Phoenix from the flames - Porsche Boxster with an Audi 2.7T

Discussion

It's not really holding it back, other than pulling a bit of ignition timing. I have the water/meth injection which is masks any poor results from the charge cooler system. It's more about just trying to make improvements and refine stuff.

I think I'm probably pushing my turbos past their efficency, next time I go to a dyno I'm going to run it at different boost levels and see what difference it makes to power. I could well be introducing a load of extra heat and making no power gains past a certain point.

My charge cooler system is completely independent of the engine cooling system. The radiator for the charge coolers is in the middle at the front.

If I was to change the charge coolers, I quite like the look of the F10 M5 ones or the Mclaren ones. I also had my eye on new turbos. I need to resist the urge to take it apart and make changes. It's fine as it is and everything is nicely integrated. I do enjoy the tinkering as much as the driving.

I think I'm probably pushing my turbos past their efficency, next time I go to a dyno I'm going to run it at different boost levels and see what difference it makes to power. I could well be introducing a load of extra heat and making no power gains past a certain point.

My charge cooler system is completely independent of the engine cooling system. The radiator for the charge coolers is in the middle at the front.

If I was to change the charge coolers, I quite like the look of the F10 M5 ones or the Mclaren ones. I also had my eye on new turbos. I need to resist the urge to take it apart and make changes. It's fine as it is and everything is nicely integrated. I do enjoy the tinkering as much as the driving.

I'll try and get some logs this evening. The ones I took before were compromised as the pump wasn't operating as I intended. I'd seen enough to know the new pump wasn't a game changer. I log air intake temp, coolant temp in and out of the charge coolers.

On the road the car only sees full throttle for probably less than 10 seconds at a time, I've got enough system capacity that this isn't long enough for me to see significantly raised temperatures on the coolant temp in. I rarely see raised temps for the coolant coming in to the charge coolers. I'm sure under constant throttle on a track (I'm going to Castle Coombe on the 16th April) I'll find it may struggle to bring the temps back down but at the moment the heat exchanger at the front rejecting heat isn't an issue.

My understanding is coolant flow rate is king (if rejecting head at the heat exchanger at the front isn't a problem). the thread I read with the heating engineer trying to re-develop the 4.0T system was all about flow rate, many of them are running 2 of these pumps I've just fitted in series.

Like I mentioned before, I'm probably pushing the turbos too hard and I also think poor efficiency of the charge coolers could be an issue. If my coolant flow has gone up but my temps haven't gone down it points to that. The S600 came out in 1999. I'm not sure how much technology has moved on in terms of core design? It might just be down to physical size. This is what they are like inside.

On the road the car only sees full throttle for probably less than 10 seconds at a time, I've got enough system capacity that this isn't long enough for me to see significantly raised temperatures on the coolant temp in. I rarely see raised temps for the coolant coming in to the charge coolers. I'm sure under constant throttle on a track (I'm going to Castle Coombe on the 16th April) I'll find it may struggle to bring the temps back down but at the moment the heat exchanger at the front rejecting heat isn't an issue.

My understanding is coolant flow rate is king (if rejecting head at the heat exchanger at the front isn't a problem). the thread I read with the heating engineer trying to re-develop the 4.0T system was all about flow rate, many of them are running 2 of these pumps I've just fitted in series.

Like I mentioned before, I'm probably pushing the turbos too hard and I also think poor efficiency of the charge coolers could be an issue. If my coolant flow has gone up but my temps haven't gone down it points to that. The S600 came out in 1999. I'm not sure how much technology has moved on in terms of core design? It might just be down to physical size. This is what they are like inside.

I had a look over the Boxster for the first time in a while. It's got a bit of an issue but I'm not sure what exactly.

When I went under it there was a small oil leak that's started (nothing making it's way onto the floor). I also noticed the dipstick had been pushed up. When I checked the oil level it was bellow the minimum mark on the dipstick. It took a litre to top it up to maximum.

IMG_20240302_175004405_HDR

IMG_20240302_175004405_HDR

I instantly thought this was a breather issue. I pulled the spark plugs and every piston was wet with oil pooling in the lowest valve cut outs. I did a compression test and all cylinders are between 180-190psi and I did a leak down issue which shows no problems. All my boost hoses are oil free and the inlet manifold is dry. The oil must be coming past the piston rings.

2024-03-03_12-38-29

2024-03-03_12-38-29

I had a look over my breather system. I monitor the crankcase pressure so I've got data to go off. I merge the 3 breathers from the engine into one pipe and run it into a catch can. There's 2 lines that come back out of the catch can. One is to the inlet manifold for off boost with a check valve. It all works fine. At idle, if I open the oil cap the crank case pressure actually goes up as the engine can't pull a vacuum on the crank case. The other line coming out of the catch can goes to the venturis in my exhaust (with a one way valve). This is how I vent it while on boost. I know this works as I logged the crank case pressure with and without, it was lower with the venturi's connected and the pressure comes down as the exhaust flow goes up.

I took it on a 20 minute drive. The crank case pressure ranged from 1006mbar to 1064mbar. Ambient pressure was 1015mbar so it's seeing 0.7psi of positive pressure. The 1064mbar peak was at 5500rpm with the engine making 3000mbar (29psi). The pressure drops slightly after that point as the exhaust flow improves the venturi effect. I've not found much information on crank case pressures but everything I've seen suggests 0.7psi is fine.

