - and picked up a couple of small issues - the cable tie ends on my side panels were facing inwards, so we re-did them to be on the outside away from the occupant's legs, the bottom of my dash (which I had decided to ask about, rather than pre-trim) needed some trim sticking on, and we needed a little extra edging on the handbrake cable joiner. these were all swiftly sorted by digging in to my mate's little bag of pre-prepared bits, with no need to deploy the Landy-workshop! It was clear that despite being his last test, our man was going to give us a proper, but also a fair test - and was happy to talk through what we had done, and how he thought things would be appropriately resolved.

We then looked at the fuel filler and I offered up pictures of the earthing and vents on the tank, which were all ok - and there was no mention of needing a drip-tray under the tank (I had not fitted one, and had wondered if that might be a point for discussion - but was happy that it went unmentioned, so was ok). The lights (apart from headlights) were tested too, and deemed all ok.

Untitled on Flickr

Untitled on Flickr

Next, I drove onto the large 4-post lift where I sat in the car while I was raised and asked to turn the wheels lock to lock - and came across another couple of small issues with one of the front brake hoses needing its clip adjusting to prevent rubbing on full lock, and a couple of sections of pipe/hose needing rubber overlays adding to prevent rubbing, which Steve duly dealt with quickly, while I sat in the car and chilled!

The headlight check was next - and the tester commented that he wasn't a fan of the "Chinese special" headlights as the beam pattern wasn't great, but he was happy enough to accept them, as they were aimed ok, just not brilliantly defined (I explained that they had already been improved a little by changing from the original bulbs to better ones).

Next stop was to roll off the ramp and to check the weights - with the corner weights working out surprisingly good, given that I had just set the coil-overs by eye! The total weight came in at 700Kg exactly (with approx 45l of fuel on board) - 388Kg front, 312 rear - so with a dry tank and some of the IVA-trim removed, 650Kg would be a reasonable target.

With the weights checked, it was brake test time - and here I was hoping that my sorting had worked (as we were getting close to the end of the test!). The brake test was looking ok until we got to the handbrake - which wouldn't disengage after the high effort test. I had a quick look, and it had pulled so far that the cable had popped loose in the caliper arm - a quick tweak and it was all ok. Thankfully, this then didn't reoccur, and wasn't raised as a fail. with the brakes numbers recorded, we moved outside for mirrors and sound level checks, while the tester took the car round the outside of the centre to check self centring.

When he joined us, the tester was very complementary about the car saying that it steered much more positively than many other kits he has tested, where they may need some help to self-centre, and that the brakes were excellent (so this gave us a confidence boost!).

The mirrors were all checked out ok, and then we came to the noise test - where I had a dB killer bung ready for the bike can just in case, but I needn't have worried - I was safely under at just 90.3dB.

So, with that, the test was over, but I wasn't sure of the final result - we were told to park up while the tester went to crunch the numbers for the brake test to see how it was. So we had a slightly anxious 15 minute wait until he then emerged... with a pass certificate, which is a result - I was confident that I had done my best to build the car properly and try to address as many points as I could ahead of time, so am very pleased that we could get it through first time!

Obviously, we were very happy with that, and so drove home, put the car away and decided to celebrate with a pub lunch and a pint!

Next job now is to fill in the DVLA forms to now get the car registered so that I can get out and enjoy it soon!

A bit of an essay, but I hope this thread has been useful to those thinking about a build - and now I can hopefully update when I get to actually drive the thing properly!

A bit of branding!

Untitled on Flickr

Untitled on FlickrWing mirrors fitted on the top tubes

Untitled on Flickr

Untitled on FlickrCable tie bases glued around the grille opening and black grille mesh fitted

Untitled on Flickr

Untitled on Flickr IMG_8955 on Flickr

IMG_8955 on Flickr IMG_8953 on Flickr

IMG_8953 on FlickrWhen we got it out of the garage, my brother took some nice pics (which show how good an iPhone can be in a decent photographer's hands!), which are quite good:

IMG_6732 on Flickr

IMG_6732 on Flickr IMG_7178 on Flickr

IMG_7178 on Flickr Untitled on Flickr

Untitled on FlickrA quick snap when I took it up for emissions/brakes check:

Untitled on Flickr

Untitled on FlickrSince then I have had a busy couple of nights, adding even more edging (I bought a 50m roll of edge trim, and probably used about 30-35m of it!), nut covers on everything (with judiscious use of the hot glue gun to hold them in place, thanks to Mazda's liking of an 11mm bolt), wrapped the back section of the exhaust and sorted out my rear brakes so the handbrake worked.

Then we get to this morning, where we loaded my mate Steve's Landy with half the contents of my garage (so we had the ability to fix pretty much anything!) and all of my paperwork in a nice big folder. Then we headed from home over to the test centre. We were lucky with the traffic and got there about 20 minutes early.

IMG_9097 on Flickr

IMG_9097 on Flickr Untitled on Flickr

Untitled on FlickrSo after a brief photo break, we were greeted by out tester who said he was looking forward to testing his first and last Exocet - it transpired that due to DVSA rearrangements, he was due to take voluntary redundancy and this was his last test - he even said that due to the changes, and a limited number of trained testers that it was likely that if I failed, I would need to go to Manchester for retest.

So the test began with pulling the car into the test lane where the speedo was checked and deemed to be bang on, so that was good. Next was to pull forward a little for the emissions test - where I had my first worry of the day! I knew the polutants were fine, but when we checked, had seen the lambda was at the top end of the MOT range - and it was the same today. With a limit of 1.03, the first test failed at 1.031, but a second test (with me holding the revs steady at 3000 - the top of the window to get everything stable between) saw the second result squeak in at 1.030! At this point, my mate was looking anxious, and thinking we were failing at the first hurdle - but we carried on!

Next was the check of edges and projections - which was interesting to watch, with our tester clearly having a thorough eye, and a system that he had used on many vehicles - and picked up a couple of small issues - the cable tie ends on my side panels were facing inwards, so we re-did them to be on the outside away from the occupant's legs, the bottom of my dash (which I had decided to ask about, rather than pre-trim) needed some trim sticking on, and we needed a little extra edging on the handbrake cable joiner. these were all swiftly sorted by digging in to my mate's little bag of pre-prepared bits, with no need to deploy the Landy-workshop! It was clear that despite being his last test, our man was going to give us a proper, but also a fair test - and was happy to talk through what we had done, and how he thought things would be appropriately resolved.

We then looked at the fuel filler and I offered up pictures of the earthing and vents on the tank, which were all ok - and there was no mention of needing a drip-tray under the tank (I had not fitted one, and had wondered if that might be a point for discussion - but was happy that it went unmentioned, so was ok). The lights (apart from headlights) were tested too, and deemed all ok.

Untitled on Flickr

Untitled on FlickrNext, I drove onto the large 4-post lift where I sat in the car while I was raised and asked to turn the wheels lock to lock - and came across another couple of small issues with one of the front brake hoses needing its clip adjusting to prevent rubbing on full lock, and a couple of sections of pipe/hose needing rubber overlays adding to prevent rubbing, which Steve duly dealt with quickly, while I sat in the car and chilled!

The headlight check was next - and the tester commented that he wasn't a fan of the "Chinese special" headlights as the beam pattern wasn't great, but he was happy enough to accept them, as they were aimed ok, just not brilliantly defined (I explained that they had already been improved a little by changing from the original bulbs to better ones).

Next stop was to roll off the ramp and to check the weights - with the corner weights working out surprisingly good, given that I had just set the coil-overs by eye! The total weight came in at 700Kg exactly (with approx 45l of fuel on board) - 388Kg front, 312 rear - so with a dry tank and some of the IVA-trim removed, 650Kg would be a reasonable target.

With the weights checked, it was brake test time - and here I was hoping that my sorting had worked (as we were getting close to the end of the test!). The brake test was looking ok until we got to the handbrake - which wouldn't disengage after the high effort test. I had a quick look, and it had pulled so far that the cable had popped loose in the caliper arm - a quick tweak and it was all ok. Thankfully, this then didn't reoccur, and wasn't raised as a fail. with the brakes numbers recorded, we moved outside for mirrors and sound level checks, while the tester took the car round the outside of the centre to check self centring.

When he joined us, the tester was very complementary about the car saying that it steered much more positively than many other kits he has tested, where they may need some help to self-centre, and that the brakes were excellent (so this gave us a confidence boost!).

The mirrors were all checked out ok, and then we came to the noise test - where I had a dB killer bung ready for the bike can just in case, but I needn't have worried - I was safely under at just 90.3dB.

So, with that, the test was over, but I wasn't sure of the final result - we were told to park up while the tester went to crunch the numbers for the brake test to see how it was. So we had a slightly anxious 15 minute wait until he then emerged... with a pass certificate, which is a result - I was confident that I had done my best to build the car properly and try to address as many points as I could ahead of time, so am very pleased that we could get it through first time!

Obviously, we were very happy with that, and so drove home, put the car away and decided to celebrate with a pub lunch and a pint!

Next job now is to fill in the DVLA forms to now get the car registered so that I can get out and enjoy it soon!

A bit of an essay, but I hope this thread has been useful to those thinking about a build - and now I can hopefully update when I get to actually drive the thing properly!

So, quick update time, and not much to report (no news is good news!)

I have been taking advantage of the good weather and making some use of the green machine - even bringing it to work a few times, where it does stand out somewhat in the car park!

Untitled on Flickr

Untitled on Flickr

I also had a morning out down at Curborough to join the annual MEV owners meeting, where I didn't venture on track this time (I want to get everything well sorted before doing so) - but did get to chat to a few of the folks that I have been comparing notes with during the build, and get a few ideas for further tweaks to do now that I'm IVA'd