500+bhp Mk3 Fiesta Project

Discussion

My new rear brakes arrived, so I couldn't resist fitting them. I will replace the disc/rotors, have the bells re-anodised and repaint the calipers.

Thanks to TompeteRS for my Quaife ATB Limited Slip Differentials and the bellhousing spacer gasket:

I have news from Ian (engine builder); my head is back from the CNC shop and now has 16 oversize valves, double valve springs and the porting to both sides, so Ian can now measure clearances and order a pair of cams to suit. I borrowed a bare block & head from him in the mean time and I hope to get the engine mounts fabricated this weekend.

Thanks to TompeteRS for my Quaife ATB Limited Slip Differentials and the bellhousing spacer gasket:

I have news from Ian (engine builder); my head is back from the CNC shop and now has 16 oversize valves, double valve springs and the porting to both sides, so Ian can now measure clearances and order a pair of cams to suit. I borrowed a bare block & head from him in the mean time and I hope to get the engine mounts fabricated this weekend.

Edited by mwstewart on Friday 6th May 14:17

shalmaneser said:

two LSDs?

I am building two gearboxes for the car:

One will be a 'sprint' gearbox which will give me 180mph at 8500rpm, and the other is a more road biased gearbox with a taller final drive to allow 220MPH (theoretical) at 8500 rpm.

With the latter gearbox I aim to break the 190mph barrier.

5potTurbo said:

I may have missed it, but has anything been done on the engine front yet?

It's currently with my engine builder. It is a 2.0 Series 3/'Black top' Zetec engine as fitted to the Mk1 Focus. It was a brand new crate engine but will have the following modifications:Oversize valves;

Custom retainers;

Ported inlet and exhaust;

Double valve spring conversion;

Custom cams;

Forged pistons;

Custom forged rods (different rod ratio);

WRC Inconel manifold;

GT30 based custom spec turbo. Internal waste gate;

Pulsar inlet with single 65mm TB;

Pectel engine management.

The last engine on the engine dyno with this sort of spec made 522BHP at 8250RPM. The build will be finished in the next week or so.

mwstewart said:

It's currently with my engine builder. It is a 2.0 Series 3/'Black top' Zetec engine as fitted to the Mk1 Focus. It was a brand new crate engine but will have the following modifications:

Oversize valves;

Custom retainers;

Ported inlet and exhaust;

Double valve spring conversion;

Custom cams;

Forged pistons;

Custom forged rods (different rod ratio);

WRC Inconel manifold;

GT30 based custom spec turbo. Internal waste gate;

Pulsar inlet with single 65mm TB;

Pectel engine management.

The last engine on the engine dyno with this sort of spec made 522BHP at 8250RPM. The build will be finished in the next week or so.

Although it will have 522Bhp, and gearing to get to xxxmph, the CoD and frontal areas need to be taken into account to understand the final speed, do you have these specs in hand?Oversize valves;

Custom retainers;

Ported inlet and exhaust;

Double valve spring conversion;

Custom cams;

Forged pistons;

Custom forged rods (different rod ratio);

WRC Inconel manifold;

GT30 based custom spec turbo. Internal waste gate;

Pulsar inlet with single 65mm TB;

Pectel engine management.

The last engine on the engine dyno with this sort of spec made 522BHP at 8250RPM. The build will be finished in the next week or so.

Its a pretty neat project, and I take my hat off to you sir.

K

warmfuzzies said:

Although it will have 522Bhp, and gearing to get to xxxmph, the CoD and frontal areas need to be taken into account to understand the final speed, do you have these specs in hand?

Its a pretty neat project, and I take my hat off to you sir.

K

Thank you very much.Its a pretty neat project, and I take my hat off to you sir.

K

I haven't been quite so scientific in that respect, at least yet. I'm basing the figure on the current top speed record for this mark of Fiesta which is 179.8mph along the 2.1 miles of Bruntinghorpe Airfield. Given I will have 100bhp more than that car, and will attempt the run over 3 miles, I am hopeful I will achieve the figure.

Having said that, I'm not building the car solely with that in mind; it'll be a bonus, nothing more.

Indestructible...I think that's optimistic

Engine mounting today.

I bought the N/S section of a Focus inner wing to help me mount the gearbox, I also bought the O/S bracket for the engine mount. It turned out I didn't really need either

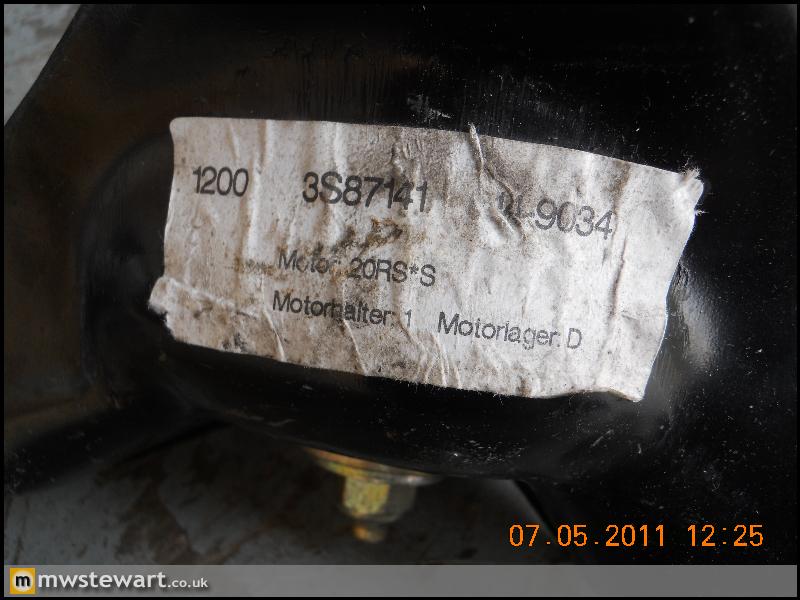

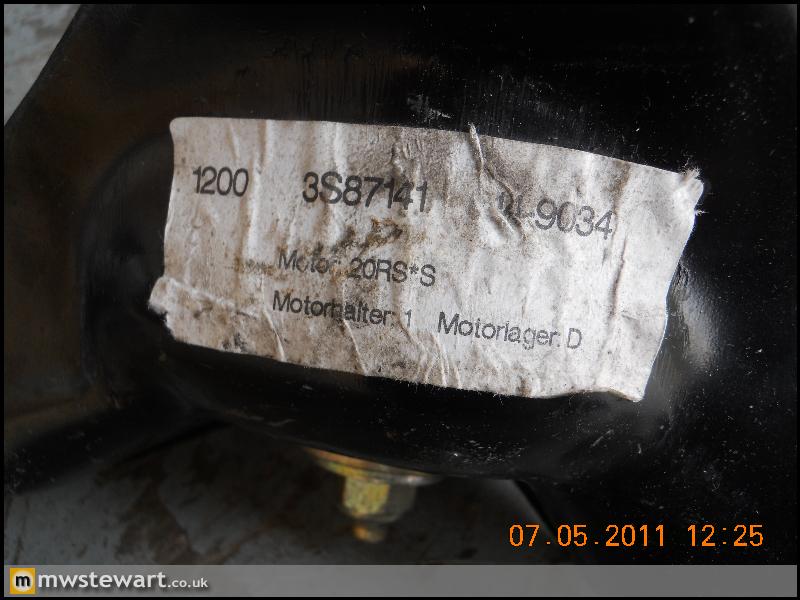

I am using Focus RS mounts. They are unique to that car and stronger than the rest of the range.

As the Black Top Zetec and MTX gearbox were never factory fitted to the Mk3 it is up to me to place the engine in the bay. This gives me a bit of flexibility in terms of engine height, but it's a careful trade off between a lower center of gravity and practicality for road use in terms of ground clearance. I settled on a final position that is just a fraction lower than the standard engine.

The old adage 'measure twice, cut once' saw me spend most of the afternoon with a tape and checking clearances everywhere, at one point I had the engine in a position where everything seemed to fit without the requirement for chassis modification, but it turned out to be too low. In the end I had to scallop a very small section from the N/.S chassis rail in order to make space for the gearbox.

The fabrication for the engine mount was actually really straight forward:

Engine bolted in: It's at a funny angle because the gearbox end is suspended via the engine hoist.

Gearbox mount tomorrow.

Engine mounting today.

I bought the N/S section of a Focus inner wing to help me mount the gearbox, I also bought the O/S bracket for the engine mount. It turned out I didn't really need either

I am using Focus RS mounts. They are unique to that car and stronger than the rest of the range.

As the Black Top Zetec and MTX gearbox were never factory fitted to the Mk3 it is up to me to place the engine in the bay. This gives me a bit of flexibility in terms of engine height, but it's a careful trade off between a lower center of gravity and practicality for road use in terms of ground clearance. I settled on a final position that is just a fraction lower than the standard engine.

The old adage 'measure twice, cut once' saw me spend most of the afternoon with a tape and checking clearances everywhere, at one point I had the engine in a position where everything seemed to fit without the requirement for chassis modification, but it turned out to be too low. In the end I had to scallop a very small section from the N/.S chassis rail in order to make space for the gearbox.

The fabrication for the engine mount was actually really straight forward:

Engine bolted in: It's at a funny angle because the gearbox end is suspended via the engine hoist.

Gearbox mount tomorrow.

Chassis mounting point fabricated to suit the Focus engine mount. Since the last update I decided to raise this by 10mm in the interests of sump preservation, given that the car will be used on the road as well as track

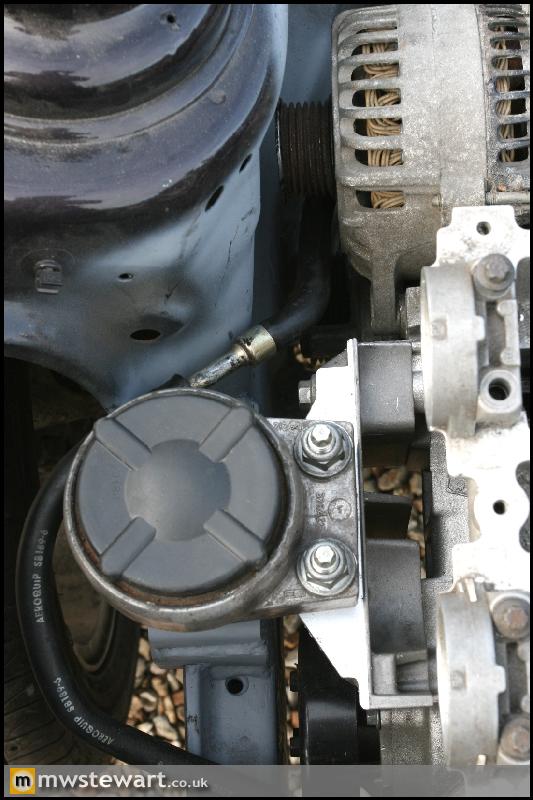

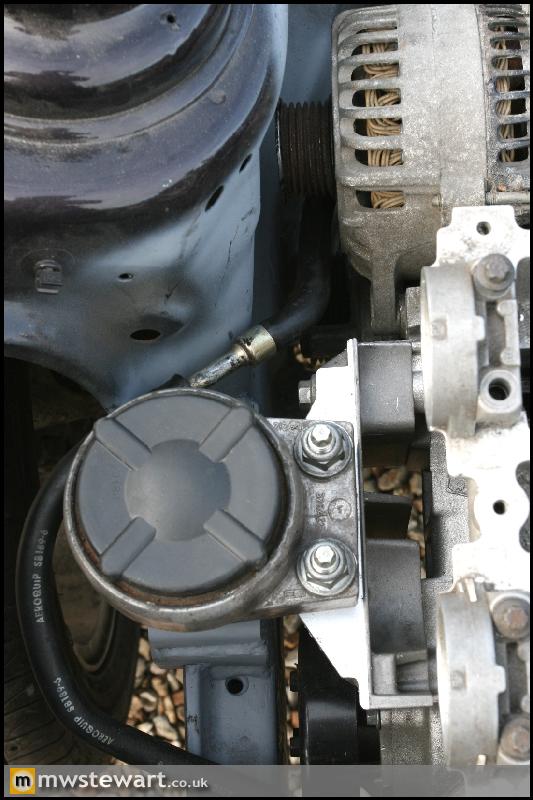

With the original Fiesta engine mount bracket removed there is sufficient room for the Focus alternator. The original bracket was welded to the area which is now covered in grey primer:

Focus gearbox top mount fabricated. The suspension turret had a protrusion half way down that took up valuable space, so I cut it out and plated over it; this let the new gearbox mount bracket sit flush with the turret. My aim was to modify the chassis to enable fitment of the standard Focus mounts, as this way they are easily replaced if anything breaks, and it also means the mount sits as far to the N/S as possible which leaves more room for the Turbo.

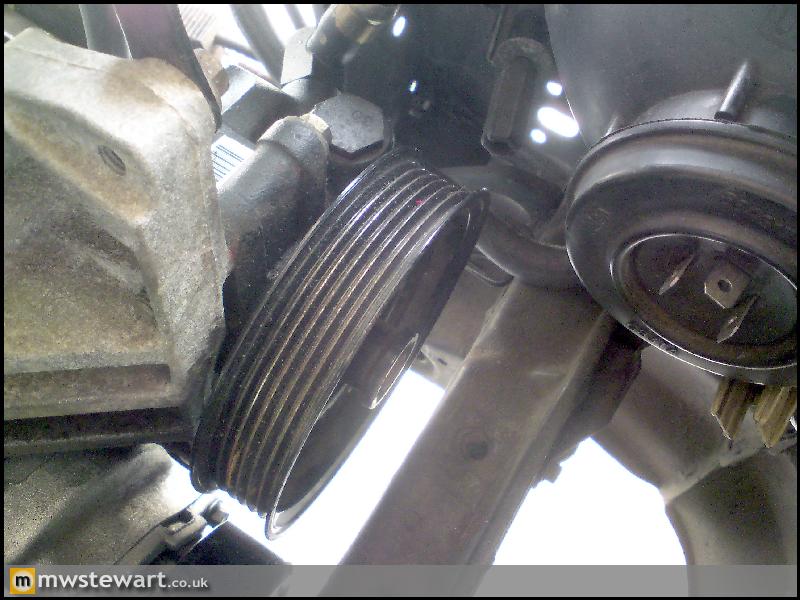

With ancillaries and manifold: all including the Air Conditioning compressor clear the chassis. The pictures show how the engine is tilted forward, which lowers the centre of Gravity. Tilting back is better but would mean major modifications to the bell housing.

Now the structural areas of the mounts are in place I can next begin to make them look more OEM by plating over the gaps etc.

With the original Fiesta engine mount bracket removed there is sufficient room for the Focus alternator. The original bracket was welded to the area which is now covered in grey primer:

Focus gearbox top mount fabricated. The suspension turret had a protrusion half way down that took up valuable space, so I cut it out and plated over it; this let the new gearbox mount bracket sit flush with the turret. My aim was to modify the chassis to enable fitment of the standard Focus mounts, as this way they are easily replaced if anything breaks, and it also means the mount sits as far to the N/S as possible which leaves more room for the Turbo.

With ancillaries and manifold: all including the Air Conditioning compressor clear the chassis. The pictures show how the engine is tilted forward, which lowers the centre of Gravity. Tilting back is better but would mean major modifications to the bell housing.

Now the structural areas of the mounts are in place I can next begin to make them look more OEM by plating over the gaps etc.

Here are the outstanding fabrication/shell prep jobs:

- Make torque link bracket with a captive nut and mount on S Brace

- Mount brake link bar

- Modify brake servo brackets and mount Focus servo by welding on new tabs. Put a bend in the tabs so they go back to the bulkhead side and act as a reinforcement (leave space for the split pin hole)

- Fit ABS module

- Mark engine bay with Ancillary and gearbox locations including how much should be removed on the N/S leg to clear gearbox. Check for feasibility of leg gussets.

- Test fit O/S headlamp and check clearance for PAS pump

- Remove mock engine/gearbox

- Add cosmetic finishing to outside of Gearbox mount (add swages), include a bracket to mount positive terminal

- Fit front arch liners to check clearance around mounts, then remove

- Bridge Gearbox mount to inner wing

- Bridge Engine mount to inner wing

- Seam weld engine bay

- Add steering rack gussets

- Add two sub frame pick up points on each chassis leg

- Decide if ST hubs can be used and mount Mk5 turrets accordingly

- Reinforce turrets to chassis leg to lower arm mount

- Check clearances for use of Mondeo or Focus radiator

- Seam weld front wheel arch areas and apply primer

- Remove spare wheel carrier brackets and apply primer

- Fit rear arch liners

- Apply 3M Sealer to underside and rear arches

- Remove centre of front cross member: cut each side at an angle to help join of new CDS tube.

- Cap front cross member with flanges & captive fittings

- Make slam panel removable – add rivnuts and prepare edges.

- Mount Focus RS gear lever mech.

- Drill hole for AC drain.

- Seam seal rear turrets

- Paint engine bay, underside and boot area.

- Make torque link bracket with a captive nut and mount on S Brace

- Mount brake link bar

- Modify brake servo brackets and mount Focus servo by welding on new tabs. Put a bend in the tabs so they go back to the bulkhead side and act as a reinforcement (leave space for the split pin hole)

- Fit ABS module

- Mark engine bay with Ancillary and gearbox locations including how much should be removed on the N/S leg to clear gearbox. Check for feasibility of leg gussets.

- Test fit O/S headlamp and check clearance for PAS pump

- Remove mock engine/gearbox

- Add cosmetic finishing to outside of Gearbox mount (add swages), include a bracket to mount positive terminal

- Fit front arch liners to check clearance around mounts, then remove

- Bridge Gearbox mount to inner wing

- Bridge Engine mount to inner wing

- Seam weld engine bay

- Add steering rack gussets

- Add two sub frame pick up points on each chassis leg

- Decide if ST hubs can be used and mount Mk5 turrets accordingly

- Reinforce turrets to chassis leg to lower arm mount

- Check clearances for use of Mondeo or Focus radiator

- Seam weld front wheel arch areas and apply primer

- Remove spare wheel carrier brackets and apply primer

- Fit rear arch liners

- Apply 3M Sealer to underside and rear arches

- Remove centre of front cross member: cut each side at an angle to help join of new CDS tube.

- Cap front cross member with flanges & captive fittings

- Make slam panel removable – add rivnuts and prepare edges.

- Mount Focus RS gear lever mech.

- Drill hole for AC drain.

- Seam seal rear turrets

- Paint engine bay, underside and boot area.

mwstewart said:

5potTurbo said:

I may have missed it, but has anything been done on the engine front yet?

It's currently with my engine builder. It is a 2.0 Series 3/'Black top' Zetec engine as fitted to the Mk1 Focus. It was a brand new crate engine but will have the following modifications:Oversize valves;

Custom retainers;

Ported inlet and exhaust;

Double valve spring conversion;

Custom cams;

Forged pistons;

Custom forged rods (different rod ratio);

WRC Inconel manifold;

GT30 based custom spec turbo. Internal waste gate;

Pulsar inlet with single 65mm TB;

Pectel engine management.

Max_Torque said:

mwstewart said:

5potTurbo said:

I may have missed it, but has anything been done on the engine front yet?

It's currently with my engine builder. It is a 2.0 Series 3/'Black top' Zetec engine as fitted to the Mk1 Focus. It was a brand new crate engine but will have the following modifications:Oversize valves;

Custom retainers;

Ported inlet and exhaust;

Double valve spring conversion;

Custom cams;

Forged pistons;

Custom forged rods (different rod ratio);

WRC Inconel manifold;

GT30 based custom spec turbo. Internal waste gate;

Pulsar inlet with single 65mm TB;

Pectel engine management.

Thanks everyone. I work in IT Finance and I don't have any formal training in this stuff; I learn by reading and working on my own cars.

Another update, but please excuse the bad image quality as the photos were taken on an old phone.

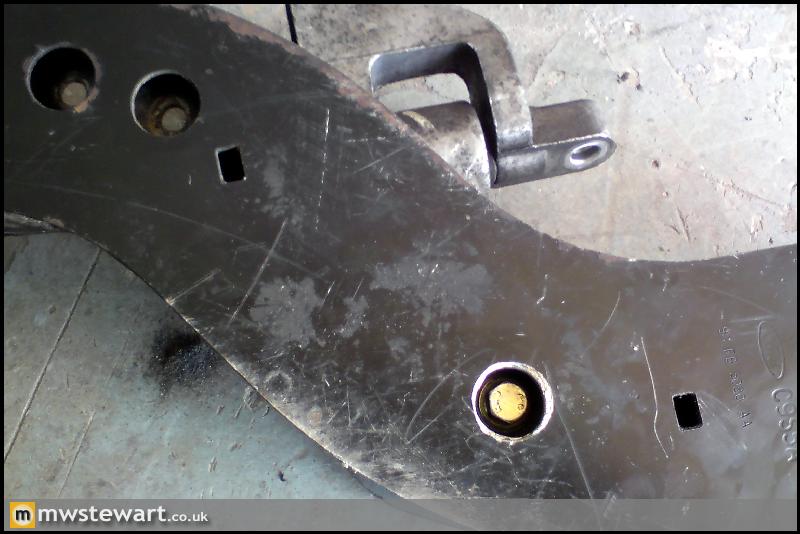

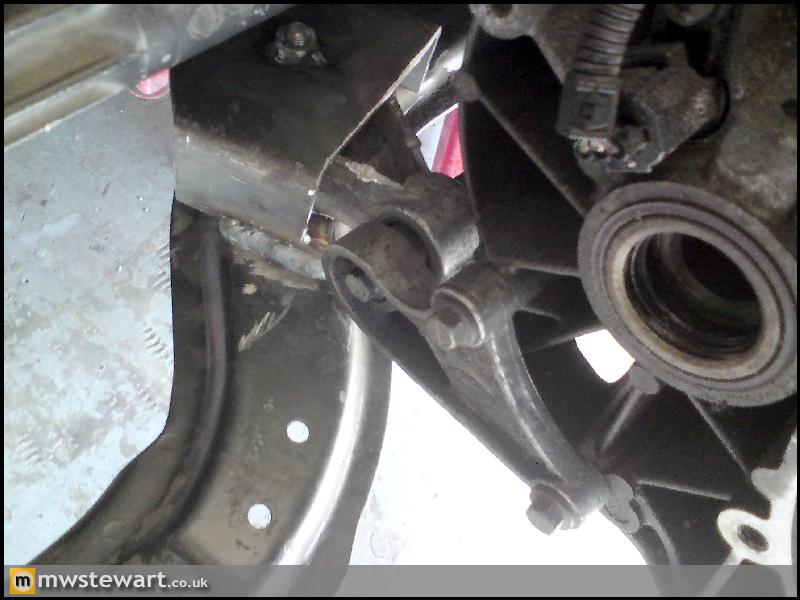

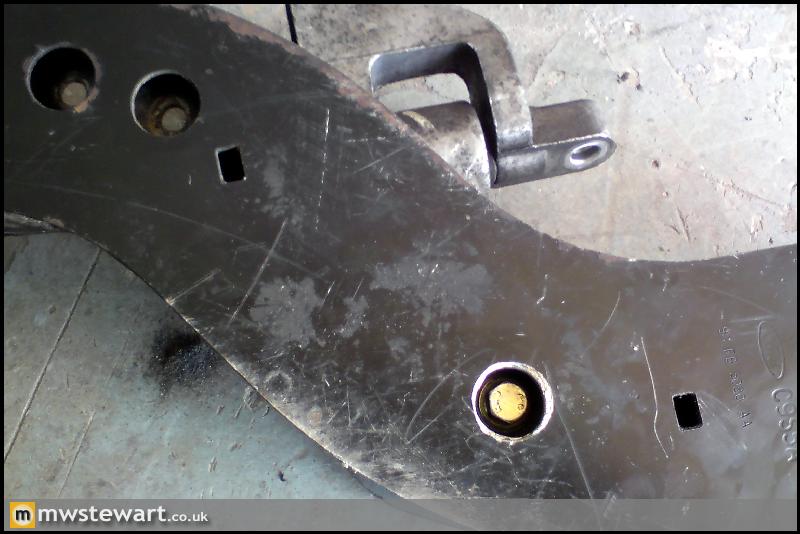

Fabrication of Gearbox Torque Link mount on to lower suspension 'S brace':

I drilled a 20mm hole in the outer skin so the bolt sits inside the brace, like Ford did with the ARB brackets to the left:

In position.

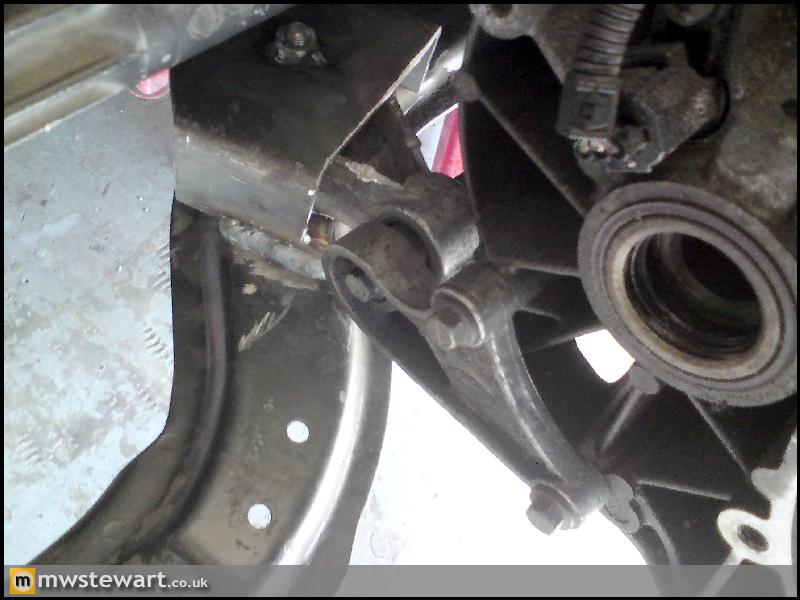

Mock up of the engine bay to allow me to check all clearances. I've now finished this stage and the mock engine has gone back to Ian (engine builder).

You may recall from my last update that I wasn't sure if the PAS pump would clear the O/S headlamp, well a trial fit conforms there is plenty of space.

ABS/Traction Control Module mounting.

I bent/cut and welded a Focus bracket to suit my engine bay:

Some new lugs on the chassis leg:

Mounted:

Fitting of Puma Turrets.

Standard Mk3 Fiesta turrets:

Removed:

Puma turrets welded in place. These turrets open the door to a good range of performance suspension; I decided on a set of KW Variant 3 coil overs.

Finally some new Focus RS parts I bought for the engine build.

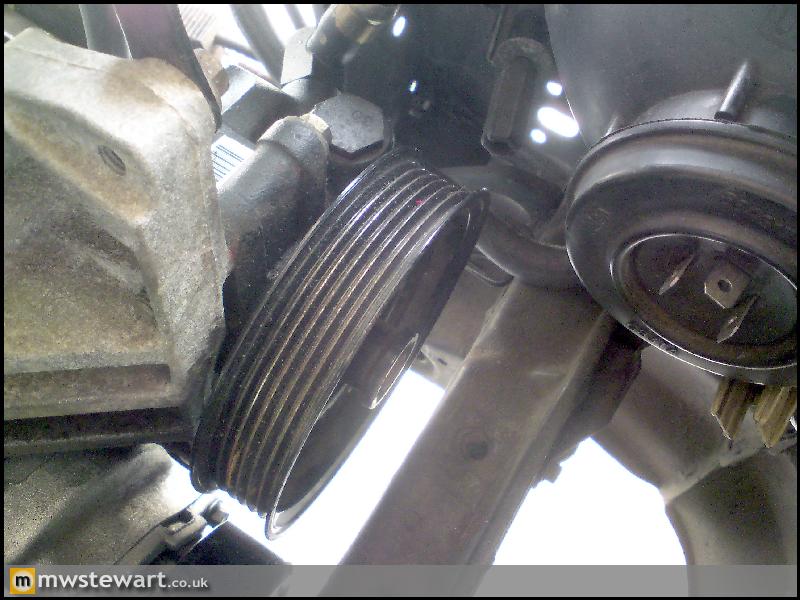

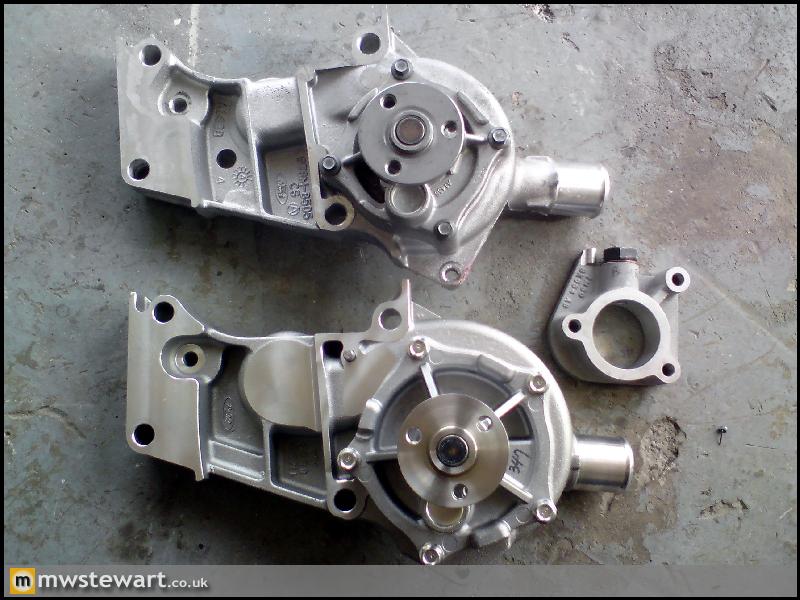

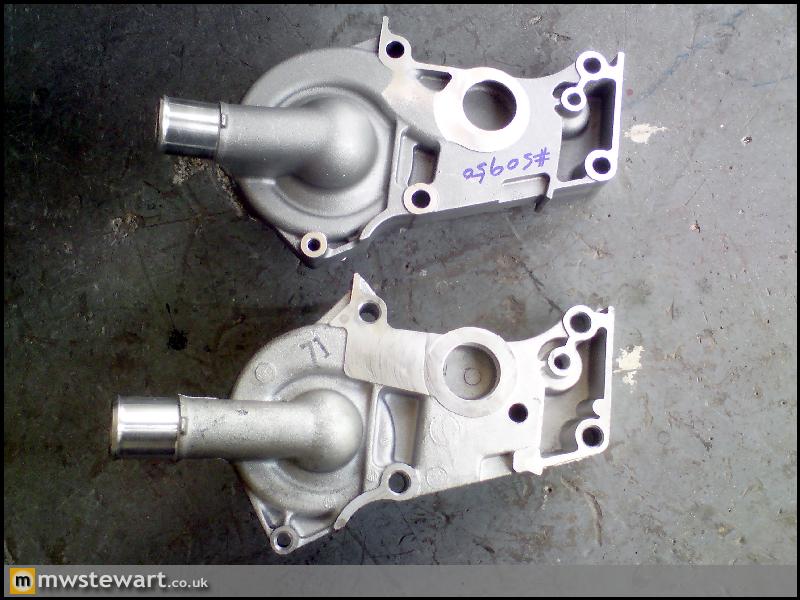

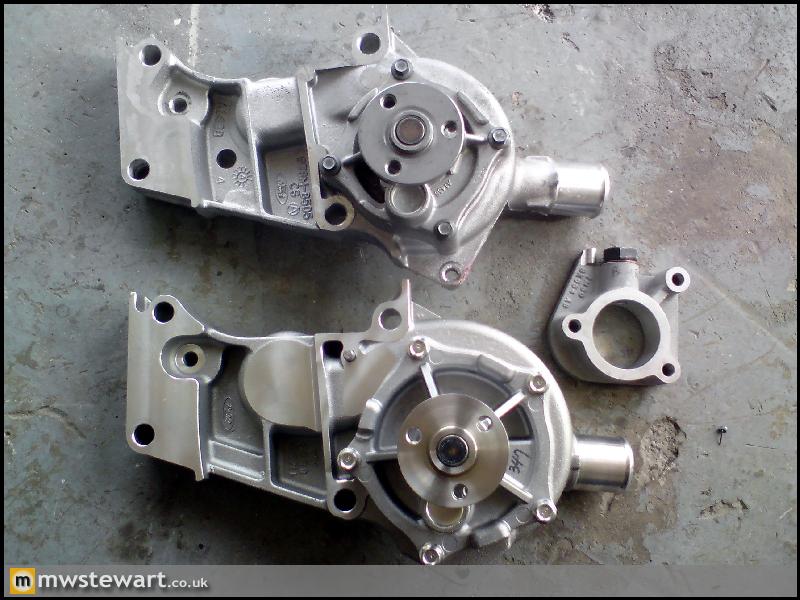

The Focus RS water pump flows 30% more than standard. While the standard water pump has been proven to 600bhp, I want to make sure I have the best components to ensure long term durability. The following photos show how large it is compared to the standard pump. Standard top, RS bottom:

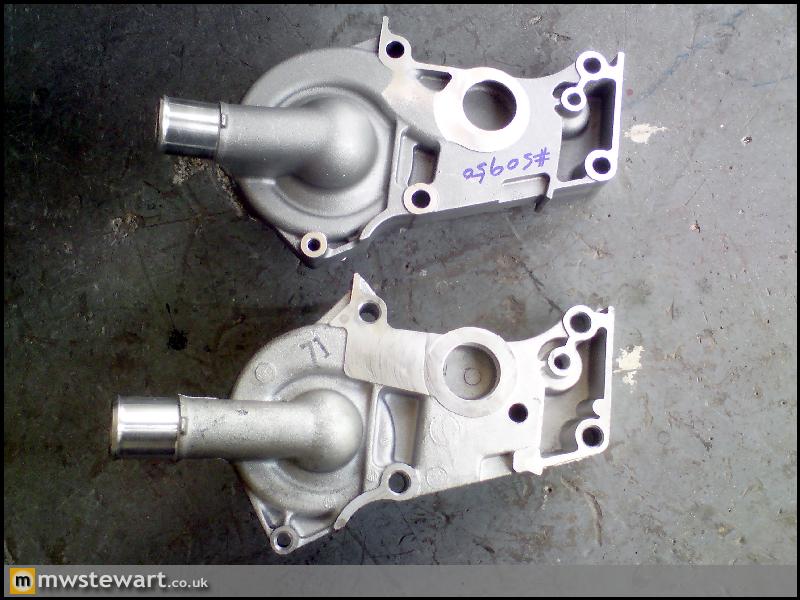

As the RS pump is so large I had to buy an RS specific pulley, Power steering mount and auxiliary belt tensioner. RS top, Standard bottom:

Focus RS thermostat housing spacer to provide a convinient take off for the Turbo water cooling feed.

I saw Ian yesterday and my bottom end is now built up. Ian says he will spend the new few days setting up the head. I've gone for the maximum size valves and a high lift cam and to accommodate this Ian ordered a set of custom cams with a different base circle, so that everything works in the head. Apparently there is a good few hours work in clearancing the valves for maximum efficiency.

Another update, but please excuse the bad image quality as the photos were taken on an old phone.

Fabrication of Gearbox Torque Link mount on to lower suspension 'S brace':

I drilled a 20mm hole in the outer skin so the bolt sits inside the brace, like Ford did with the ARB brackets to the left:

In position.

Mock up of the engine bay to allow me to check all clearances. I've now finished this stage and the mock engine has gone back to Ian (engine builder).

You may recall from my last update that I wasn't sure if the PAS pump would clear the O/S headlamp, well a trial fit conforms there is plenty of space.

ABS/Traction Control Module mounting.

I bent/cut and welded a Focus bracket to suit my engine bay:

Some new lugs on the chassis leg:

Mounted:

Fitting of Puma Turrets.

Standard Mk3 Fiesta turrets:

Removed:

Puma turrets welded in place. These turrets open the door to a good range of performance suspension; I decided on a set of KW Variant 3 coil overs.

Finally some new Focus RS parts I bought for the engine build.

The Focus RS water pump flows 30% more than standard. While the standard water pump has been proven to 600bhp, I want to make sure I have the best components to ensure long term durability. The following photos show how large it is compared to the standard pump. Standard top, RS bottom:

As the RS pump is so large I had to buy an RS specific pulley, Power steering mount and auxiliary belt tensioner. RS top, Standard bottom:

Focus RS thermostat housing spacer to provide a convinient take off for the Turbo water cooling feed.

I saw Ian yesterday and my bottom end is now built up. Ian says he will spend the new few days setting up the head. I've gone for the maximum size valves and a high lift cam and to accommodate this Ian ordered a set of custom cams with a different base circle, so that everything works in the head. Apparently there is a good few hours work in clearancing the valves for maximum efficiency.

It's quite frustrating as a non Ford owner reading how easy it is to mix and match parts between different cars/engines  Wish Peugeot had been even half as helpful!

Wish Peugeot had been even half as helpful!

Is that S brace designed to be used as a gearbox mount? The mk3's usually use a cross member IIRC.

Great build by the way!

Wish Peugeot had been even half as helpful!

Wish Peugeot had been even half as helpful! Is that S brace designed to be used as a gearbox mount? The mk3's usually use a cross member IIRC.

Great build by the way!

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff

when I see threads like this!

when I see threads like this!