The engine isn't visibly burning oil, the spark plugs were clean. All pistons are equally wet, it's not like I've got one worse than all the others. After a drive it looked like this. Still some oil on pooled (left side on the pic).

2024-03-06_21-08-06

2024-03-06_21-08-06

The one thing I don't understand, I've had engines with bad valve stem seals, they smoke like a chimney as soon as it's started up, the oil burns off quickly. That's not happening on mine which made me think it's not oil. It could be poorly atomised fuel at idle which would explain why it looks wet although It doesn't evaporate though if I leave the plugs out so probably not.

So I don't know where I'm at with it, dipstick popped up, oil leak started and lost a litre of oil says I've got a problem. The fact it runs great and doesn't visibly burn oil makes me think I might be worrying too much. I've got a track day booked next month, I'll keep an eye the oil consumption and crank case pressure.

I'm running 5w30 oil. Maybe I'll put some 10w40 in it on the next oil change.

In other news I bought some Mclaren 12c charge coolers. Try as I might I couldn't get them in, I just don't have enough space. I'd have had to re-locate the expansion tank into the boot and get my A/C lines re-made. The whole thing is a tight package with everything built around everything else so changes now will have too many knock on effects. It's a shame as they look the business.

IMG_20240303_194345087

IMG_20240303_194345087

When I went under it there was a small oil leak that's started (nothing making it's way onto the floor). I also noticed the dipstick had been pushed up. When I checked the oil level it was bellow the minimum mark on the dipstick. It took a litre to top it up to maximum.

IMG_20240302_175004405_HDR

IMG_20240302_175004405_HDRI instantly thought this was a breather issue. I pulled the spark plugs and every piston was wet with oil pooling in the lowest valve cut outs. I did a compression test and all cylinders are between 180-190psi and I did a leak down issue which shows no problems. All my boost hoses are oil free and the inlet manifold is dry. The oil must be coming past the piston rings.

2024-03-03_12-38-29

2024-03-03_12-38-29I had a look over my breather system. I monitor the crankcase pressure so I've got data to go off. I merge the 3 breathers from the engine into one pipe and run it into a catch can. There's 2 lines that come back out of the catch can. One is to the inlet manifold for off boost with a check valve. It all works fine. At idle, if I open the oil cap the crank case pressure actually goes up as the engine can't pull a vacuum on the crank case. The other line coming out of the catch can goes to the venturis in my exhaust (with a one way valve). This is how I vent it while on boost. I know this works as I logged the crank case pressure with and without, it was lower with the venturi's connected and the pressure comes down as the exhaust flow goes up.

I took it on a 20 minute drive. The crank case pressure ranged from 1006mbar to 1064mbar. Ambient pressure was 1015mbar so it's seeing 0.7psi of positive pressure. The 1064mbar peak was at 5500rpm with the engine making 3000mbar (29psi). The pressure drops slightly after that point as the exhaust flow improves the venturi effect. I've not found much information on crank case pressures but everything I've seen suggests 0.7psi is fine.

The engine isn't visibly burning oil, the spark plugs were clean. All pistons are equally wet, it's not like I've got one worse than all the others. After a drive it looked like this. Still some oil on pooled (left side on the pic).

2024-03-06_21-08-06

2024-03-06_21-08-06The one thing I don't understand, I've had engines with bad valve stem seals, they smoke like a chimney as soon as it's started up, the oil burns off quickly. That's not happening on mine which made me think it's not oil. It could be poorly atomised fuel at idle which would explain why it looks wet although It doesn't evaporate though if I leave the plugs out so probably not.

So I don't know where I'm at with it, dipstick popped up, oil leak started and lost a litre of oil says I've got a problem. The fact it runs great and doesn't visibly burn oil makes me think I might be worrying too much. I've got a track day booked next month, I'll keep an eye the oil consumption and crank case pressure.

I'm running 5w30 oil. Maybe I'll put some 10w40 in it on the next oil change.

In other news I bought some Mclaren 12c charge coolers. Try as I might I couldn't get them in, I just don't have enough space. I'd have had to re-locate the expansion tank into the boot and get my A/C lines re-made. The whole thing is a tight package with everything built around everything else so changes now will have too many knock on effects. It's a shame as they look the business.

IMG_20240303_194345087

IMG_20240303_194345087Peanut Gallery said:

Have fun on your track day!

0.7 psi is low, hope this is not an issue and it was just a one-off!

I have driven a car with no synchro as my dad had been told to increase the viscosity of the oil in the gearbox to do a long trailer tow, this in turn meant no oil made it into the synchro, and cooked it... Could the increase also up oil pressures more? - I don't think you have had any issues with your oil feed side, I am just curious!

Thanks, I'm looking forward to it. The plan is to start off easy and work my way into it.0.7 psi is low, hope this is not an issue and it was just a one-off!

I have driven a car with no synchro as my dad had been told to increase the viscosity of the oil in the gearbox to do a long trailer tow, this in turn meant no oil made it into the synchro, and cooked it... Could the increase also up oil pressures more? - I don't think you have had any issues with your oil feed side, I am just curious!

I think it's fairly common for people to run these engines on 5w40 and 10w40 looking on the forums.

poppopbangbang said:

Where is the pressure tapping for the crank case pressure sensor located?

