Is this detonation damage?

Discussion

Why the holes are there and not in the rest of the head is a good question. Can I offer the possible explanation that they were there all the time, but have simply been uncovered by the events in the combustion chamber? I've seen it before whereby a perfectly sound and smooth combustion chamber has come out looking a bit porous (but with smaller holes) after being in a blast cabinet which picked them out.

Boosted LS1 said:

^ OP says the pitting's confined to the squish bands. Have you read the whole thread?

Yes, I have read the whole thread.If you look closely you'll see areas outside the combustion chamber that look very much like porosity ready to open up. The areas that have been subject to cylinder pressure have certainly been opened up significantly by pressure and heat, but not in a way that is definitively knock-related. There is also no marking on the piston crown that correlates with knock damage - only debris impact.

If it was knocking, it wasn't for very long and certainly not long enough to destroy a piston ring land - that failure has other causes. Porosity aside, it has left no trace on the cylinder head if it happened at all.

AER said:

Yes, I have read the whole thread.

If you look closely you'll see areas outside the combustion chamber that look very much like porosity ready to open up. The areas that have been subject to cylinder pressure have certainly been opened up significantly by pressure and heat, but not in a way that is definitively knock-related. There is also no marking on the piston crown that correlates with knock damage - only debris impact.

If it was knocking, it wasn't for very long and certainly not long enough to destroy a piston ring land - that failure has other causes. Porosity aside, it has left no trace on the cylinder head if it happened at all.

Small, thin parts of the piston have wilted.If you look closely you'll see areas outside the combustion chamber that look very much like porosity ready to open up. The areas that have been subject to cylinder pressure have certainly been opened up significantly by pressure and heat, but not in a way that is definitively knock-related. There is also no marking on the piston crown that correlates with knock damage - only debris impact.

If it was knocking, it wasn't for very long and certainly not long enough to destroy a piston ring land - that failure has other causes. Porosity aside, it has left no trace on the cylinder head if it happened at all.

Hi guys. Thanks again for all the replies. Sorry for not coming back sooner Had a mental week at work.

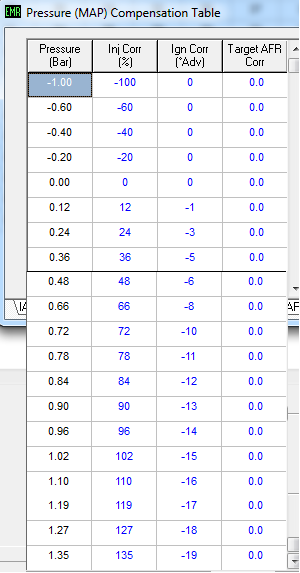

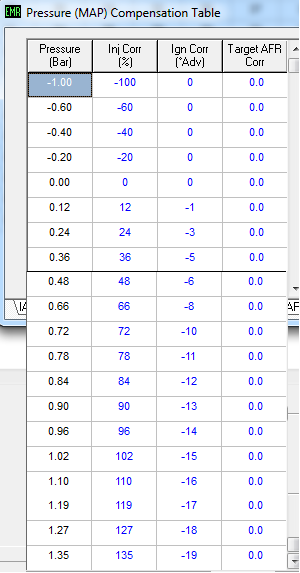

MAP compensation table:

Boosted LS1 said:

OP, plug 2 doesn't show if it was hot or not but I can't see far enough inside to check fueling. Can you get a picture that shows a fueling band/ring at the base of the insulator?

Can you show a picture side on of the earth electrode?

These are the best pics I can get:Can you show a picture side on of the earth electrode?

FordPrefect56 said:

Maybe the OP can post his ignition maps including most importantly the boost retard values.

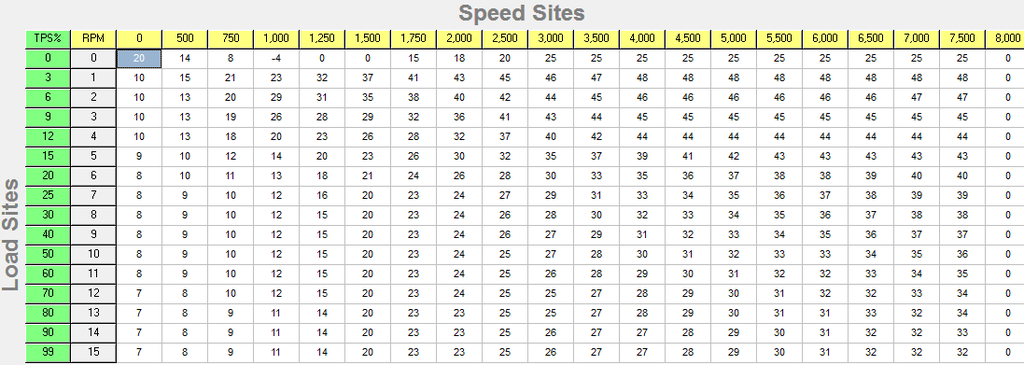

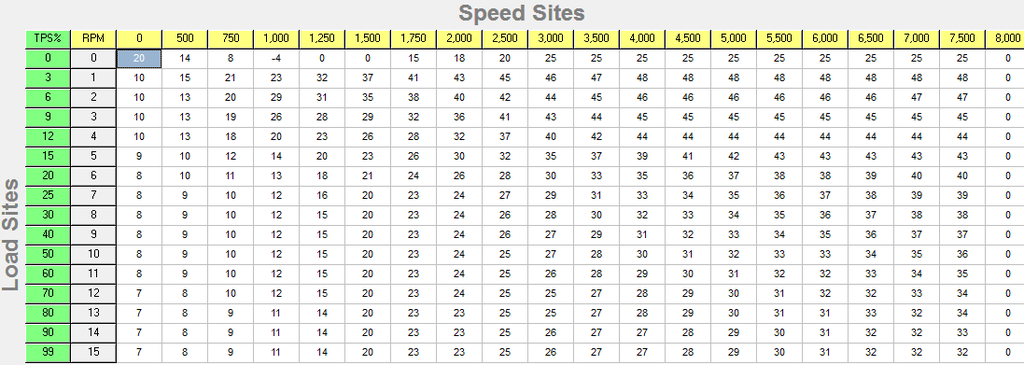

Ignition map:

MAP compensation table:

AER said:

If you look closely you'll see areas outside the combustion chamber that look very much like porosity ready to open up.

Porosity did occur to me as a possibility as k-series heads are often known to expose porosity even with a light skim.First plug picture running slightly hot on the earth electrode, could maybe try one grade cooler. Also looking inside, a fuel rings happening but as the plug looks new it hasn't had time to move towards the insulator tip yet. Colouring looks good though. Any bits of splatter could be from the damaged cylinder. The plug tip itself looks good imo.

Second plug. Good colouring of the fuel ring. The rest of the plug just says the cylinder f ked up, misfired and left me looking in a sorry state. IMO of course :-)

ked up, misfired and left me looking in a sorry state. IMO of course :-)

Second plug. Good colouring of the fuel ring. The rest of the plug just says the cylinder f

ked up, misfired and left me looking in a sorry state. IMO of course :-)

ked up, misfired and left me looking in a sorry state. IMO of course :-)Edited by Boosted LS1 on Saturday 18th June 20:35

AER said:

What's a fuel ring...?

http://www.dragstuff.com/techarticles/plug-pictures.htmlProblem with checking plugs....is unless they were almost new at the start, and the engine was shutdown exactly at the moment you want to inspect the engines running conditions...then they can be almost meaningless. And they already need to be of a correct heat range.

Well other than if they or the engine is already f

ked...in which case they're a little useless too as you already know it's f

ked...in which case they're a little useless too as you already know it's f ked.

ked.Some yanks love it, and I always ask how can the plug tell you the difference the engine wants in terms of fuel/spark at 3000, 4000, 5000, 6000, 7000, 8000 rpm etc ? Or perhaps tuning via plugs is telling them what that particular spark plug wants, rather than the engine wants ?

Amazingly there are modern technologies these days that will help with that task and you dont need to f

k about shutting hot engines down, or taking stuff apart.

k about shutting hot engines down, or taking stuff apart.I'm sure plug reading has it's place somewhere though.

You've got far too much ignition advance in the base map. That looks like 2v per cylinder numbers rather than 4v. 4v engines burn very fast and need little advance. Usually mid 20s degrees at high rpm and WOT. 2v engines with decent combustion chambers usually end up around 30 to 32 degrees. Maybe just under 30 if it's a compact chamber and a small bore engine.

You've got well over 30 degrees at high TPS openings. 33 degrees at 6500 rpm and 80% TPS. Now there's quite a lot of boost retard but that can't solve the problem of det at low or no boost. I would say your problem area like this is when you first open the throttle but before the turbo has had time to spool up. The boost retard won't kick in until it's actually showing boost but the base map timing is very likely going to give you det briefly until that happens. The part throttle advance is also pretty mental. You've also got to bear in mind that TPS% is not linear with torque demand, especially at lower rpms. 50% TPS is probably full throttle at low rpm and even at high rpm 80% TPS is more or less WOT.

We see this far too often on here. Pretty much every 4v turbo that goes pop actually. People start off with a generic ignition map, usually off a 2v engine with too much advance, the rolling road operator doesn't know enough to adjust it first and they always spend far too much time on fueling and not nearly enough on ignition anyway. By the time they've got the fueling close the engine has already blown up!

Back in the days of distributors this didn't used to happen. The RR guy would do a quick check to see what full advance was, pull that back to what he knew was normal for the type of engine and you were then stuck with the advance curve built in to the springs and bobweights and the vac advance from the can on the side. However in general clever people had got both of those pretty much right, and on the safe side back at the factory. But sadly the average mappable ecu ignition base map is far more complex than the brain of the average rolling road guy and you can stick all sorts of weird stuff in there without anyone necessarily noticing.

The entire shape of your map is also wrong. Again go back to distributors and this was all taken care of for you at the factory. Advance doesn't need to keep increasing with rpm!!!! For most engines it rises until about 3000, 3500 rpm, peaks and then stays the same. In cylinder turbulence keeps increasing and speeds up the burn in about the same proportion as rpm increases leading to advance in crank degrees wanting to stay about the same. You've actually got a decent set of advance numbers at 3000 rpm but then it keeps going up and up straight into engine pop territory.

If I had my time over again I probably wouldn't have done the flowbench development, porting and actual engine building. You earn sweet FA doing that and it's hard dirty work. But rolling roads charge a fortune per hour and most of them don't know their arse from their elbow. I could have been a rich man doing that instead properly. The engine builder agonises for hours about compression ratio, cam duration, port shapes and valve seat profiles and then some cu nt of a RR operator blows it all up in a few minutes because it dets its tits off.

You've got well over 30 degrees at high TPS openings. 33 degrees at 6500 rpm and 80% TPS. Now there's quite a lot of boost retard but that can't solve the problem of det at low or no boost. I would say your problem area like this is when you first open the throttle but before the turbo has had time to spool up. The boost retard won't kick in until it's actually showing boost but the base map timing is very likely going to give you det briefly until that happens. The part throttle advance is also pretty mental. You've also got to bear in mind that TPS% is not linear with torque demand, especially at lower rpms. 50% TPS is probably full throttle at low rpm and even at high rpm 80% TPS is more or less WOT.

We see this far too often on here. Pretty much every 4v turbo that goes pop actually. People start off with a generic ignition map, usually off a 2v engine with too much advance, the rolling road operator doesn't know enough to adjust it first and they always spend far too much time on fueling and not nearly enough on ignition anyway. By the time they've got the fueling close the engine has already blown up!

Back in the days of distributors this didn't used to happen. The RR guy would do a quick check to see what full advance was, pull that back to what he knew was normal for the type of engine and you were then stuck with the advance curve built in to the springs and bobweights and the vac advance from the can on the side. However in general clever people had got both of those pretty much right, and on the safe side back at the factory. But sadly the average mappable ecu ignition base map is far more complex than the brain of the average rolling road guy and you can stick all sorts of weird stuff in there without anyone necessarily noticing.

The entire shape of your map is also wrong. Again go back to distributors and this was all taken care of for you at the factory. Advance doesn't need to keep increasing with rpm!!!! For most engines it rises until about 3000, 3500 rpm, peaks and then stays the same. In cylinder turbulence keeps increasing and speeds up the burn in about the same proportion as rpm increases leading to advance in crank degrees wanting to stay about the same. You've actually got a decent set of advance numbers at 3000 rpm but then it keeps going up and up straight into engine pop territory.

If I had my time over again I probably wouldn't have done the flowbench development, porting and actual engine building. You earn sweet FA doing that and it's hard dirty work. But rolling roads charge a fortune per hour and most of them don't know their arse from their elbow. I could have been a rich man doing that instead properly. The engine builder agonises for hours about compression ratio, cam duration, port shapes and valve seat profiles and then some cu nt of a RR operator blows it all up in a few minutes because it dets its tits off.

Dave, he's tuned it with MAP compensation.

So at those higher numbers you need to reduce timing by around 15deg at say 1 bar.

I very much dislike that method of tuning because the numbers in the main tables you work with, may not actually relate to what is seen at the engine. It just confuses things for no benefit.

And has the CR ever been stated ?

So at those higher numbers you need to reduce timing by around 15deg at say 1 bar.

I very much dislike that method of tuning because the numbers in the main tables you work with, may not actually relate to what is seen at the engine. It just confuses things for no benefit.

And has the CR ever been stated ?

stevieturbo said:

Dave, he's tuned it with MAP compensation.

So at those higher numbers you need to reduce timing by around 15deg at say 1 bar.

I very much dislike that method of tuning because the numbers in the main tables you work with, may not actually relate to what is seen at the engine. It just confuses things for no benefit.

And has the CR ever been stated ?

Ummm, he's just posted the MAP table so yes I know! Not sure what you're trying to say. CR is 9.0.So at those higher numbers you need to reduce timing by around 15deg at say 1 bar.

I very much dislike that method of tuning because the numbers in the main tables you work with, may not actually relate to what is seen at the engine. It just confuses things for no benefit.

And has the CR ever been stated ?

And to the OP. You've spent thousands of hours on this, mainly on the shiny bits, but taken it for mapping with a totally unsuitable ignition map. I have great sympathy but a chain is only as strong as its weakest link and for the sake of that last bit of learning and research this would still be running. You wondered why it wouldn't idle in your build thread. Have you figured that out yet?? It's a bit of a no brainer.

Finally the cracked valve spring cap you had. That looks very like what happens when the collets are non std and not the same included angle as the cap.

FordPrefect56 said:

Ummm, he's just posted the MAP table so yes I know! Not sure what you're trying to say. CR is 9.0.

And to the OP. You've spent thousands of hours on this, mainly on the shiny bits, but taken it for mapping with a totally unsuitable ignition map. I have great sympathy but a chain is only as strong as its weakest link and for the sake of that last bit of learning and research this would still be running. You wondered why it wouldn't idle in your build thread. Have you figured that out yet?? It's a bit of a no brainer.

Finally the cracked valve spring cap you had. That looks very like what happens when the collets are non std and not the same included angle as the cap.

No, he posted a load table which is TPS vs RPM, where you are seeing timing figures of approx 30deg up top.And to the OP. You've spent thousands of hours on this, mainly on the shiny bits, but taken it for mapping with a totally unsuitable ignition map. I have great sympathy but a chain is only as strong as its weakest link and for the sake of that last bit of learning and research this would still be running. You wondered why it wouldn't idle in your build thread. Have you figured that out yet?? It's a bit of a no brainer.

Finally the cracked valve spring cap you had. That looks very like what happens when the collets are non std and not the same included angle as the cap.

And he also posted a table of MAP compensations, where at say 1 bar it then pulls 15deg of timing from that 30.

15deg of timing isnt huge...again depending on setup.

FordPrefect56 said:

And to the OP. You've spent thousands of hours on this, mainly on the shiny bits, but taken it for mapping with a totally unsuitable ignition map. I have great sympathy but a chain is only as strong as its weakest link and for the sake of that last bit of learning and research this would still be running. You wondered why it wouldn't idle in your build thread. Have you figured that out yet?? It's a bit of a no brainer.

Finally the cracked valve spring cap you had. That looks very like what happens when the collets are non std and not the same included angle as the cap.

Sure I built it myself because I wanted to learn how to do that. But when it came to mapping I just had to place my trust in a mapper. I couldn't have done that myself. I researched a lot and the place I used had a great reputation. I had no choice but to give them the car and trust them to do it properly. Obviously I'm gutted with the outcome but it's easy for me to say with hindsight that I should have used a different mapper. I guess my mistake there was not knowing he should have been wearing det cans.Finally the cracked valve spring cap you had. That looks very like what happens when the collets are non std and not the same included angle as the cap.

Cracked valve spring cap was on completely stock standard VVC valve train.

So do people generally prefer MAP/RPM mapping? The first mapper did it that way and that was when i had the trouble with it idling.

Stuballs said:

Sure I built it myself because I wanted to learn how to do that. But when it came to mapping I just had to place my trust in a mapper. I couldn't have done that myself. I researched a lot and the place I used had a great reputation. I had no choice but to give them the car and trust them to do it properly. Obviously I'm gutted with the outcome but it's easy for me to say with hindsight that I should have used a different mapper. I guess my mistake there was not knowing he should have been wearing det cans.

Cracked valve spring cap was on completely stock standard VVC valve train.

So do people generally prefer MAP/RPM mapping? The first mapper did it that way and that was when i had the trouble with it idling.

He doesnt need to be wearing det cans....but obviously he needs some reliable means of detecting detonation whilst tuning.Cracked valve spring cap was on completely stock standard VVC valve train.

So do people generally prefer MAP/RPM mapping? The first mapper did it that way and that was when i had the trouble with it idling.

Whether it's MAP based or TPS based will make no difference to how it idles, unless you've big cams, throttle bodies etc

How it idles will just depend on tuning...and also how good the ecu's idle control actually is ( and the hardware it is working with )

Stuballs said:

Sure I built it myself because I wanted to learn how to do that. But when it came to mapping I just had to place my trust in a mapper. I couldn't have done that myself. I researched a lot and the place I used had a great reputation. I had no choice but to give them the car and trust them to do it properly. Obviously I'm gutted with the outcome but it's easy for me to say with hindsight that I should have used a different mapper. I guess my mistake there was not knowing he should have been wearing det cans.

It's nothing really to do with det cans and no you didn't have to "entirely" rely on a mapper. What you don't, or didn't, realise is that most of these people started off just as general car mechanics and then realised there's a lot more money in RR work. Some of them are good but a lot are really not very bright, most of them don't really understand how engines work and one in a thousand has even a clue about ignition maps. What you needed to do before even starting the car up or taking it anywhere near one of these people was get a nice SAFE ignition base map in there that was suitable for your type of engine. Even if that means just putting 20 degrees everywhere and letting the mapper increase it where necessary. But of course you can do much better than that. You haven't been around very long and haven't seen the carnage I've watched these people wreak over 40 years. More threads in here than I care to mention where a months long build thread turns into a trip back home on the back of an RAC van the first time the mapper gets his hands on it.If you start off with too much advance in the base map these people will blow your engine up pretty much as a certainty before they ever realise there's a problem. Anyway, now you are a little older and a little wiser you can do your due diligence on ignition advance parameters for various types of engine and see what you come up with. I've already given you the basics.

Stuballs said:

Sure I built it myself because I wanted to learn how to do that. But when it came to mapping I just had to place my trust in a mapper. I couldn't have done that myself. I researched a lot and the place I used had a great reputation. I had no choice but to give them the car and trust them to do it properly. Obviously I'm gutted with the outcome but it's easy for me to say with hindsight that I should have used a different mapper. I guess my mistake there was not knowing he should have been wearing det cans.

Cracked valve spring cap was on completely stock standard VVC valve train.

So do people generally prefer MAP/RPM mapping? The first mapper did it that way and that was when i had the trouble with it idling.

Stu,Cracked valve spring cap was on completely stock standard VVC valve train.

So do people generally prefer MAP/RPM mapping? The first mapper did it that way and that was when i had the trouble with it idling.

i have mapped my car both with MAP and with TPS based load detection schemes.

I went back to TPS. Why?

My engine runs similar duration cams to yours, Newman ph2. My idea vacuum is only -300mbar. This is rather low.

The car was actually very nice to drive with MAP based load detection, nicer than with TPS. Very smooth. It was feeling very OEM like to drive. TPS is also good, but as good as MAP. And I have spend a fair amount of hours on the TPS mapping vs. the MAP mapping.

Just getting it to idle well was rather hard. The revs would tend to oscillate. I had to retard some map spots to stop this, but then would you hit the retarded spots while driving off.

On a engine with shorter duration cams and a good vacuum, I'd go MAP again.

But with the cams as they are and the Emerald not being able to apply dynamic changes to the IACV as well as ignition to regulate idle like MEMS1.9, but just ignition, it fails to maintain idle at all times.

Edited by Ive on Sunday 19th June 19:53

stevieturbo said:

He doesn't need to be wearing det cans....but obviously he needs some reliable means of detecting detonation whilst tuning.

What would that be out of interest? I'm thinking you've only got 5 senses, your sight and touch is already taken with the laptop in front of you, you can't taste or smell det, so that only leaves sound....227bhp said:

What would that be out of interest? I'm thinking you've only got 5 senses, your sight and touch is already taken with the laptop in front of you, you can't taste or smell det, so that only leaves sound....

There are actually electronic methods too you know

And just because someone is wearing det cans....doesnt mean they've the first clue what they're listening for. Same with any knock detection, it needs to be calibrated and functioning correctly.

stevieturbo said:

There are actually electronic methods too you know

And just because someone is wearing det cans....doesn't mean they've the first clue what they're listening for. Same with any knock detection, it needs to be calibrated and functioning correctly.

Yeah, but seriously, what are they? Visual? It's like spinning plates as it is....

And just because someone is wearing det cans....doesn't mean they've the first clue what they're listening for. Same with any knock detection, it needs to be calibrated and functioning correctly.

Agreeably, some mappers may aswell be receiving local radio or a self help CD on 'How to map cars' through their earphones.

stevieturbo said:

FordPrefect56 said:

Ummm, he's just posted the MAP table so yes I know! Not sure what you're trying to say. CR is 9.0.

And to the OP. You've spent thousands of hours on this, mainly on the shiny bits, but taken it for mapping with a totally unsuitable ignition map. I have great sympathy but a chain is only as strong as its weakest link and for the sake of that last bit of learning and research this would still be running. You wondered why it wouldn't idle in your build thread. Have you figured that out yet?? It's a bit of a no brainer.

Finally the cracked valve spring cap you had. That looks very like what happens when the collets are non std and not the same included angle as the cap.

No, he posted a load table which is TPS vs RPM, where you are seeing timing figures of approx 30deg up top.And to the OP. You've spent thousands of hours on this, mainly on the shiny bits, but taken it for mapping with a totally unsuitable ignition map. I have great sympathy but a chain is only as strong as its weakest link and for the sake of that last bit of learning and research this would still be running. You wondered why it wouldn't idle in your build thread. Have you figured that out yet?? It's a bit of a no brainer.

Finally the cracked valve spring cap you had. That looks very like what happens when the collets are non std and not the same included angle as the cap.

And he also posted a table of MAP compensations, where at say 1 bar it then pulls 15deg of timing from that 30.

15deg of timing isnt huge...again depending on setup.

Gassing Station | Engines & Drivetrain | Top of Page | What's New | My Stuff