RE: 4 Stroke Redesigned

Discussion

If you want to do wave power, these are the people to talk to;

http://www.mech.ed.ac.uk/research/wavepower/

Check out the vids, it's pretty serious stuff! If you don't already have real player, it's worth it;

http://boombox.ucs.ed.ac.uk/ramgen/waves/225k/wave...

http://boombox.ucs.ed.ac.uk/ramgen/waves/225k/wave...

http://www.mech.ed.ac.uk/research/wavepower/

Check out the vids, it's pretty serious stuff! If you don't already have real player, it's worth it;

http://boombox.ucs.ed.ac.uk/ramgen/waves/225k/wave...

http://boombox.ucs.ed.ac.uk/ramgen/waves/225k/wave...

Edited by dilbert on Tuesday 4th November 03:05

[quote=dilbert].....I think we can agree that a system of pulleys is better in many ways than a gearbox.

The big problem with reciprocation though is that the torque at the output varies throughout the cycle......

With the wind turbine, I still think the optimum solution is the gearbox.[quote]

Dear Dilbert, I agree with problem in With synchronization for period of wave dynamo Beam . I think , so need computer positionings element beam, which answers for period of work beam .It must be positioned element mechanically . Thans too for nice your links.

In Beam Dynamo we can change input data using set off pulles.

This pull my story:You know last time my distaste for transmission cogged ??

First principle pulles:

Regards Andrew

The big problem with reciprocation though is that the torque at the output varies throughout the cycle......

With the wind turbine, I still think the optimum solution is the gearbox.[quote]

Dear Dilbert, I agree with problem in With synchronization for period of wave dynamo Beam . I think , so need computer positionings element beam, which answers for period of work beam .It must be positioned element mechanically . Thans too for nice your links.

In Beam Dynamo we can change input data using set off pulles.

This pull my story:You know last time my distaste for transmission cogged ??

First principle pulles:

Regards Andrew

I live in Alderney and we're about to have a massive (subject to testing) tidal flow power system installed.

http://www.openhydro.com/images.html

http://www.openhydro.com/images.html

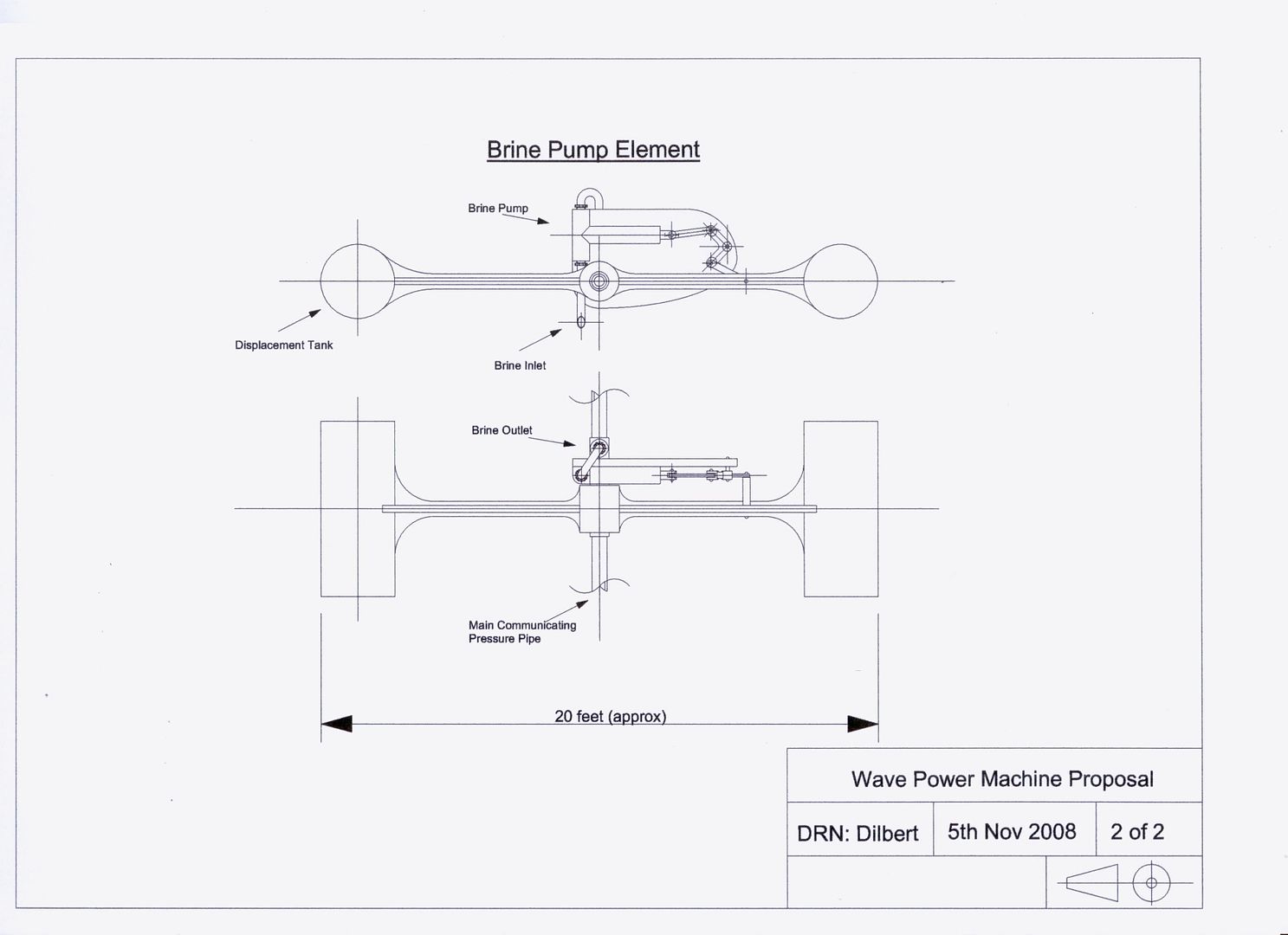

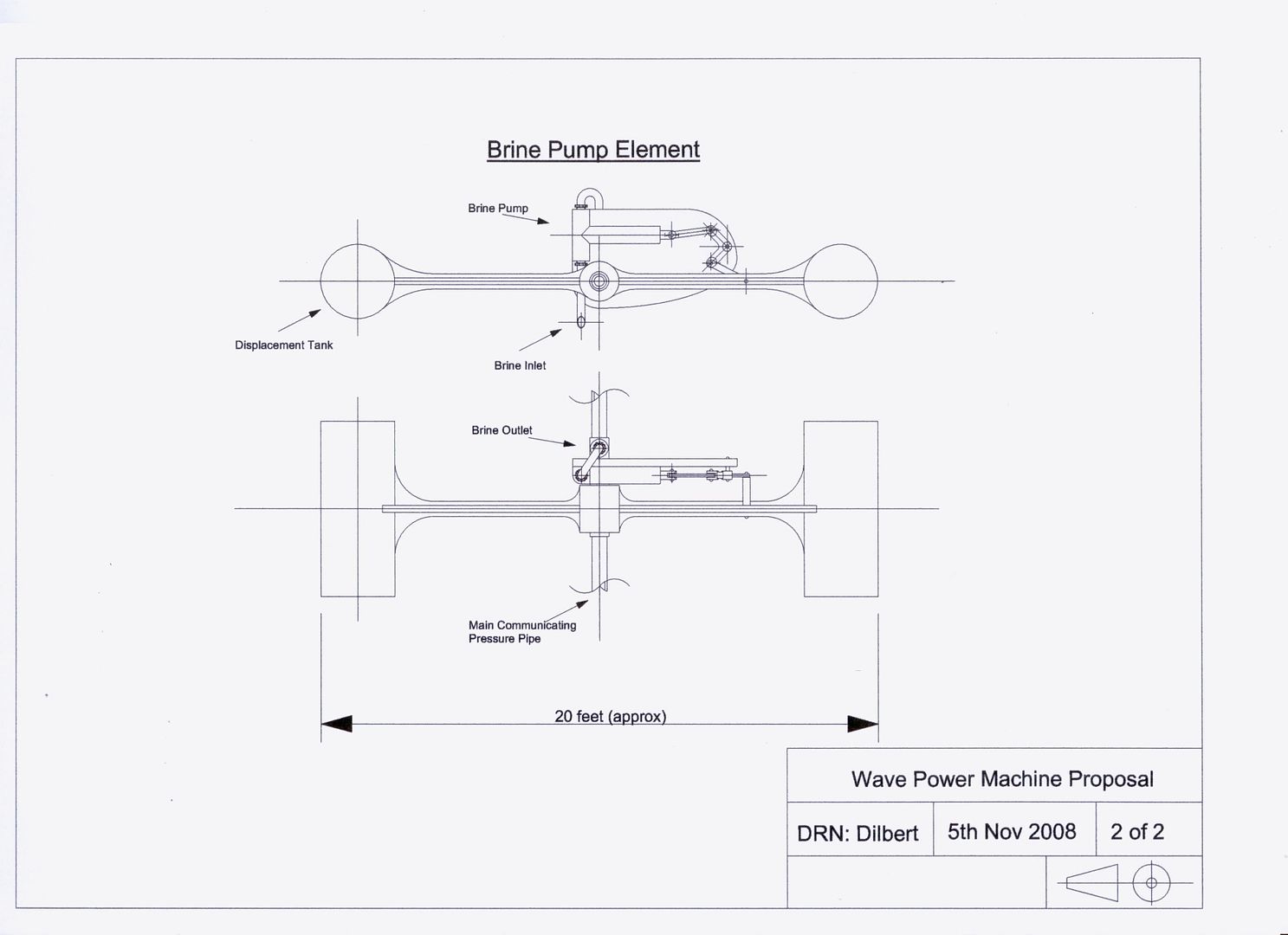

Allright, so I don't have 3D CAD or the capacity to animate, but I drew up an idea I have for a really simple wave power machine. There are certainly some problems that would have to be overcome, but most are doable.

The biggest technical challenge is getting the main pipe right. It would have to be made of a material that would resist twisting quite strongly, but allow flexibility along it's length. If you can find something to do that, then the whole deal is sewn up.

The proposal shows an array of pumps that float on the sea surface and they collectively, in chains of say a hundred, simply pressurise seawater and pump it ashore, due to the force of the waves.

What I'm proposing is that on the shore there is a receiver, which is like a cylinder with a piston that has a massive concrete weight on top. The pressurised brine lifts the concrete weight. The best comparison I can think of is something that we have in this country called a gasometer (shown below);

The pressure in the container would be more or less the same from empty to full, but would drop off quickly when empty, and rise very fast once full.

Once the weight is lifted then the pressure within can be used to propel a standard hydroelectric turbine. Clearly it will be possible to exhaust the supply of energy in the receiver, as it would for the receiver to become hydraulicly locked. The optimum way to extract the energy, would be to let the receiver fill to say 90% and then let it empty to around 10% to avoid the receiver exploding, or the system having to be primed regularly.

Anyway the drawings are below. Perhaps you could knock up one of those 3D animated models from my drawing.

If I can be bothered I might draw out some sections across the pump, but it's probably not necassary. It's just a piston and cylinder, with two non-return valves.

Hope you like!!

ETA;

I think it looks a bit organic actually, perhaps like a spine. Might keep the ecomentalists happy!

The biggest technical challenge is getting the main pipe right. It would have to be made of a material that would resist twisting quite strongly, but allow flexibility along it's length. If you can find something to do that, then the whole deal is sewn up.

The proposal shows an array of pumps that float on the sea surface and they collectively, in chains of say a hundred, simply pressurise seawater and pump it ashore, due to the force of the waves.

What I'm proposing is that on the shore there is a receiver, which is like a cylinder with a piston that has a massive concrete weight on top. The pressurised brine lifts the concrete weight. The best comparison I can think of is something that we have in this country called a gasometer (shown below);

The pressure in the container would be more or less the same from empty to full, but would drop off quickly when empty, and rise very fast once full.

Once the weight is lifted then the pressure within can be used to propel a standard hydroelectric turbine. Clearly it will be possible to exhaust the supply of energy in the receiver, as it would for the receiver to become hydraulicly locked. The optimum way to extract the energy, would be to let the receiver fill to say 90% and then let it empty to around 10% to avoid the receiver exploding, or the system having to be primed regularly.

Anyway the drawings are below. Perhaps you could knock up one of those 3D animated models from my drawing.

If I can be bothered I might draw out some sections across the pump, but it's probably not necassary. It's just a piston and cylinder, with two non-return valves.

Hope you like!!

ETA;

I think it looks a bit organic actually, perhaps like a spine. Might keep the ecomentalists happy!

Edited by dilbert on Thursday 6th November 05:55

Dear Dilbert,See this animations , if is good , added hydraulic accummulator.

http://www.ceto.com.au/ceto-technology/what-is-cet...

Ma be using my half rotate pumps??

Ragards Andrew

http://www.ceto.com.au/ceto-technology/what-is-cet...

Ma be using my half rotate pumps??

Ragards Andrew

Edited by Feliks on Thursday 6th November 13:10

Feliks said:

Dear Dilbert,See this animations , if is good , added hydraulic accummulator.

http://www.ceto.com.au/ceto-technology/what-is-cet...

Ma be using my half rotate pumps??

Ragards Andrew

I quite like that idea, but I think that having a single baloon connected to an individual pump is going to be problematic, even if the baloon is arranged to be "in the surf". You could, I guess have a spring at the bottom, to keep the rope tight, bit I'm thinking that it's better to have two baloons, one at each end of the rope, and then have a loop that wraps a pulley at the bottom.http://www.ceto.com.au/ceto-technology/what-is-cet...

Ma be using my half rotate pumps??

Ragards Andrew

Edited by Feliks on Thursday 6th November 13:10

I also wondered if your rotary reciprocating engine could be reversed into a pump especially for either of, the design I drew, or the baloon idea.

Feliks said:

New steam engine (only one) using in Big Boy locomotive,ships, tractor, or enegy plant.

Possible fuel: biomass ,wood,peat, russet coal,coal,ethanol,biooils,oil,hydrogen,biogas,LPG,natural gas,uranium,fusion.

Regards Andrew

For break anew animations :Possible fuel: biomass ,wood,peat, russet coal,coal,ethanol,biooils,oil,hydrogen,biogas,LPG,natural gas,uranium,fusion.

Regards Andrew

Edited by Feliks on Thursday 19th April 10:52

Big Boy with Stephenson Second engine are going.

Ride it where ?

Andrew

ps Need new electronic valave drive system.

Feliks said:

Dear Dilbert,See this animations.....

Ma be using my half rotate pumps??

Advantages of half rotate pumps are additional possible regulations.Ma be using my half rotate pumps??

In normal piston pump, we have two elements definition pumps – diameter of piston and stroke piston In half rotate pump we have too same elements: diameter “piston” and long “piston” and additional important possible regulations TORQUE of drive pump on arm with some hole...

This regulation are without additional gear .

For salt water I think better solution made aal this pump PCW , or ABS, or propose - ceramic

Regards Andrew

Forget steam power on trains. Once a line is electrified then it makes much more sense to move the steam / electrical power generation plant to a fixed position. That way the train doesn't have to lug about huge amounts of fuel, water, boilers, heavy pistons etc and the power generation system can be physically bigger, remotely located near the fuel source and benefit from economies of scale. Or, as they are colloquially known, "power stations".

Looks like some has already got a half rotation engine to work....

http://www.ls1tech.com/forums/advanced-engineering...

Cheers,

Chris.

http://www.ls1tech.com/forums/advanced-engineering...

Cheers,

Chris.

chuntington101 said:

Looks like some has already got a half rotation engine to work....

http://www.ls1tech.com/forums/advanced-engineering...

Cheers,

Chris.

That's a really nice link. There's a vid on that thread of the engine being turned over.http://www.ls1tech.com/forums/advanced-engineering...

Cheers,

Chris.

http://uk.youtube.com/watch?v=ZI1JLbnW3Sg

It's essentially this anim;

But with more flaps. I don't think he uses quite the same arrangement for cycling the flaps, it looks like some sort of epicyclic, but the same general concept.

I don't think it's the same idea as felix half rotate job. There's still time!!

Also check out the end of the vid. He sounds like a really nice guy, I hope his idea does well for him.

Without any cogged gear .Last I don't prefer cogged gear.

Animation drive truck without any cogged wheel.

Rod differ, two clutch ( maybe hydraulic)and half rotate engine ,same parameters "Hercules C130" - Vintake= 250 liter. Without any gearbox.

For truck are good parameters.

Regards Andrew

Animation drive truck without any cogged wheel.

Rod differ, two clutch ( maybe hydraulic)and half rotate engine ,same parameters "Hercules C130" - Vintake= 250 liter. Without any gearbox.

For truck are good parameters.

Regards Andrew

What is this?

This is a hydraulic pump of widmill

Manner of utilization is next my proposal instead of mechanical transmission

in producing windmills electric current :Hallf Rotete Pump

Main principle of operation on following drawing and has enclosed animation

Solution has many advantages from haf rotate pump. Expensive

substitute is first most important and noisy, emergency transmission

of mechanical windmill .