How viable is it to move it and take the pressure reading off the top of the dipstick tube?

Two thought processes on this, the first is a second reading from elsewhere gives you another data set from a system with lots of variance in it, the second is to validate if the dipstick popped out because of crank case pressure or if it popped out because it's a long length of spring steel (I think it is on the 2.7?) being rung at a frequency that makes it walk.

If the dipstick gets out does it cock the rest of the crank case ventilation system effectiveness up?

I've got the pressure sensor in the middle of the Vee. It's mounted in an aluminium housing which has the breather port on it I'll get another sensor and put it on the dipstick and wire it up to see if there is a difference in the pressure. How viable is it to move it and take the pressure reading off the top of the dipstick tube?

Two thought processes on this, the first is a second reading from elsewhere gives you another data set from a system with lots of variance in it, the second is to validate if the dipstick popped out because of crank case pressure or if it popped out because it's a long length of spring steel (I think it is on the 2.7?) being rung at a frequency that makes it walk.

If the dipstick gets out does it cock the rest of the crank case ventilation system effectiveness up?

I think the dipstick might have been pushed up for a while, looking at logs it's made no difference to the peak pressure, still around 1060mbar but on the over run and idle the pressure was a bit higher as it didn't pull a vacuum.

mercedeslimos said:

Before you go to a semi-synthetic 10w40, I'd go to a BMW-spec fully synthetic 5w40. I did this on my 20v TT and oil consumption went down from 1 litre/1000 miles to 0.1 litre/1000 miles. Would a catch can vented to atmosphere smell terrible? I know the 20v and Audi 30v share design, they are heavy breathers in general I think?

Thanks for the suggestion. If I do end up change the oil grade I'll give this a go. I'm going to wait and see what the consumption is like on track and make a descision after that. A while back I fitted the 2.4 cylinder heads with the larger intake ports. It always bothered me that the inlet manifold ports were smaller. The general wisdom on the Audi forums and Facebook groups was you don't need to upgrade as people have made 700+bhp on the small port intakes. I'm not really buying it, Audi (or Cosworth?) gave the RS4 larger intake ports and obviously a manifold that matched with a larger throttle body also, that was an engine that made 380bhp as standard. I think I'm at the power level where it might make a decent difference.

It's something I've wanted to do for a while but the cost of the RS4 intake set-up is mental. One popped up locally at what I thought was a reasonable price. I went to go get it but it turned out it wasn't an RS4 manifold. That planted the seed though, I found another one and spent a bit more. RS4 manifold with fuel rail.

This is the fuel injectors from the old manifold are longer than RS4 ones

IMG_20240307_191451297

IMG_20240307_191451297

I haven't got the clearance to raise the fuel rail up this much so I needed to get new injectors. My plan was to measure the difference in injector duty cycle after swapping the manifold and tuning for it to see how much difference it had made. That's out of the window now. I bought another set of injectors, these are 1150cc at 4 bar.

The Audi S4 uses a smaller throttle body which has a rubber intake boot where the pipes connect, the RS4 uses a larger throttle, a cast aluminium pipe to replace the boot and then larger boost pipes. I didn't buy any of that stuff as I wasn't sure if it would fit my car. I wanted to ditch the rubber intake boot, it's a known point of failure and I've split one myself previously. My plan was to buy a 74mm throttle body was the aftermarket offers a bolt on flange for it which you can used a clamp on. I can only weld stainless steel, the only place I could get the bits I needed was from Australia. Ended up costing a fair whack as they had a minimum order level.

This is the pipe I came up with, it was way more difficult than I expected. It's dual 2.25" merging into 3". I used a merge I saved from the exhaust I had on the Boxster that caught fire. I was tight on clearance with the bulkhead and also the power steering pump. I couldn't make it symmetrical as I needed to go over gear cables on one side and under the power steering high pressure line on the other side. Being able to fit it and remove it was another concern. It took me ages to make it and I wasn't sure it would work until pretty late on so I'm pleased with it.

Here's all the bits, I had to buy all new silicone pipes and hose clamps as I've stepped from 2" to 2.25". I had the cam covers and intake manifold powder coated as it was painted before it flakes off all the time.

All fitted. A lot of it was done while the manifold was off being powder coated so I wasn't totally sure it'd all go together nicely. It did. The only thing that's a bit of a shame is the clamp on the throttle body doesn't come off as it won't clear the power steering pump so I need to remove the manifold to head bolts so I can lift the inlet up a bit.

Unfortunately I started it up and it's not running well. Baldur looked at a log for me and the throttle body is sticking. I've spent about twice what I thought it was going to cost so I bought a used throttle body to save a few quid, I regret that now. It's actually the part number which would have come on my Boxster originally. So now I've ordered a brand new one.

I'm looking forward to tuning it and see if there's much difference. Easiest way will be to time 100-200 in 4th. Whatever the difference it won't have been worth the outlay.

It's something I've wanted to do for a while but the cost of the RS4 intake set-up is mental. One popped up locally at what I thought was a reasonable price. I went to go get it but it turned out it wasn't an RS4 manifold. That planted the seed though, I found another one and spent a bit more. RS4 manifold with fuel rail.

This is the fuel injectors from the old manifold are longer than RS4 ones

IMG_20240307_191451297

IMG_20240307_191451297I haven't got the clearance to raise the fuel rail up this much so I needed to get new injectors. My plan was to measure the difference in injector duty cycle after swapping the manifold and tuning for it to see how much difference it had made. That's out of the window now. I bought another set of injectors, these are 1150cc at 4 bar.

The Audi S4 uses a smaller throttle body which has a rubber intake boot where the pipes connect, the RS4 uses a larger throttle, a cast aluminium pipe to replace the boot and then larger boost pipes. I didn't buy any of that stuff as I wasn't sure if it would fit my car. I wanted to ditch the rubber intake boot, it's a known point of failure and I've split one myself previously. My plan was to buy a 74mm throttle body was the aftermarket offers a bolt on flange for it which you can used a clamp on. I can only weld stainless steel, the only place I could get the bits I needed was from Australia. Ended up costing a fair whack as they had a minimum order level.

This is the pipe I came up with, it was way more difficult than I expected. It's dual 2.25" merging into 3". I used a merge I saved from the exhaust I had on the Boxster that caught fire. I was tight on clearance with the bulkhead and also the power steering pump. I couldn't make it symmetrical as I needed to go over gear cables on one side and under the power steering high pressure line on the other side. Being able to fit it and remove it was another concern. It took me ages to make it and I wasn't sure it would work until pretty late on so I'm pleased with it.

Here's all the bits, I had to buy all new silicone pipes and hose clamps as I've stepped from 2" to 2.25". I had the cam covers and intake manifold powder coated as it was painted before it flakes off all the time.

All fitted. A lot of it was done while the manifold was off being powder coated so I wasn't totally sure it'd all go together nicely. It did. The only thing that's a bit of a shame is the clamp on the throttle body doesn't come off as it won't clear the power steering pump so I need to remove the manifold to head bolts so I can lift the inlet up a bit.

Unfortunately I started it up and it's not running well. Baldur looked at a log for me and the throttle body is sticking. I've spent about twice what I thought it was going to cost so I bought a used throttle body to save a few quid, I regret that now. It's actually the part number which would have come on my Boxster originally. So now I've ordered a brand new one.

I'm looking forward to tuning it and see if there's much difference. Easiest way will be to time 100-200 in 4th. Whatever the difference it won't have been worth the outlay.

poppopbangbang said:

It's always been the case that the more you optimise the less the improvement actually is. The first 80% is easy but the next 20% is expensive and often hard.

However I'd argue that on yours that was worth the effort. It looks great and it's one of those things you're always going to ponder as being not quite right, or at least not as optimal as it could be!

Yeah, since the day I fitted the N/A heads it bothered me that the ports didn't match up so it's something I've wanted to do for a while. RS4's seem to make stronger numbers than S4's on the same turbos, so I am expecting to see a gain from it. Ideally with less restriction I could make the same sort of power as I do currently and not have to push the turbos as hard to do it. However I'd argue that on yours that was worth the effort. It looks great and it's one of those things you're always going to ponder as being not quite right, or at least not as optimal as it could be!

Stick Legs said:

I think it's fantastic.

I mean at this point anyone rational should have, would have abandoned it and walked off to just buy a used 911...

...but any fool can do that, this is up there with Hillary climbing Everest, Shackleton's lifeboat journey and Colin Furze's tunnel.

Because it can be done, and you are the only one brave enough to try it.

Anyone can get a loan and buy a car.

This is something else, in a sea of older Porsches your car & PopPopBangBang's are unique and fascinating.

Your perseverance and solution-eering are admirable and the site is richer for it.

Thanks. In my mind the performance it has makes it rational. Based off 100-200 times it's 997 GT2RS fast for 997 Carrera money. I'm quite proud of that so I'll forgive it the odd broken clutch or oil leak.I mean at this point anyone rational should have, would have abandoned it and walked off to just buy a used 911...

...but any fool can do that, this is up there with Hillary climbing Everest, Shackleton's lifeboat journey and Colin Furze's tunnel.

Because it can be done, and you are the only one brave enough to try it.

Anyone can get a loan and buy a car.

This is something else, in a sea of older Porsches your car & PopPopBangBang's are unique and fascinating.

Your perseverance and solution-eering are admirable and the site is richer for it.

The pressure has been on to get it ready for the track day on the 16th. I replaced the faulty throttle body with a brand new one.

IMG_20240402_140652905

IMG_20240402_140652905

Since the dump valves had been relocated I'd noticed that at idle they open up. Since I don't use a MAF I don't think it makes any odds other than drawing in some unfiltered air but I figured I'd change them. Nothing special, just Chinese ones off Amazon but they are adjustable so you can set the pre-load so they won't open up at idle. I know DV's are considered a bit uncool and there's an argument they aren't needed but I like them for Max Power era nostalgia reasons. Ppppttsssshhhh!

IMG_20240406_084855230_HDR

IMG_20240406_084855230_HDR

Changing anything throttle related tends to be hard work on the ECU side of it. It took me a while to get all the calibrations correct and the car running nice. Once that was done I could start tuning the fuel for the new injectors. I noticed I was making full boost a couple of hundred RPM later. I decided to pressure test the boost pipes, then spray soapy water around to see any leaks. I found a few, breather hose that connected to the PCV valve, a leak on a boost pipe clamp (not the red one on the throttle body) and a few leaks on the pipe I'd made.

IMG_20240407_200030957

IMG_20240407_200030957

Sorting out this pipe took me longer than expected. I had a booking to get a new pair of tyres fitted and had to put it all back together so I could get down there then take it all back apart to carry on. At least I've worked out a simple way to get the pipe on and off now.

IMG_20240407_212009315_HDR

IMG_20240407_212009315_HDR

The tyres were a bit of a pain. I'd ordered them from Asda. I've gone with Yokohama AD09's, 295/30/19. I got them sent to my local ETB Autocentre, it's new, about a year old. They were due to be fitted a week ago. ETB emailed me to say they couldn't fit them, I questioned it and they said they don't have the right equipment. Clearly b ks, they just took one look at them and couldn't be bothered, maybe Asda don't pay them much?

ks, they just took one look at them and couldn't be bothered, maybe Asda don't pay them much?

Asda were good about it, they rang around local fitters explained the type and size of tyre and made sure they'd be willing to fit them as I couldn't risk this happening a second time. They then got them sent somewhere else for me.

IMG_20240412_161805258

IMG_20240412_161805258

Showing the tread pattern. First thoughts are positive, they hook up better than the AD08R's that came off. They were a few years old though. Hopefully I don't ruin them on the track day.

IMG_20240412_223155417

IMG_20240412_223155417

Then I went for a test drive/tuning during a flat foot shift it wouldn't go into gear. I instantly knew the issue as it happened a few months ago. I'd panicked the first time thinking I'd done the gearbox. It's a shifter cable that's popped out of it's bracket. I thought it was a one off the first time it happened but clearly not. There was a hole in the top of the bracket so I could thread a cable tie through to hold it place so it doesn't happen again. Easy enough fix but defiantly not something I'd be able to do at a track day so I'm glad it happened now and not on my first lap at Coombe.

