Mazda MX-5e Tesla Powered

Discussion

Interesting project and a good read so far, I can certainly appreciate the thought, time and effort going into the project.

Although I kinda feel conversions like this are a bit of a functional safety dumpster fire, are you going to have any indication like a HV sticker externally visible on the vehicle to differentiate it from a normal MX5 in case (god forbid) of an accident the emergency services have to respond to?

Although I kinda feel conversions like this are a bit of a functional safety dumpster fire, are you going to have any indication like a HV sticker externally visible on the vehicle to differentiate it from a normal MX5 in case (god forbid) of an accident the emergency services have to respond to?

The test driver said:

Interesting project and a good read so far, I can certainly appreciate the thought, time and effort going into the project.

Although I kinda feel conversions like this are a bit of a functional safety dumpster fire, are you going to have any indication like a HV sticker externally visible on the vehicle to differentiate it from a normal MX5 in case (god forbid) of an accident the emergency services have to respond to?

EVs are safe. I've had a lot more incidents with petrol and hot oil in my vehicles over the last 35+ years. There is just so much less to go wrong in an EV too. I've got a Telsa Powerwall in my garage and I have no concerns with that either. The battery pack will be about 400V and this will kill you if you do something stupid. So will all cars though.Although I kinda feel conversions like this are a bit of a functional safety dumpster fire, are you going to have any indication like a HV sticker externally visible on the vehicle to differentiate it from a normal MX5 in case (god forbid) of an accident the emergency services have to respond to?

robcollingridge said:

EVs are safe.

I'm not saying they aren't, what I'm talking about is functional safety. So for example if you disconnect one of the HV connections, how do you guarantee the system is isolated and intrinsically safe to work on or touch without specialist (i.e you) intervention?robcollingridge said:

I've got a Telsa Powerwall in my garage and I have no concerns with that either.

Similar in potential but a very different proposition, the powerwall's been designed, engineered and signed off for static use not dynamic on road, but I'd imagine it will have had to demonstrate certain key safety features like automatic disconnects and HV circuit monitoring too.Do you have anything in place to monitor the HV wire insulation for shorting or grounding?

My emergency services comment was aimed at a scenario of if the fire services ever had to interact with the vehicle, how would they know where the isolator is? Where could they cut the vehicle body without contacting HV components?

Don't get me wrong and I really don't want to come across as a bit of a knob who dislikes EV's as that isn't me but it's these type of questions that are going to catch out HV conversion'ists very soon.

I'd hate for you to have spent so much time and effort into build something which is quite cool, for the government to catch on and amend sva regs.

Edited by The test driver on Wednesday 20th March 12:52

robcollingridge said:

tight fart said:

How heavy will the battery pack be and where are you going to put it?

(Sorry if I’ve missed that)

30kWh will be about 175kg and will mostly be in the engine bay. If we need more room, then some of it will go where the petrol tank currently is.(Sorry if I’ve missed that)

The test driver said:

Similar in potential but a very different proposition, the powerwall's been designed, engineered and signed off for static use not dynamic on road, but I'd imagine it will have had to demonstrate certain key safety features like automatic disconnects and HV circuit monitoring too.

Do you have anything in place to monitor the HV wire insulation for shorting or grounding?

My emergency services comment was aimed at a scenario of if the fire services ever had to interact with the vehicle, how would they know where the isolator is? Where could they cut the vehicle body without contacting HV components?

Don't get me wrong and I really don't want to come across as a bit of a knob who dislikes EV's as that isn't me but it's these type of questions that are going to catch out HV conversion'ists very soon.

I'd hate for you to have spent so much time and effort into build something which is quite cool, for the government to catch on and amend sva regs.

I understand your concerns and we will document the whole build. The HV side has isolators for the battery pack and these are standard practice in EV conversions. The battery pack itself has a safety breaker, to ensure it is safe to remove as a complete module. All of the danger and potential danger is in the battery pack really. The HV cables have serious insulation and the cable is mounted on special mounts, to avoid wear. There are a lot of fuses in the system too.Do you have anything in place to monitor the HV wire insulation for shorting or grounding?

My emergency services comment was aimed at a scenario of if the fire services ever had to interact with the vehicle, how would they know where the isolator is? Where could they cut the vehicle body without contacting HV components?

Don't get me wrong and I really don't want to come across as a bit of a knob who dislikes EV's as that isn't me but it's these type of questions that are going to catch out HV conversion'ists very soon.

I'd hate for you to have spent so much time and effort into build something which is quite cool, for the government to catch on and amend sva regs.

Edited by The test driver on Wednesday 20th March 12:52

MesoForm said:

Is there an efficiency gain / loss from spreading the batteries out instead of having them all in once place?

Not really. You spread them out to improve weight distribution and lower the centre of gravity. We are doing an obsessive amount of stuff to reduce the weight of this car and make it lighter as an EV

My last car build was 450kg with half a tank of fuel. A Fisher Fury R1 with a Yamaha bike engine and 6-speed sequential gearbox with direct cable paddle shift and a 12,000rpm red-line. https://youtu.be/eNiIzyqP0N0

The test driver said:

Similar in potential but a very different proposition, the powerwall's been designed, engineered and signed off for static use not dynamic on road, but I'd imagine it will have had to demonstrate certain key safety features like automatic disconnects and HV circuit monitoring too.

Do you have anything in place to monitor the HV wire insulation for shorting or grounding?

My emergency services comment was aimed at a scenario of if the fire services ever had to interact with the vehicle, how would they know where the isolator is? Where could they cut the vehicle body without contacting HV components?

Don't get me wrong and I really don't want to come across as a bit of a knob who dislikes EV's as that isn't me but it's these type of questions that are going to catch out HV conversion'ists very soon.

I'd hate for you to have spent so much time and effort into build something which is quite cool, for the government to catch on and amend sva regs.

Being pedantic here, but since its my specialist area in a related industry. Its my understanding that in automotive terms "Functional Safety" isn't related to the general safe work practices and electrical isolation of parts or components during maintenance, its more associated with correct hardware design and software coding practices to ensure safety critical systems operate on demand or continuously to ensure safety e.g. braking systems, cruise control, autonomous driving, clutch release / gearbox systems etc. Do you have anything in place to monitor the HV wire insulation for shorting or grounding?

My emergency services comment was aimed at a scenario of if the fire services ever had to interact with the vehicle, how would they know where the isolator is? Where could they cut the vehicle body without contacting HV components?

Don't get me wrong and I really don't want to come across as a bit of a knob who dislikes EV's as that isn't me but it's these type of questions that are going to catch out HV conversion'ists very soon.

I'd hate for you to have spent so much time and effort into build something which is quite cool, for the government to catch on and amend sva regs.

Edited by The test driver on Wednesday 20th March 12:52

That is unless you was referring to the battery and power management systems to stop the things from catching fire or exploding, in which case I would agree with you (but also not surprised if there was a separate standard covering these?)

Edited by Pete102 on Thursday 21st March 06:51

Pete102 said:

Being pedantic here, but since its my specialist area in a related industry. Its my understanding that in automotive terms "Functional Safety" isn't related to the general safe work practices and electrical isolation of parts or components during maintenance, its more associated with correct hardware design and software coding practices to ensure safety critical systems operate on demand or continuously to ensure safety e.g. braking systems, cruise control, autonomous driving, clutch release / gearbox systems etc.

That is unless you was referring to the battery and power management systems to stop the things from catching fire or exploding, in which case I would agree with you (but also not surprised if there was a separate standard covering these?)

Yes, functional safety in the automotive industry is usually the former.That is unless you was referring to the battery and power management systems to stop the things from catching fire or exploding, in which case I would agree with you (but also not surprised if there was a separate standard covering these?)

Edited by Pete102 on Thursday 21st March 06:51

Craikeybaby said:

Pete102 said:

Being pedantic here, but since its my specialist area in a related industry. Its my understanding that in automotive terms "Functional Safety" isn't related to the general safe work practices and electrical isolation of parts or components during maintenance, its more associated with correct hardware design and software coding practices to ensure safety critical systems operate on demand or continuously to ensure safety e.g. braking systems, cruise control, autonomous driving, clutch release / gearbox systems etc.

That is unless you was referring to the battery and power management systems to stop the things from catching fire or exploding, in which case I would agree with you (but also not surprised if there was a separate standard covering these?)

Yes, functional safety in the automotive industry is usually the former.That is unless you was referring to the battery and power management systems to stop the things from catching fire or exploding, in which case I would agree with you (but also not surprised if there was a separate standard covering these?)

Edited by Pete102 on Thursday 21st March 06:51

Not to deride the Op's thread though

Might be of interest to Op, when going through his design processes for components and systems to not always consider the happy path and take into consideration what the impact of a part failing could be.

I good overview of ISO-26262 instead of having to pay and read the entire reg- https://fscdn.rohm.com/en/products/databook/white_...

If he's a real sadist then regs applicable to HV construction are beyond numerous.

Edited by The test driver on Thursday 21st March 11:49

We have now completely stripped all of the wiring out of the MX-5e and started to rewire it with a much lighter, custom loom. We removed lots of redundant wiring that wasn't even used in the original car, much of it for options that were no fitted. I wired my Fisher Fury R1 from scratch so this is not a big job for me and doing it will save us about 8kg off the final weight of the car.

Picked up some "new" mk2.5 leather seats for the MX-5e. These are in really good condition and have the added bonus of being heated. Heated seats make a lot of sense in an open top sports EV, so I am adding genuine Mazda switches and the wiring for these. They can be used to keep you warm, with each seat using just 65W. This is very preferrable to switching on the cabin PTC heater as this can use 3000W. The seats are currently being cleaned and refurbished.

Edited by robcollingridge on Friday 5th April 17:07

Picked up some switches for the heated seats on eBay for not a lot. We are running out of places to put switches, so I’ve designed a 3D printed plate to replace the cubby hole under the radio. This is just a template to check my measurements initially but, they were spot on.

Took the doors off, to get to the last few bits of rust on this car. We are using Buzzweld glass reinforced primer and Buzzweld WAR underseal to protect the car.

We got the LSD aluminium diff casing back from G19 Engineering today. It’s looking really good! We don’t know if this is overkill for our MX-5e but, we have an upgrade path to 215hp and 400Nm of torque, so it makes sense to do it right. We plan to replace the side seals before putting it all back together.

More shiny bits in the post from Inductive Automotive (USA based). This 3-part kit allows us to remotely mount the Nissan Leaf inverter from the Nissan Leaf motor and to supply 400V dc to the inverter. Lots of billet aluminium parts. Yes, it was expensive but, this level of fabrication is beyond my skill set. When we come to register the MX-5e as an EV, we want the DVLA inspector to look at and think these guys did it right

We are on the home straight! It feels like it has taken ages but, restoring a 30+ year old car does take a while. We have now removed the rear sub-frame and the fuel tank, so we can clean up and treat the last part of the car. This will then be painted with Buzzweld glass reinforced primer and several coats of Buzzweld WAR underseal.

The sub-frame is being shot blasted and powder coated, along with the suspension arms. These will then be fitted to my son's 1990 Eunos Roadster. I have a newly powder coated sub-frame and suspension parts to go back on the MX-5e.

The empty fuel tank weighs 11.1kg. The underside of the car is in pretty good condition, with just a few bits of surface rust.

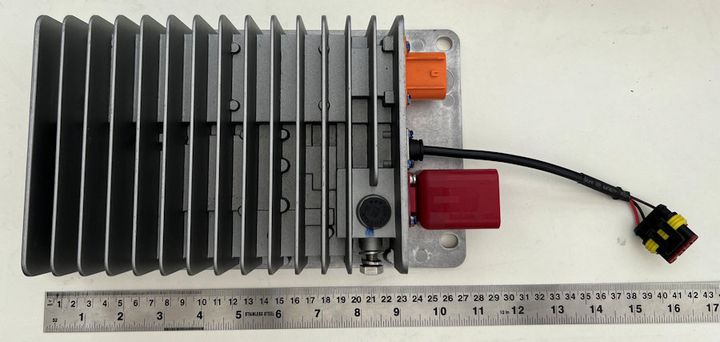

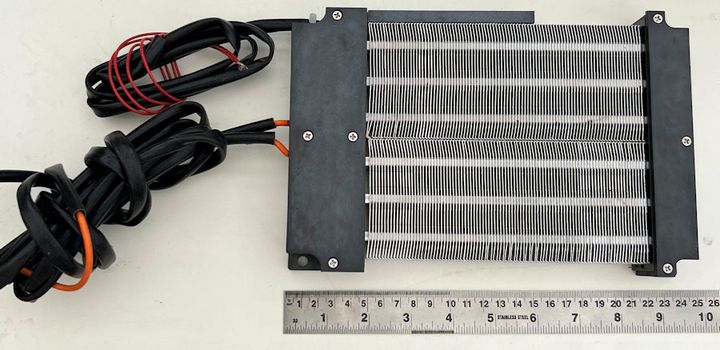

A delivery from Fellten today. We now have a dc-dc converter to run the 12V side of the car and to charge the 12V battery from our HV battery pack. It weighs 2505g and is air cooled. Also have a 3kW PTC heater to fit into the old Eunos heater matrix. It weighs just 1500g.

The sub-frame is being shot blasted and powder coated, along with the suspension arms. These will then be fitted to my son's 1990 Eunos Roadster. I have a newly powder coated sub-frame and suspension parts to go back on the MX-5e.

The empty fuel tank weighs 11.1kg. The underside of the car is in pretty good condition, with just a few bits of surface rust.

A delivery from Fellten today. We now have a dc-dc converter to run the 12V side of the car and to charge the 12V battery from our HV battery pack. It weighs 2505g and is air cooled. Also have a 3kW PTC heater to fit into the old Eunos heater matrix. It weighs just 1500g.

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff