500+bhp Mk3 Fiesta Project

Discussion

RC1807 said:

Likewise... Very useful to know.

My Fiesta ST of 2014 vintage has some broken fixings on the heat shield. This wasn't mentioned on the recent MoT (equivalent) so presumably it's not a worry to them. I'll get a new shield and fixings, and will grease 'em up!

Yep, same on my Boxster. Discovered one hard to reach fixing up above the exhaust had pulled through when cleaning the rear arches and surrounding areas last year. Fixed now, but that was a right game!My Fiesta ST of 2014 vintage has some broken fixings on the heat shield. This wasn't mentioned on the recent MoT (equivalent) so presumably it's not a worry to them. I'll get a new shield and fixings, and will grease 'em up!

Heaveho said:

RC1807 said:

Likewise... Very useful to know.

My Fiesta ST of 2014 vintage has some broken fixings on the heat shield. This wasn't mentioned on the recent MoT (equivalent) so presumably it's not a worry to them. I'll get a new shield and fixings, and will grease 'em up!

Yep, same on my Boxster. Discovered one hard to reach fixing up above the exhaust had pulled through when cleaning the rear arches and surrounding areas last year. Fixed now, but that was a right game!My Fiesta ST of 2014 vintage has some broken fixings on the heat shield. This wasn't mentioned on the recent MoT (equivalent) so presumably it's not a worry to them. I'll get a new shield and fixings, and will grease 'em up!

Max M4X WW said:

Are those stainless washers available online Mark? Assuming mine are not already disintegrated it would be good to salvage them!

Good idea. Here you go https://www.ebay.co.uk/itm/PENNY-REPAIR-WASHERS-A2...M6 x 25mm

mwstewart said:

Max M4X WW said:

Are those stainless washers available online Mark? Assuming mine are not already disintegrated it would be good to salvage them!

Good idea. Here you go https://www.ebay.co.uk/itm/PENNY-REPAIR-WASHERS-A2...M6 x 25mm