IMG_20240413_192912295

IMG_20240413_192912295

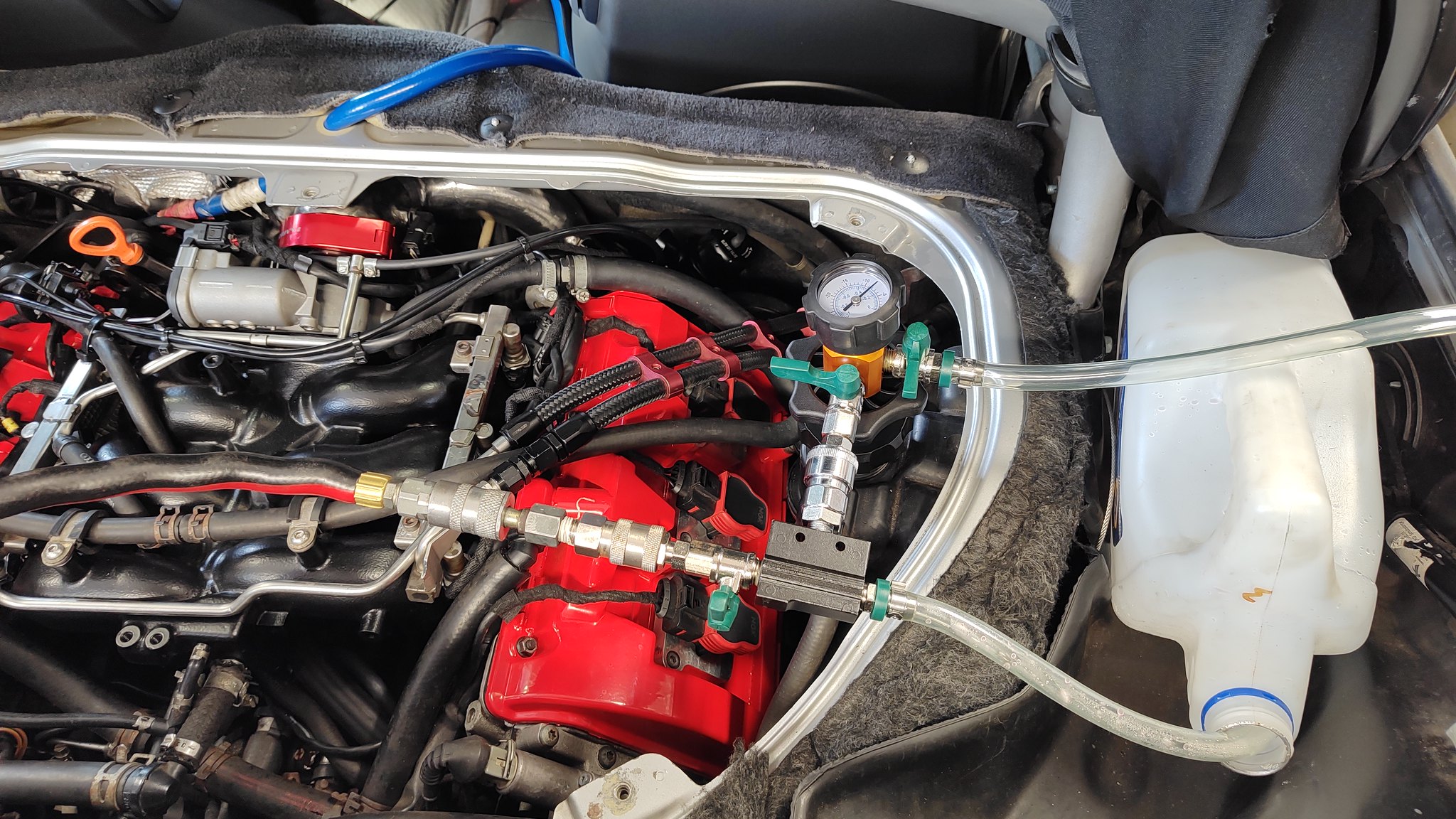

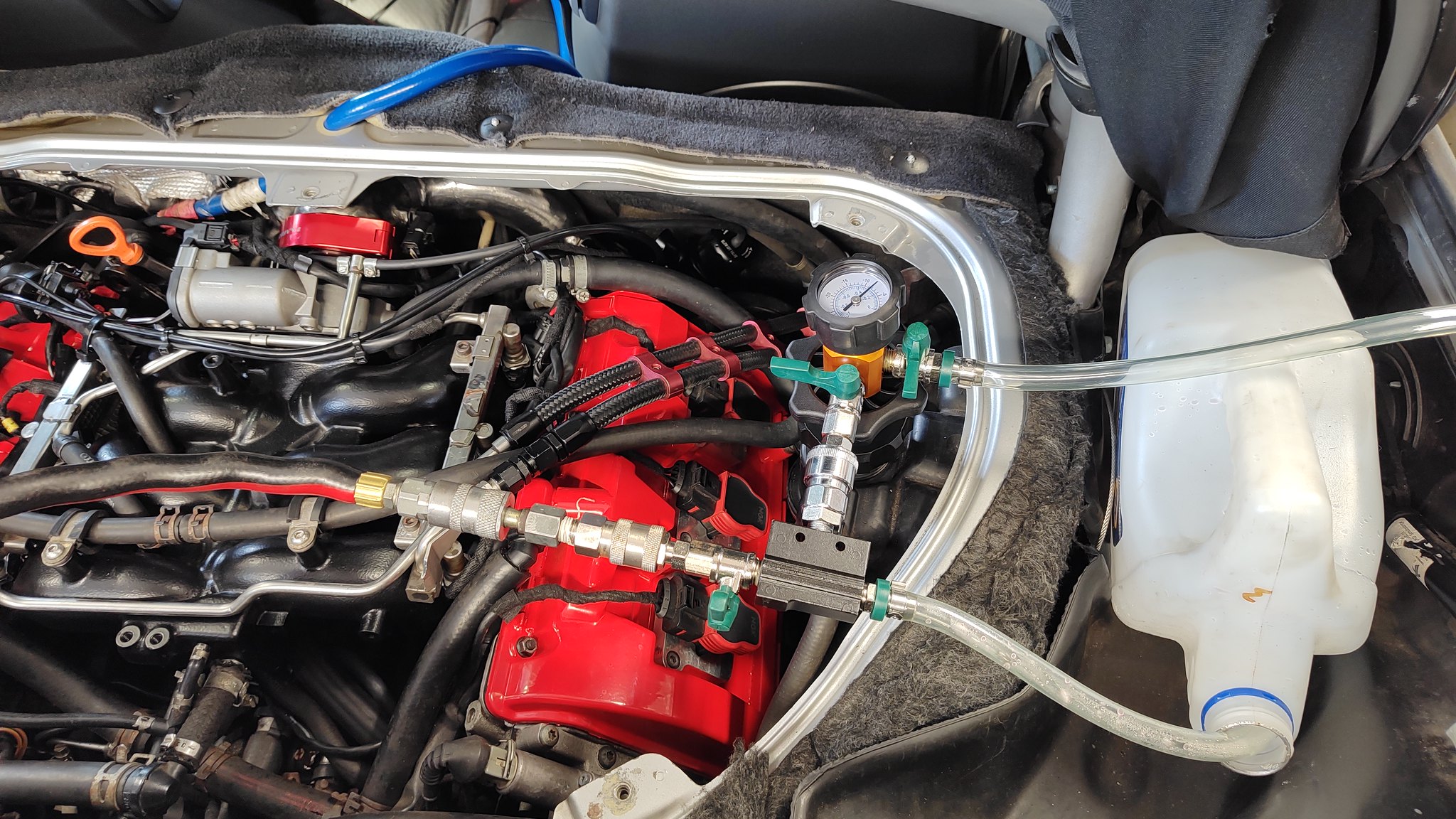

There was a small coolant leak from a banjo bolt on a turbo. I would also notice coolant boiling in one turbo after a drive but not the other one. I decided to buy a vacuum coolant filler. I had bought one previously (red box) but it was dog s t, never worked, at first I thought user error then I pretty much forgot about it. It won't pull a vacuum and it leaks air all over the place. I decided to buy a decent one this time.

t, never worked, at first I thought user error then I pretty much forgot about it. It won't pull a vacuum and it leaks air all over the place. I decided to buy a decent one this time.

IMG_20240414_161046413

IMG_20240414_161046413

That's it all connected up, simple to use. I decided I'd give it a go on my charge cooler system. I could hear the vacuum pull a load of air from the charge coolers in the engine compartment all the way to the front. It was unexpected but such a good feeling.

IMG_20240414_161734959

IMG_20240414_161734959

I didn't take a photo but I also fitted a pair of Brembo Sport HP2000 brake pads on the front, I had them a while, I have been trying to find a garage that can skim discs while on the car, could only find one place locally and they didn't want to do it was the discs are grooved. I think these machines are a fad that's been and gone. Since the track day is coming up I decided to just fit them.

I've got the tuning done. The jury is out with regards to the new inlet manifold making any difference. It did a 100-200 half a second slower than before at the same boost. I only got one run so it's not conclusive. I'll look into this a bit more after the track day.

I've run out of time now so I'll keep and eye on the logs while I'm at the track. I've set-up a low oil pressure cut off on the ECU. One of the things I'm concerned about is oil starvation. These engines aren't known for it but in the middle of a Porsche is a different proposition than the front of an Audi. I might also play about with the coilover damping.

A couple of photos of the engine as it all stands. That should be it now, no more planned changes.

IMG_20240414_165147831

IMG_20240414_165147831

IMG_20240414_165155524_HDR

IMG_20240414_165155524_HDR

IMG_20240414_165141539

IMG_20240414_165141539

IMG_20240402_140652905

IMG_20240402_140652905Since the dump valves had been relocated I'd noticed that at idle they open up. Since I don't use a MAF I don't think it makes any odds other than drawing in some unfiltered air but I figured I'd change them. Nothing special, just Chinese ones off Amazon but they are adjustable so you can set the pre-load so they won't open up at idle. I know DV's are considered a bit uncool and there's an argument they aren't needed but I like them for Max Power era nostalgia reasons. Ppppttsssshhhh!

IMG_20240406_084855230_HDR

IMG_20240406_084855230_HDRChanging anything throttle related tends to be hard work on the ECU side of it. It took me a while to get all the calibrations correct and the car running nice. Once that was done I could start tuning the fuel for the new injectors. I noticed I was making full boost a couple of hundred RPM later. I decided to pressure test the boost pipes, then spray soapy water around to see any leaks. I found a few, breather hose that connected to the PCV valve, a leak on a boost pipe clamp (not the red one on the throttle body) and a few leaks on the pipe I'd made.

IMG_20240407_200030957

IMG_20240407_200030957Sorting out this pipe took me longer than expected. I had a booking to get a new pair of tyres fitted and had to put it all back together so I could get down there then take it all back apart to carry on. At least I've worked out a simple way to get the pipe on and off now.

IMG_20240407_212009315_HDR

IMG_20240407_212009315_HDRThe tyres were a bit of a pain. I'd ordered them from Asda. I've gone with Yokohama AD09's, 295/30/19. I got them sent to my local ETB Autocentre, it's new, about a year old. They were due to be fitted a week ago. ETB emailed me to say they couldn't fit them, I questioned it and they said they don't have the right equipment. Clearly b

ks, they just took one look at them and couldn't be bothered, maybe Asda don't pay them much?

ks, they just took one look at them and couldn't be bothered, maybe Asda don't pay them much? Asda were good about it, they rang around local fitters explained the type and size of tyre and made sure they'd be willing to fit them as I couldn't risk this happening a second time. They then got them sent somewhere else for me.

IMG_20240412_161805258

IMG_20240412_161805258Showing the tread pattern. First thoughts are positive, they hook up better than the AD08R's that came off. They were a few years old though. Hopefully I don't ruin them on the track day.

IMG_20240412_223155417

IMG_20240412_223155417Then I went for a test drive/tuning during a flat foot shift it wouldn't go into gear. I instantly knew the issue as it happened a few months ago. I'd panicked the first time thinking I'd done the gearbox. It's a shifter cable that's popped out of it's bracket. I thought it was a one off the first time it happened but clearly not. There was a hole in the top of the bracket so I could thread a cable tie through to hold it place so it doesn't happen again. Easy enough fix but defiantly not something I'd be able to do at a track day so I'm glad it happened now and not on my first lap at Coombe.

IMG_20240413_192912295

IMG_20240413_192912295There was a small coolant leak from a banjo bolt on a turbo. I would also notice coolant boiling in one turbo after a drive but not the other one. I decided to buy a vacuum coolant filler. I had bought one previously (red box) but it was dog s

t, never worked, at first I thought user error then I pretty much forgot about it. It won't pull a vacuum and it leaks air all over the place. I decided to buy a decent one this time.

t, never worked, at first I thought user error then I pretty much forgot about it. It won't pull a vacuum and it leaks air all over the place. I decided to buy a decent one this time.  IMG_20240414_161046413

IMG_20240414_161046413That's it all connected up, simple to use. I decided I'd give it a go on my charge cooler system. I could hear the vacuum pull a load of air from the charge coolers in the engine compartment all the way to the front. It was unexpected but such a good feeling.

IMG_20240414_161734959

IMG_20240414_161734959I didn't take a photo but I also fitted a pair of Brembo Sport HP2000 brake pads on the front, I had them a while, I have been trying to find a garage that can skim discs while on the car, could only find one place locally and they didn't want to do it was the discs are grooved. I think these machines are a fad that's been and gone. Since the track day is coming up I decided to just fit them.

I've got the tuning done. The jury is out with regards to the new inlet manifold making any difference. It did a 100-200 half a second slower than before at the same boost. I only got one run so it's not conclusive. I'll look into this a bit more after the track day.