It is presented next advantage on former drawing

for one dynamo driven manner of connection

of whole farm of windmill hydraulic engine serious too.

This way, we save several most expensive elements of windmills,

treating such farm windmill as integrity .( Complex design)

Regards Andrew Santa Claus

This is a hydraulic pump of widmill

Manner of utilization is next my proposal instead of mechanical transmission

in producing windmills electric current :Hallf Rotete Pump

Main principle of operation on following drawing and has enclosed animation

Solution has many advantages from haf rotate pump. Expensive

substitute is first most important and noisy, emergency transmission

of mechanical windmill .

It is presented next advantage on former drawing

for one dynamo driven manner of connection

of whole farm of windmill hydraulic engine serious too.

This way, we save several most expensive elements of windmills,

treating such farm windmill as integrity .( Complex design)

Regards Andrew Santa Claus

Edited by Feliks on Friday 5th December 23:58

Feliks said:

What is this?

This is a hydraulic pump of widmill

Manner of utilization is next my proposal instead of mechanical transmission

in producing windmills electric current :Hallf Rotete Pump

Main principle of operation on following drawing and has enclosed animation

Solution has many advantages from haf rotate pump. Expensive

substitute is first most important and noisy, emergency transmission

of mechanical windmill .

It is presented next advantage on former drawing

for one dynamo driven manner of connection

of whole farm of windmill hydraulic engine serious too.

This way, we save several most expensive elements of windmills,

treating such farm windmill as integrity .( Complex design)

Regards Andrew Santa Claus

I can't see that pump design of yours having any efficiency, cost or package benefits over existing Gear, Vane or Piston pumps

This is a hydraulic pump of widmill

Manner of utilization is next my proposal instead of mechanical transmission

in producing windmills electric current :Hallf Rotete Pump

Main principle of operation on following drawing and has enclosed animation

Solution has many advantages from haf rotate pump. Expensive

substitute is first most important and noisy, emergency transmission

of mechanical windmill .

It is presented next advantage on former drawing

for one dynamo driven manner of connection

of whole farm of windmill hydraulic engine serious too.

This way, we save several most expensive elements of windmills,

treating such farm windmill as integrity .( Complex design)

Regards Andrew Santa Claus

Edited by Feliks on Friday 5th December 23:58

Its too big for the displacement.

The nature of the reciprocating motion will create over centre conditions, resulting in significant pump ripple.

There are too many parts, too many wear points.

As a generation system it will be no more efficient than using a gearbox and certainly less efficient than using a direct drive generator.

[quote]I can't see that pump design of yours having any efficiency, cost or package benefits over existing Gear, Vane or Piston pumps

Its too big for the displacement.

The nature of the reciprocating motion will create over centre conditions, resulting in significant pump ripple.

As a generation system it will be no more efficient than using a gearbox and certainly less efficient than using a direct drive generator.

[/quote]

You like a Santa Claus?

"direct drive generator" you think about this: ?

[quote=Feliks]You know last time my distaste for transmission cogged ??

Visit Ricardo Company - http://www.ricardo.com/engineeringservices/newEner... I see many problem with it.

My solve: Wind motion my oscillating dynamo packs, without any cogged transmission:

Regards Andrew

[/quote]

Are you know flywheel ? Big flywheel make concrete. And add hydraulic accumulator.

All gearbox have no more efficient as efficient hydraulic gear. Everything it depends on tubes .Big diameter tube -big efficient.

Andrew

Its too big for the displacement.

The nature of the reciprocating motion will create over centre conditions, resulting in significant pump ripple.

As a generation system it will be no more efficient than using a gearbox and certainly less efficient than using a direct drive generator.

[/quote]

You like a Santa Claus?

"direct drive generator" you think about this: ?

[quote=Feliks]You know last time my distaste for transmission cogged ??

Visit Ricardo Company - http://www.ricardo.com/engineeringservices/newEner... I see many problem with it.

My solve: Wind motion my oscillating dynamo packs, without any cogged transmission:

Regards Andrew

[/quote]

Are you know flywheel ? Big flywheel make concrete. And add hydraulic accumulator.

All gearbox have no more efficient as efficient hydraulic gear. Everything it depends on tubes .Big diameter tube -big efficient.

Andrew

Edited by Feliks on Saturday 6th December 16:11

Gassing Station | Engines & Drivetrain | Top of Page | What's New | My Stuff