Rear Brake Hoses

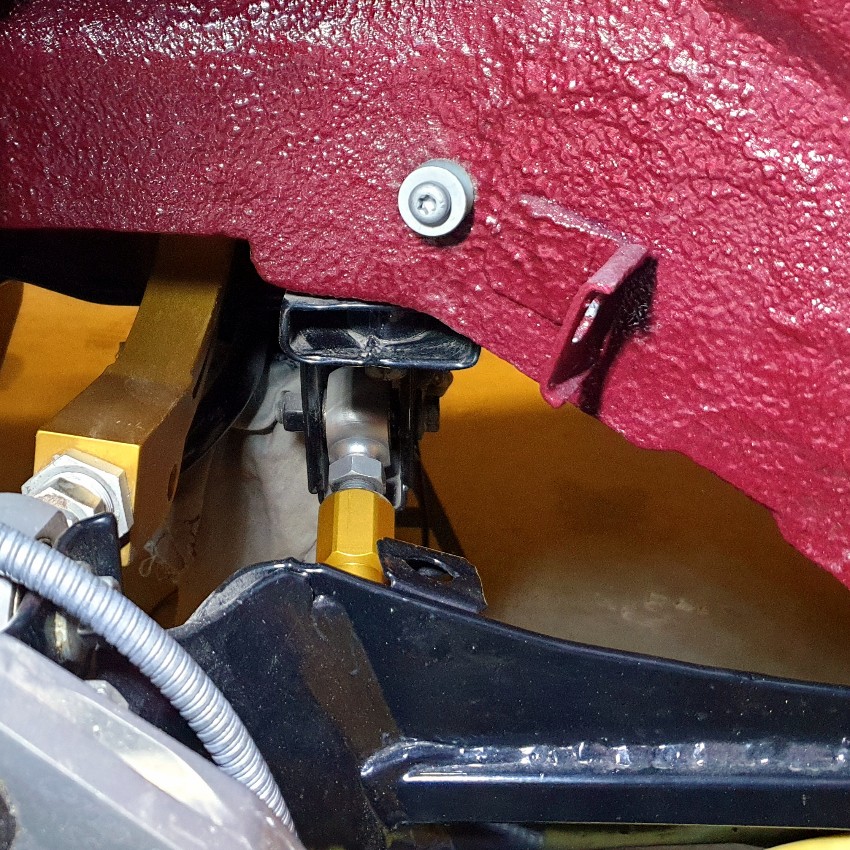

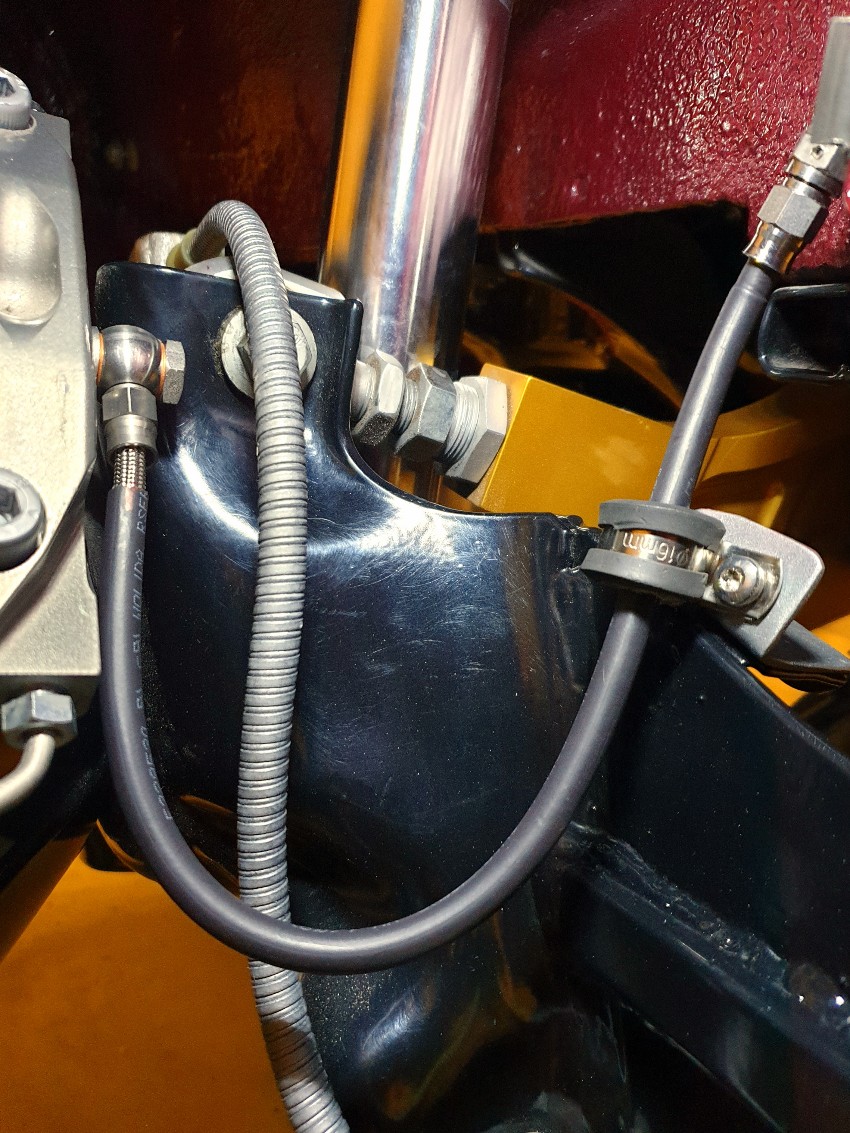

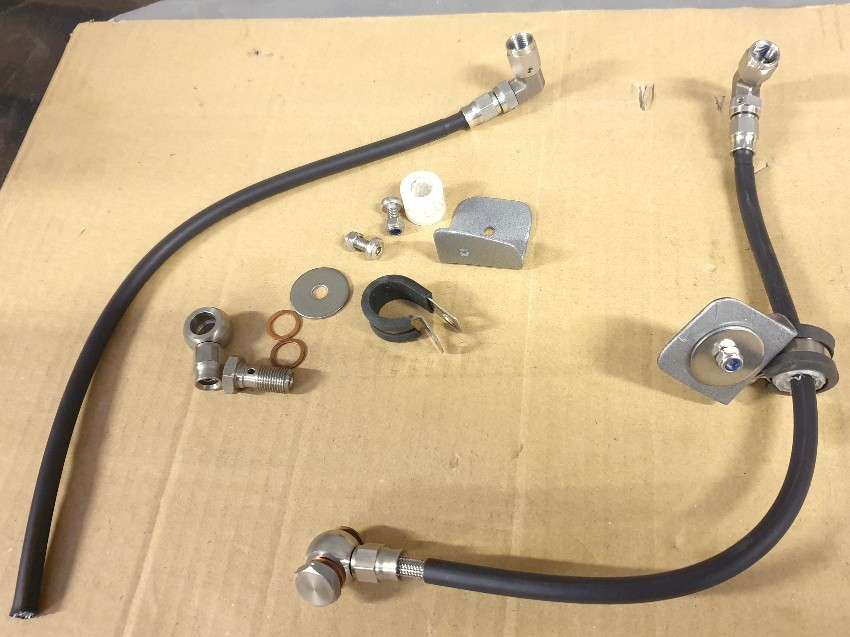

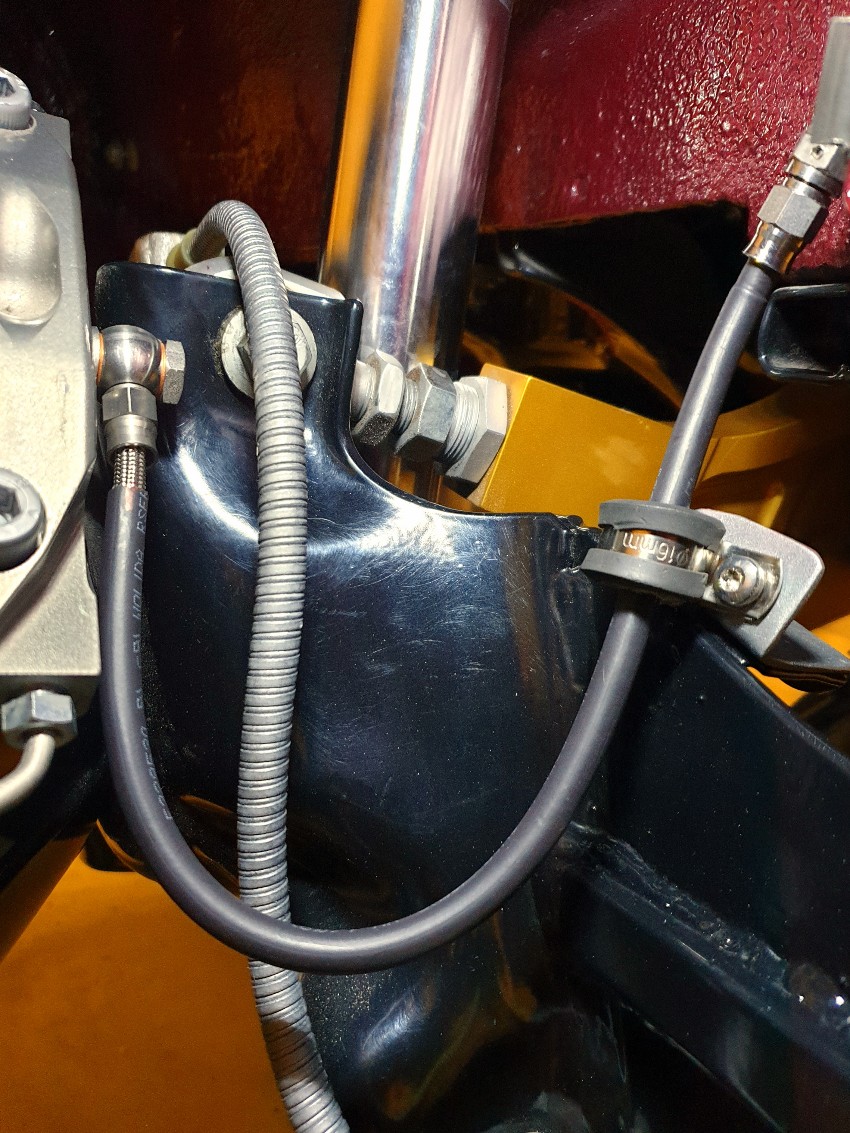

The rear lines are completely bespoke: Fiesta wheelarch mount, Focus trailing arms, and AP Racing calipers mounted in a unique location. The photo below shows what I had to work with.

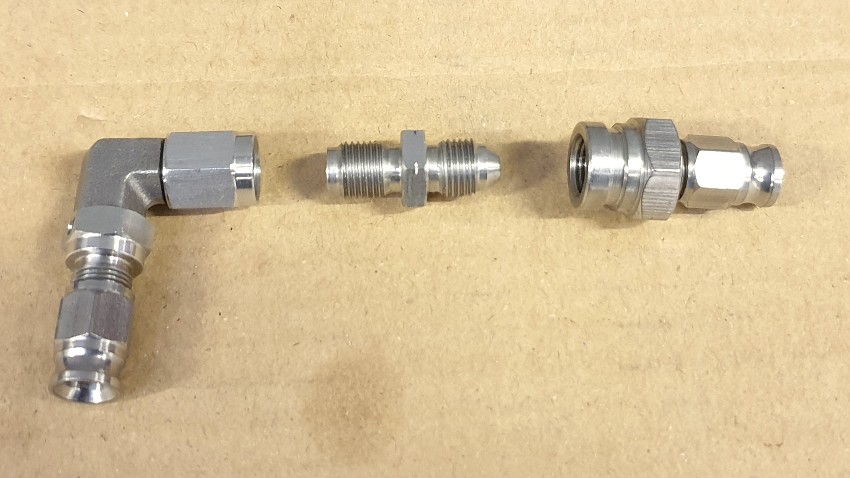

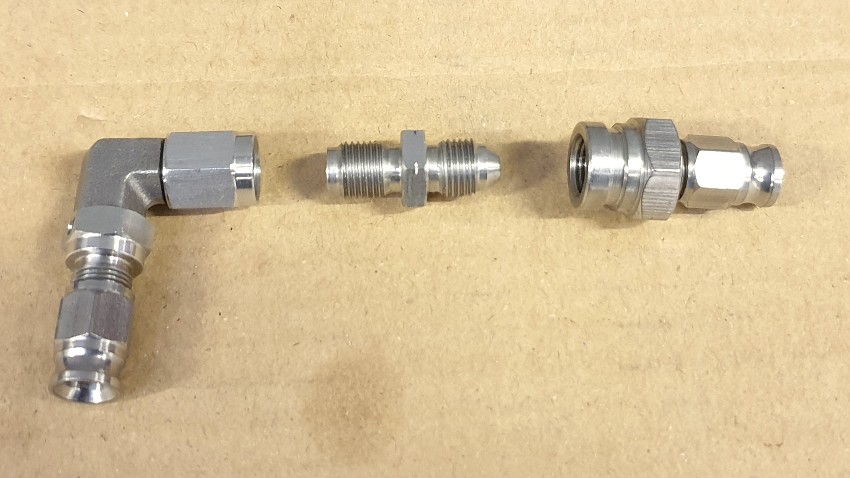

The design uses a particular set of fittings that are a mix of convex and concave seats, and required a male/male adapter to suit. All fittings are stainless steel.

