K-Series headgasket questions (it went pop)...

Discussion

The head gasket on my trusty little Rover 214i went pop over the weekend and I need to get all the bits together to sort it out.

I was wondering if anybody has any advice or any tips to make it easier to do the job?

It's only the 80bhp 1.4 8 valve model so not too complex, I do plan to check the head and get it skimmed if there is any warpage and I want to fit the uprated head gasket kit (if it is available for the 1.4).

Where is the best place to get the head gasket and manifold kit, cam belt, drive belts and new cylinder head bolts from? Is there a complete kit available with everything in it?

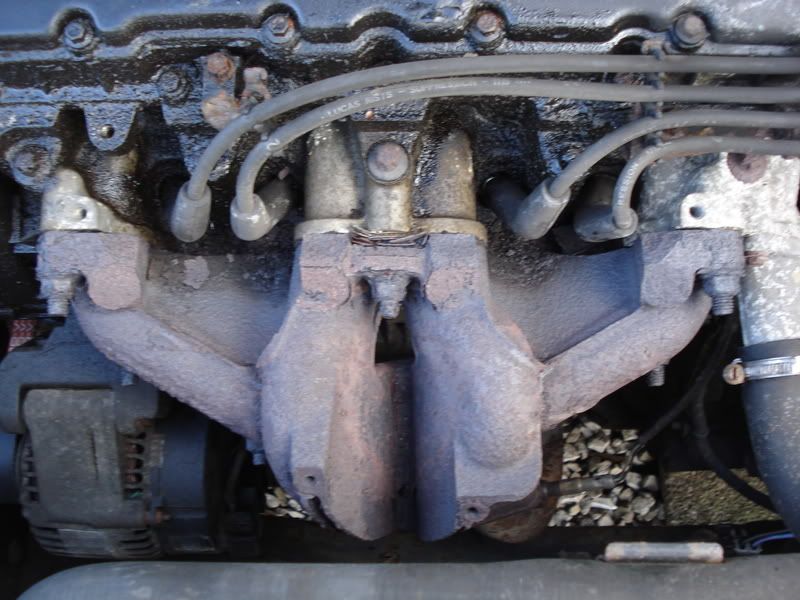

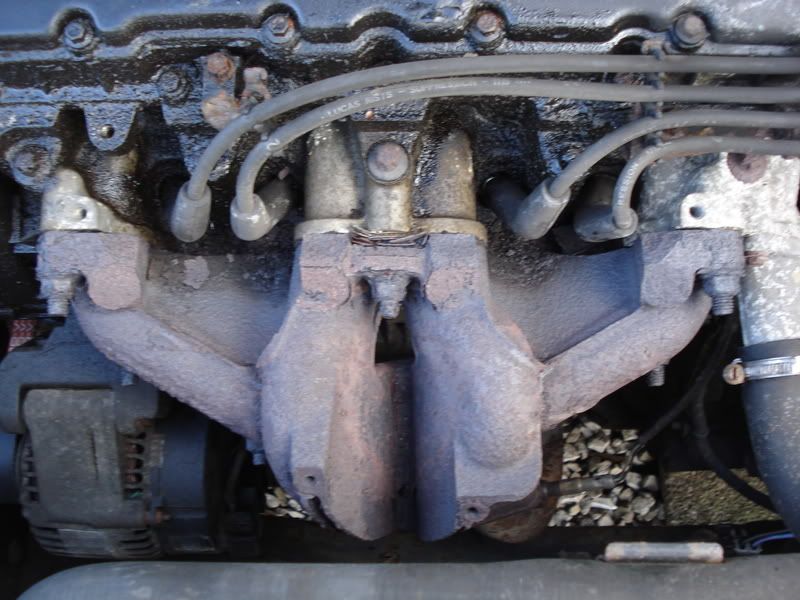

I do have one problem and that is all my exhaust manifold nuts look like this:

The best way I can think of getting the manifold off is to cut off the nuts, take off the manifold and then screw two nuts on what is left of the stud and unbolt the stud from the head, if that makes sense. Would this be the best way or would a 'nut cracker' be the better option?

It's been a cracking little car and the only reason this has happened is because I didn't keep a close enough eye on the coolant level. There is no rush on to get it sorted as I am back at work, I just want to get all the right bits together now so I can do it when I'm back home for a weekend.

Cheers for any advice in advance.

I was wondering if anybody has any advice or any tips to make it easier to do the job?

It's only the 80bhp 1.4 8 valve model so not too complex, I do plan to check the head and get it skimmed if there is any warpage and I want to fit the uprated head gasket kit (if it is available for the 1.4).

Where is the best place to get the head gasket and manifold kit, cam belt, drive belts and new cylinder head bolts from? Is there a complete kit available with everything in it?

I do have one problem and that is all my exhaust manifold nuts look like this:

The best way I can think of getting the manifold off is to cut off the nuts, take off the manifold and then screw two nuts on what is left of the stud and unbolt the stud from the head, if that makes sense. Would this be the best way or would a 'nut cracker' be the better option?

It's been a cracking little car and the only reason this has happened is because I didn't keep a close enough eye on the coolant level. There is no rush on to get it sorted as I am back at work, I just want to get all the right bits together now so I can do it when I'm back home for a weekend.

Cheers for any advice in advance.

I suggest you first read the tool use and dismantling techniques article on my website.

http://www.pumaracing.co.uk/ToolUse.htm

Lots of hammer first and the tightest fitting socket you can find, preferably a 6 pointed one. Do that and most of the studs will probably come out with the nuts still attached and then you can replace them. Just twist away at them like the average amateur and most of them will snap like carrots.

Dave Baker

http://www.pumaracing.co.uk/ToolUse.htm

Lots of hammer first and the tightest fitting socket you can find, preferably a 6 pointed one. Do that and most of the studs will probably come out with the nuts still attached and then you can replace them. Just twist away at them like the average amateur and most of them will snap like carrots.

Dave Baker

Cheers for the link Dave, I've got a few old 6 point sockets lying around which I can use to remove the bolts, they are just so badly corroded that I can see somthing breaking when I attempt to remove them.

Everything else on the engine looks pretty straight forward, I've never worked on a K series before (apart from servicing and changing a rocker cover gasket) so any advice is most welcome!

Everything else on the engine looks pretty straight forward, I've never worked on a K series before (apart from servicing and changing a rocker cover gasket) so any advice is most welcome!

Pumaracing said:

I suggest you first read the tool use and dismantling techniques article on my website.

http://www.pumaracing.co.uk/ToolUse.htm

Lots of hammer first and the tightest fitting socket you can find, preferably a 6 pointed one. Do that and most of the studs will probably come out with the nuts still attached and then you can replace them. Just twist away at them like the average amateur and most of them will snap like carrots.

Dave Baker

Interesting reading, i'd replace hammer with rubber mallet though far more effective at cracking sealed rusty things a metal hammer tends to "bounce" the rubber mallet will provide more of the force going to the target.http://www.pumaracing.co.uk/ToolUse.htm

Lots of hammer first and the tightest fitting socket you can find, preferably a 6 pointed one. Do that and most of the studs will probably come out with the nuts still attached and then you can replace them. Just twist away at them like the average amateur and most of them will snap like carrots.

Dave Baker

Also don't fall into the trap of removing completely any that do come undone leaving the tricky ones until last. They were the tightest to start with and are now even tighter as they're taking the entire gasket load. Each time you get a stud loose do it back up again hard to take the load off the others and mark it with tippex. When you've got the final one loose they can all come out.

Thanks Herman, I don't think I have a rubber mallet, I'll have to go out and buy one, in the past I've always just given a gentle 'tap' with a hammer to break the seal.

Dave - Sound advice again, thanks, I have indeed fallen into that trap in the past...

The car will be laid up for a few weeks until I can get back home. I want to get everything together now so I can dive right in when I get back.

Dave - Sound advice again, thanks, I have indeed fallen into that trap in the past...

The car will be laid up for a few weeks until I can get back home. I want to get everything together now so I can dive right in when I get back.

Not impossible I'll have to do this in a few weeks on my girlfriends car too, exactly the same engine as yours, exactly the same leaking rocker box gasket, exactly the same rotten exhaust nuts!!!

At least they were consistent with the faults!

The only hint this one has an issue is the coolant is dropping slightly (no rad leak or header tank leaks) and one spark plug (did a service today) looks suspiciously clean! There isn't any white smoke so guessing a tiny bit of coolant is making it's way in to cylinder one very slowly while driving (it loses more when I drive it).

Trouble is the car isn't worth much (early bubble shape 96 on an N in gay purple) and I'm really not that sure it's worth doing unless it gets worse as she's getting rid in 6 months. Sods law says do the job and it would have been fine, don't do it and it will get drastically worse and damage the head/liner.

To make the choice harder frankly I can't see it going through MOT next time and can see it being a break for bits and weigh in the rest job, shame as it's a nice car in many ways.

At least they were consistent with the faults!

The only hint this one has an issue is the coolant is dropping slightly (no rad leak or header tank leaks) and one spark plug (did a service today) looks suspiciously clean! There isn't any white smoke so guessing a tiny bit of coolant is making it's way in to cylinder one very slowly while driving (it loses more when I drive it).

Trouble is the car isn't worth much (early bubble shape 96 on an N in gay purple) and I'm really not that sure it's worth doing unless it gets worse as she's getting rid in 6 months. Sods law says do the job and it would have been fine, don't do it and it will get drastically worse and damage the head/liner.

To make the choice harder frankly I can't see it going through MOT next time and can see it being a break for bits and weigh in the rest job, shame as it's a nice car in many ways.

Herman Toothrot said:

Interesting reading, i'd replace hammer with rubber mallet though far more effective at cracking sealed rusty things a metal hammer tends to "bounce" the rubber mallet will provide more of the force going to the target.

No it won't. It will be about as much use a chocolate teapot. If you don't know anything about removing stuck fixings at least be good enough to give no advice rather than incorrect advice.Edited by Pumaracing on Monday 13th October 23:44

wildoliver said:

Not impossible I'll have to do this in a few weeks on my girlfriends car too, exactly the same engine as yours, exactly the same leaking rocker box gasket, exactly the same rotten exhaust nuts!!!

At least they were consistent with the faults!

The only hint this one has an issue is the coolant is dropping slightly (no rad leak or header tank leaks) and one spark plug (did a service today) looks suspiciously clean! There isn't any white smoke so guessing a tiny bit of coolant is making it's way in to cylinder one very slowly while driving (it loses more when I drive it).

Trouble is the car isn't worth much (early bubble shape 96 on an N in gay purple) and I'm really not that sure it's worth doing unless it gets worse as she's getting rid in 6 months. Sods law says do the job and it would have been fine, don't do it and it will get drastically worse and damage the head/liner.

To make the choice harder frankly I can't see it going through MOT next time and can see it being a break for bits and weigh in the rest job, shame as it's a nice car in many ways.

My mates car looked exactly the same too...At least they were consistent with the faults!

The only hint this one has an issue is the coolant is dropping slightly (no rad leak or header tank leaks) and one spark plug (did a service today) looks suspiciously clean! There isn't any white smoke so guessing a tiny bit of coolant is making it's way in to cylinder one very slowly while driving (it loses more when I drive it).

Trouble is the car isn't worth much (early bubble shape 96 on an N in gay purple) and I'm really not that sure it's worth doing unless it gets worse as she's getting rid in 6 months. Sods law says do the job and it would have been fine, don't do it and it will get drastically worse and damage the head/liner.

To make the choice harder frankly I can't see it going through MOT next time and can see it being a break for bits and weigh in the rest job, shame as it's a nice car in many ways.

I'll keep posting on how the job goes when I get round to doing doing it, at least then it will give you an idea of what it will be like to do and then you can decide whether you should do it or not.

My car is a '99 V and I've had it for years, it's not really worth much but it seems to be part of the family now so I want to get it sorted out and back on the road.

bob1179 said:

wildoliver said:

Not impossible I'll have to do this in a few weeks on my girlfriends car too, exactly the same engine as yours, exactly the same leaking rocker box gasket, exactly the same rotten exhaust nuts!!!

At least they were consistent with the faults!

The only hint this one has an issue is the coolant is dropping slightly (no rad leak or header tank leaks) and one spark plug (did a service today) looks suspiciously clean! There isn't any white smoke so guessing a tiny bit of coolant is making it's way in to cylinder one very slowly while driving (it loses more when I drive it).

Trouble is the car isn't worth much (early bubble shape 96 on an N in gay purple) and I'm really not that sure it's worth doing unless it gets worse as she's getting rid in 6 months. Sods law says do the job and it would have been fine, don't do it and it will get drastically worse and damage the head/liner.

To make the choice harder frankly I can't see it going through MOT next time and can see it being a break for bits and weigh in the rest job, shame as it's a nice car in many ways.

My mates car looked exactly the same too...At least they were consistent with the faults!

The only hint this one has an issue is the coolant is dropping slightly (no rad leak or header tank leaks) and one spark plug (did a service today) looks suspiciously clean! There isn't any white smoke so guessing a tiny bit of coolant is making it's way in to cylinder one very slowly while driving (it loses more when I drive it).

Trouble is the car isn't worth much (early bubble shape 96 on an N in gay purple) and I'm really not that sure it's worth doing unless it gets worse as she's getting rid in 6 months. Sods law says do the job and it would have been fine, don't do it and it will get drastically worse and damage the head/liner.

To make the choice harder frankly I can't see it going through MOT next time and can see it being a break for bits and weigh in the rest job, shame as it's a nice car in many ways.

I'll keep posting on how the job goes when I get round to doing doing it, at least then it will give you an idea of what it will be like to do and then you can decide whether you should do it or not.

My car is a '99 V and I've had it for years, it's not really worth much but it seems to be part of the family now so I want to get it sorted out and back on the road.

Go I hate changing OHC headgaskets.

wildoliver said:

To be honest it sounds like I may have no choice, in 20 miles it used it's entire header tank last night apparently.

Go I hate changing OHC headgaskets.

Bugger.Go I hate changing OHC headgaskets.

Mine blew lots of steam and nastiness and went out in big style! I don't mind doing OHC engines, I've done a few BMW engines and a Peugeot TU engine. I do cheat and lock both the crank and camshaft to make sure they don't move, then you can just skip the belt back on and do up the tensioner.

Of course this won't work if you're taking the head to bits to get it skimmed...

Let me know how it goes!

Well I've just done a bit of research and found in a lot of cases apparently it isn't the gasket that goes at all, while yours obviously is the head gasket apparently often it is the inlet manifold gasket (must be a heated inlet manifold) that breaks down allowing the engine to suck water in, or there is a pipe on the thermostat housing that leaks apparently. Certainly these sound promising as the car isn't chucking steam out (well it wasn't yesterday) so for the sake of doing the job I may as well try.

Pumaracing said:

Herman Toothrot said:

Interesting reading, i'd replace hammer with rubber mallet though far more effective at cracking sealed rusty things a metal hammer tends to "bounce" the rubber mallet will provide more of the force going to the target.

No it won't. It will be about as much use a chocolate teapot. If you don't know anything about removing stuck fixings at least be good enough to give no advice rather than incorrect advice.Edited by Pumaracing on Monday 13th October 23:44

Hammer on a ring spanner and hit it with a rubber dead weight mallet will work far better with far less chance of snapping a stud than just trying to do it with brute force.

I was advised to try that method after trying tapping with metal hammer, heating with blow torch, hammering on a socket, bigger and bigger extension bars all failed miserably. Since then if I ever need to remove anything that looks problematic a squirt of anti-seize, leave for 20 mins, spanner and rubber dead weight mallet has never failed, never snapped anything.

Suggest you try it before you rubbish it.

Quick update on our engine.

Read around and discovered the water leak was more likely to be either manifold gasket or water pump outlet O ring.

Changed inlet gasket (easy about an hours work but fiddly) no change still losing water.

So next job I need to get underneath and see if I can find where it is dripping from, I hope it doesn't need a waterpump as that is cambelt change as well, hopefully it is just the outlet dripping, it is a stupid design the plastic outlet pushes in to a metal tube and I understand all that seals it is this o ring.

Oh and I broke the dipstick (£3 for a landrover metal one) and now have the rocker box gasket (fiver).

Read around and discovered the water leak was more likely to be either manifold gasket or water pump outlet O ring.

Changed inlet gasket (easy about an hours work but fiddly) no change still losing water.

So next job I need to get underneath and see if I can find where it is dripping from, I hope it doesn't need a waterpump as that is cambelt change as well, hopefully it is just the outlet dripping, it is a stupid design the plastic outlet pushes in to a metal tube and I understand all that seals it is this o ring.

Oh and I broke the dipstick (£3 for a landrover metal one) and now have the rocker box gasket (fiver).

Herman Toothrot said:

Hammer on a ring spanner and hit it with a rubber dead weight mallet will work far better with far less chance of snapping a stud than just trying to do it with brute force.

I was advised to try that method after trying tapping with metal hammer, heating with blow torch, hammering on a socket, bigger and bigger extension bars all failed miserably. Since then if I ever need to remove anything that looks problematic a squirt of anti-seize, leave for 20 mins, spanner and rubber dead weight mallet has never failed, never snapped anything.

Suggest you try it before you rubbish it.

If you'd read my article properly I'm not talking about hitting the spanner with a hammer. I'm talking about hitting the stud or bolt vertically to shock the threads loose first and as I said a rubber hammer is about as much use at doing that as a chocolate teapot.I was advised to try that method after trying tapping with metal hammer, heating with blow torch, hammering on a socket, bigger and bigger extension bars all failed miserably. Since then if I ever need to remove anything that looks problematic a squirt of anti-seize, leave for 20 mins, spanner and rubber dead weight mallet has never failed, never snapped anything.

Suggest you try it before you rubbish it.

Gassing Station | Engines & Drivetrain | Top of Page | What's New | My Stuff