Ducati 996 engine custom build

Discussion

Made a stand today to keep it upright and safe in the garage… The wheels are idler bearing i changed on a car recently when I did a can belt... makes it roll nicely. Also fitted the seat badge and tank protector.... with all the Corvid 19 issues its looking like I won’t be riding it for a while…

As an aside from working on the Ducati.... I have been busy doing a job on my Harley V-Rod today...I changed the oil and filter and in doing that took the opportunity to check on the timing bolt in the engine that can come loose on some bikes, which wrecks the engine! nice and easy job, just drain the oil and remove the alternator cover which comes off easily. I checked the torque of the bolt before I removed it and it was tight... However to be on the safe side I removed it and cleaned both the internal thread and the bolt, and used some high strength thread lock on there as advised by the factory...

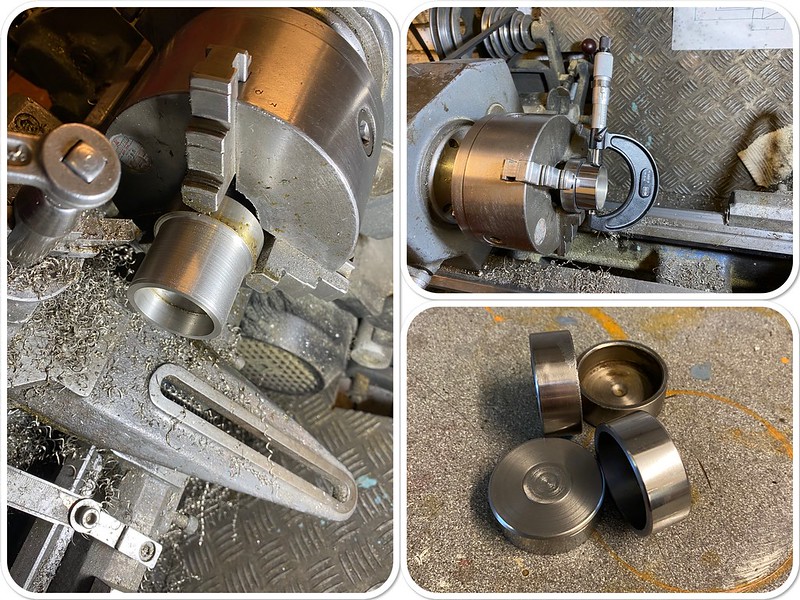

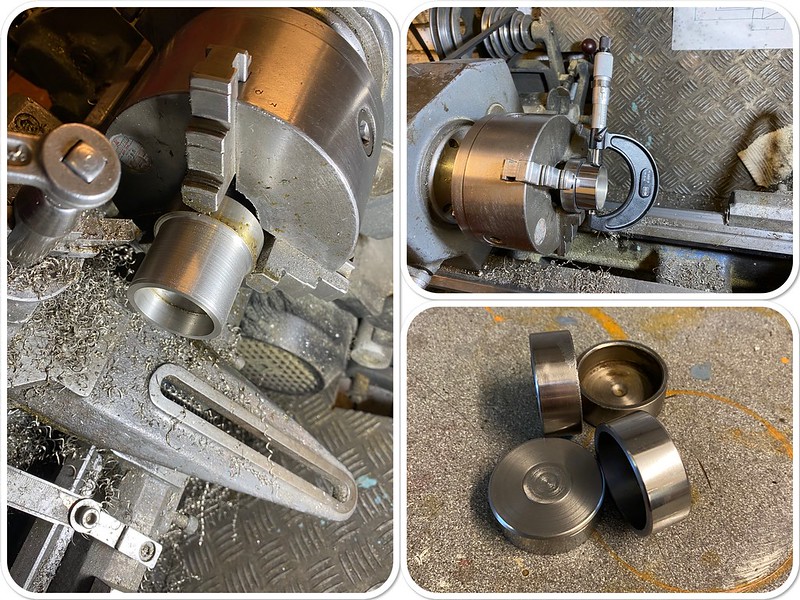

None Ducati this time, but with lockdown still in place I helped a mate out who needed some brake calliper pistons for a Norton Commando he is rebuilding...

I made two out of stainless steel for him as the originals were pitted quite badly... took a while to grind a tool to the correct angles and get the speed of the lathe right to get a nice finish, but I got there in the end...

I made two out of stainless steel for him as the originals were pitted quite badly... took a while to grind a tool to the correct angles and get the speed of the lathe right to get a nice finish, but I got there in the end...

Nice work Buzzer! You're really not helping me want a lathe, I used to have access to one and the amount of times I'd jump on it to just do a 5 minute job...

Now to get the same deal it's hours on end or asking for favours!

I presume if I buy a lathe I inherit all the abilities you show off too?

Now to get the same deal it's hours on end or asking for favours!

I presume if I buy a lathe I inherit all the abilities you show off too?

Been a while since I updated....early May, lockdown continues, still can’t ride, it’s very frustrating to have bikes on the drive and not ride them!!

done a few more jobs like programme the ignition advance to get a steady tick over, and importantly retard the ignition at cranking speed to give the starter motor an easier time.

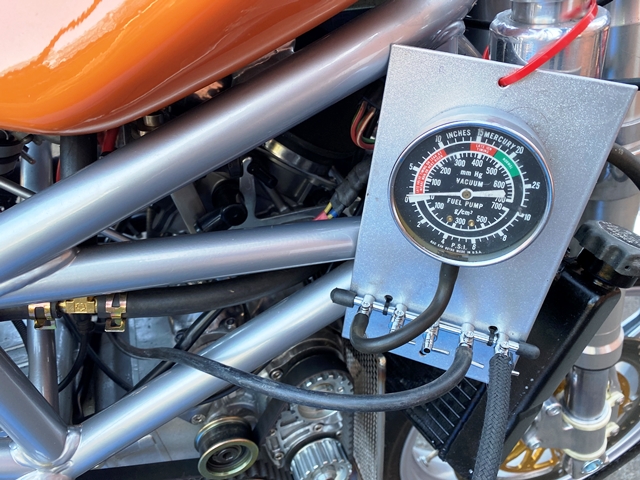

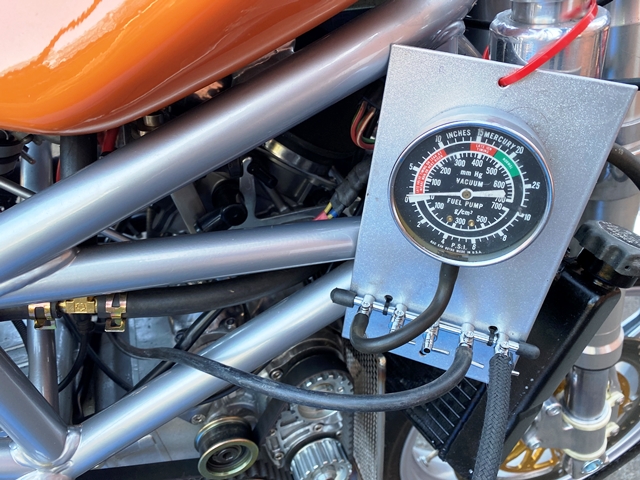

Also balanced the carbs. for years I used a mercury gauge for this but a mate borrowed them and broke it! so I bought a set of gauges, but noticed I could get it closer by ear! so I checked the gauges by connecting them to a single vacuum source and found they were all reading differently! hence the single gauge with 5 valves. the 5th valve provides damping to the gauge. I have found you can get a perfect tick over with this method.

lets hope we can ride soon!

done a few more jobs like programme the ignition advance to get a steady tick over, and importantly retard the ignition at cranking speed to give the starter motor an easier time.

Also balanced the carbs. for years I used a mercury gauge for this but a mate borrowed them and broke it! so I bought a set of gauges, but noticed I could get it closer by ear! so I checked the gauges by connecting them to a single vacuum source and found they were all reading differently! hence the single gauge with 5 valves. the 5th valve provides damping to the gauge. I have found you can get a perfect tick over with this method.

lets hope we can ride soon!

Middle of may and lockdown has eased a little and I have been out doing a few miles... It runs REALLY well on the carbs! the throttle response is amazing and it feels very crisp and lively! made a few adjustments to the timing at low RPM, but the jetting feels OK, and a plug chop confirmed its not far out... just need to put a few miles on it now... its VERY loud though!

will post a video soon as I can get someone to take it!

will post a video soon as I can get someone to take it!

Been out and about the last few days bedding things in after the rebuild... one thing I noticed was its slow to turn over when you start it. I had upgraded the cables, and the starter itself was good, so I had another look at the timing. When I did the map, I had the first RPM point at 400 with 10 degrees BTDC and the second at 1000 again with 10 degrees... so i changed this to 5 degrees from 400 to 1000, so there is not so much advance at cranking speed.

I also configured the software so it did two full dead revolutions before it sparks... this means the engine is properly spinning before it fires... It really spins over now and starts MUCH better

I also configured the software so it did two full dead revolutions before it sparks... this means the engine is properly spinning before it fires... It really spins over now and starts MUCH better

The earth connection for these engines ( behind the clutch casing ) is notoriously poor - each of mine I've added a supplementary earth lead from the battery to the engine mounts which makes a big difference as well as giving the sprag clutch an easier life as they don't like trying to turn the motor over slowly.

thought I would update this... been using the bike all summer and have done quite a few miles... here is a short video with sound :-)

https://youtu.be/rfqe5zYf5Kw

https://youtu.be/rfqe5zYf5Kw

Gassing Station | Biker Banter | Top of Page | What's New | My Stuff