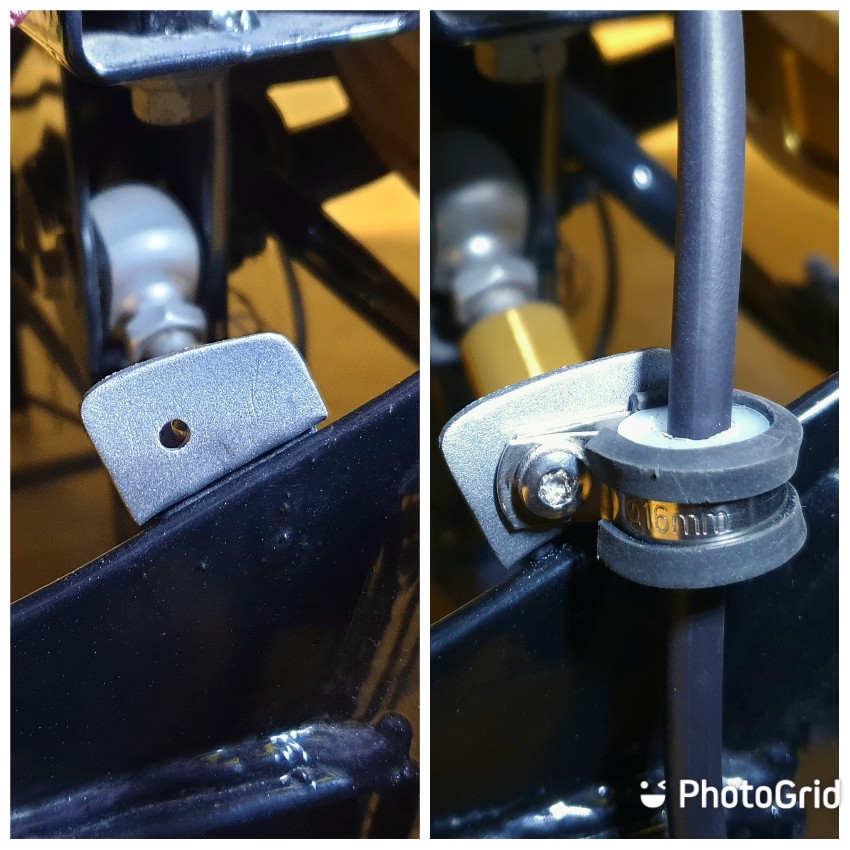

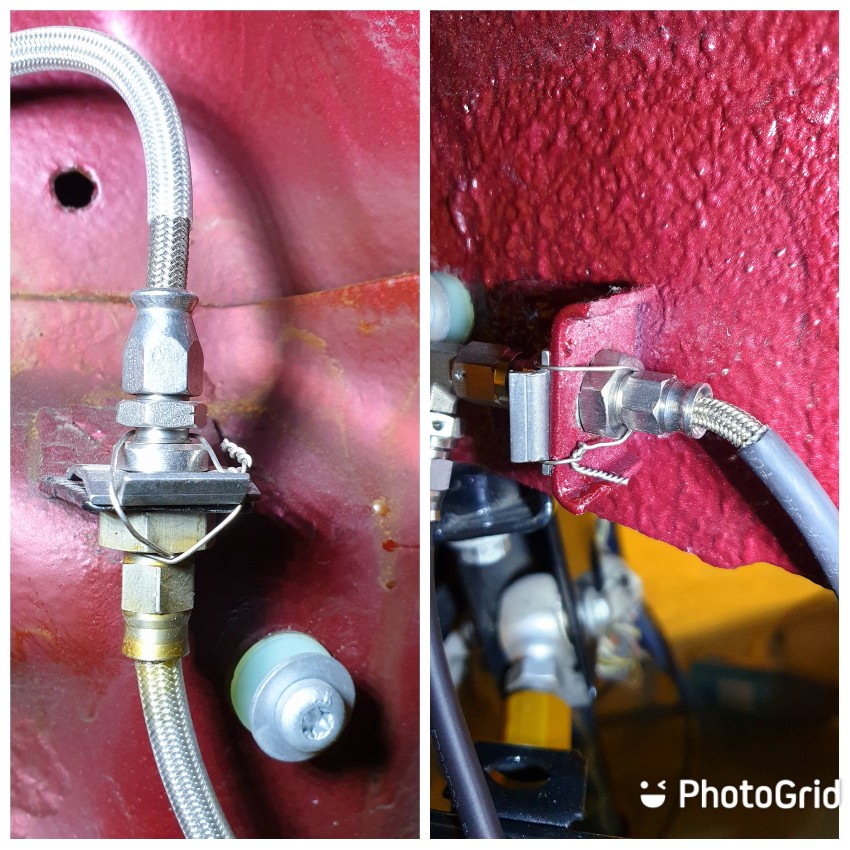

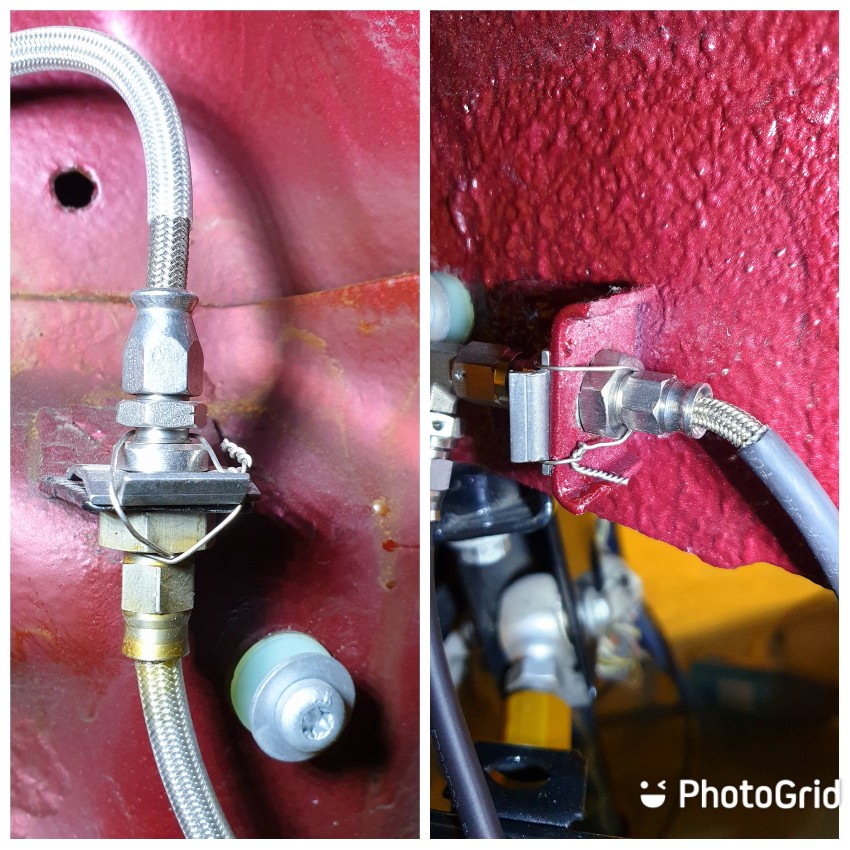

The Fiesta wheelarch bulkhead mount is keyed to prevent the fitting from twisting, so I've filed flats on the bulkhead fittings to match.