I've run out of time now so I'll keep and eye on the logs while I'm at the track. I've set-up a low oil pressure cut off on the ECU. One of the things I'm concerned about is oil starvation. These engines aren't known for it but in the middle of a Porsche is a different proposition than the front of an Audi. I might also play about with the coilover damping.

A couple of photos of the engine as it all stands. That should be it now, no more planned changes.

IMG_20240414_165147831

IMG_20240414_165147831 IMG_20240414_165155524_HDR

IMG_20240414_165155524_HDR IMG_20240414_165141539

IMG_20240414_165141539Edited by Escy on Monday 15th April 00:52

The track day didn't start off great, I discovered a bolt in my front tyre and had to go and get it repaired after I'd done the check in.

IMG_20240416_090650602

IMG_20240416_090650602

Then after my first lap I got a vibration. My wishbone was moving in the subframe. This defiantly wasn't happing on the road, just goes to show the extra load on it on track. The bolt was still tight even though it was moving. We tightened it up, marked it, I drove around the car park, checked it and it had moved. We managed to get it tight enough so it didn't move any more. I'll need to replace the bolt, it must be stretch or a damaged thread.. My alignment was now out, it drove fine but the steering wheel wasn't central anymore. Luckily others had tools I could borrow as I didn't have enough with me to sort that out.

IMG_20240416_103413519

IMG_20240416_103413519

Not the best start. I got it out on track and got a few laps in. The ABS was kicking in all the time, it's been alright on the road but it couldn't handle the track. In the end I turned off a canbus message which put the ABS into an error state, so it was basically off but I still had all the vehicle speed sensors working.

I've decided track days aren't my thing. I'm not truly in the moment as I know I need to drive it home. After a few laps I'd get into a rhythm go a bit faster and start to feel like I'm pushing my luck and come in. I wasn't good enough or brave enough get anywhere near the limit of the car, most of my time I was on the wastegate pressure or the low boost setting, I never use those maps on the road.

Glad I've done it but that's probably it. I think I'd be better off in a cheap and cheerful hot hatch that's trailered in.

Opentrack Castle Combe 16.4.24 - 0209 by Opentrack Track Days, on Flickr

Opentrack Castle Combe 16.4.24 - 0209 by Opentrack Track Days, on Flickr

Opentrack Castle Combe 16.4.24 - 1043 by Opentrack Track Days, on Flickr

Opentrack Castle Combe 16.4.24 - 1043 by Opentrack Track Days, on Flickr

Opentrack Castle Combe 16.4.24 - 1002 by Opentrack Track Days, on Flickr

Opentrack Castle Combe 16.4.24 - 1002 by Opentrack Track Days, on Flickr

Opentrack Castle Combe 16.4.24 - 0904 by Opentrack Track Days, on Flickr

Opentrack Castle Combe 16.4.24 - 0904 by Opentrack Track Days, on Flickr

IMG_20240416_090650602

IMG_20240416_090650602Then after my first lap I got a vibration. My wishbone was moving in the subframe. This defiantly wasn't happing on the road, just goes to show the extra load on it on track. The bolt was still tight even though it was moving. We tightened it up, marked it, I drove around the car park, checked it and it had moved. We managed to get it tight enough so it didn't move any more. I'll need to replace the bolt, it must be stretch or a damaged thread.. My alignment was now out, it drove fine but the steering wheel wasn't central anymore. Luckily others had tools I could borrow as I didn't have enough with me to sort that out.

IMG_20240416_103413519

IMG_20240416_103413519Not the best start. I got it out on track and got a few laps in. The ABS was kicking in all the time, it's been alright on the road but it couldn't handle the track. In the end I turned off a canbus message which put the ABS into an error state, so it was basically off but I still had all the vehicle speed sensors working.

I've decided track days aren't my thing. I'm not truly in the moment as I know I need to drive it home. After a few laps I'd get into a rhythm go a bit faster and start to feel like I'm pushing my luck and come in. I wasn't good enough or brave enough get anywhere near the limit of the car, most of my time I was on the wastegate pressure or the low boost setting, I never use those maps on the road.

Glad I've done it but that's probably it. I think I'd be better off in a cheap and cheerful hot hatch that's trailered in.

Opentrack Castle Combe 16.4.24 - 0209 by Opentrack Track Days, on Flickr

Opentrack Castle Combe 16.4.24 - 0209 by Opentrack Track Days, on Flickr Opentrack Castle Combe 16.4.24 - 1043 by Opentrack Track Days, on Flickr

Opentrack Castle Combe 16.4.24 - 1043 by Opentrack Track Days, on Flickr Opentrack Castle Combe 16.4.24 - 1002 by Opentrack Track Days, on Flickr

Opentrack Castle Combe 16.4.24 - 1002 by Opentrack Track Days, on Flickr Opentrack Castle Combe 16.4.24 - 0904 by Opentrack Track Days, on Flickr

Opentrack Castle Combe 16.4.24 - 0904 by Opentrack Track Days, on FlickrThanks guys. I was pleased with those photos they take, a nice touch.

MDifficult said:

Delighted that it went well! (Especially in light of your other thread) and any trackday you can drive home from is a good one.

Yeah, I was about to go back out on track when I got the phone call about the breakdown, I thought better of it! Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff