2007 Lotus 2-Eleven

Discussion

Not screenshotted is the error/diagnostics page, which pointed out that my yaw sensor and front right wheel speed sensors both had faults.

Turns out neither were plugged in. Fixed that, and the MIL went out.

Now to figure out why my ADU wasn't showing any CAN data from the ABS. I initially suspected my config, but as the sniffer couldn't see the relevant channels being broadcast either I suspected something else.

After chatting with a fellow Lotus owner who has the SCS ABS, he asked whether I'd selected the correct CAN profile in the software. This rang a bell from a few months ago when I first played with the software but I didn't recall seeing the option recently.

Out of interest, I installed an older version of the client on a different PC and found the setting immediately. Seems SCS have made it redundant.

Long story short, the early versions of the ABS supported switchable CAN profiles, with the intention of allowing it to plug and play with various OEMs. SCS have decided to discontinue this, and ship all with the Bosch M4/M5 profile which is becoming somewhat of a standard it seems. In an aid to be helpful, SCS had hardcoded mine to the Lotus S3 ABS profile - so this explained the missing channels.

With all this knowledge, I used the old client to switch mine back to Bosch M4/M5 and everything sprung to life. Well, sort of. I'd cocked some things up but the main stuff was there. Wheel speed, slip switch position... but no brake pressure sensor data from either circuit.

I spent ages cocking about with multi meter etc, as the software wasn't seeing any brake pressure either. Finally realised that me reaching into the cockpit with my hand and pushing the pedal wasn't applying enough force to generate enough pressure to register. As soon as I sat in the car and used my foot, it all sprang to life. Doh.

My final drama was when following the SCS documented "first start" list. It instructed to monitor the system voltages for ABS Solenoids, and that they should drop to zero when turning the ABS unit off. Mine did not, it dropped to 1.6V. I wonder if this was my parasitic drain?!

Spoiler alert: It wasn't, it was a documentation error. SCS confirmed that 1.6V was proper, and they promptly updated the documentation. I've since been measuring the battery every night and it hasn't had any notable drain, nor any draw when measuring between negative terminal and the negative lead - so I guess I did just run it flat.

Pretty dry update, but it does represent a lot of progress. At time of writing other than some small dash tweaks - everything is working as it should. I've spent tonight putting the interior back in including a tweak to the driver tillet to raise it up a bit. It does bring my knees a bit close to the steering column, but I was missing a bit of 'apex visibility' on track, so will see if this helps.

Next steps are to run the proper laptop-driven brake bleed procedure, do one more leak test and then I guess put the bodywork back on!

Turns out neither were plugged in. Fixed that, and the MIL went out.

Now to figure out why my ADU wasn't showing any CAN data from the ABS. I initially suspected my config, but as the sniffer couldn't see the relevant channels being broadcast either I suspected something else.

After chatting with a fellow Lotus owner who has the SCS ABS, he asked whether I'd selected the correct CAN profile in the software. This rang a bell from a few months ago when I first played with the software but I didn't recall seeing the option recently.

Out of interest, I installed an older version of the client on a different PC and found the setting immediately. Seems SCS have made it redundant.

Long story short, the early versions of the ABS supported switchable CAN profiles, with the intention of allowing it to plug and play with various OEMs. SCS have decided to discontinue this, and ship all with the Bosch M4/M5 profile which is becoming somewhat of a standard it seems. In an aid to be helpful, SCS had hardcoded mine to the Lotus S3 ABS profile - so this explained the missing channels.

With all this knowledge, I used the old client to switch mine back to Bosch M4/M5 and everything sprung to life. Well, sort of. I'd cocked some things up but the main stuff was there. Wheel speed, slip switch position... but no brake pressure sensor data from either circuit.

I spent ages cocking about with multi meter etc, as the software wasn't seeing any brake pressure either. Finally realised that me reaching into the cockpit with my hand and pushing the pedal wasn't applying enough force to generate enough pressure to register. As soon as I sat in the car and used my foot, it all sprang to life. Doh.

My final drama was when following the SCS documented "first start" list. It instructed to monitor the system voltages for ABS Solenoids, and that they should drop to zero when turning the ABS unit off. Mine did not, it dropped to 1.6V. I wonder if this was my parasitic drain?!

Spoiler alert: It wasn't, it was a documentation error. SCS confirmed that 1.6V was proper, and they promptly updated the documentation. I've since been measuring the battery every night and it hasn't had any notable drain, nor any draw when measuring between negative terminal and the negative lead - so I guess I did just run it flat.

Pretty dry update, but it does represent a lot of progress. At time of writing other than some small dash tweaks - everything is working as it should. I've spent tonight putting the interior back in including a tweak to the driver tillet to raise it up a bit. It does bring my knees a bit close to the steering column, but I was missing a bit of 'apex visibility' on track, so will see if this helps.

Next steps are to run the proper laptop-driven brake bleed procedure, do one more leak test and then I guess put the bodywork back on!

Some more chunks of progress at the weekend:

Jamie popped round and took the role of laptop jockey whilst doing the ABS bleed procedure.

The procedure was pretty straight forward, I stood near a caliper with a spanner and a hose. The Master Cylinders were under pressure from my pressure bleeder, and Jamie was in the car with the laptop connected and a foot poised over the brake pedal.

Once the sequence started, Jamie just followed the on-screen instructions and I cracked the nipples when instructed to do so. The ABS pump whirred away, and gave me some lovely satisfying streams of bubbles whilst doing it's thing.

During the start of the process, Jamie needed to press the brake pedal very hard for the software to recognise that he had done so. This correlated with the fact the brake pressure sensors didn't start registering until you'd applied a considerable force (hence me being unable to do it with my arm leaning into the footwell).

As the process progressed, the sensors detected pressure sooner and sooner - and by the time we got onto the last corner, just breathing on the pedal was registering pressure. Such is the effect of air in the system!

I mentioned before that the pedal feel was lovely even before doing this process, and it very much was. Jamie also commented on it. As we got to the final caliper, Jamie was getting quite excited about how the pedal now felt.

I was eager to try it, so we swapped seats and my golly gosh, the pedal was absolutely fantastic. Unfair to just say it's "hard", that's only part of it. It's hard, solid but has a lovely progression to it as you pile on the pressure. No spongeyness at all, just a very direct and robust movement. Really excited to see how this translates when actually applying the brakes at speed.

In terms of the brake pressures, pre-bleeding the most I could muster was 50bar per circuit. It was now just a lick over 100bar (1450psi per line!). Sound like massive numbers, but I've got no idea what a reference is.

Moving away from brakes, another winter job I had was to inspect the chargecooler pump. I'd noticed the flowrate into the header tank was looking a bit miserable. I've commented a few times in this thread that the 2-Eleven IAT's are a bit higher than the Exige ones were, so investigating this seemed like a sensible route.

When first taking the bodywork off the car back in December I quickly found this. A kink in the pipe where it had been forced around the OE ABS unit a bit.

In addition to this, I had another kink directly at the pump inlet as it bent around the chassis into the sill.

Prior to finding these kinks, I'd fully intended to just stick a more powerful pump on, but now I was less sure of that route. Instead I've decided to fix the kinks, and see how we get on. IAT's are "fine", so it's not like this was an urgent task - if I get no improvement from fixing this, I won't lose sleep over it. It would just be a bonus.

So, fluid out:

With the ABS relocated I could cut the front lines and take about a foot of pipework out, deleting the kinked bit and making for a straighter run:

...and at the pump inlet I swapped the kinked straight pipe out for a preformed 90deg piece to clear the corner of the sill.

Observing the flow rate into a bucket now looks much healthier, but that's not particularly scientific.

I was now quickly running out of jobs to do before putting the bodywork back on. The NS side panel had remained undisturbed through this work so far, but annoyingly it had the vacuum hose running through it for the MIA brake booster. I did consider just bunging the pipe and leaving it in place, but eventually I stopped being lazy and whipped the side off the car to remove it properly.

I'll cap this off at the throttlebody.

That brings us up to speed. Later this week I'll look to get the bodywork back on, or at least enough of it to allow me to get the car outside and do a few basic tests of the brakes.

Jamie popped round and took the role of laptop jockey whilst doing the ABS bleed procedure.

The procedure was pretty straight forward, I stood near a caliper with a spanner and a hose. The Master Cylinders were under pressure from my pressure bleeder, and Jamie was in the car with the laptop connected and a foot poised over the brake pedal.

Once the sequence started, Jamie just followed the on-screen instructions and I cracked the nipples when instructed to do so. The ABS pump whirred away, and gave me some lovely satisfying streams of bubbles whilst doing it's thing.

During the start of the process, Jamie needed to press the brake pedal very hard for the software to recognise that he had done so. This correlated with the fact the brake pressure sensors didn't start registering until you'd applied a considerable force (hence me being unable to do it with my arm leaning into the footwell).

As the process progressed, the sensors detected pressure sooner and sooner - and by the time we got onto the last corner, just breathing on the pedal was registering pressure. Such is the effect of air in the system!

I mentioned before that the pedal feel was lovely even before doing this process, and it very much was. Jamie also commented on it. As we got to the final caliper, Jamie was getting quite excited about how the pedal now felt.

I was eager to try it, so we swapped seats and my golly gosh, the pedal was absolutely fantastic. Unfair to just say it's "hard", that's only part of it. It's hard, solid but has a lovely progression to it as you pile on the pressure. No spongeyness at all, just a very direct and robust movement. Really excited to see how this translates when actually applying the brakes at speed.

In terms of the brake pressures, pre-bleeding the most I could muster was 50bar per circuit. It was now just a lick over 100bar (1450psi per line!). Sound like massive numbers, but I've got no idea what a reference is.

Moving away from brakes, another winter job I had was to inspect the chargecooler pump. I'd noticed the flowrate into the header tank was looking a bit miserable. I've commented a few times in this thread that the 2-Eleven IAT's are a bit higher than the Exige ones were, so investigating this seemed like a sensible route.

When first taking the bodywork off the car back in December I quickly found this. A kink in the pipe where it had been forced around the OE ABS unit a bit.

In addition to this, I had another kink directly at the pump inlet as it bent around the chassis into the sill.

Prior to finding these kinks, I'd fully intended to just stick a more powerful pump on, but now I was less sure of that route. Instead I've decided to fix the kinks, and see how we get on. IAT's are "fine", so it's not like this was an urgent task - if I get no improvement from fixing this, I won't lose sleep over it. It would just be a bonus.

So, fluid out:

With the ABS relocated I could cut the front lines and take about a foot of pipework out, deleting the kinked bit and making for a straighter run:

...and at the pump inlet I swapped the kinked straight pipe out for a preformed 90deg piece to clear the corner of the sill.

Observing the flow rate into a bucket now looks much healthier, but that's not particularly scientific.

I was now quickly running out of jobs to do before putting the bodywork back on. The NS side panel had remained undisturbed through this work so far, but annoyingly it had the vacuum hose running through it for the MIA brake booster. I did consider just bunging the pipe and leaving it in place, but eventually I stopped being lazy and whipped the side off the car to remove it properly.

I'll cap this off at the throttlebody.

That brings us up to speed. Later this week I'll look to get the bodywork back on, or at least enough of it to allow me to get the car outside and do a few basic tests of the brakes.

FTW said:

Great update, thank you. Does the ECUMaster ADU recognise the Bosch CAN structure or do you have translate it? Sorry if that’s a silly question.

The ECUMaster ADUs look very customisable, does it display the TC level setting?

It doesn't recognise is natively, the ADU doesn't do anything natively though! It's flexibility is its downfall, it's about as far away as plug and play as you get. The ECUMaster ADUs look very customisable, does it display the TC level setting?

So yeah you need to configure it to "listen" for the Bosch CAN messages, then once you have them defined you just map them to gauges, labels, etc. All CAN messages are also logged, so when I review the lap times etc I'll be able to see my exact brake balance at that time, plus when/where ABS triggers and on which wheel.

Yeah my dash does display the TC level too. That's a knob connected to an analogue input on my ECU, and the ECU sends that to ADU via CAN.

Yazza54 said:

If you wind up changing the pump a lot of people with forced induction cars run / upgrade to pierburg CWA100. I use one on the spire as a main coolant pump, works great.

Yeah that rings a bell, perhaps the one I'd chosen. I even setup a PWM config on the ECU to lower the pump speed at idle to reduce noise. Oh well, one for next year!Well progress on the car fell very flat, very quickly. Can't believe it's been over a month since last update!

Still, it was all for the greater good.

I'd had a dialogue open with the builders who did my kitchen knockthrough a few years ago about doing a bit of a garage project. Talks picked up again this Winter about working me in between their other big jobs - and suddenly, we got a slot!

This meant the car had to leave, sharpish. I had about a week to get the car in a fit state to go hide in the trailer and get all delicates/bodywork out of the garage too. It was a rushed few evenings after work but I lobbed the clams back on and got it into the trailer. My first and only experience to date of driving the car on the new brakes was summarised by "wow, they do NOTHING at low pedal force".

I think the biggest thing you miss when dropping a booster is that real low effort/low load end of the scale when pottering around a carpark, driveway or trailer. You're used to just brushing the pedal to stop the car, but it now needs a bit more effort.

As for the garage work, plan was to get rid of these:

..and fit a single double width door in their place.

This would allow me to rearrange internally to put the ramp in the middle, and gain storage down each side wall.

Old layout:

This meant sticking an RSJ in.

Due to the way garage door suppliers seem to work, I couldn't get a site survey done until AFTER the steel was in, which means several weeks with an OSB facia to my garage instead of doors.

With a centralised ramp position, this got me thinking about moving to a four post lift. This idea is still being internally debated, and thoughts on the decision are welcome - but the summary is:

Pro:

- Can store two cars in the garage, one above the other

Cons:

- Four poster is a much more imposing install, making the large workshop space feel small again

- Four poster might actually be worse for the type of spannering I do, but this can be mitigated by jacking beams etc.

- Ceiling height is a little low to comfortable get two cars one atop the other. Two Lotus type cars would be fine, but if I wanted my FF to sit beneath it for example, it would be very very tight.

In order to proactively address the last 'Con, the builders proposed changing the strusses for the centre two, effectively opening out a square. The trusses were reinforced further up, and they then replastered the ceiling to create a bit of a ceiling feature:

Though quite a large feature, it's actually only intended to give the 2-Eleven rollbar the extra inch or so it needed to comfortably allow the FF to sit under it, if a four post ramp does get installed. Until then, it's just a fancy light feature and nothing more as my scissor doesn't raise that high anyway!

Between builder visits, door delivery and bad weather I bought a load of garage furniture and got to building flatpacks on a night:

I also did many, many tip runs. Think I counted 12 exclusively on garage stuff.

Floor got covered in plaster, so that came out to be jetwashed:

I did some sheeting and some painting:

The builders uncovered the previous DIY job (not mine) of the garage lighting, and were shocked I was still alive.

Which meant scope creep to run new lighting. This was an excuse to reposition all the spots too. No hexlights were harmed in the making of this garage.

Was my job to blank, fill and paint the old spot locations:

Bought and built a new workbench:

Dropped my tools:

Dropped my wine:

But eventually things started to come together:

Finally new door day came. It was a 5m insulated jobby from Aluroll.

With the door in, I could get on with the last bit of tidying, more scrubbing of the floor and retrimming a few floor pieces to suit the new layout.

..after some more tip runs

et voila.

Retrieval of the 2-Eleven was a very exciting day, spoiled only by the discovery the battery was completely dead - so had to unceremoniously push it into its new home.

Added some cabinet lights for the workbench:

Battery confirmed to be dead. 4v seems to be somewhat of a failure mode for a LifePo4. I've ordered a new one, but have also charged this one up - so will see what it does. 48hrs in and it's still holding 13.8v.

The garage really has worked out a treat.

I now have excellent working space all around the car. With a full size car in here it's always going to be cramped due to length. With the FF in for instance, it will almost be flush bumper to bumper.

Jury is still very much out on the four poster. It really would be a huge unit inside the garage and it might get annoying to step around the posts etc... but being able to have two project cars on the go is very enticing. Well, maybe not two projects - but at least two cars that justify garage storage.

I wouldn't be able to spanner on a car whilst it sits above something else, so whatever takes the second spot would be regularly pushed out onto the drive under a cover between garage sessions but would still be workable, particularly if it was something small and definitely not FF sized. Input welcome from anyone who has installed a 4Post at home.

I now have very little time to finish the 2-Eleven off ready for first track outing (Easter Sunday), so really need to get cracking!

Still, it was all for the greater good.

I'd had a dialogue open with the builders who did my kitchen knockthrough a few years ago about doing a bit of a garage project. Talks picked up again this Winter about working me in between their other big jobs - and suddenly, we got a slot!

This meant the car had to leave, sharpish. I had about a week to get the car in a fit state to go hide in the trailer and get all delicates/bodywork out of the garage too. It was a rushed few evenings after work but I lobbed the clams back on and got it into the trailer. My first and only experience to date of driving the car on the new brakes was summarised by "wow, they do NOTHING at low pedal force".

I think the biggest thing you miss when dropping a booster is that real low effort/low load end of the scale when pottering around a carpark, driveway or trailer. You're used to just brushing the pedal to stop the car, but it now needs a bit more effort.

As for the garage work, plan was to get rid of these:

..and fit a single double width door in their place.

This would allow me to rearrange internally to put the ramp in the middle, and gain storage down each side wall.

Old layout:

This meant sticking an RSJ in.

Due to the way garage door suppliers seem to work, I couldn't get a site survey done until AFTER the steel was in, which means several weeks with an OSB facia to my garage instead of doors.

With a centralised ramp position, this got me thinking about moving to a four post lift. This idea is still being internally debated, and thoughts on the decision are welcome - but the summary is:

Pro:

- Can store two cars in the garage, one above the other

Cons:

- Four poster is a much more imposing install, making the large workshop space feel small again

- Four poster might actually be worse for the type of spannering I do, but this can be mitigated by jacking beams etc.

- Ceiling height is a little low to comfortable get two cars one atop the other. Two Lotus type cars would be fine, but if I wanted my FF to sit beneath it for example, it would be very very tight.

In order to proactively address the last 'Con, the builders proposed changing the strusses for the centre two, effectively opening out a square. The trusses were reinforced further up, and they then replastered the ceiling to create a bit of a ceiling feature:

Though quite a large feature, it's actually only intended to give the 2-Eleven rollbar the extra inch or so it needed to comfortably allow the FF to sit under it, if a four post ramp does get installed. Until then, it's just a fancy light feature and nothing more as my scissor doesn't raise that high anyway!

Between builder visits, door delivery and bad weather I bought a load of garage furniture and got to building flatpacks on a night:

I also did many, many tip runs. Think I counted 12 exclusively on garage stuff.

Floor got covered in plaster, so that came out to be jetwashed:

I did some sheeting and some painting:

The builders uncovered the previous DIY job (not mine) of the garage lighting, and were shocked I was still alive.

Which meant scope creep to run new lighting. This was an excuse to reposition all the spots too. No hexlights were harmed in the making of this garage.

Was my job to blank, fill and paint the old spot locations:

Bought and built a new workbench:

Dropped my tools:

Dropped my wine:

But eventually things started to come together:

Finally new door day came. It was a 5m insulated jobby from Aluroll.

With the door in, I could get on with the last bit of tidying, more scrubbing of the floor and retrimming a few floor pieces to suit the new layout.

..after some more tip runs

et voila.

Retrieval of the 2-Eleven was a very exciting day, spoiled only by the discovery the battery was completely dead - so had to unceremoniously push it into its new home.

Added some cabinet lights for the workbench:

Battery confirmed to be dead. 4v seems to be somewhat of a failure mode for a LifePo4. I've ordered a new one, but have also charged this one up - so will see what it does. 48hrs in and it's still holding 13.8v.

The garage really has worked out a treat.

I now have excellent working space all around the car. With a full size car in here it's always going to be cramped due to length. With the FF in for instance, it will almost be flush bumper to bumper.

Jury is still very much out on the four poster. It really would be a huge unit inside the garage and it might get annoying to step around the posts etc... but being able to have two project cars on the go is very enticing. Well, maybe not two projects - but at least two cars that justify garage storage.

I wouldn't be able to spanner on a car whilst it sits above something else, so whatever takes the second spot would be regularly pushed out onto the drive under a cover between garage sessions but would still be workable, particularly if it was something small and definitely not FF sized. Input welcome from anyone who has installed a 4Post at home.

I now have very little time to finish the 2-Eleven off ready for first track outing (Easter Sunday), so really need to get cracking!

Thanks for the comments so far.

2 post I'd sort of ruled out because it has more demands on the underlying concrete which is suspect, and also less ideal for long term storage without ways to fit drip trays etc.

I have no immediate plans to add a second garage car so I have time to get the feel for my new space and take it from there. That said, plans change quickly...

If I could find some convenient car storage close to home it would make the problem go away.

2 post I'd sort of ruled out because it has more demands on the underlying concrete which is suspect, and also less ideal for long term storage without ways to fit drip trays etc.

I have no immediate plans to add a second garage car so I have time to get the feel for my new space and take it from there. That said, plans change quickly...

If I could find some convenient car storage close to home it would make the problem go away.

New battery arrived promptly so got that in, and car fired to life as hoped.

Gone with same brand/model as before. It's a straight fit for "PC680" formfactor so no messing with brackets etc, straight in to the 2-Eleven factory bracket.

I did attach a quick release lead for my LifePo4 charger though so I don't need to rip the seats out if I have a problem with this one.

Up next, whilst the seats were out I had some replacement seat rails to fit from Tillet. They issued a safety recall on a couple of items over Winter, so great service and was reassuring to get these sent out so quickly.

Seems like they just got a bit taller, with more material between the mounting holes and top edge:

The powdercoat had suffered a bit after a year of the originals, probably not helped by how exposed they are in the 2-Eleven but still a little disappointing. Gave these a good waxy coat of Dynax UC to keep the worst of the Anglesey out.

Nice feeling getting the seats back in, getting very close to going for a drive now.

Over the next couple of evenings I tidied away some odd jobs, got the oil/filter change done.

Then got to repairing some missing/broken fixings inside the front clam. Lotus just bonded some nuts in, and most of them have suffered. This means that to fit my splitter/front under tray I'm often fishing around with big repair washers and nuts which is a PITA.

I used my multi tool to carefully grind the old adhesive off and give me a flat surface:

Then fitted a bunch of these captive nuts, using small rivets:

I've not had the time, energy or patience to make up a fresh splitter this winter so I chose the least crap of my old damaged ones and bolted that on. I fancy a nice summer evening job sanding down a new one with a beer. Winter joinery just isn't fun.

Refitted the carbon 'buckets' inside the wheel arches to cover over all my hard work for the Winter, and hide what I hope to be a very dry and very sealed braking system.

Really small jobs now, plates bolted/velcroed back on:

Then did the annual nip-up of the weep I seem to develop every winter on the front rad hose.

With all that done, it was time for the grand finale and one of the most annoying jobs with a scissor lift... the undertray. Luckily I'd treated myself to a new toy over Christmas which makes it slightly less awful.

...and I think I'm ready for tax!

I have a bit of calibration to do with the ABS once the car is up and running, but job one is just to go out and do some basic tests and see how the brake balance feels. Once I get the bias adjustment somewhere in the ballpark, I can start messing with the ABS. Excited!

Gone with same brand/model as before. It's a straight fit for "PC680" formfactor so no messing with brackets etc, straight in to the 2-Eleven factory bracket.

I did attach a quick release lead for my LifePo4 charger though so I don't need to rip the seats out if I have a problem with this one.

Up next, whilst the seats were out I had some replacement seat rails to fit from Tillet. They issued a safety recall on a couple of items over Winter, so great service and was reassuring to get these sent out so quickly.

Seems like they just got a bit taller, with more material between the mounting holes and top edge:

The powdercoat had suffered a bit after a year of the originals, probably not helped by how exposed they are in the 2-Eleven but still a little disappointing. Gave these a good waxy coat of Dynax UC to keep the worst of the Anglesey out.

Nice feeling getting the seats back in, getting very close to going for a drive now.

Over the next couple of evenings I tidied away some odd jobs, got the oil/filter change done.

Then got to repairing some missing/broken fixings inside the front clam. Lotus just bonded some nuts in, and most of them have suffered. This means that to fit my splitter/front under tray I'm often fishing around with big repair washers and nuts which is a PITA.

I used my multi tool to carefully grind the old adhesive off and give me a flat surface:

Then fitted a bunch of these captive nuts, using small rivets:

I've not had the time, energy or patience to make up a fresh splitter this winter so I chose the least crap of my old damaged ones and bolted that on. I fancy a nice summer evening job sanding down a new one with a beer. Winter joinery just isn't fun.

Refitted the carbon 'buckets' inside the wheel arches to cover over all my hard work for the Winter, and hide what I hope to be a very dry and very sealed braking system.

Really small jobs now, plates bolted/velcroed back on:

Then did the annual nip-up of the weep I seem to develop every winter on the front rad hose.

With all that done, it was time for the grand finale and one of the most annoying jobs with a scissor lift... the undertray. Luckily I'd treated myself to a new toy over Christmas which makes it slightly less awful.

...and I think I'm ready for tax!

I have a bit of calibration to do with the ABS once the car is up and running, but job one is just to go out and do some basic tests and see how the brake balance feels. Once I get the bias adjustment somewhere in the ballpark, I can start messing with the ABS. Excited!

Re: Ratchet. I had a Ryobi version for a few years but it was a bit underwhelming in a couple of areas. It was too bulky thanks to the Ryobi battery format, but also was a very slow ratchet. Went for the ultra fast Milwaukee one and it's a corker.

MDifficult said:

Outstanding work on the garage! I have fantasies about doing the same to my double garage but always give up because the effort involved just seems insurmountable

1. SO much crap (I'm guessing possibly double your dozen tip runs)

2. I have a huge column in the middle of the garage that holds up the corner of the upper story. B*stard stupid house design!

Fingers crossed the weather comes to us soon and we can just be out of the garage instead

Yeah the garage clutter is/was a real problem. I'm trying to change my ways - but already slipping, as those old pre-recall Tillett rails which are useless to anybody are just sat in a box waiting to go up into the loft. I should just scrap them and move on...

1. SO much crap (I'm guessing possibly double your dozen tip runs)

2. I have a huge column in the middle of the garage that holds up the corner of the upper story. B*stard stupid house design!

Fingers crossed the weather comes to us soon and we can just be out of the garage instead

friss said:

First wanted to say thank you for sharing your 2 Eleven journey. I recently picked up one myself in the States and there isn't much said about these cars so this was a great read to learn more.

As for a 4 post lift, I have a 2 car wide 4 post lift in my garage and I have found it to be pretty helpful for most jobs. Namely basic maintenance where you just need to remove the under tray or just working at one wheel (or side) at a time. My lift currently doesn't have the rolling lifters in the middle so I just use pancake/air bag jacks to lift one or both sides at a time. Without the lifters in the middle you can't easily get all 4 wheels off. But you also lose that ease of use and access when using them.

That said I have replaced the engine & trans in each of my Evora's so far on this lift.

I'm too new to post a direct link but here is my lift: i.imgur.com/GoRWiFJ.png

Thank you, and thanks for the lift info!As for a 4 post lift, I have a 2 car wide 4 post lift in my garage and I have found it to be pretty helpful for most jobs. Namely basic maintenance where you just need to remove the under tray or just working at one wheel (or side) at a time. My lift currently doesn't have the rolling lifters in the middle so I just use pancake/air bag jacks to lift one or both sides at a time. Without the lifters in the middle you can't easily get all 4 wheels off. But you also lose that ease of use and access when using them.

That said I have replaced the engine & trans in each of my Evora's so far on this lift.

I'm too new to post a direct link but here is my lift: i.imgur.com/GoRWiFJ.png

I'm fairly sure that with a jacking beam (or two) I can do all the work I currently do... it's just battling with how much the lift will encroach on my workshop space. Even a narrow lift is 2.6m from pillar to pillar in terms of width. In a 5m garage, with 600mm units at each side that leaves me barely 500mm of walkway clearance between the pillars and my units. Granted the pillars aren't particularly large... but still, needs some thought and maybe even a massive cardboard mockup

The "proper" answer is probably just to find some local car storage that works for me. I only have the time/energy to be spannering on a single car at once. Hiding in the trailer is an option, but carries risks and is a bit inconvenient at times. We'll see.

In the meantime...

With the weekend forecast to be grim, and with the following weekend booked away - I had to grab a dryish half hour at lunch time on Friday to give the car an initial shakedown.

Slapped some tax on, and off we go!

Initial impressions on the brakes were that I really wasn't getting much stopping force at all. Even with all of my might going through my leg into the now unassisted pedal. The car slowed up, and the pedal felt great - but nowhere near the stopping force it once had.

Still, discs were covered in rust, pads cold, tyres cold, etc. Tried not to judge too much.

Put a splash of fuel in, and worked to generate some temperature. As the brakes cleaned up, things got a little better. I was getting a lot of intrusion though from the new ABS. It feels very different to factory ABS, much higher resolution in the pulses and feels "sandy" to the OEM "rocky" feel is the best way I can word it.

I flicked through the adjustment knob settings of the ABS and could certainly feel it backing off at the "dry" end of the scale, to the point I got the odd chirp of a locking wheel.

Out of interest, I then disabled the intervention completely. I honestly barely breathed on the pedal and I had a massive lockup at the rear! Could feel the car yaw a bit at the back and mirrors were full of tyre smoke.

With that in mind, I dialled the bias knob several clicks forward and through a few iterations I felt the braking get dramatically stronger and stronger. Eventually I was getting a front to lock, felt by a slight twitch in the steering wheel - so left the settings there and then re-engaged ABS.

Now when I slammed on, it was face detachingly strong. ABS still interfering but very subtly now.

I did a small handful of miles and then brought it back for a data dump. I did have some slight calibration issues that needed sorting...

I fettled some bits on the canbus to correct my dodgy data (The ABS Data was fine, so it wasn't affecting the strategy - just was a problem with how my dash interpetted it).

Also checked some logs, and could see just how often ABS kicked in when it was switched on, but granted I being overly aggressive on the brakes as part of testing.

After making my tweaks, I squeezed another half hour in at the end of the day before it rained and the braking was loads better.

In terms of bias now at the master cylinders I'm approx 55/45 F/R. The actual bias at the calipers will be different still due to different caliper dimensions, pad/piston surface etc. This does contradict my prior calculations though, at 50:50 at the MC I was expecting 60/40 F/R which should have been right bang in the zone. The fact I've had to go 55/45 at the MC suggests that my rear braking is still stronger than I calculated/anticipated, it's a good job I added bias adjustment I guess!

I think all of this could be subject to change once on a warm race track with everything properly up to temp, and being actually "on it". I think I may need a spotter when I first go out on some knackered tyres and just try to find the sweetspot of locking the fronts a smidge before the rears go.

What is clear though is just how many sins the ABS covers up in terms of a badly balanced brake system. Despite the lower overall braking force I experienced when the bias was too far rear, the car was perfectly stable and very safe. I know from experience with the OE ABS that when I had too much rear bias, the car was borderline undrivable, so the ABS is already proving its worth.

On the topic of ABS, it does need calibrating properly still. I have it running with some placeholder data which is there or thereabouts, but I need to do some measuring to get it properly sorted.

Brakes aside, the car felt fantastic - nothing sounded/felt loose and the engine pulled strong and smooth.

With the weather predictably bad at the weekend I used the opportunity to be dragged round IKEA, not missing out on an opportunity for more garage storage in the form of a Kallax helmet shelf.

I picked some wheels up from seriouslylotus a few months ago, who subsequently shod them in A052 for me.

Will be my first time on these flavour of the year tyres, so looking forward to them - but I remain a staunch AR1 fan. The AR1 have lasted me brilliantly with no notable drop off in performance. Very keen to see how the CR-S is.

Can't have a set of new wheels without protecting them from the legend that is performance friction brake dust.

Wheels are the same as the later Elise Cup cars, and are very light. The A052 is notably lighter than the AR1, and the wheels are also lighter than my 240R forged - which adds up nicely.

I then got onto making some measurements for the ABS Cal.

That left me with two more measurements to make.

Wheel circumference, easy enough but the recommendation from SCS is to measure the distance the car travels after 10x rotations, then divide that by 10 to average out tyre squish and whatever other factors are involved rather than just running a string or tape around the outside of the tyre... so I'll do that when it's dry.

Then finally vehicle weight. I have some data from last year when I was on the scales at SeriouslyLotus but this was an excuse to unveil a new toy..

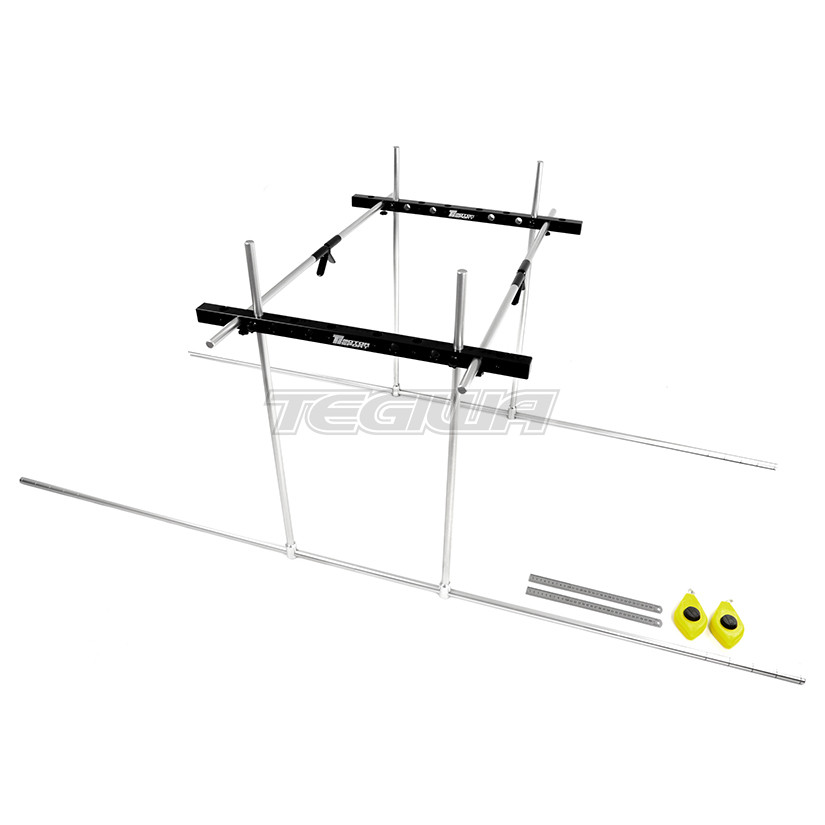

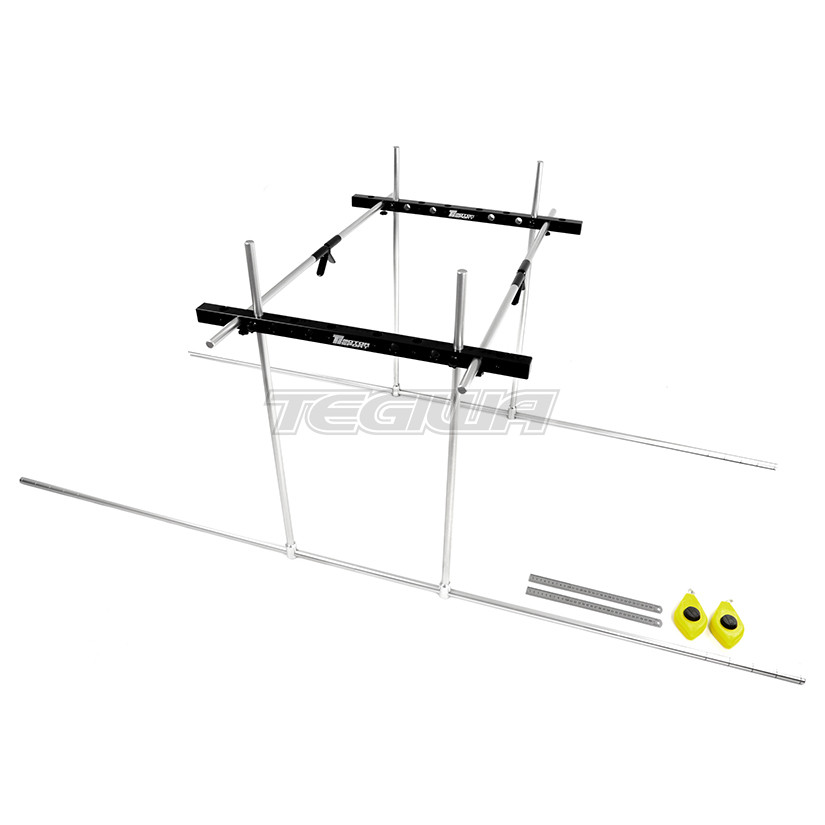

I've kept my eyes out for some used corner scales for years, trying to nab a bargain but they just rarely come up - or are miles away when they do. Then these popped up, they're a new product from a small fabrication place in Sheffield. They are a fraction of the price of most of the mainstream offerings, and are definitely on the 'small fabrication operation' end of the production scale, 3D printed components etc.

As a result, they lack some of the features of most purpose built corner scales such as the ability to tell you F/R ratio and cross-weight ratio, and instead just gives you the four weight readings for you to figure out yourself. Luckily there's an app for that.

I bought them via the eBay shop, and I've never ever had such a better service from an eBay seller. They're made on demand, so is a 2-3 week wait but all the way through I was getting photos and regular text updates. Seriously impressive, and I LOVE projects like this. His kit is very much aimed at the trackday geek/clubman racer and I believe started out as a one-off project to satisfy his own requirements.

So far, I'm dead impressed. They have adjustable feet so you don't need separate levellers, and comes with custom made laser levellers to help you line it all up, but they were the only miss so far as I think they're a bit wonky. I've tried them against known flat surfaces and they don't line up with each other.

With that in mind, I reverted to one of my alignment poles and a spirit level to get my platform all straight.

Also sat each scale on a thick piece of steel that I've had in the bottom of a cupboard for about 18months whilst building up my collection of alignment toys.

The display box:

With it all hooked up and zeroed, I lowered the car onto them and gave each corner a good bounce.

The aforementioned app for plugging the data in:

Definitely not taking this too seriously

I calibrated the scales against a few known quantities and they look bang on. I also had some reference data from SL's scales last year and everything is believable. I've got too much fuel in it technically, should be on half a tank for the ABS Cal so I can tweak this later - or just take off ~15kg.

As per last year though, no adjustment needed - it's within tolerance for the right cross weights so that's good. Note how it just hovers around +/- 0.1% tolerance with and without driver, just shows I guess how close the driver is to the COG of the car.

Brings me up to date, I'll show off my other geo toys next week maybe. I'd like to at least check it even if I don't make any adjustments before my first track outing, but this year I would like to experiment with something a bit more aggressive.

Will be my first time on these flavour of the year tyres, so looking forward to them - but I remain a staunch AR1 fan. The AR1 have lasted me brilliantly with no notable drop off in performance. Very keen to see how the CR-S is.

Can't have a set of new wheels without protecting them from the legend that is performance friction brake dust.

Wheels are the same as the later Elise Cup cars, and are very light. The A052 is notably lighter than the AR1, and the wheels are also lighter than my 240R forged - which adds up nicely.

I then got onto making some measurements for the ABS Cal.

That left me with two more measurements to make.

Wheel circumference, easy enough but the recommendation from SCS is to measure the distance the car travels after 10x rotations, then divide that by 10 to average out tyre squish and whatever other factors are involved rather than just running a string or tape around the outside of the tyre... so I'll do that when it's dry.

Then finally vehicle weight. I have some data from last year when I was on the scales at SeriouslyLotus but this was an excuse to unveil a new toy..

I've kept my eyes out for some used corner scales for years, trying to nab a bargain but they just rarely come up - or are miles away when they do. Then these popped up, they're a new product from a small fabrication place in Sheffield. They are a fraction of the price of most of the mainstream offerings, and are definitely on the 'small fabrication operation' end of the production scale, 3D printed components etc.

As a result, they lack some of the features of most purpose built corner scales such as the ability to tell you F/R ratio and cross-weight ratio, and instead just gives you the four weight readings for you to figure out yourself. Luckily there's an app for that.

I bought them via the eBay shop, and I've never ever had such a better service from an eBay seller. They're made on demand, so is a 2-3 week wait but all the way through I was getting photos and regular text updates. Seriously impressive, and I LOVE projects like this. His kit is very much aimed at the trackday geek/clubman racer and I believe started out as a one-off project to satisfy his own requirements.

So far, I'm dead impressed. They have adjustable feet so you don't need separate levellers, and comes with custom made laser levellers to help you line it all up, but they were the only miss so far as I think they're a bit wonky. I've tried them against known flat surfaces and they don't line up with each other.

With that in mind, I reverted to one of my alignment poles and a spirit level to get my platform all straight.

Also sat each scale on a thick piece of steel that I've had in the bottom of a cupboard for about 18months whilst building up my collection of alignment toys.

The display box:

With it all hooked up and zeroed, I lowered the car onto them and gave each corner a good bounce.

The aforementioned app for plugging the data in:

Definitely not taking this too seriously

I calibrated the scales against a few known quantities and they look bang on. I also had some reference data from SL's scales last year and everything is believable. I've got too much fuel in it technically, should be on half a tank for the ABS Cal so I can tweak this later - or just take off ~15kg.

As per last year though, no adjustment needed - it's within tolerance for the right cross weights so that's good. Note how it just hovers around +/- 0.1% tolerance with and without driver, just shows I guess how close the driver is to the COG of the car.

Brings me up to date, I'll show off my other geo toys next week maybe. I'd like to at least check it even if I don't make any adjustments before my first track outing, but this year I would like to experiment with something a bit more aggressive.

With time ticking before the first track outing of the year, I got on with some finishing touches.

Hoovered my mats.

"We" washed it.

..and spent some time measuring the final bit of calibration for the ABS. The Wheel circumference.

The SCS recommendation is to rotate the wheels 10x times, measure the difference travelled and then divide by 10 to reduce any measurement errors. I did this in steps of 2x rotations, as I didn't have a 20m tape measure!

Spent an hour or so of the delightful BH weekend to do some final checks on the ECU, ABS and Dash configs. I spotted one problem with the calculated gear ratios, so the dash doesn't quite know what gear I'm in with the new wheelspeed data... small job to fix when I get time just to run it up and down the road in all gears.

Then that's it, off to the races!

Hoovered my mats.

"We" washed it.

..and spent some time measuring the final bit of calibration for the ABS. The Wheel circumference.

The SCS recommendation is to rotate the wheels 10x times, measure the difference travelled and then divide by 10 to reduce any measurement errors. I did this in steps of 2x rotations, as I didn't have a 20m tape measure!

Spent an hour or so of the delightful BH weekend to do some final checks on the ECU, ABS and Dash configs. I spotted one problem with the calculated gear ratios, so the dash doesn't quite know what gear I'm in with the new wheelspeed data... small job to fix when I get time just to run it up and down the road in all gears.

Then that's it, off to the races!

First track outing as ever was to be at Blyton Park. My Local track, and a great one for shaking down winter tweaks.

Would be a little different this year though, as it was a Javelin Sprint Series taster day with a morning of open pit lane trackday, and an afternoon of timed sprint runs.

Not an ideal environment for testing so many changes to the car, but I'd had every intention of doing a "normal" OPL day before this... just the garage works put a stop to that.

Arrived to a rather crisp morning, but was forecast dry for the day. All good.

Plan was to go out on the old AR1 tyres for a couple of sessions and just check I wasn't locking brakes up left right and centre. Didn't want to ruin the A052 if so!

First session I went as hard as I could onto the brakes on T1 after the start just to get a feel of how well the car would stop on the sprint laps later when everything is cold. The answer was, not well. I got lots of ABS triggering and the car just about hauled itself up, but it wasn't a great feeling.

As the laps piled on and the tyres ballooned in pressure the car felt quicker and quicker and by the end the brakes felt great. Really strong pedal feel, good modulation and was quite intuitive as to when ABS would trigger. On warm pads/tyres, the ABS triggering was few and far between. Fair amount of traffic on this session, so hard to measure anything useful - but the brakes didn't fall off, so there's that.

On the second session, I reset the hot tyre pressures and managed to get a few clear laps.

I had no inclination to play with brake balance at all, because the car felt 'right'. Stable in braking and seemed to be hauling itself up just fine. I did back the ABS off a bit, if 1 = Fully Wet, most intrusion and 10 = Fully dry, most allowable yaw I ended up running a setting of 7.

This gave me just a bit of movement in the car on turn-in when still trailing the brakes, and the odd chirp of a locking tyre (but nothing sustained with tyre smoke everywhere). If I dialled it closer to 10, the car was noticeably less stable on the brakes, but I imagine on a properly warm day where I'm really pushing on this will be a great setting.

I knew grip would be compromised in the afternoon due to cold tyres, so I kept it at 7 for the rest of the day.

On this second session, I was already matching the best times I'd ever done at Blyton which was rather promising. The car didn't feel anywhere near as close to the edge either to hit those times, in fact I still felt like I was warming up.

The noticeable difference with the car compared to last time aside from the brakes is the changes I made to engine mapping. Previously I had a "slow" map of 260bhp, and a "fast" map of 300bhp. But I was scared to use the 300 one in fear of smashing the gearbox.

Now I have a slow of 260, and a fast of 280. As such, I'm now using the fast one on trackdays and in effect, am up on power from previous visits.

There's "a line" that gains a lot of time at Blyton, and involves somewhat straight lining over a curb at "The Ump". Figured I'd see if I could clear it in case I got a bit competetive in the afternoon...

Turns out the answer is "sort of". Splitter catches it, get a lovely smell of smouldering sawdust for a few more corners but the chassis-proper remains unscathed. Free time, woo!

Now that I felt I had a decent baseline, I came in and swapped over for the A052 tyres which seem to have generated legend status.

First outing would be a 'scrubbing' one, bring them up to temp and just get a feel. Immediately I noticed that the sidewalls felt softer and more forgiving. This gave the car less of a 'racey' feel compared to the AR1 but no question the grip was there in return.

Slowly ramped up and was pretty much on the pace from earlier sessions by the time I came in with once again, ballooned tyres.

https://www.youtube.com/watch?v=nTCfnwJ_pQQ

Video of a lap from that session. Front end not quite where I expected it to be on a couple of corners which sent me for a nice bumpy ride over the finish line. Interestingly this lap is within fractions of my best ever at Blyton but looks considerably slower. No doubt I was leaving lots on the table at the weekend, but it's promising to know the car has some core performance unlocked within it.

I Reset pressures to go out again and then was hit with a red flag which would keep the track closed right up until just before lunch. Annoyingly with some oil down on the Bishops corner and a load of cement dust really compromising the track and stopping me from getting a proper session in on the 52s.

Onto the lunch break and was still not sure exactly what I thought about the 52s. No doubt they have more grip to offer, but they feel noticeably more "road-like" in their steering response. That's not to say it's a bad thing, just what jumped out at me on a back to back test.

Going into the sprint afternoon and we'd have one untimed practise run, then 3 (turned out to be 4) timed runs depending on how quickly they rotated the field. Cars were numbered in an approximate class system, not the proper classes they use for championship events but just to roughly get us in performance order. I was granted #12, so in the first group to launch.

Practise run went 'Ok'. Was aiming to do fairly gentle launches, 3-4k RPM then slip the clutch out to let the clutch take the beating rather than the gearbox, but the TC was far too disruptive and bogged me down a bit when trying to get on full power. Still, it got away well and the rest of the run went without drama. Brakes and tyres performed better than I expected after cooling off over lunch so that was reassuring.

The cement dust at Bishops was still really unnerving though. Not sure how other participants attacked it but I'd say I was 6/10ths at best through there for the rest of the afternoon.

First timed run came round very quickly, so off we went. Launch went even worse this time, TC to blame but I eventually spluttered away and got on with it.

Car felt great through the back half of the circuit, and my sector times concurred. Came across the line with a 1.10.X, which matched by previous best time at this event on my Exige - so decent start. P3 overall.

I knew the car had loads more left in it, so the competitive bug started to nibble away at this point.

Next session came around and I disabled the TC. Plan would be to disable it for the launch then flick it back on down the first straight. I wouldn't say the car is traction limited, but the TC is very useful at arresting the spinning inside wheel I get on some corners courtesy of the open differential, so I quite liked to have it in place.

Launch was LOADS better, no stink of clutch, no hopping of the drive train, just a nice smooth amount of slip and launched me on my way. This brought my 0.60ft time to within 0.2sec of the AWD cars that occupied the times ahead of me. In all of the overthinking of the TC settings though, I forgot to switch to my faster map - so when I crossed the line with a 1.09.X it felt like a wasted opportunity.

Next session came around, and was the final scheduled one. I completely fluffed the 1st-2nd gear change off the launch and then was just distracted for the rest of the lap. Still, another 1.09.X and had slipped to 4th in the overall table as some faster cars started showing up.

I went in for a brew to calm myself down at this point and get ready for the trailer loading operation, but then the WhatsApp group pinged to say we did indeed have time for a fourth run.

I got lined up, map definitely in the 'fast' one. TC definitely switched off. All good.

Set off, another good launch and fired down the start straight. This car really does fly off to 70-80mph insanely quickly even when fortunate enough to have an EV and a V12 Ferrari on the drive to compare it to.

I distinctly remember getting to T1 and being way to cautious. Probably just bottled it a bit knowing it was the first run, but hey ho that's the way it goes.

Got round the rest of the lap without much drama, generally felt very conservative but the stopwatch didn't lie as I came in to a high 1.08.

https://www.youtube.com/watch?v=nCoQH8Tpyuw

Happy to at least keep improving on the day, but I know there's an easy second or two still in the car!

All in all, a really successful day. The ABS was almost completely transparent in its contributions which is exactly what you'd hope for. Not playing with brake bias was probably a missed opportunity based on what I've since learned in data logs (looks like I'm still over biased towards the rear, so losing some brake performance due to that. ABS is hiding the implications a treat, but is robbing me of ultimate performance).

The ability to turn into T1 really early whilst still heavily on the brakes was novel. Not sure if it's quicker, but it really opens options up for corners like that where you feel like you're compromised no matter how you approach it.

The only niggles with the car were the gear ratio calculations being wrong on the dash, and I think my brake pedal sensor needs backing off a bit as it occasionally came on whilst the car was parked.

Oh, and a niggle resurfaced from the end of last season which I totally forgot about. The Clutch pedal occasionally feels slow to return to the top of its travel. I'll stick my head in the footwell and make sure all is well with the return spring etc, but open to other possibilities/suggestions.

I'm back to Blyton in a couple of weeks for a good old fashioned OPL day, so really hope to spend more time with the brake bias and the A052 tyres for that.

Two notable observations from the data logs:

1) Only using around 40bar of brakeline pressure when on track. Can generate 90+ when static in the garage.

2) Rear brake line pressure is fluctuating on really heavy stops, which correlates with ABS triggering so I *think* the rear is still over braking. Ideally it's the front that locks/triggers first. That said, the resolution on the data logging is not quick enough to really tell me for sure so I've made some config tweaks to hopefully get more granular data next time out.

Would be a little different this year though, as it was a Javelin Sprint Series taster day with a morning of open pit lane trackday, and an afternoon of timed sprint runs.

Not an ideal environment for testing so many changes to the car, but I'd had every intention of doing a "normal" OPL day before this... just the garage works put a stop to that.

Arrived to a rather crisp morning, but was forecast dry for the day. All good.

Plan was to go out on the old AR1 tyres for a couple of sessions and just check I wasn't locking brakes up left right and centre. Didn't want to ruin the A052 if so!

First session I went as hard as I could onto the brakes on T1 after the start just to get a feel of how well the car would stop on the sprint laps later when everything is cold. The answer was, not well. I got lots of ABS triggering and the car just about hauled itself up, but it wasn't a great feeling.

As the laps piled on and the tyres ballooned in pressure the car felt quicker and quicker and by the end the brakes felt great. Really strong pedal feel, good modulation and was quite intuitive as to when ABS would trigger. On warm pads/tyres, the ABS triggering was few and far between. Fair amount of traffic on this session, so hard to measure anything useful - but the brakes didn't fall off, so there's that.

On the second session, I reset the hot tyre pressures and managed to get a few clear laps.

I had no inclination to play with brake balance at all, because the car felt 'right'. Stable in braking and seemed to be hauling itself up just fine. I did back the ABS off a bit, if 1 = Fully Wet, most intrusion and 10 = Fully dry, most allowable yaw I ended up running a setting of 7.

This gave me just a bit of movement in the car on turn-in when still trailing the brakes, and the odd chirp of a locking tyre (but nothing sustained with tyre smoke everywhere). If I dialled it closer to 10, the car was noticeably less stable on the brakes, but I imagine on a properly warm day where I'm really pushing on this will be a great setting.

I knew grip would be compromised in the afternoon due to cold tyres, so I kept it at 7 for the rest of the day.

On this second session, I was already matching the best times I'd ever done at Blyton which was rather promising. The car didn't feel anywhere near as close to the edge either to hit those times, in fact I still felt like I was warming up.

The noticeable difference with the car compared to last time aside from the brakes is the changes I made to engine mapping. Previously I had a "slow" map of 260bhp, and a "fast" map of 300bhp. But I was scared to use the 300 one in fear of smashing the gearbox.

Now I have a slow of 260, and a fast of 280. As such, I'm now using the fast one on trackdays and in effect, am up on power from previous visits.

There's "a line" that gains a lot of time at Blyton, and involves somewhat straight lining over a curb at "The Ump". Figured I'd see if I could clear it in case I got a bit competetive in the afternoon...

Turns out the answer is "sort of". Splitter catches it, get a lovely smell of smouldering sawdust for a few more corners but the chassis-proper remains unscathed. Free time, woo!

Now that I felt I had a decent baseline, I came in and swapped over for the A052 tyres which seem to have generated legend status.

First outing would be a 'scrubbing' one, bring them up to temp and just get a feel. Immediately I noticed that the sidewalls felt softer and more forgiving. This gave the car less of a 'racey' feel compared to the AR1 but no question the grip was there in return.

Slowly ramped up and was pretty much on the pace from earlier sessions by the time I came in with once again, ballooned tyres.

https://www.youtube.com/watch?v=nTCfnwJ_pQQ

Video of a lap from that session. Front end not quite where I expected it to be on a couple of corners which sent me for a nice bumpy ride over the finish line. Interestingly this lap is within fractions of my best ever at Blyton but looks considerably slower. No doubt I was leaving lots on the table at the weekend, but it's promising to know the car has some core performance unlocked within it.

I Reset pressures to go out again and then was hit with a red flag which would keep the track closed right up until just before lunch. Annoyingly with some oil down on the Bishops corner and a load of cement dust really compromising the track and stopping me from getting a proper session in on the 52s.

Onto the lunch break and was still not sure exactly what I thought about the 52s. No doubt they have more grip to offer, but they feel noticeably more "road-like" in their steering response. That's not to say it's a bad thing, just what jumped out at me on a back to back test.

Going into the sprint afternoon and we'd have one untimed practise run, then 3 (turned out to be 4) timed runs depending on how quickly they rotated the field. Cars were numbered in an approximate class system, not the proper classes they use for championship events but just to roughly get us in performance order. I was granted #12, so in the first group to launch.

Practise run went 'Ok'. Was aiming to do fairly gentle launches, 3-4k RPM then slip the clutch out to let the clutch take the beating rather than the gearbox, but the TC was far too disruptive and bogged me down a bit when trying to get on full power. Still, it got away well and the rest of the run went without drama. Brakes and tyres performed better than I expected after cooling off over lunch so that was reassuring.

The cement dust at Bishops was still really unnerving though. Not sure how other participants attacked it but I'd say I was 6/10ths at best through there for the rest of the afternoon.

First timed run came round very quickly, so off we went. Launch went even worse this time, TC to blame but I eventually spluttered away and got on with it.

Car felt great through the back half of the circuit, and my sector times concurred. Came across the line with a 1.10.X, which matched by previous best time at this event on my Exige - so decent start. P3 overall.

I knew the car had loads more left in it, so the competitive bug started to nibble away at this point.

Next session came around and I disabled the TC. Plan would be to disable it for the launch then flick it back on down the first straight. I wouldn't say the car is traction limited, but the TC is very useful at arresting the spinning inside wheel I get on some corners courtesy of the open differential, so I quite liked to have it in place.

Launch was LOADS better, no stink of clutch, no hopping of the drive train, just a nice smooth amount of slip and launched me on my way. This brought my 0.60ft time to within 0.2sec of the AWD cars that occupied the times ahead of me. In all of the overthinking of the TC settings though, I forgot to switch to my faster map - so when I crossed the line with a 1.09.X it felt like a wasted opportunity.

Next session came around, and was the final scheduled one. I completely fluffed the 1st-2nd gear change off the launch and then was just distracted for the rest of the lap. Still, another 1.09.X and had slipped to 4th in the overall table as some faster cars started showing up.

I went in for a brew to calm myself down at this point and get ready for the trailer loading operation, but then the WhatsApp group pinged to say we did indeed have time for a fourth run.

I got lined up, map definitely in the 'fast' one. TC definitely switched off. All good.

Set off, another good launch and fired down the start straight. This car really does fly off to 70-80mph insanely quickly even when fortunate enough to have an EV and a V12 Ferrari on the drive to compare it to.

I distinctly remember getting to T1 and being way to cautious. Probably just bottled it a bit knowing it was the first run, but hey ho that's the way it goes.

Got round the rest of the lap without much drama, generally felt very conservative but the stopwatch didn't lie as I came in to a high 1.08.

https://www.youtube.com/watch?v=nCoQH8Tpyuw

Happy to at least keep improving on the day, but I know there's an easy second or two still in the car!

All in all, a really successful day. The ABS was almost completely transparent in its contributions which is exactly what you'd hope for. Not playing with brake bias was probably a missed opportunity based on what I've since learned in data logs (looks like I'm still over biased towards the rear, so losing some brake performance due to that. ABS is hiding the implications a treat, but is robbing me of ultimate performance).

The ability to turn into T1 really early whilst still heavily on the brakes was novel. Not sure if it's quicker, but it really opens options up for corners like that where you feel like you're compromised no matter how you approach it.

The only niggles with the car were the gear ratio calculations being wrong on the dash, and I think my brake pedal sensor needs backing off a bit as it occasionally came on whilst the car was parked.

Oh, and a niggle resurfaced from the end of last season which I totally forgot about. The Clutch pedal occasionally feels slow to return to the top of its travel. I'll stick my head in the footwell and make sure all is well with the return spring etc, but open to other possibilities/suggestions.

I'm back to Blyton in a couple of weeks for a good old fashioned OPL day, so really hope to spend more time with the brake bias and the A052 tyres for that.

Two notable observations from the data logs:

1) Only using around 40bar of brakeline pressure when on track. Can generate 90+ when static in the garage.

2) Rear brake line pressure is fluctuating on really heavy stops, which correlates with ABS triggering so I *think* the rear is still over braking. Ideally it's the front that locks/triggers first. That said, the resolution on the data logging is not quick enough to really tell me for sure so I've made some config tweaks to hopefully get more granular data next time out.

FTW said:

Cleaning the footwell matts before a trackday is impressive prep!

Great update on the ABS, good luck not getting too lost in all the settings and bias positions!

How much current does it draw during big interventions? Do you have a PDM or using a traditional fuse?

Honestly not sure on the draw during interventions but it has a dedicated feed to the battery via a fuse - all included on the SCS Wiring loom. But more on that in a bit...Great update on the ABS, good luck not getting too lost in all the settings and bias positions!

How much current does it draw during big interventions? Do you have a PDM or using a traditional fuse?

Carl-H said:

I've just spent almost a week going through this from start to finish whenever I've had 10 minutes spare.

It's made for a brilliant read, the detail you go to not only with the car but on here too is exceptional. I'll admit I was completely lost whenever you were talking about electronics and reading the same paragraph 2 or 3 times didn't help, but I've never really understood that side of things at all. It's been fascinating though, looking forward to your next update.

Glad you've enjoyed, plenty more to come I hope!It's made for a brilliant read, the detail you go to not only with the car but on here too is exceptional. I'll admit I was completely lost whenever you were talking about electronics and reading the same paragraph 2 or 3 times didn't help, but I've never really understood that side of things at all. It's been fascinating though, looking forward to your next update.

I try to keep the electronic bits to a minimum because it's both pretty dry/boring but also I don't actually know much about it myself - so the more I say, the more chance there is that I'll be exposed

I investigate the slow to return clutch pedal between events, and guided by John @seriouslylotus I retrieved the clutch line from the slave cylinder.

Where the plastic bit is, this separates with the removal of the clip and can then be rebuilt without the centre part.

The centre part has a restrictor in it with a pinprick hole. Got it plumbed back in and bled, will see how that goes.

Whilst under the car, also adjusted the handbrake cable up a bit.

I took a look at my front camber shims too to see if I could sneak a bit more camber. This is in response to the very unscientific indicator that I'm starting to scrub the wear markers on the tyre shoulders a bit. Unfortunately nowt' doing now without going aftermarket, or machined arms. (the 2-Eleven ones are already different to allow the camber I've got).

It was then time to get trailered up to head back to Blyton. Clocked off work on a nice warm Friday evening and got ready for the quick 20min job to load up.

...Until I found the 2-Eleven battery to be completely flat

It's a LifePO4 one, and charger was no longer recognising it so it was proper dead. Luckily had a spare, but meant the seats needed to come out so I could do the swap.

This is all down to the new ABS unit (I suspect). The 2-Eleven has no parasitic draws in factory trim, what with no alarm, immob, radio, etc. It has an isolator, but the ABS power feed connected directly to the battery.

For now I'll keep the spare battery plugged in between use - but next time I get seats out I'll extend the ABS power cable a bit and connect it to the isolator switch instead I reckon. Can't always have it on trickle especially when it's hiding in the trailer.

20min trailer load turned into 2 hours.

Onto Blyton again, good old fashioned trackday and was excited to just settle into a rhythm of messing with the brake balance.

Another change I'd made was a digital one. My ADU dash/data logger has a limited quota for how much data it can log per second across all channels. It logs a LOT, and so I was able to reduce the log rate of some less important channels and in return increase the granularity of the wheelspeed sensor and brake pressure sensor data considerably.

Wheelspeed and brake pressure got bumped up to 250hz, and Longitude G force up to 125hz. My hope was that the logs would clearly tell me which axle was triggering the ABS to help guide my adjustments. (Having the ABS output a message to say which solenoid is firing would be too convenient...)

I won't do the usual blow by blow account of the day, but the summary is that it all went very well and without drama. Enjoyed some laps with a passenger (ages since I've tracked the car with one it seems) and made plenty of bias tweaks throughout the day.

Example of a log prior to my config changes from a single braking event:

Main observations are that the brake pressure traces (red = rear circuit, blue = front circuit) closely follow each other, and wheel speed traces show that the rear sensors (purple and blue) show a couple of drops, perhaps indicating that rear is trying to lock.

If I compare this to another log (same corner, different day) with my new logging settings I get this:

As you can see it has the desired effect and the log data is much more granular. I can now see pressure spikes on the rear circuit which correspond to the wheelspeed drops. Rear axle is definitely trying to lock!

Also note a drop in longitude g-force as this happens, showing an observational lack of deceleration as ABS is triggering.

Impressive stuff, less so impressive is how bad I am at maintaining brake pedal pressure during heal/toe (TPS blip on the topmost graph) but we'll focus on fine tuning 0.0003% performance from hardware rather than on the 40% I could probably gain by not being crap.

Armed with this info, I gradually crept brake bias forward through the day and was feeling a notable improvement as a result. Brakes felt more responsive, particularly from cold and stopping performance ramped up nicely.

In hindsight I should have bumped the bias forward in much bigger increments, as by the end of the day I was getting much fewer ABS interventions but it was still the rear if/when it happened... so clear I'm still a bit overbraked at the back, I think?

I also played with the ABS adjustment knob to give me more or less intrusion. It had a notable effect on stability - probably not helped by the fact my rear is still the end moving around. I'll revisit this once I'm happier with the brake balance.

Aside from brakes, I was also testing out the A052 tyres properly. I'm still not sure what I think, to be honest. It's clear they have grip - and probably more peak grip than the AR1, but they don't feel as nice to me when accessing that grip. They feel much more like a road tyre, and I really miss the direct response of the AR1. Ultimately they didn't unlock me a heap of performance, felt worse, and are more expensive - so I'll make some efforts to do some back to back sessions on my next trackday before properly concluding. Might be some damper, alignment or pressure settings I can adjust to get more out of them but for now just feel a bit underwhelmed. Perhaps I just overhyped them in my head!

The car was notable slower through the exit of Port Froid (the fast chicane) compared to my last visit on AR1. I noted it on track, and data logs agree. Up to 10kph down on minimum speed.

An important factor in defense of the A052 is that I run narrower sizes of those compared to AR1 (225/195 vs 235/205).

Photographer got some nice shots:

Traffic was pretty gnarly most of the day, with some absolutely shocking driving standards. I even taddled to Javelin late morning because there were some repeat occasions of some pretty dangerous stuff. I've never ever felt the need to report somebody before, in 10 years of trackdaying - I consider myself pretty tolerant.

I wasn't the only one, saw them getting spoken to at least three times, but still were exhibiting similar behaviour in the final session of the day. No idea how many warnings you get...

Oh, clutch pedal return thing totally resolved. By all accounts the restrictor allows for a mechanically imposed slip of the clutch during launch control. I much prefer it gone.

One more graph, sorry.

Can use the same data to look at wheelspin on corner exit too. Where I've written #1 is the exist to bunga bunga which has always been one for spinning up the inside rear.

Back to the brake balance to finish off. I've still got adjustment range to move it forward incrementally during my next trackday, but I will start running out of adjustability soon - and I don't think it's ideal to be on the extreme end of a balance bar.

The fix for this may well be taking a revisit to my master cylinder sizes. I run 0.75" front and rear currently, and dropping front circuit to a 0.7" should in theory move the bias naturally forward a touch and also give me a slightly softer pedal - which honestly I think I'd like. I could barely walk on Sunday!

Where the plastic bit is, this separates with the removal of the clip and can then be rebuilt without the centre part.

The centre part has a restrictor in it with a pinprick hole. Got it plumbed back in and bled, will see how that goes.

Whilst under the car, also adjusted the handbrake cable up a bit.