In order to make the plumbing work the bulkhead fittings will be installed in reverse orientation, but doing so leaves less room for the securing clips due to the design of the mounting bracket. I'm using stainless clips rather than OEM steel and I managed to find a second, shorter design which are a perfect fit.

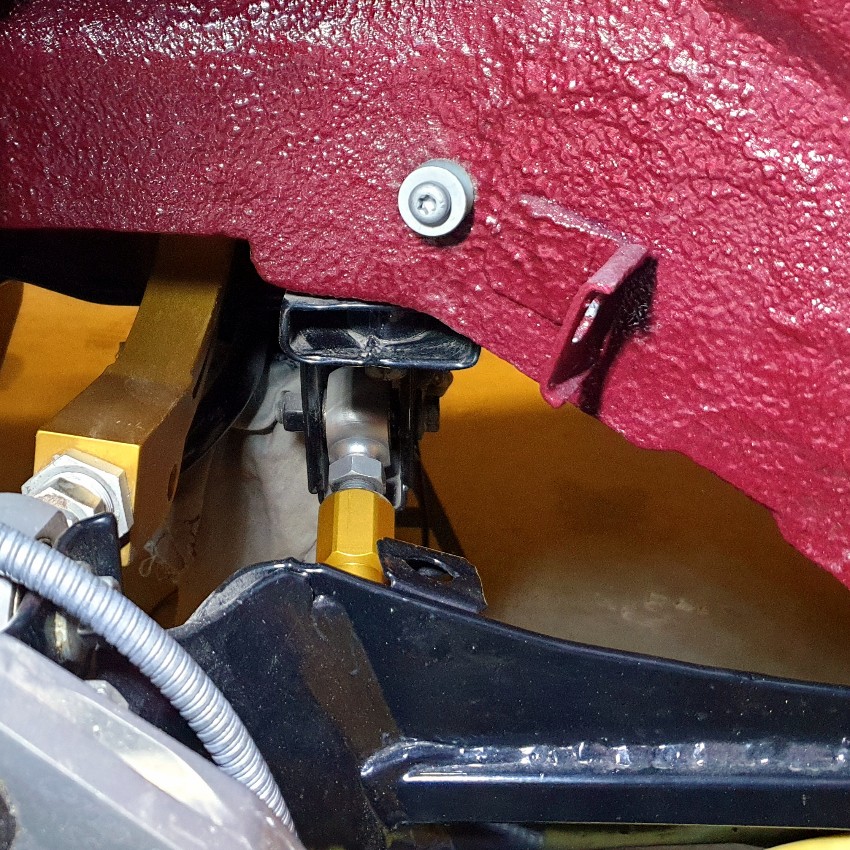

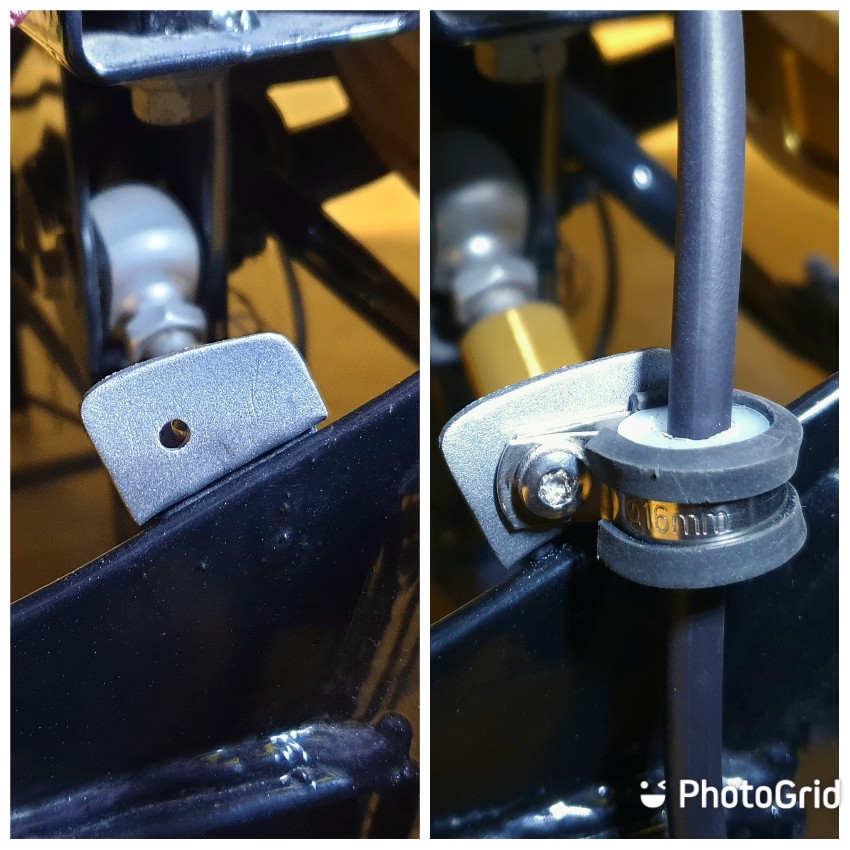

I've designed a mounting bracket that allows the hose to slide through it as the suspension compresses. I made it from a Delrin bush which is held in a P clip attached to an aluminium bracket.

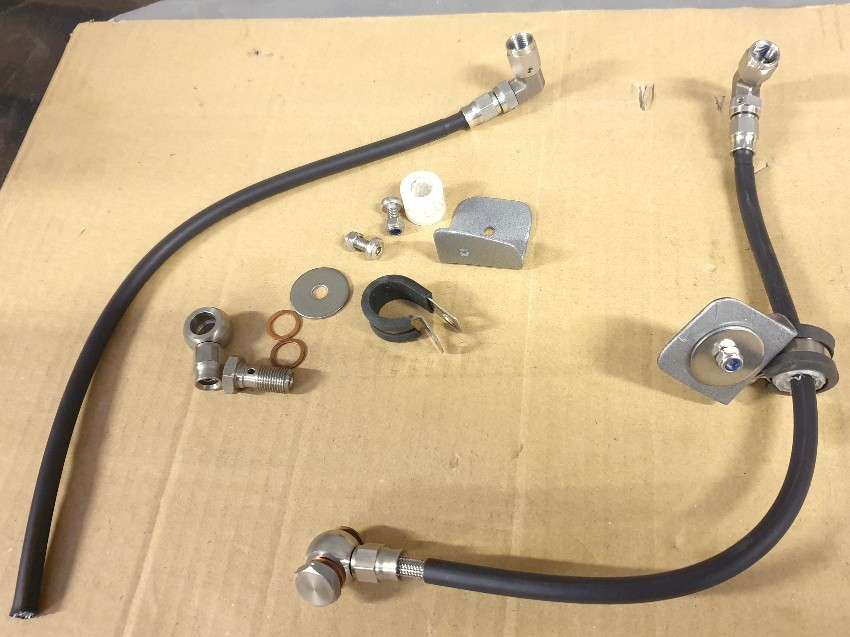

The hose brackets bolt through the original bulkhead fitting mounts on the Focus trailing arm. The brackets were etch primed and painted silver.

Hose assemblies partially complete. The stainless hose has a PVC sheath but I've added some black heatshrink in places to make it look more OEM.

Completed.

I have lockwired the brake cable mounts. I'm thinking ahead to a top speed run should I change the gear ratios.

The rear lines are completely bespoke: Fiesta wheelarch mount, Focus trailing arms, and AP Racing calipers mounted in a unique location. The photo below shows what I had to work with.

The design uses a particular set of fittings that are a mix of convex and concave seats, and required a male/male adapter to suit. All fittings are stainless steel.

The Fiesta wheelarch bulkhead mount is keyed to prevent the fitting from twisting, so I've filed flats on the bulkhead fittings to match.

In order to make the plumbing work the bulkhead fittings will be installed in reverse orientation, but doing so leaves less room for the securing clips due to the design of the mounting bracket. I'm using stainless clips rather than OEM steel and I managed to find a second, shorter design which are a perfect fit.

I've designed a mounting bracket that allows the hose to slide through it as the suspension compresses. I made it from a Delrin bush which is held in a P clip attached to an aluminium bracket.

The hose brackets bolt through the original bulkhead fitting mounts on the Focus trailing arm. The brackets were etch primed and painted silver.

Hose assemblies partially complete. The stainless hose has a PVC sheath but I've added some black heatshrink in places to make it look more OEM.

Completed.

I have lockwired the brake cable mounts. I'm thinking ahead to a top speed run should I change the gear ratios.

Max M4X WW said:

Looking good Mark, I assume the 'sliding' brake hose mounts will be acceptable to a picky MOT tester?

Cheers Max. The standard Fiesta doesn't have brackets, so I've added them to keep the lines in check at speed. The MOT check on flexible hoses is for condition and not mounting arrangement.HughG said:

Looks great Mark. Do the brake line and handbrake cable maintain separation through the range of suspension travel?

Thank you. Good spot - in those photos the handbrake cable mounts were WIP.mwstewart said:

Max M4X WW said:

Looking good Mark, I assume the 'sliding' brake hose mounts will be acceptable to a picky MOT tester?

Cheers Max. The standard Fiesta doesn't have brackets, so I've added them to keep the lines in check at speed. The MOT check on flexible hoses is for condition and not mounting arrangement.Exhaust Heat Shield - Rear

The rear silencer on my car will be mounted transversely behind the rear axle, unlike longitudinally on the O/S of the boot floor, as standard. I researched various cars with this exhaust configuration including the TT, Quattro Audis and others. In the end I decided that I could make a Mercedes-Benz CLA part work. Part number A2466820171.

With my Mercedes discount the part came in around £20 which is considerably less than those offered on eBay - with the usual mark-up. I bought two so that I could use one as a prototype.

After some time spent hammering and reshaping I was happy with the fit. I cut up the prototype shield and used it to extend the good one. The following pic shows the initial extension (top) and then the reshaping to fit my installation (bottom), including a relief to access the camber adjustment bolts on the rear subframe. All edges were folded over and hammered flat to create a smooth seam.

I used stainless peel rivets to join the extension. This was the first time that I've used them, and they were perfect for the job.

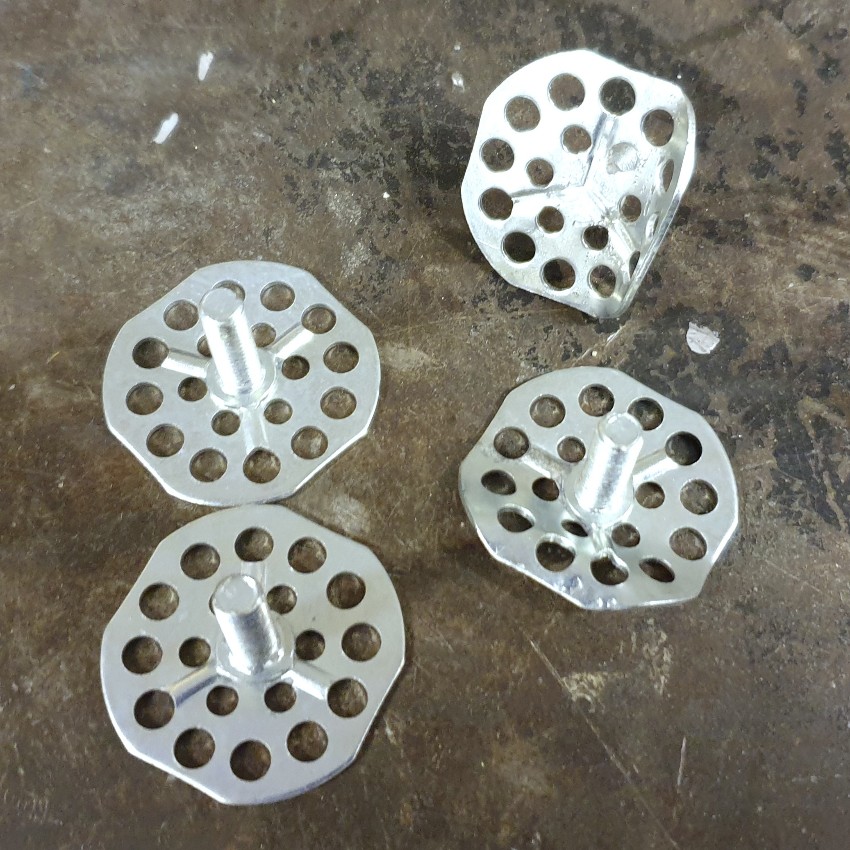

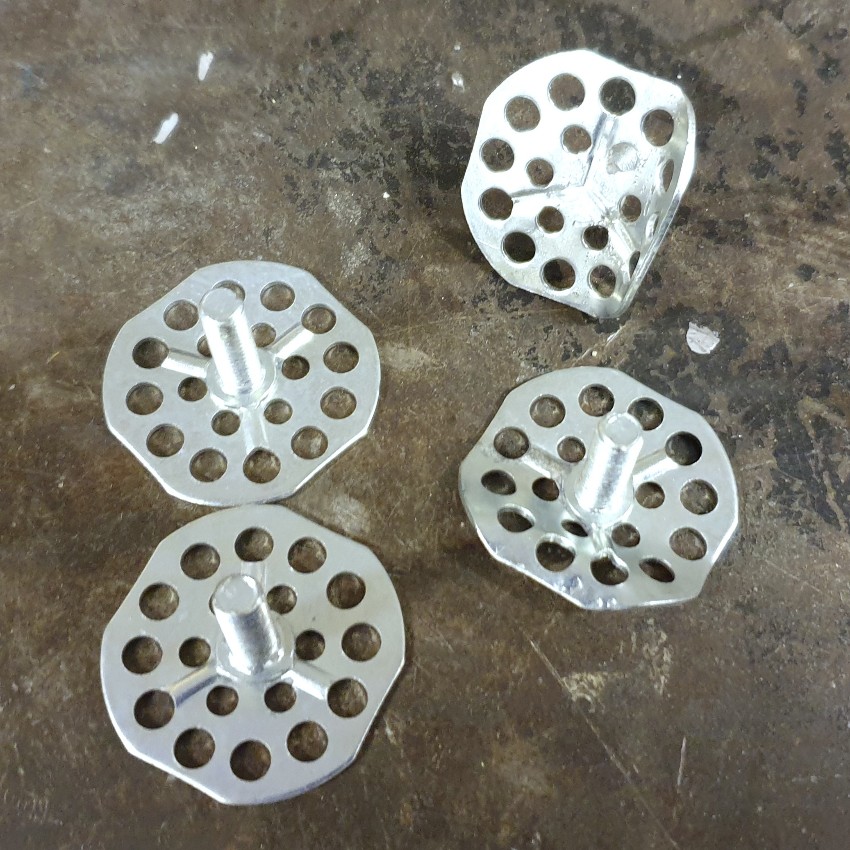

I didn't want to drill the floor, so I used 'big head' bonding studs and secured them to the boot floor with RTV. These were bent into shape to suit the contours of the boot floor.

I've chosen Focus ST/RS exhaust mounts. Ford part number 1688752. These have a most unusual smell! Like liquorice mixed with surfboard wax.

Complete. When preparing the shell I had made provision for three additional exhaust mounts. I'm very pleased with how this job turned out.

Handbrake Cable - Rear Brackets

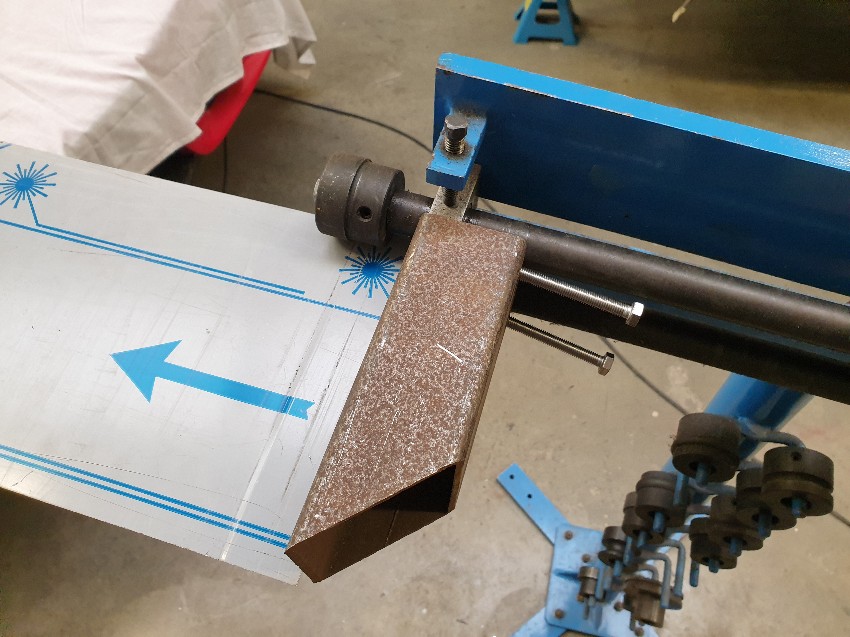

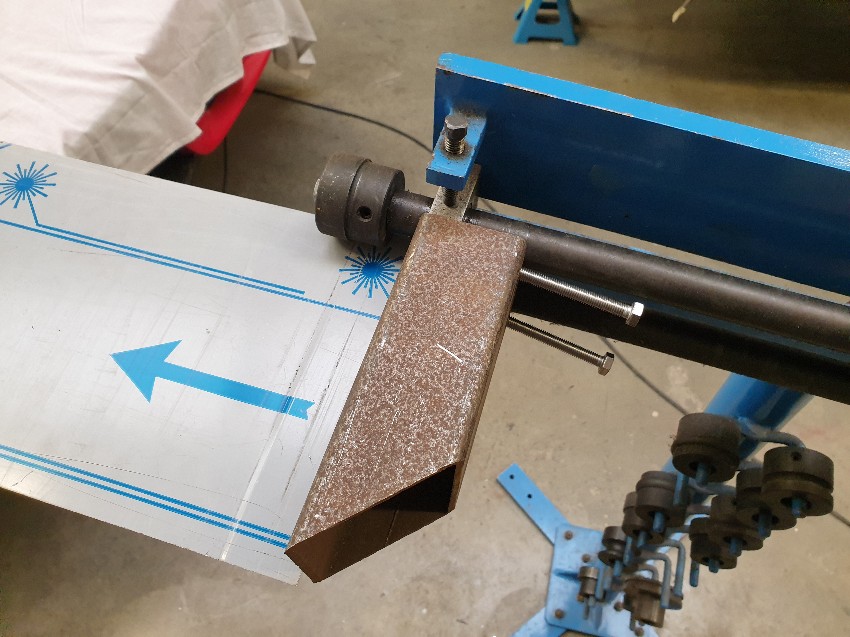

The handbrake cable position and routing is completely unique to my car and required custom brackets. For the first time in years I made use of the bead roller - I fashioned a sightly Heath Robinson looking guard to make the job simpler.

Brackets fabricated from stainless steel.

Brackets mounted. The lower bracket is drilled and tapped into the 3mm reinforcement section that I welded to the Focus trailing arm, which is a sealed section, so I took the opportunity to inject some wax. The upper mount is attached to the AP caliper mounting bolt.

Wheel Spacers & Extended Studs

Changing to the Ford wheels has reduced caliper clearance by 10mm; 3mm due to ET35 rather than ET38, and 7mm due to the wheel design. The Team Dynamics wheels required a 3mm spacer therefore the Ford wheels require 13mm.

I couldn't find spacers in the required thickness, so I ordered 16mm and I'll have them milled to spec. I've ordered longer studs to suit - for reference these are M12 x 1.5, 13mm spline, 42mm thread. I really dislike the spaced wheel look but thankfully due to the rolled and flared arches I can still retain a decent inset within the wheel arch.

I hammered out the existing studs and managed to fit the replacements through a clearance hole in the disc back plate, and wind them home by locking the hub with a long screwdriver.

Studs and spacers fitted. Spacers yet to be milled.

The rear silencer on my car will be mounted transversely behind the rear axle, unlike longitudinally on the O/S of the boot floor, as standard. I researched various cars with this exhaust configuration including the TT, Quattro Audis and others. In the end I decided that I could make a Mercedes-Benz CLA part work. Part number A2466820171.

With my Mercedes discount the part came in around £20 which is considerably less than those offered on eBay - with the usual mark-up. I bought two so that I could use one as a prototype.

After some time spent hammering and reshaping I was happy with the fit. I cut up the prototype shield and used it to extend the good one. The following pic shows the initial extension (top) and then the reshaping to fit my installation (bottom), including a relief to access the camber adjustment bolts on the rear subframe. All edges were folded over and hammered flat to create a smooth seam.

I used stainless peel rivets to join the extension. This was the first time that I've used them, and they were perfect for the job.

I didn't want to drill the floor, so I used 'big head' bonding studs and secured them to the boot floor with RTV. These were bent into shape to suit the contours of the boot floor.

I've chosen Focus ST/RS exhaust mounts. Ford part number 1688752. These have a most unusual smell! Like liquorice mixed with surfboard wax.

Complete. When preparing the shell I had made provision for three additional exhaust mounts. I'm very pleased with how this job turned out.

Handbrake Cable - Rear Brackets

The handbrake cable position and routing is completely unique to my car and required custom brackets. For the first time in years I made use of the bead roller - I fashioned a sightly Heath Robinson looking guard to make the job simpler.

Brackets fabricated from stainless steel.

Brackets mounted. The lower bracket is drilled and tapped into the 3mm reinforcement section that I welded to the Focus trailing arm, which is a sealed section, so I took the opportunity to inject some wax. The upper mount is attached to the AP caliper mounting bolt.

Wheel Spacers & Extended Studs

Changing to the Ford wheels has reduced caliper clearance by 10mm; 3mm due to ET35 rather than ET38, and 7mm due to the wheel design. The Team Dynamics wheels required a 3mm spacer therefore the Ford wheels require 13mm.

I couldn't find spacers in the required thickness, so I ordered 16mm and I'll have them milled to spec. I've ordered longer studs to suit - for reference these are M12 x 1.5, 13mm spline, 42mm thread. I really dislike the spaced wheel look but thankfully due to the rolled and flared arches I can still retain a decent inset within the wheel arch.

I hammered out the existing studs and managed to fit the replacements through a clearance hole in the disc back plate, and wind them home by locking the hub with a long screwdriver.

Studs and spacers fitted. Spacers yet to be milled.

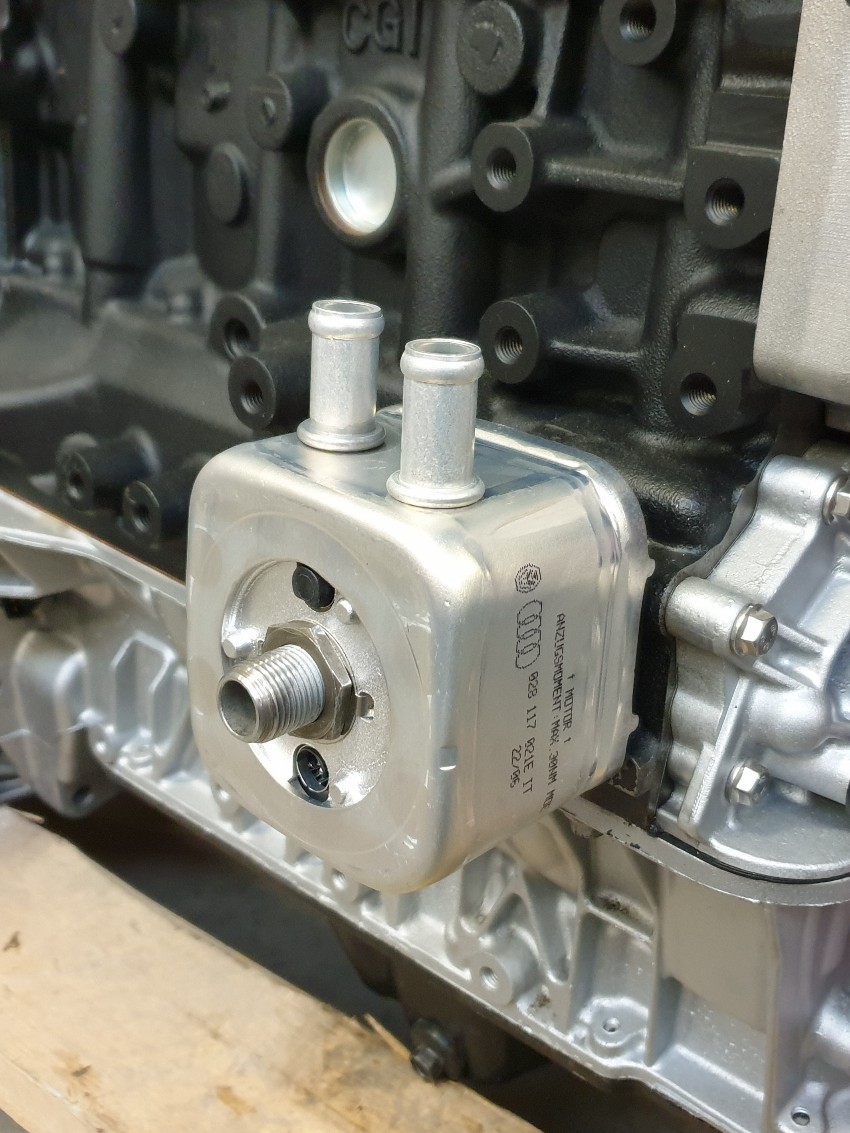

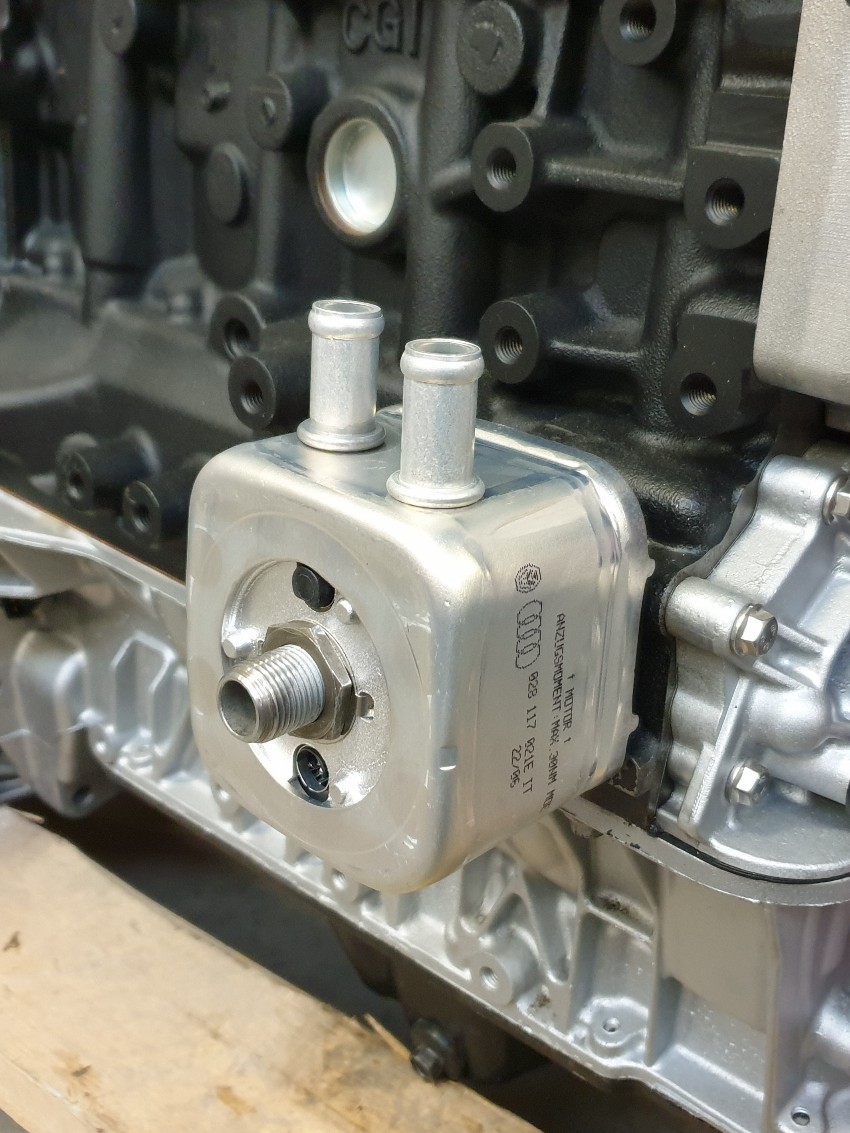

Engine Oil Cooler

A short segway into engine preparation. I wanted to fit an OEM sandwich oil cooler - technically more of an oil temperature management device because they both aid warm up and prevent high temperatures. The Ford part is steel, rusts at the water unions, and is heavy. I wanted an aluminium part and an upgrade to double capacity.

I found a Ford part used in the US market which at some point switched to aluminium, but I couldn't pin down exactly when, so I looked elsewhere. Many VAG cars use a double capacity sandwich cooler, so I tried part 038 117 021A. A trial fit showed this to be unsuitable because the seal arrangement is designed for installation in reverse orientation to the Zetec.

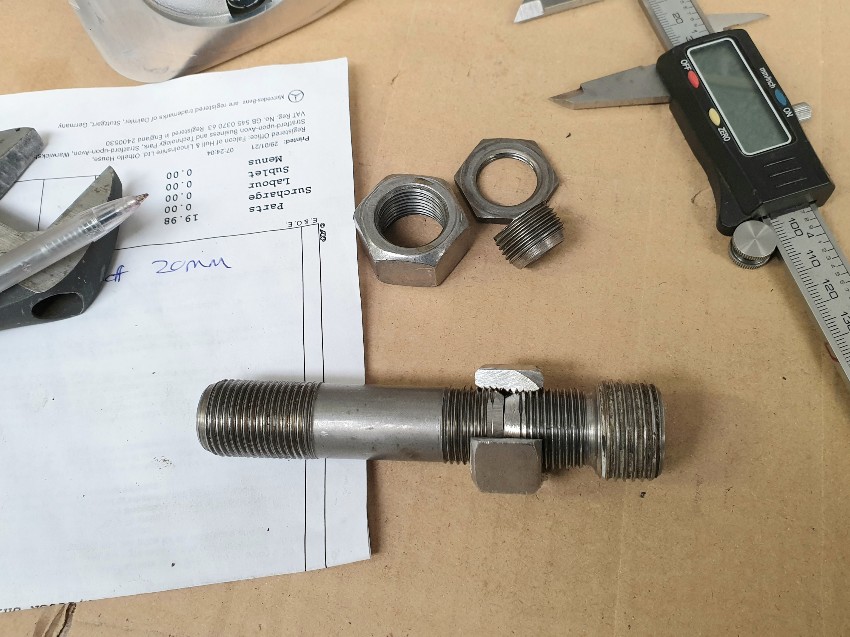

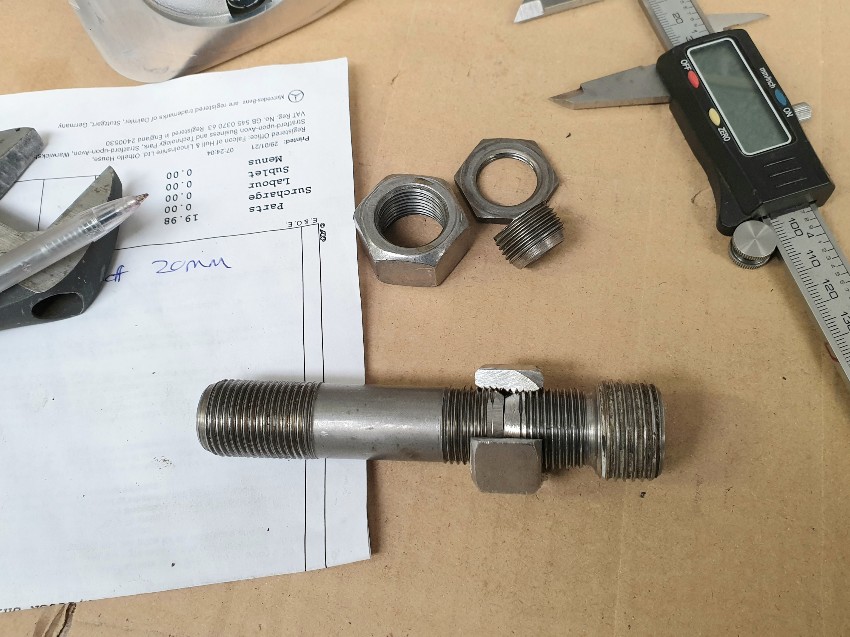

Whilst I was searching for a suitable part I turned my attention to the mounting stanchion/oil supply tube. It must be extended or replaced in order to accommodate a double capacity cooler in addition to the screw-on filter. Ford use a 3/4 UNF thread for the filter, which is fairly common, so I bought a used VAG oil filter housing 06A115405BP for the stanchion and half nut to lock the cooler in place. Aftermarket oil coolers have a screw on extension tube but this won't work with the VAG coolers.

The Zetec stanchion has a different thread at one end to suit that used in the block. I determined the exact length required, and cut down the VAG part to suit ready to weld to the Ford part. I made a jig to align the two parts for welding by cutting an access window in a 3/4 UNF nut.

The following collage shows the original stanchion, double nut method used to remove, and the extended version that I made.

Here is the completed solution. VAG part 028117021E proved to be perfect and is a higher quality part than the friction welded plate type that I originally tried.

A short segway into engine preparation. I wanted to fit an OEM sandwich oil cooler - technically more of an oil temperature management device because they both aid warm up and prevent high temperatures. The Ford part is steel, rusts at the water unions, and is heavy. I wanted an aluminium part and an upgrade to double capacity.

I found a Ford part used in the US market which at some point switched to aluminium, but I couldn't pin down exactly when, so I looked elsewhere. Many VAG cars use a double capacity sandwich cooler, so I tried part 038 117 021A. A trial fit showed this to be unsuitable because the seal arrangement is designed for installation in reverse orientation to the Zetec.

Whilst I was searching for a suitable part I turned my attention to the mounting stanchion/oil supply tube. It must be extended or replaced in order to accommodate a double capacity cooler in addition to the screw-on filter. Ford use a 3/4 UNF thread for the filter, which is fairly common, so I bought a used VAG oil filter housing 06A115405BP for the stanchion and half nut to lock the cooler in place. Aftermarket oil coolers have a screw on extension tube but this won't work with the VAG coolers.

The Zetec stanchion has a different thread at one end to suit that used in the block. I determined the exact length required, and cut down the VAG part to suit ready to weld to the Ford part. I made a jig to align the two parts for welding by cutting an access window in a 3/4 UNF nut.

The following collage shows the original stanchion, double nut method used to remove, and the extended version that I made.

Here is the completed solution. VAG part 028117021E proved to be perfect and is a higher quality part than the friction welded plate type that I originally tried.

ATM said:

What's the plan for the exhaust?

Is it made already?

Who will be making it?

It will be an equal length, divided/twin-scroll manifold into a T4 flange to suit a Borg Warner EFR turbo. The rest of the system will be 3" with a V band cat towards the front of the car, and a single silencer at the rear with a rectangular tailpipe in keeping with the original Ford FRST exhaust, only a little bit larger in diameter.Is it made already?

Who will be making it?

I may go with http://www.ojzengineering.co.uk/gallery_albums.php

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff