500+bhp Mk3 Fiesta Project

Discussion

This project is amazing! why anybody would bother to do all this to a mk3 Fiesta i have no idea, but I'm glad you have. The attention to detail is stunning, with fitting all of these toys it's like a currrent day fiesta, but if it has 500 bhp it will be a monster as well. Xenons, side airbags (I would hope those are never needed), heated seats and you're fitting parking sensors as well? Also I think I saw something about keyless entry earlier in the thread as well, although i may have made that one up.

Thanks chaps! Here's some more.

I have fitted an ECU bracket from a later Fiesta. I will retain the Ford ECU to control the engine fans, A/C compressor and a few other functions. I'll make use of the existing PATS immobiliser to secure power to the fuel pump and the Pectel ECU I'll use to actually run the engine.

The Mk5 heater box is now in together with the air ducts. The eagle eyed may spot that the sound deadening material around the scuttle now has a grey finish; I found out that some models had a layer of mass loaded vinyl on top of the standard underlay type material (as per the bulkhead below). This arrangement offers improved sound deadening over a layer of foam alone.

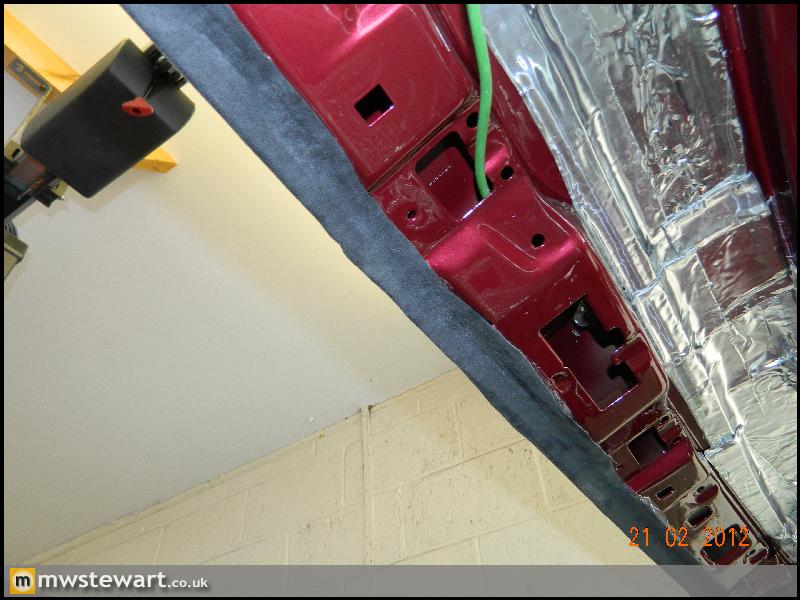

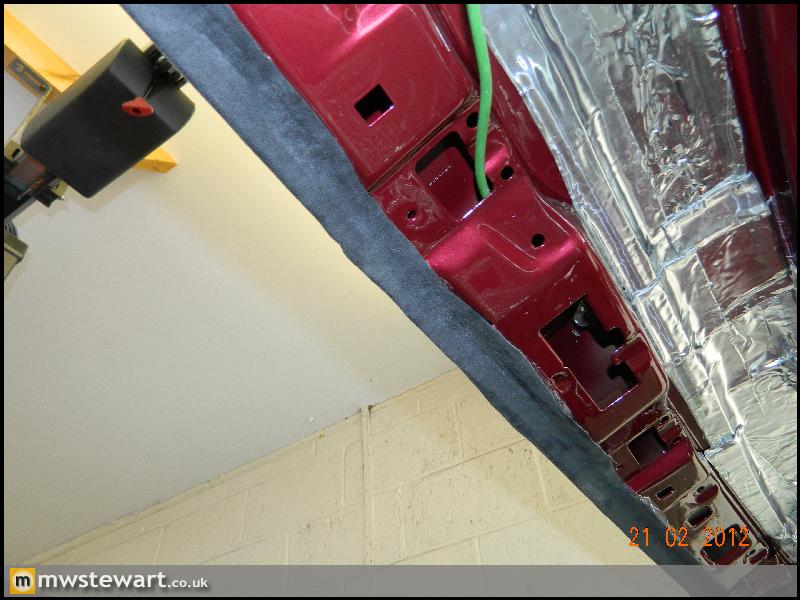

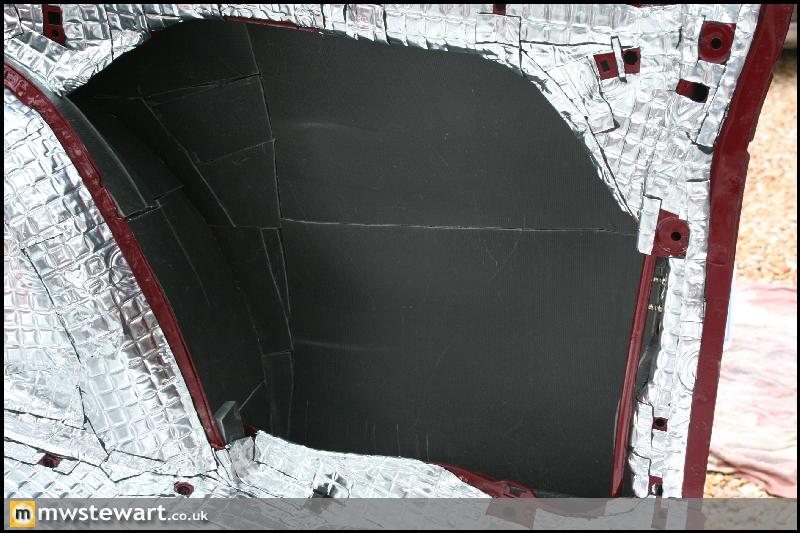

My Dad kindly helped out again by adding vibration damping material to the front floor pan and rear seat area. I ran out of pads which is shy there is a square shaped gap at the bottom of the first photo The other cut outs are for the seat mounts and handbrake.

The other cut outs are for the seat mounts and handbrake.

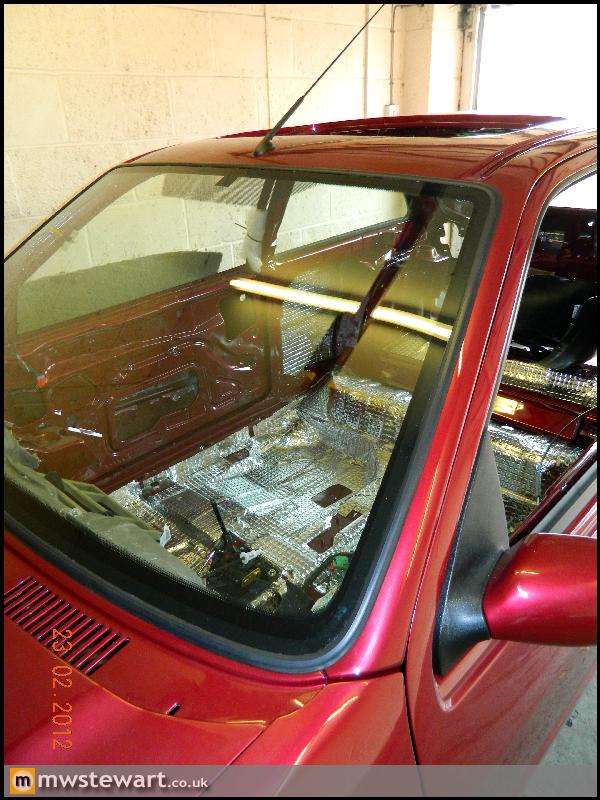

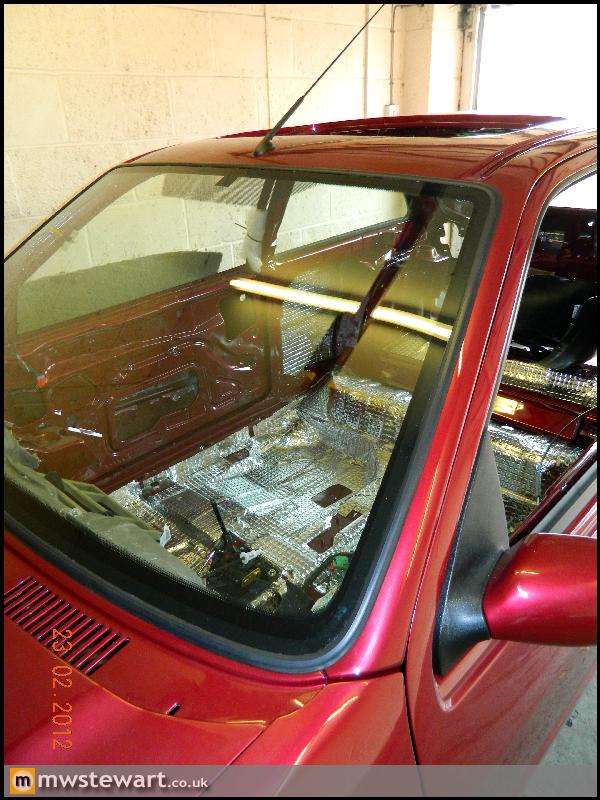

The Mk3 Fiesta never came with a bonded windscreen and instead it used the traditional rubber seal arrangement. I'm using a bonded screen because it actually adds to the cars structure and it also looks neater, but the downside to that is the Mk3 headlining doesn't finish flush with the screen; it finishes around 10mm further back to leave room for the standard rubber weather seal. To ensure everything looks neat I had Aldridge send a strip of Alcantara which I've glued to the windscreen aperture, so when the headlining is finally fitted everything will look neat.

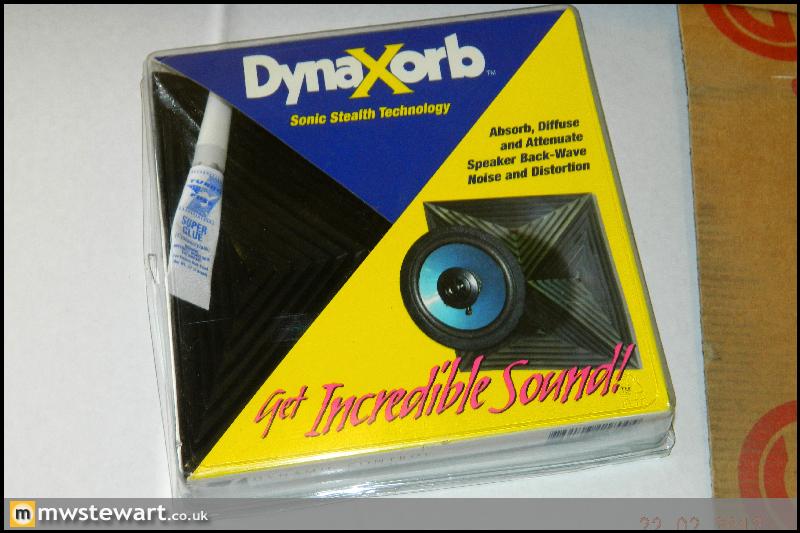

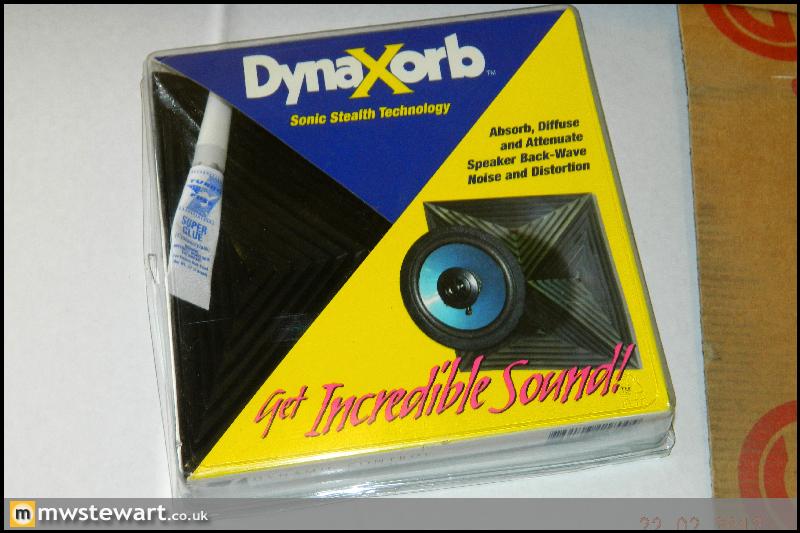

I bought this product from Dynamat. It's supposed to attenuate rear wave from the front midrange drivers (or in fact any speaker you place it behind). Like speaker cable choice it is a fairly subjective thing, but given that many people have said they do make a difference and they aren't expensive, I have fitted a set anyway.

New Ford heated screen bonded in.

Mk5 Fiesta pollen filter housing and new charcoal filter added.

I rebuilt the Mk3 wiper motor and linkage using new Ford parts and some of the old parts that I had Zinc plated. I have new Ford wiper arms and wipers to go on too.

It probably looks more complicated than it actually is!

These parts of the spindle usually rot away underneath the outer cosmetic cover, so I have smeared them with grease.

Mk5 heater matrix pipes and Air Con evaporator pipes. I fitted a new Ford heater control valve/solenoid, it's the latest revision which has finally cured a long standing issue with the part which can leave the HVAC either stuck on cold or hot.

I'm pleased with how the AC pipes have turned out, they look like they were meant to be there.

Even though I bought new Ford door catches I've had them re-plated in a thicker coating. They look better now.

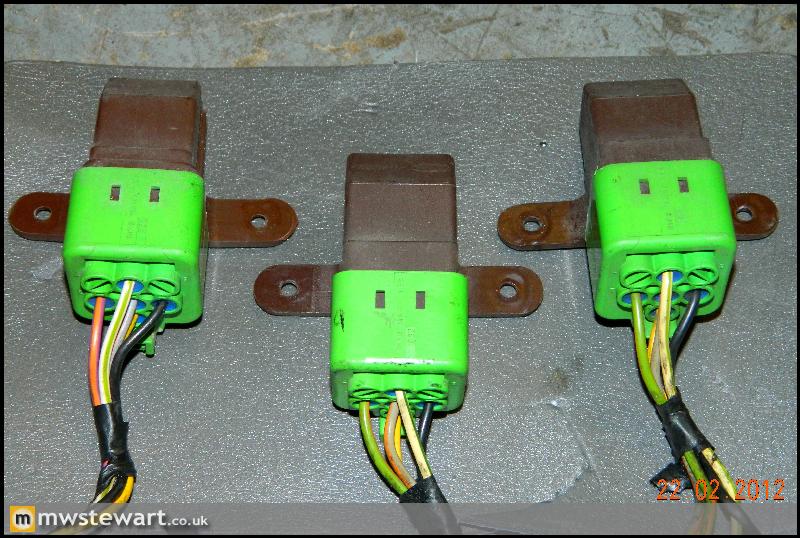

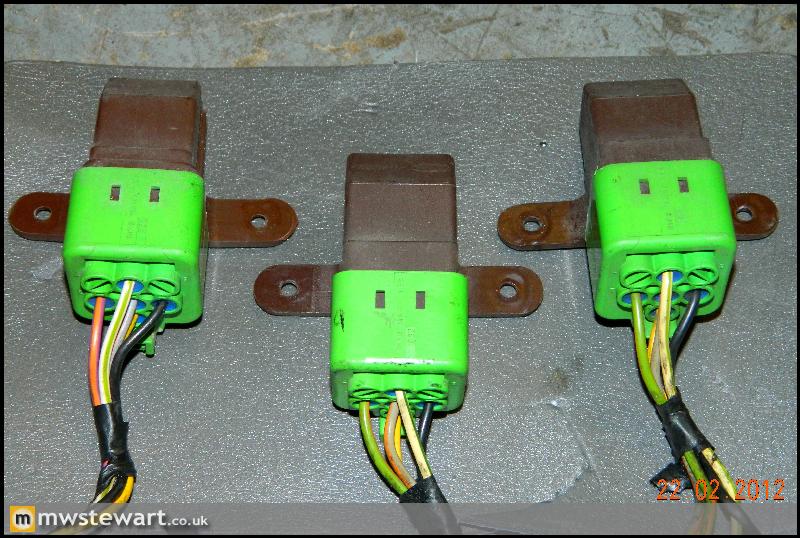

Another add on: one touch electric window relays from a Mondeo. I will use three to provide one touch down for the two driver switches and the passenger switch.

I have fitted an ECU bracket from a later Fiesta. I will retain the Ford ECU to control the engine fans, A/C compressor and a few other functions. I'll make use of the existing PATS immobiliser to secure power to the fuel pump and the Pectel ECU I'll use to actually run the engine.

The Mk5 heater box is now in together with the air ducts. The eagle eyed may spot that the sound deadening material around the scuttle now has a grey finish; I found out that some models had a layer of mass loaded vinyl on top of the standard underlay type material (as per the bulkhead below). This arrangement offers improved sound deadening over a layer of foam alone.

My Dad kindly helped out again by adding vibration damping material to the front floor pan and rear seat area. I ran out of pads which is shy there is a square shaped gap at the bottom of the first photo

The other cut outs are for the seat mounts and handbrake.

The other cut outs are for the seat mounts and handbrake.

The Mk3 Fiesta never came with a bonded windscreen and instead it used the traditional rubber seal arrangement. I'm using a bonded screen because it actually adds to the cars structure and it also looks neater, but the downside to that is the Mk3 headlining doesn't finish flush with the screen; it finishes around 10mm further back to leave room for the standard rubber weather seal. To ensure everything looks neat I had Aldridge send a strip of Alcantara which I've glued to the windscreen aperture, so when the headlining is finally fitted everything will look neat.

I bought this product from Dynamat. It's supposed to attenuate rear wave from the front midrange drivers (or in fact any speaker you place it behind). Like speaker cable choice it is a fairly subjective thing, but given that many people have said they do make a difference and they aren't expensive, I have fitted a set anyway.

New Ford heated screen bonded in.

Mk5 Fiesta pollen filter housing and new charcoal filter added.

I rebuilt the Mk3 wiper motor and linkage using new Ford parts and some of the old parts that I had Zinc plated. I have new Ford wiper arms and wipers to go on too.

It probably looks more complicated than it actually is!

These parts of the spindle usually rot away underneath the outer cosmetic cover, so I have smeared them with grease.

Mk5 heater matrix pipes and Air Con evaporator pipes. I fitted a new Ford heater control valve/solenoid, it's the latest revision which has finally cured a long standing issue with the part which can leave the HVAC either stuck on cold or hot.

I'm pleased with how the AC pipes have turned out, they look like they were meant to be there.

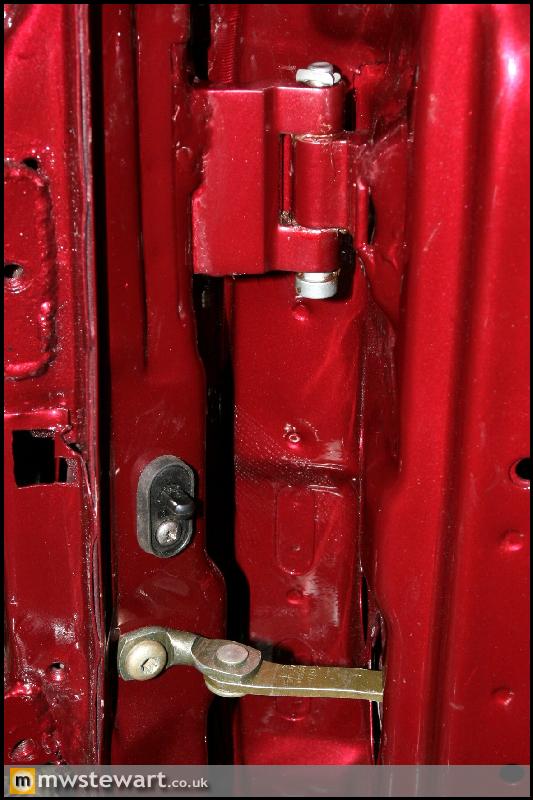

Even though I bought new Ford door catches I've had them re-plated in a thicker coating. They look better now.

Another add on: one touch electric window relays from a Mondeo. I will use three to provide one touch down for the two driver switches and the passenger switch.

Thanks all

I've been on holiday hence the lack of updates. The interior will be ready for collection on 23/03 and I plan to get it fitted over the following weekend, so that should be the next big update.

I will indeed attain an engineers report to verify the quality of work, and as I'll insure for an agreed value its also fairly standard procedure to provide a spec list and build log containing photos of the project.

I've been on holiday hence the lack of updates. The interior will be ready for collection on 23/03 and I plan to get it fitted over the following weekend, so that should be the next big update.

I will indeed attain an engineers report to verify the quality of work, and as I'll insure for an agreed value its also fairly standard procedure to provide a spec list and build log containing photos of the project.

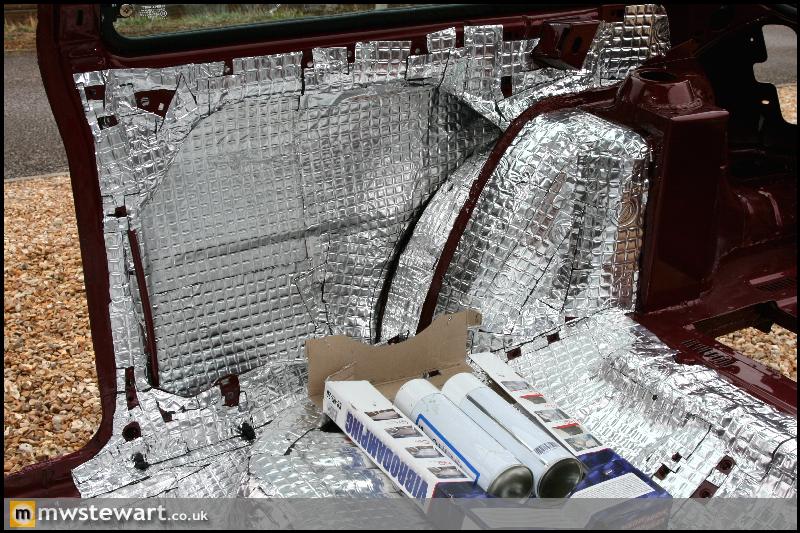

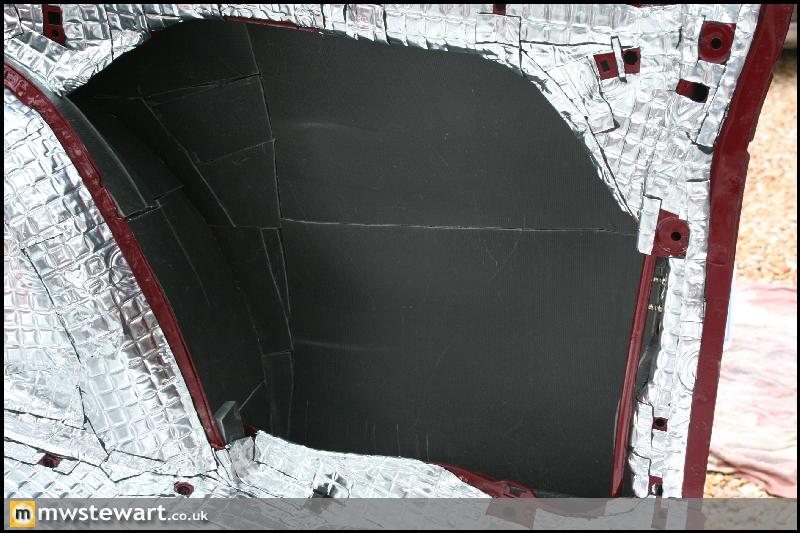

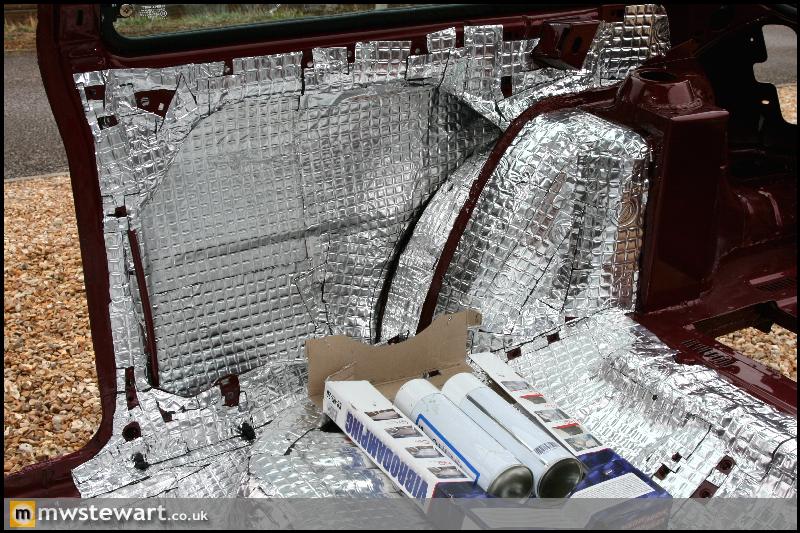

Now that the vibration damping process is well under way the sound deadening work can start. I'm using 'Luxury Liner Pro' made by Second Skin, it is a Mass Loaded Vinyl product that comprises a layer of foam to absorb the various frequencies and a dense Vinyl layer to decouple the foam layer and reflect sound back through the various deadening materials. The egg carton type material in the background is a soft foam product which sticks behind trim to alleviate vibrations and trim rattles.

The rear quarter areas are now vibration damped and sound deadened.

O/S door vibration damped and sound deadened. Thanks to my Dad again for giving up a lot of his time to help with this stage.

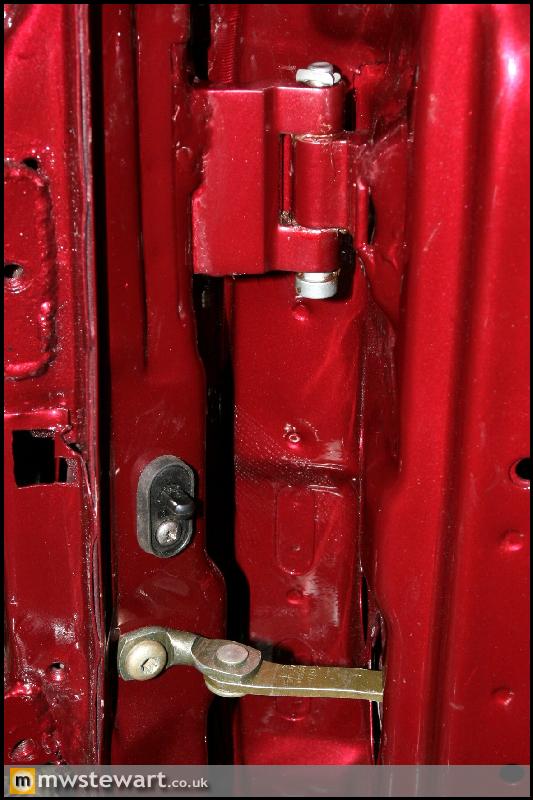

Now the O/S sound work was finished I could build up the rest of the door. The lock barrel and central/deadlocking motor was first.

New door pins, check strap and door ajar switch fitted with a stainless screw.

New window motor/regular fitted.

I have these bags of closed cell foam made from recycled car parts, which are used to fill voids in the shell to further reduce noise and drone.

Some trim fastenings in the car make use of spire clips which slot into punched rectangular holes in the shell, and then the screw passes through a circular punched hole. The photos probably make more sense than my explanation! The fastenings aren't great as they mean only around 1mm of material is available for the screw to grip, and so to improve on this I have removed the spire clips altogether and fitted M5 Rivnuts in the circular hole.

I'm replacing the standard speaker cable with Van Damme Blue Studio Grade cable, and I've chosen Audison Sonus RCA interconnects. Both cables have a good reputation for high sound quality.

New Wiper arms and Wipers fitted. I'll swap to Bosch Aerotwin blades later on.

I've decided to get another rear bumper painted, this time one with parking sensor holes and a modified exhaust cut out area.I've cut the exhaust area from a scrap bumper which will be used to extend the length of mine so that I can fit a twin tail pipes that are similar in size to the S3 8P.

The rear quarter areas are now vibration damped and sound deadened.

O/S door vibration damped and sound deadened. Thanks to my Dad again for giving up a lot of his time to help with this stage.

Now the O/S sound work was finished I could build up the rest of the door. The lock barrel and central/deadlocking motor was first.

New door pins, check strap and door ajar switch fitted with a stainless screw.

New window motor/regular fitted.

I have these bags of closed cell foam made from recycled car parts, which are used to fill voids in the shell to further reduce noise and drone.

Some trim fastenings in the car make use of spire clips which slot into punched rectangular holes in the shell, and then the screw passes through a circular punched hole. The photos probably make more sense than my explanation! The fastenings aren't great as they mean only around 1mm of material is available for the screw to grip, and so to improve on this I have removed the spire clips altogether and fitted M5 Rivnuts in the circular hole.

I'm replacing the standard speaker cable with Van Damme Blue Studio Grade cable, and I've chosen Audison Sonus RCA interconnects. Both cables have a good reputation for high sound quality.

New Wiper arms and Wipers fitted. I'll swap to Bosch Aerotwin blades later on.

I've decided to get another rear bumper painted, this time one with parking sensor holes and a modified exhaust cut out area.I've cut the exhaust area from a scrap bumper which will be used to extend the length of mine so that I can fit a twin tail pipes that are similar in size to the S3 8P.

Excellent progress! I love what you've been doing so far.

mwstewart said:

Some trim fastenings in the car make use of spire clips which slot into punched rectangular holes in the shell, and then the screw passes through a circular punched hole. The photos probably make more sense than my explanation! The fastenings aren't great as they mean only around 1mm of material is available for the screw to grip, and so to improve on this I have removed the spire clips altogether and fitted M5 Rivnuts in the circular hole.

This sort of attention to detail is what pushes an amazing build into a phenomenal build. Edited by Perd Hapley on Tuesday 13th March 23:18

Perd Hapley said:

mwstewart said:

Some trim fastenings in the car make use of spire clips which slot into punched rectangular holes in the shell, and then the screw passes through a circular punched hole. The photos probably make more sense than my explanation! The fastenings aren't great as they mean only around 1mm of material is available for the screw to grip, and so to improve on this I have removed the spire clips altogether and fitted M5 Rivnuts in the circular hole.

This sort of attention to detail is what pushes an amazing build into a phenomenal build. I absolutely *love* this thread - it's like you're trying to create the best mk3 Fiesta you possibly could (far better than Ford ever could with time, budgetary restraints, etc) - I love that and I take my hat off to you, sir.

The attention to detail is both mind-blowing and commendable. Very very well done.

The attention to detail is both mind-blowing and commendable. Very very well done.

pistonpie said:

what is the car going to look like from the outside? is it going to be a stock look but with a modern twist? or is it going to look like a 1990s fiesta? this build is amazing!

I'm hoping it's going to look totally standard to the untrained eye, but with the odd clue, such as twin exhausts.Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff