Converting to Fuel Injection

Discussion

My car has seemed to generate some interest in this topic. Rather than clogging the picture thread we can discuss the relative merits of converting a "classic" mini to fuel injection and mapped ignition on the A series engine.

You might ask why bother, a lot of people are/were convinced that this will never work, but I know of 3 or 4 people using a similar setup and one is running it in a turbo configuration. It's not cheap and similar power outputs are readily available using carbs and distributors. I did this for a few reasons:

1.Fuel injection and mapped ignition is ultimately flexible. You can use your PC to configure fuelling and spark timing throughout the rev and load range. More importantly it is consistent and you will get the same result every time. Unlike carbs and distributors which can wander and wear over time.

2.The maps can be created to provide the type of engine response you are looking for. I have 3 active maps that can be switched in real time. One is designed to be a clean running and fuel efficient specification, one is a full advance full fuel “track” map and one is somewhere in between the two.

3.The upgrade path is simpler and I have enough capacity (with an injector change) to fuel up to 200hp. My engine is less than half that but I know the turbo guys are easily getting 150 and 200 is not far away.

4.Using a wideband lambda the system is almost self tuning. You still need a rolling road setup.

5.Everyone said I couldn't make it work, being in a non engineering role I wanted to prove them wrong. I have read about FI since the days of cars and car conversions and always wanted to give it a try.

So all that said my car is currently the following specification:

1275cc

MG Metro Cam + 1.5 Rockers

Calver Sports Spec head

10.75 Compression ratio

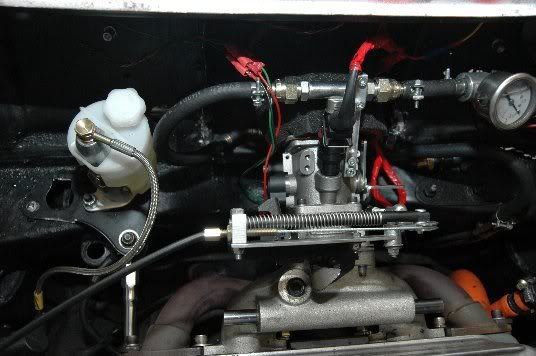

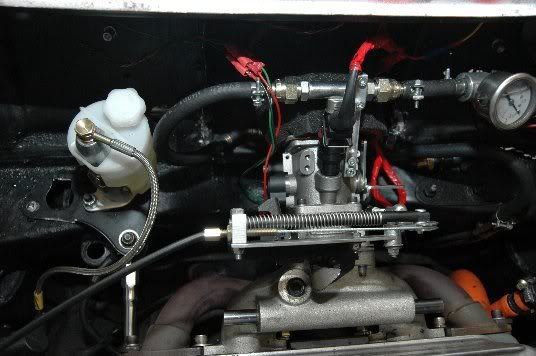

Emerald K3 ECU using TPS & MAP (Alpha-N+MAP). 3 Switchable igntion and fuel maps.

Specialist Components trigger wheel and Ford SEN8D pickup

Ford Dual coil pack (Focus not EDIS)with custom leads

Jenvey SF45 Dual Injector Throttle Body with 2 x 310cc Bosch injectors. Custom Tank and Swirl pot. Dual fuel pumps (high and low pressure)

Innovate LC-1 wideband lambda

Suppliers

http://www.emeraldm3d.com/

http://www.calverst.com/

http://www.specialist-components.co.uk/

http://www.alloyracingfabrications.com/

http://www.kad-uk.com/

All the ford bits were from Ebay or a local motor factors.

The car is not finished yet but the engine is up and running nicely. I am happy with it and confident that this intial build will get me to my 85hp target. I can then build on it and get more power later, when I am happy with the suspension and brake set-up, but that's a whole other story

You might ask why bother, a lot of people are/were convinced that this will never work, but I know of 3 or 4 people using a similar setup and one is running it in a turbo configuration. It's not cheap and similar power outputs are readily available using carbs and distributors. I did this for a few reasons:

1.Fuel injection and mapped ignition is ultimately flexible. You can use your PC to configure fuelling and spark timing throughout the rev and load range. More importantly it is consistent and you will get the same result every time. Unlike carbs and distributors which can wander and wear over time.

2.The maps can be created to provide the type of engine response you are looking for. I have 3 active maps that can be switched in real time. One is designed to be a clean running and fuel efficient specification, one is a full advance full fuel “track” map and one is somewhere in between the two.

3.The upgrade path is simpler and I have enough capacity (with an injector change) to fuel up to 200hp. My engine is less than half that but I know the turbo guys are easily getting 150 and 200 is not far away.

4.Using a wideband lambda the system is almost self tuning. You still need a rolling road setup.

5.Everyone said I couldn't make it work, being in a non engineering role I wanted to prove them wrong. I have read about FI since the days of cars and car conversions and always wanted to give it a try.

So all that said my car is currently the following specification:

1275cc

MG Metro Cam + 1.5 Rockers

Calver Sports Spec head

10.75 Compression ratio

Emerald K3 ECU using TPS & MAP (Alpha-N+MAP). 3 Switchable igntion and fuel maps.

Specialist Components trigger wheel and Ford SEN8D pickup

Ford Dual coil pack (Focus not EDIS)with custom leads

Jenvey SF45 Dual Injector Throttle Body with 2 x 310cc Bosch injectors. Custom Tank and Swirl pot. Dual fuel pumps (high and low pressure)

Innovate LC-1 wideband lambda

Suppliers

http://www.emeraldm3d.com/

http://www.calverst.com/

http://www.specialist-components.co.uk/

http://www.alloyracingfabrications.com/

http://www.kad-uk.com/

All the ford bits were from Ebay or a local motor factors.

The car is not finished yet but the engine is up and running nicely. I am happy with it and confident that this intial build will get me to my 85hp target. I can then build on it and get more power later, when I am happy with the suspension and brake set-up, but that's a whole other story

Most people want to go from injection to twin 1.5" SU's to get up to about 115 bhp+ from 1275cc.

Unless it's for racing, any small increase over what twin carbs and a decent manifold will give could be lost in the poor traction of the front wheel drive. I'm not trying to be dismissive (as if!), but it does seem a lot of work for no real gain in overall road performance. Carbs are just so easy and reliable to work with too. A fairly standard 1275 'A-Plus' engine will give 85 bhp with just a minor cam change (say a Kent 266 or Swiftune SW5), ncrease in comp. ratio to about 10.4:1 and a bit of cleaning up in the head, still retaining a single 1.5 SU

Unless it's for racing, any small increase over what twin carbs and a decent manifold will give could be lost in the poor traction of the front wheel drive. I'm not trying to be dismissive (as if!), but it does seem a lot of work for no real gain in overall road performance. Carbs are just so easy and reliable to work with too. A fairly standard 1275 'A-Plus' engine will give 85 bhp with just a minor cam change (say a Kent 266 or Swiftune SW5), ncrease in comp. ratio to about 10.4:1 and a bit of cleaning up in the head, still retaining a single 1.5 SU

Cooperman - That output/spec on a single 1.5 inch SU? I'd need to see a dynoplot to be convinced that is acheviable. I simply have never seen those sort of figures, no matter how well set-up. On an HIF44 No problem.

The custom fuel injection route is a real innovation and continues to bring the Mini on in terms of development. DH is to be applauded for his efforts. To be honest, understanding the system parameters on something fairly stock (and inexpensive if it anything goes awry) is a sight more intelliugent than screwing together an all singing-dancing bottom end/head and then buggering it up because of inexperience. I think DH explained it was stepping stone to greater things... Good on him for doing something different. The other benefits that mapped ignition will bring is fantastic drivability and even if the car is running a radical cam, better fuel economy and emissions over a carb set-up. As things get tighter on Emission regs... we all might have to re-consider this in the near future. As with many things...If you've not tried it, don't knock it.

Good on him for doing something different. The other benefits that mapped ignition will bring is fantastic drivability and even if the car is running a radical cam, better fuel economy and emissions over a carb set-up. As things get tighter on Emission regs... we all might have to re-consider this in the near future. As with many things...If you've not tried it, don't knock it.

I'll be interested to see how this thread develops. There is a guy sprinting in the West Mids area (applejack green Mini - V.Cool colour!) that is running a 998 unit, Turboed with Custom SPi and mapped using Emerald Software. The thing is ballistic.

The custom fuel injection route is a real innovation and continues to bring the Mini on in terms of development. DH is to be applauded for his efforts. To be honest, understanding the system parameters on something fairly stock (and inexpensive if it anything goes awry) is a sight more intelliugent than screwing together an all singing-dancing bottom end/head and then buggering it up because of inexperience. I think DH explained it was stepping stone to greater things...

Good on him for doing something different. The other benefits that mapped ignition will bring is fantastic drivability and even if the car is running a radical cam, better fuel economy and emissions over a carb set-up. As things get tighter on Emission regs... we all might have to re-consider this in the near future. As with many things...If you've not tried it, don't knock it.

Good on him for doing something different. The other benefits that mapped ignition will bring is fantastic drivability and even if the car is running a radical cam, better fuel economy and emissions over a carb set-up. As things get tighter on Emission regs... we all might have to re-consider this in the near future. As with many things...If you've not tried it, don't knock it.I'll be interested to see how this thread develops. There is a guy sprinting in the West Mids area (applejack green Mini - V.Cool colour!) that is running a 998 unit, Turboed with Custom SPi and mapped using Emerald Software. The thing is ballistic.

Edited by FWDRacer on Thursday 8th November 16:47

FWDRacer said:

Cooperman - That output/spec on a single 1.5 inch SU? I'd need to see a dynoplot to be convinced that is acheviable. I simply have never seen those sort of figures, no matter how well set-up. On an HIF44 No problem.

The custom fuel injection route is a real innovation and continues to bring the Mini on in terms of development. DH is to be applauded for his efforts. To be honest, understanding the system parameters on something fairly stock (and inexpensive if it anything goes awry) is a sight more intelliugent than screwing together an all singing-dancing bottom end/head and then buggering it up because of inexperience. I think DH explained it was stepping stone to greater things... Good on him for doing something different. The other benefits that mapped ignition will bring is fantastic drivability and even if the car is running a radical cam, better fuel economy and emissions over a carb set-up. As things get tighter on Emission regs... we all might have to re-consider this in the near future. As with many things...If you've not tried it, don't knock it.

Good on him for doing something different. The other benefits that mapped ignition will bring is fantastic drivability and even if the car is running a radical cam, better fuel economy and emissions over a carb set-up. As things get tighter on Emission regs... we all might have to re-consider this in the near future. As with many things...If you've not tried it, don't knock it.

I'll be interested to see how this thread develops. There is a guy sprinting in the West Mids area (applejack green Mini - V.Cool colour!) that is running a 998 unit, Turboed with Custom SPi and mapped using Emerald Software. The thing is ballistic.

FWD, I apologise, I should have said a 1.75". I got 84 bhp at the flywheel on my 1990 Cooper 1275, out to 1330, when I did just a bit of a clean up, 35.5 mm inlets, 10.6 c.r., I used a Metro GT cam and timed it in at 2 deg advanced from nominal (110 deg). In theory it was a standard engine, but I did open out the inlet and exhaust tracts a little and clean up the chambers. It was very driveable and quite quick, but nothing like my 64 'S', of course.The custom fuel injection route is a real innovation and continues to bring the Mini on in terms of development. DH is to be applauded for his efforts. To be honest, understanding the system parameters on something fairly stock (and inexpensive if it anything goes awry) is a sight more intelliugent than screwing together an all singing-dancing bottom end/head and then buggering it up because of inexperience. I think DH explained it was stepping stone to greater things...

Good on him for doing something different. The other benefits that mapped ignition will bring is fantastic drivability and even if the car is running a radical cam, better fuel economy and emissions over a carb set-up. As things get tighter on Emission regs... we all might have to re-consider this in the near future. As with many things...If you've not tried it, don't knock it.

Good on him for doing something different. The other benefits that mapped ignition will bring is fantastic drivability and even if the car is running a radical cam, better fuel economy and emissions over a carb set-up. As things get tighter on Emission regs... we all might have to re-consider this in the near future. As with many things...If you've not tried it, don't knock it.I'll be interested to see how this thread develops. There is a guy sprinting in the West Mids area (applejack green Mini - V.Cool colour!) that is running a 998 unit, Turboed with Custom SPi and mapped using Emerald Software. The thing is ballistic.

Edited by FWDRacer on Thursday 8th November 16:47

Cooperman, I agree that this can be done with carbs and a dizzy  and for 99% of people thats cool. I just wanted to see if I could get it going with FI as an experiment. I dont expect any major power advantage, just the major advantages of predictability and reliability. It may be a massive waste of time (and expense) but I doubt it

and for 99% of people thats cool. I just wanted to see if I could get it going with FI as an experiment. I dont expect any major power advantage, just the major advantages of predictability and reliability. It may be a massive waste of time (and expense) but I doubt it

FWD. I have some pictures of the one you are thinking of that I got from another forum.

These are NOT my car and if they are yours, please let me know if you want me to take the pictures down. I found these after I had started so it is good to know that someone has made this work with a turbo.

Welcome to the world of tomorrow, I actually had a bluetooth serial port on my ECU and was tuning the car from the warmth of the house . That feature alone has to be worth it

. That feature alone has to be worth it

Again, I am notoriously slow in getting my act together but hopefully I can pull my finger out over the next few months.

and for 99% of people thats cool. I just wanted to see if I could get it going with FI as an experiment. I dont expect any major power advantage, just the major advantages of predictability and reliability. It may be a massive waste of time (and expense) but I doubt it

and for 99% of people thats cool. I just wanted to see if I could get it going with FI as an experiment. I dont expect any major power advantage, just the major advantages of predictability and reliability. It may be a massive waste of time (and expense) but I doubt it

FWD. I have some pictures of the one you are thinking of that I got from another forum.

These are NOT my car and if they are yours, please let me know if you want me to take the pictures down. I found these after I had started so it is good to know that someone has made this work with a turbo.

Welcome to the world of tomorrow, I actually had a bluetooth serial port on my ECU and was tuning the car from the warmth of the house

. That feature alone has to be worth it

. That feature alone has to be worth it

Again, I am notoriously slow in getting my act together but hopefully I can pull my finger out over the next few months.

i think us old school boys like pete and me will always want to think that su's will be better than injection because we have such a deep understanding of them. it always amazes me how many people cannot set twin carbs (or even single carbs up - if that crappy win su program cannot tell people the needle they need they just seem to give up!). my road going 1071 runs so well on twin su's its untrue.

ive always wanted to try injection on a mini, right from the mid 1990's when the first diy conversions started to appear in ccc mag, i even started to make a pair of injected twin 1 1/2's before realising that getting them working was far beyond my brain and wallet. the stuff to do it is so avalible and cheap (ish) nowadays that i think that its a natural progresion for people to want to try and see if it works, so big respect for the dark helmet for trying something new...

its like my shell im doing, so many people have said 'why bother', or 'you'll never get that finished', that if anything, its spured me on!

i personally think that more and more project minis will end up running mapped ignition and injection because of the cheaper cost and the sort of knowledge that yonger kids (god i feel old!!) have in car tuning now.

ive actually had to set the carbs and dizzy up on a MG C for someone recentley, this guy was 15+ years time served mechanic (and he is bloody good), but as he pointed out he served his apprenticship on ktronc (the old xr3 stuff) - he had never been taught how to set carbs up and was absolutly stuck on a pair of twins.........

ive always wanted to try injection on a mini, right from the mid 1990's when the first diy conversions started to appear in ccc mag, i even started to make a pair of injected twin 1 1/2's before realising that getting them working was far beyond my brain and wallet. the stuff to do it is so avalible and cheap (ish) nowadays that i think that its a natural progresion for people to want to try and see if it works, so big respect for the dark helmet for trying something new...

its like my shell im doing, so many people have said 'why bother', or 'you'll never get that finished', that if anything, its spured me on!

i personally think that more and more project minis will end up running mapped ignition and injection because of the cheaper cost and the sort of knowledge that yonger kids (god i feel old!!) have in car tuning now.

ive actually had to set the carbs and dizzy up on a MG C for someone recentley, this guy was 15+ years time served mechanic (and he is bloody good), but as he pointed out he served his apprenticship on ktronc (the old xr3 stuff) - he had never been taught how to set carbs up and was absolutly stuck on a pair of twins.........

The only thing I missed off my 84 bhp spec was the dizzy which I changed for an Aldon 'Red' unit. That does make such a difference.My 'S' has a specially curved custom Aldon unit and when I changed from the 'Red' I had put in originally I could tell the difference even before it went back on the rollers just by setting it to the same static as the 'Red' one.

My W&P 1380cc Mini has Webber alpha twin point injection. Was fitted many years ago now though, but when I drove it, it always worked well, and made a lovely rorty noise.

My thinking was that if for no other reason, it was nice to be rid of the dizzy! Gives a little more room up front to get at bits & pieces.

I hear the ECU's are a sod to program now though, as not many people can do it, so im wondering, if & when I get it back on the road (Or may sell it as is) I may try to use an Emerald ECU instead. If it doesn't create some big wiring headache that is..

P,

PS, Im liking the look of that injected turbo motor! Might be an idea for my Turbo 30..

My thinking was that if for no other reason, it was nice to be rid of the dizzy! Gives a little more room up front to get at bits & pieces.

I hear the ECU's are a sod to program now though, as not many people can do it, so im wondering, if & when I get it back on the road (Or may sell it as is) I may try to use an Emerald ECU instead. If it doesn't create some big wiring headache that is..

P,

PS, Im liking the look of that injected turbo motor! Might be an idea for my Turbo 30..

Edited by PJR on Wednesday 14th November 23:16

I wouldn't do it at all. Somewhere I read (on minimania.com) that the suck-suck-gap-gap characteristic of the mini ports causes it to be a positive nightmare. I have read a major Vizard style treatise of it by a chap who was trying to do his own. I think he was an automotive engineer.

here you go, just found it:-

http://www.starchak.ca/efi/efi.htm

I reckon 4 intake ports is the way to go.

here you go, just found it:-

http://www.starchak.ca/efi/efi.htm

I reckon 4 intake ports is the way to go.

Nice link, but this is a different configuration to mine. He is trying to achieve one injector per inlet port, as per the Rover MPI. This needs a cam position sensor and a way to fire the injectors in AABB sequence rather than ABAB that most cars use. I can fire my injectors anyway I want but dont have any cam sensor in there to detect engine phase. I suppose I could use a distributor trigger, but using my "wet manifold" configuration basically I have an electronic SU and the engine takes the fuel in as if a carb was there. I agree it is not as efficient as having the injector in the inlet tract, but I think the losses are probably minimal.

There are some guys on turbominis who are rewriting Megasquirt to operate in the right sequence for a Mini but I know they have been having some issues with injector timing, amongst other things.

You are right that a 7 or 8 port head is the right way to do it, but that another couple of grand I am thinking of spending the money on a turbo conversion instead.

I am thinking of spending the money on a turbo conversion instead.

Cheers

There are some guys on turbominis who are rewriting Megasquirt to operate in the right sequence for a Mini but I know they have been having some issues with injector timing, amongst other things.

You are right that a 7 or 8 port head is the right way to do it, but that another couple of grand

I am thinking of spending the money on a turbo conversion instead.

I am thinking of spending the money on a turbo conversion instead.Cheers

dark_helmet said:

Nice link, but this is a different configuration to mine. He is trying to achieve one injector per inlet port, as per the Rover MPI. This needs a cam position sensor and a way to fire the injectors in AABB sequence rather than ABAB that most cars use. I can fire my injectors anyway I want but dont have any cam sensor in there to detect engine phase. I suppose I could use a distributor trigger, but using my "wet manifold" configuration basically I have an electronic SU and the engine takes the fuel in as if a carb was there. I agree it is not as efficient as having the injector in the inlet tract, but I think the losses are probably minimal.

There are some guys on turbominis who are rewriting Megasquirt to operate in the right sequence for a Mini but I know they have been having some issues with injector timing, amongst other things.

You are right that a 7 or 8 port head is the right way to do it, but that another couple of grand I am thinking of spending the money on a turbo conversion instead.

I am thinking of spending the money on a turbo conversion instead.

Cheers

It's worth looking for a copy of the original patent for the mini MPI injection system. This was invented by a guy called Mike Theaker when at Rover (incidentally Mike is now responsible for the engineering of the John Cooper Works Upgrade packs).There are some guys on turbominis who are rewriting Megasquirt to operate in the right sequence for a Mini but I know they have been having some issues with injector timing, amongst other things.

You are right that a 7 or 8 port head is the right way to do it, but that another couple of grand

I am thinking of spending the money on a turbo conversion instead.

I am thinking of spending the money on a turbo conversion instead.Cheers

His injection method gets around the fact that two cylinders share one port and one injector (i.e. the first cylinder to open scavenges the fuel that would be sprayed in advance of the second cylinder opening if you used conventional injection timing), by timing a single pulse so that half of it gets sucked up by each cylinder. i.e. half gets sucked up by the end of the valve event for the first cyl, half by the start of the valve event of the second, IIRC.

So both pulse width and start of injection have to change by a fairly significant amount throughout the speed / load curve of the engine.

IIUC this means that it's relatively difficult to modify this setup.

A couple of alternatives spring to mind:

1. run EFI as a carb alternative - i.e. supplying nice homogeneous mixed fuel and air well upstream of the port, like SPI injection. You could do this with one or two SPI injectors, or use conventional MPI injectors but they'd have to be well upstream.

2. use high flow injectors and always time the injection pulse so that it's squirting onto an open inlet valve event. This would get rid of cylinder to cylinder scavenging but at the expense of poor fuel atomisation. They would need to be pretty meaty injectors, firstly becase each has to supply two cylinders not one, secondly because the maximum pulse width will be half a revolution, whereas often at full speed / full load injectors are open almost 100%.

hope this helps - and apologies if I've included any tech errors (I stopped being an engine designer / developer about 10 years ago!)

Nick

Thanks for the notes. I am using method 1 as you describe.

I have actually ramped up activity on the car and spent most of the weekend welding and installing my roll cage. I had not started the car for 3 or 4 months and it fired on the first turn of the key, made me laugh as previous minis would not start after 3 or 4 minutes of standing idle

I have gathered most of the bits I need to build my semi-race spec engine, actually reading that Cooperman has retired is interesting, it might speed things up a bit if I sent it down to him. Anyone have a good SC/CR gearbox for sale?

Anyone have a good SC/CR gearbox for sale?

Cheers

I have actually ramped up activity on the car and spent most of the weekend welding and installing my roll cage. I had not started the car for 3 or 4 months and it fired on the first turn of the key, made me laugh as previous minis would not start after 3 or 4 minutes of standing idle

I have gathered most of the bits I need to build my semi-race spec engine, actually reading that Cooperman has retired is interesting, it might speed things up a bit if I sent it down to him.

Anyone have a good SC/CR gearbox for sale?

Anyone have a good SC/CR gearbox for sale?Cheers

Cooperman said:

The only thing I missed off my 84 bhp spec was the dizzy which I changed for an Aldon 'Red' unit. That does make such a difference.My 'S' has a specially curved custom Aldon unit and when I changed from the 'Red' I had put in originally I could tell the difference even before it went back on the rollers just by setting it to the same static as the 'Red' one.

Peter, for a fairly relaxed MG Metro engine: 1330, decked block, standard MG head, Minispares "evolution" cam, would you say a yellow is better than a red? Car pinks a little under load, up a hill, unless revs are kept up.(this started off with me looking to buy new cap and leads for the standard dizzy.......)

Added after the dog and bairn have departed from under the computer:

LCB, HIF44,

Edited by Skyedriver on Sunday 9th December 21:55

Skyedriver said:

Cooperman said:

The only thing I missed off my 84 bhp spec was the dizzy which I changed for an Aldon 'Red' unit. That does make such a difference.My 'S' has a specially curved custom Aldon unit and when I changed from the 'Red' I had put in originally I could tell the difference even before it went back on the rollers just by setting it to the same static as the 'Red' one.

Peter, for a fairly relaxed MG Metro engine: 1330, decked block, standard MG head, Minispares "evolution" cam, would you say a yellow is better than a red? Car pinks a little under load, up a hill, unless revs are kept up.(this started off with me looking to buy new cap and leads for the standard dizzy.......)

Added after the dog and bairn have departed from under the computer:

LCB, HIF44,

Edited by Skyedriver on Sunday 9th December 21:55

The problem with 'hot' A-series engines is that if you have a non-vacuum dizzy and set it to give max power at, say, 6200 rpm, it can be the case that the resultant ststic advance is so much that the engine won't turn over to start it, especially when hot when the compression is highest. You then have to back it off until it will turn over and thus lose several degrees and several bhp at the top end.

My 1275 'S' always felt good with the Aldon 'Red' unit until I decided to get one custom-curved. The difference then was really noticeable and I think I got an extra 5 bhp at over 6000, plus it started OK as the static was only about 5 degrees. The custom one has, I believe, 4.5 degrees more max advance and different springs which prevent detonation at between 2500 and 4500 rpm with full throttle.

Still interesting stuff though as I have based my intial ignition map on the 123 distributor curves. I will be interested to know what it ends up at when it reaches the rolling road.

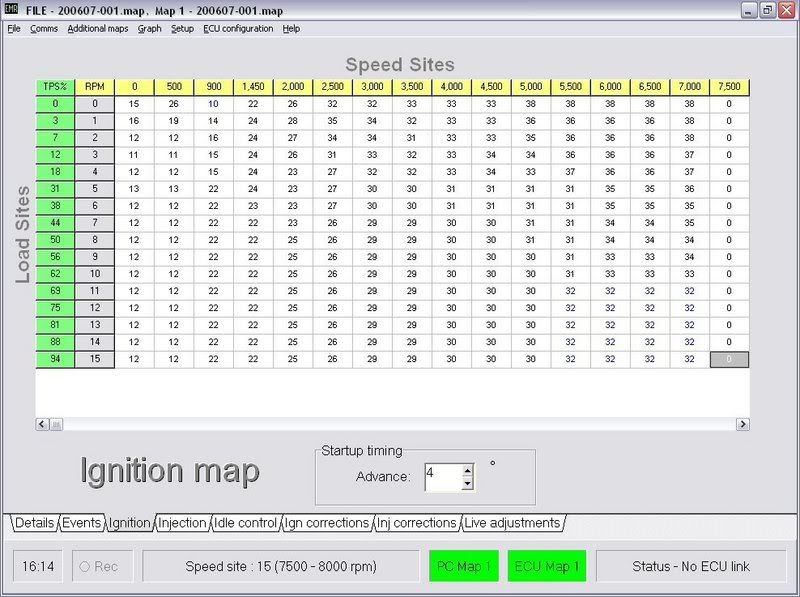

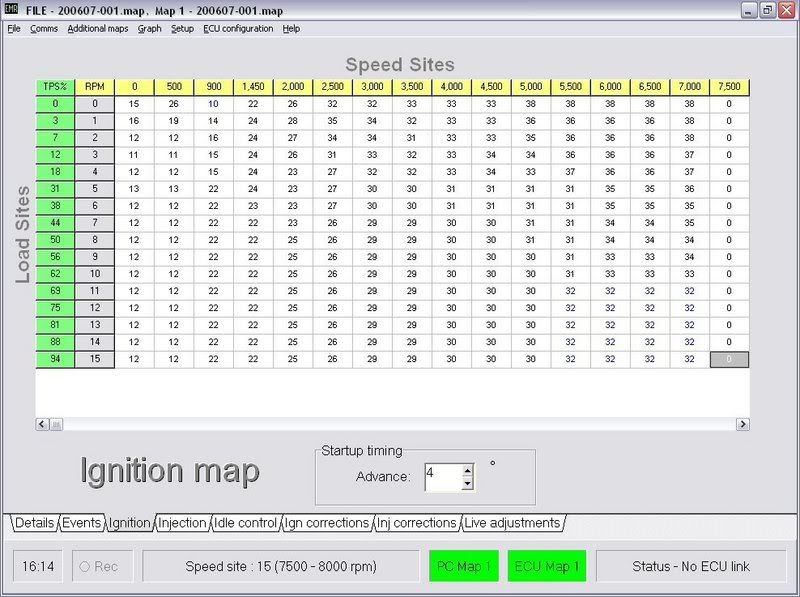

This is my base map, not tuned yet. The Zero's at the 7500 RPM are not 0 degrees advance, I have a hard cut limit at 7250 so there is no point adding above this. Also the high advance at 500rpm is to give it a kick if stalling. There is also an idle control function in the ECU that swings the timing to even out the idle.

I am almost finished with the bodywork and pretty much ready for painting. I can then get the wiring finalised and get it mapped up and the suspension aligned.

Also I have almost collected all the bits I need to build my more powerful 1330 or 1380 engine (just need pistons) that should then go out to the machine shop after Xmas.

This is my base map, not tuned yet. The Zero's at the 7500 RPM are not 0 degrees advance, I have a hard cut limit at 7250 so there is no point adding above this. Also the high advance at 500rpm is to give it a kick if stalling. There is also an idle control function in the ECU that swings the timing to even out the idle.

I am almost finished with the bodywork and pretty much ready for painting. I can then get the wiring finalised and get it mapped up and the suspension aligned.

Also I have almost collected all the bits I need to build my more powerful 1330 or 1380 engine (just need pistons) that should then go out to the machine shop after Xmas.

dh,

I've been looking into doing this for ages. Unfortunately, pressures of a student budget, and lack of facilities whilst away at University have put it on the back burner. (Anyone know of cheap/free garage space in Exeter - or anywhere in Devon for that matter?)

Looking forward to seeing the car and thread progress, and hopefully see the car in the flesh sometime. Keep up the good work!!

Charlie

ETA: Very tidy engine bay. I like.

I've been looking into doing this for ages. Unfortunately, pressures of a student budget, and lack of facilities whilst away at University have put it on the back burner. (Anyone know of cheap/free garage space in Exeter - or anywhere in Devon for that matter?)

Looking forward to seeing the car and thread progress, and hopefully see the car in the flesh sometime. Keep up the good work!!

Charlie

ETA: Very tidy engine bay. I like.

Edited by bitwrx on Monday 10th December 18:36

Well after not touching the car for a few months I have ramped up on getting the thing back in one piece. Spent the last few weekends getting all the rust out and doing a final fit on the carbon fibre bits and the chromework. Hope to get it in paint within the next month and then get back to messing around trying to set up the injection system

Cheers

Cheers

Gassing Station | Classic Minis | Top of Page | What's New | My Stuff