Discussion

Thought I'd bump this rather than open a new thread. I'm thinking of a 3D printer as a typical dad Christmas present for my son like Lego when he was little ie I'll but it for him but end up playing with it myself. Happy to spend a bit of money if it's worth it but I'm completely lost on what features are or aren't worth happening, Hoping too that there may be some good offers around on Black Friday to take advantage of. Any pointers much appreciated

Sorry, this will be a somewhat rushed and unstructured set of points.

I'm going to make the assumption that you will be looking at FDM printers (plastic weld / glue gun on a moving gantry type thing) as they are relatively cheap to buy and use and don't involve horrible resins.

I would be tempted to start off with a machine that is reliable and easy to set up and run as there is nothing worse than a horribly complex slicer program being used to run a machine that only fancies working properly when set up perfectly...

Having prints repeatedly fail after an hour or two (lifting off the bed, extruder clogging etc) will quickly lead to frustration especially when trying to get kids interested (my 9 y/o daughter's always asking me to print stuff now she's seen figurines and trinkets printed on demand).

Commenting from my own narrow experience, I have several machines that I use for prototyping and the one that is the most reliable and easiest to use is a Cetus (Beijing Tiertime). The software, Up Studio, is extremely simple and the machine is both reliable and quiet. Print quality is very good and the machine is fast (for a relatively cheap 3d printer).

Something else to consider is where the machine might be used, e.g. garage, spare room , dining table (I get grumbled at for that! ) etc. The hot end of the machine will run anywhere from 200°C up to close to 300°C (machine and material dependent) and almost all machines feature some kind of slide positioning system. There's obvious hazards here from a nasty burn on little hands and also the potential for entrapment and crunching in the moving parts.

) etc. The hot end of the machine will run anywhere from 200°C up to close to 300°C (machine and material dependent) and almost all machines feature some kind of slide positioning system. There's obvious hazards here from a nasty burn on little hands and also the potential for entrapment and crunching in the moving parts.

Also to consider are the fumes from the printing. PLA and PETG from what I can tell are mostly harmless but if you get into ABS and other materials there can be a nasty smell and potentially iffy gases / particles. Some machines (Flashforge for example) will come with an enclosure.

Running out of time to reply here but also look at build volume. Big isn't always better as FDM printing is not a particularly quick process.

As far as machine cost goes, there are various cheap Chinese machines for not a lot of money but I have my reservations about the quality of the electronics and mechanics. Having said that, Creality produce machines that appear to be fairly well built, reasonably priced and popular.

Another thing to consider is downloading some slicing software beforehand (Slic3r and Cura are both free) to see if you can get the hang of it (you will also need to find 3d models online or produce your own).

I'm going to make the assumption that you will be looking at FDM printers (plastic weld / glue gun on a moving gantry type thing) as they are relatively cheap to buy and use and don't involve horrible resins.

I would be tempted to start off with a machine that is reliable and easy to set up and run as there is nothing worse than a horribly complex slicer program being used to run a machine that only fancies working properly when set up perfectly...

Having prints repeatedly fail after an hour or two (lifting off the bed, extruder clogging etc) will quickly lead to frustration especially when trying to get kids interested (my 9 y/o daughter's always asking me to print stuff now she's seen figurines and trinkets printed on demand).

Commenting from my own narrow experience, I have several machines that I use for prototyping and the one that is the most reliable and easiest to use is a Cetus (Beijing Tiertime). The software, Up Studio, is extremely simple and the machine is both reliable and quiet. Print quality is very good and the machine is fast (for a relatively cheap 3d printer).

Something else to consider is where the machine might be used, e.g. garage, spare room , dining table (I get grumbled at for that!

) etc. The hot end of the machine will run anywhere from 200°C up to close to 300°C (machine and material dependent) and almost all machines feature some kind of slide positioning system. There's obvious hazards here from a nasty burn on little hands and also the potential for entrapment and crunching in the moving parts.

) etc. The hot end of the machine will run anywhere from 200°C up to close to 300°C (machine and material dependent) and almost all machines feature some kind of slide positioning system. There's obvious hazards here from a nasty burn on little hands and also the potential for entrapment and crunching in the moving parts.Also to consider are the fumes from the printing. PLA and PETG from what I can tell are mostly harmless but if you get into ABS and other materials there can be a nasty smell and potentially iffy gases / particles. Some machines (Flashforge for example) will come with an enclosure.

Running out of time to reply here but also look at build volume. Big isn't always better as FDM printing is not a particularly quick process.

As far as machine cost goes, there are various cheap Chinese machines for not a lot of money but I have my reservations about the quality of the electronics and mechanics. Having said that, Creality produce machines that appear to be fairly well built, reasonably priced and popular.

Another thing to consider is downloading some slicing software beforehand (Slic3r and Cura are both free) to see if you can get the hang of it (you will also need to find 3d models online or produce your own).

i am no expert on 3d printing but have 2 machines which i can really recommend. The Creality Ender 3, £150 from banggood.com or a bit more for next day delivery from Amazon.

I had one for personal projects but needed some parts for work made so bought another machine, i have ran both machines for about 20hrs a day for the last 2 weeks solid and they are working great. Lots of videos on youtube about the ender 3 and a great facebook group with people happy to help if you have problems.

I had one for personal projects but needed some parts for work made so bought another machine, i have ran both machines for about 20hrs a day for the last 2 weeks solid and they are working great. Lots of videos on youtube about the ender 3 and a great facebook group with people happy to help if you have problems.

I've been 3d printing for years now and I'll share my experience (I'm prob repeating stuff here as I've not read all the threads.

I have a home built Prusa i3 - cheap and works superbly. BUT, here are the important bits, ignore them at your peril :-)

1 - take TIME setting up the mechanics. Use a digital caliper for measurements.

2 - have self levelling fo some sort. 3D printing without is horrible. I use the built in marlin firmware self levelling with a micro servo on the X carriage. Works perfectly. Printing without self levelling is almost pointless.

3 - PLA is easy to print and it sticks to almost anything. I use Kapton tape on glass. Have a heated bed.

4 - ABS - small is fine - use prit stick or similar on glass. Sticks so well you'll need to remove the glass to get the print off. But then you have auto levelling so removing the glass doesn't matter :-)

5 - ABS - large - you NEED a heated enclosure, or forget it. As you have a heated enclosure, you can't have any PLA parts that make up yoru printer :-) They'll melt / deform. I avoid printing large in ABS like the plague. ABS slurry works but its messy and no better than prit stick.

6 - Stick with PLA :-) - or, and I've not tried it, some of the new PET variants. Like PETG

7 - buy a good quality print head - bin the one your ebay kit came with. No more jams.

8 - if you go down the Prusa / Marlin (Marlin = 3D firmware(software) on Arduino) route then buy a raspberry pi and install Octoprint. You can then print from your desktop direct.

Have fun!

p.s. this is an (old)vid of my printer self levelling

https://www.youtube.com/watch?v=YKsnBn5a5Y0

I have a home built Prusa i3 - cheap and works superbly. BUT, here are the important bits, ignore them at your peril :-)

1 - take TIME setting up the mechanics. Use a digital caliper for measurements.

2 - have self levelling fo some sort. 3D printing without is horrible. I use the built in marlin firmware self levelling with a micro servo on the X carriage. Works perfectly. Printing without self levelling is almost pointless.

3 - PLA is easy to print and it sticks to almost anything. I use Kapton tape on glass. Have a heated bed.

4 - ABS - small is fine - use prit stick or similar on glass. Sticks so well you'll need to remove the glass to get the print off. But then you have auto levelling so removing the glass doesn't matter :-)

5 - ABS - large - you NEED a heated enclosure, or forget it. As you have a heated enclosure, you can't have any PLA parts that make up yoru printer :-) They'll melt / deform. I avoid printing large in ABS like the plague. ABS slurry works but its messy and no better than prit stick.

6 - Stick with PLA :-) - or, and I've not tried it, some of the new PET variants. Like PETG

7 - buy a good quality print head - bin the one your ebay kit came with. No more jams.

8 - if you go down the Prusa / Marlin (Marlin = 3D firmware(software) on Arduino) route then buy a raspberry pi and install Octoprint. You can then print from your desktop direct.

Have fun!

p.s. this is an (old)vid of my printer self levelling

https://www.youtube.com/watch?v=YKsnBn5a5Y0

I always find 3d printer discussions interesting for the various didactic comments. What one person swears by other completely disregards. I have a BigBox UK model which I have had for a number of years through various iterations of E3d components. BigBox was basically a self build make for experimental enthusiasts. Almost all of it is self printed. I have just finished putting it back together with new linear rails, with two carriages sharing a rail and just got marlin 1.9 working on it..

Despite previous comments it prints ABS with no problems despite the majority of the printer being PLA. This is mainly because at 220 odd degrees anything plastic would melt, so fans are designed into a project to keep the cool bits cool. Its not fully enclosed.

Most PLA is printed straight onto glass without adhesive of any sort. I used to have bed levelling with infrared, then changed to a bltouch. Then went pezio, but am now back to manual levelling as its more accurate and reproducible. I've printed flexibles, high temp ABS and petG all with fairly good success. Even recently started doing lost PLA moulding.

My advice is to ignore all the conflicting advice on here and experiment. Its really good fun.

.

julian64 said:

I always find 3d printer discussions interesting for the various didactic comments. What one person swears by other completely disregards. I have a BigBox UK model which I have had for a number of years through various iterations of E3d components. BigBox was basically a self build make for experimental enthusiasts. Almost all of it is self printed. I have just finished putting it back together with new linear rails, with two carriages sharing a rail and just got marlin 1.9 working on it..

Despite previous comments it prints ABS with no problems despite the majority of the printer being PLA. This is mainly because at 220 odd degrees anything plastic would melt, so fans are designed into a project to keep the cool bits cool. Its not fully enclosed.

Most PLA is printed straight onto glass without adhesive of any sort. I used to have bed levelling with infrared, then changed to a bltouch. Then went pezio, but am now back to manual levelling as its more accurate and reproducible. I've printed flexibles, high temp ABS and petG all with fairly good success. Even recently started doing lost PLA moulding.

My advice is to ignore all the conflicting advice on here and experiment. Its really good fun.

.

There has to be some generalisation. It's helpful. Advice based on averages.Despite previous comments it prints ABS with no problems despite the majority of the printer being PLA. This is mainly because at 220 odd degrees anything plastic would melt, so fans are designed into a project to keep the cool bits cool. Its not fully enclosed.

Most PLA is printed straight onto glass without adhesive of any sort. I used to have bed levelling with infrared, then changed to a bltouch. Then went pezio, but am now back to manual levelling as its more accurate and reproducible. I've printed flexibles, high temp ABS and petG all with fairly good success. Even recently started doing lost PLA moulding.

My advice is to ignore all the conflicting advice on here and experiment. Its really good fun.

.

Forums are full of people with abs printing difficulties. It is generally accepted to be far harder to work with than pla. Also no one I've spoken to who uses self levelling would dream of going back to manual, even though you prefer it (perhaps you never got it quite right , trying three different types? I have, like most, found it so reproducible that I never even think about the first layer any more)

Someone came in here asking for advice, so that's that we've done. Given advice. Your advice, is to ignore the advice. :-)

Your advice to experiment is sound, however it is very handy to know there are escape paths when you run into problems, like bed levelling , for example)

Edited by anonymous-user on Tuesday 13th November 09:04

RogerDodger said:

Someone came in here asking for advice, so that's that we've done. Given advice. Your advice, is to ignore the advice. :-)

Your advice to experiment is sound, however it is very handy to know there are escape paths when you run into problems, like bed levelling , for example)

And ultimately this is the sort of advice I was expecting/hoping for. A couple of years ago he got a €30 drone, crashed it quite a lot but had fun so now he's gone and spent €500 on one. I think we'll take a similar track with a 3D printer but maybe look to spend €200 now and then I might invest more later. Clearly there isn't a right answer but at least I now have some ideas of risks and options.Your advice to experiment is sound, however it is very handy to know there are escape paths when you run into problems, like bed levelling , for example)

Edited by RogerDodger on Tuesday 13th November 09:04

Okay translating my ramblings into advice. If you have a budget concentrate on the best extruder you can buy ahead of everything else. If there is money left in the budget go for a heated bed.

An enclosure and bed levelling is way down the pecking order but nice to have.

Beware of some of the cheap Chinese products who tick all the boxes but do them all badly. There is no way back for those machines apart from starting again. Seeing someone demonstrate a machine is 100x better than what someone writes on the internet. . Good luck.

. Good luck.

An enclosure and bed levelling is way down the pecking order but nice to have.

Beware of some of the cheap Chinese products who tick all the boxes but do them all badly. There is no way back for those machines apart from starting again. Seeing someone demonstrate a machine is 100x better than what someone writes on the internet.

. Good luck.

. Good luck. A good starting model would be something like the Creality Cr-10. Very simple to assemble in well under an hour and get up and printing. It has quite a large heated bed so once you have mastered the basics you can print some large items. I would also spend a little bit extra and get the latest Cr-10 model with the dual z axis motors. I tried an Anet A8 first of all and spent about 6hrs assembley, then it was a total nightmare to bed level correctly.

Software wise i tend to use Fusion 360 along with whatever the latest version of Cura is for slicing.

If you do go down the Cr-10 route upgrade the extruder to a metal version with metal feed cog, this helps stop filament skipping, again i think the latest CR-10 model has this as standard.

I also print PLA striaght onto glass and use hairspray for the bed adhesion and once a month give the glass a good hot wash to remove debris.

Software wise i tend to use Fusion 360 along with whatever the latest version of Cura is for slicing.

If you do go down the Cr-10 route upgrade the extruder to a metal version with metal feed cog, this helps stop filament skipping, again i think the latest CR-10 model has this as standard.

I also print PLA striaght onto glass and use hairspray for the bed adhesion and once a month give the glass a good hot wash to remove debris.

jimmyjimjim said:

sausage76 said:

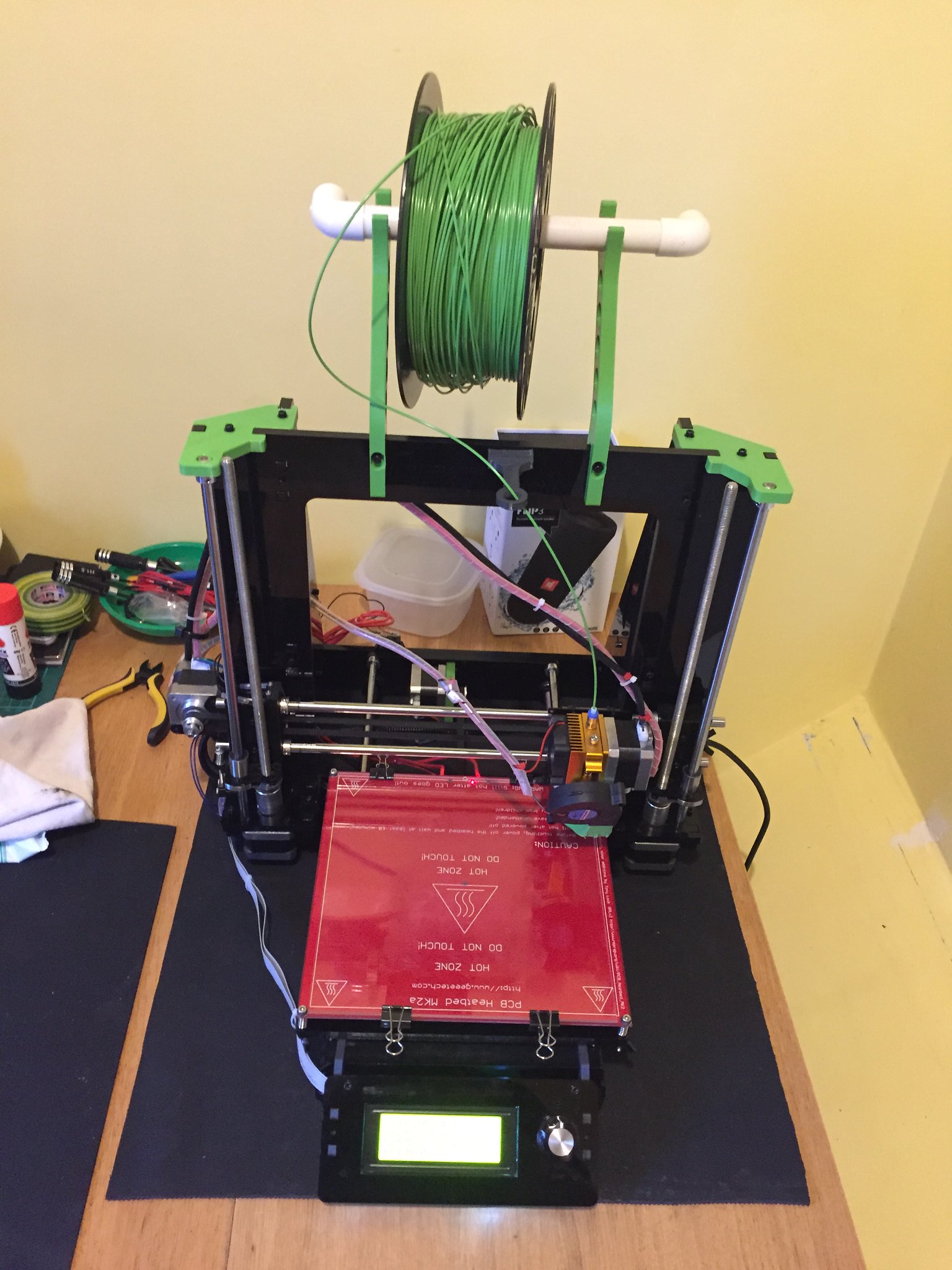

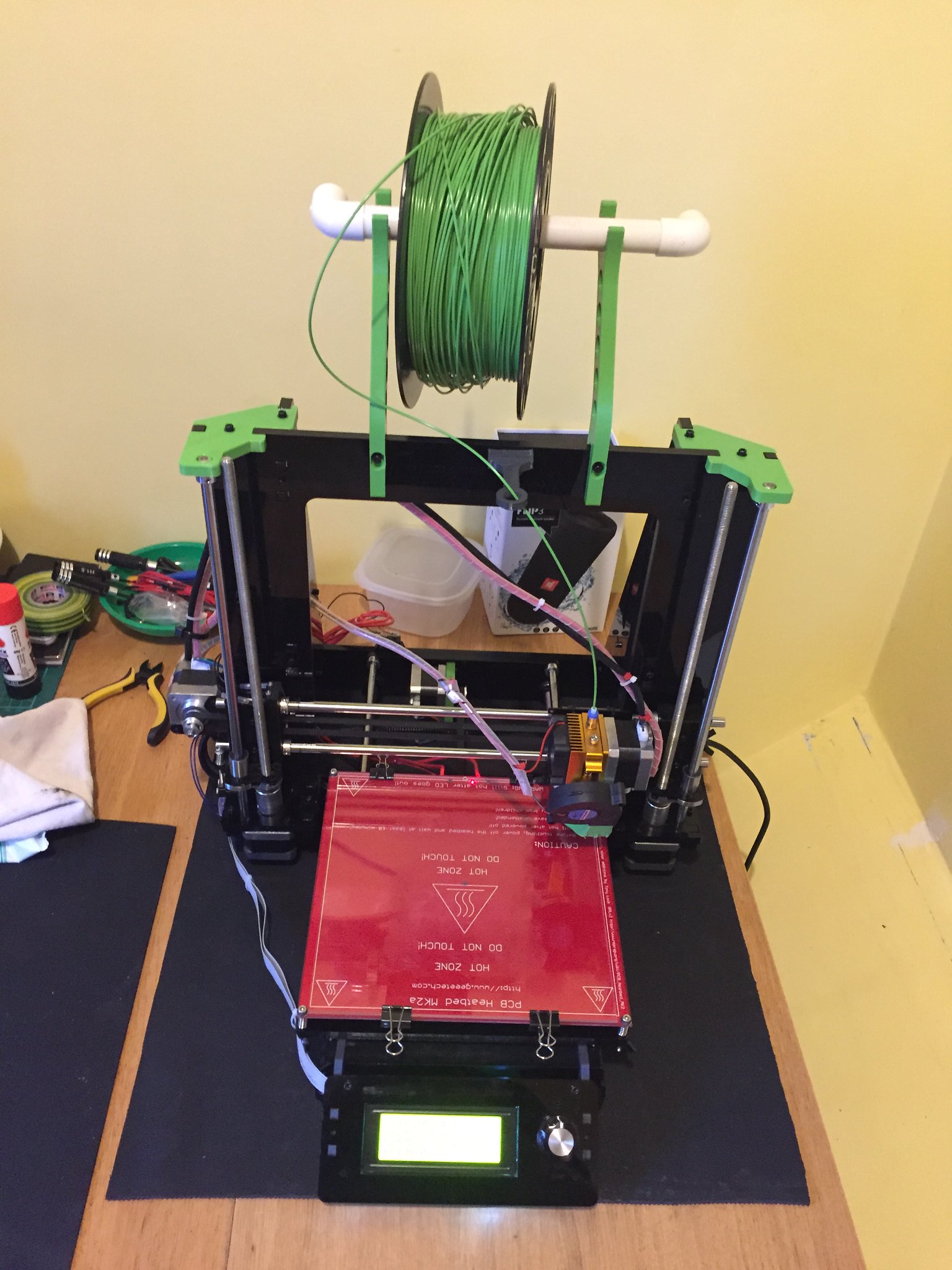

Here is my little Geeetech i3

IMG_7420 by mattcut, on Flickr

IMG_7420 by mattcut, on Flickr

Then some prints after alot of messing about

IMG_7424 by mattcut, on Flickr

IMG_7424 by mattcut, on Flickr

That's not very nice - nozzle issues? IMG_7420 by mattcut, on Flickr

IMG_7420 by mattcut, on FlickrThen some prints after alot of messing about

IMG_7424 by mattcut, on Flickr

IMG_7424 by mattcut, on FlickrHere's mine:

Prusa i3 Mk3.

Sorted along with many other issues after alot of messing about.

Now get great prints everytime and know how to fix any problems. Its a big learning curve thats for sure.

I was very pleased to only have a few issues to deal with for the i3; a faulty cable, not understanding what button to press and when on the display, a leveling issue and a limit problem.

It took maybe half a day of faffing around to resolve all of them, and another half day to work out how to set the first layer height correctly, all good after that.

It took maybe half a day of faffing around to resolve all of them, and another half day to work out how to set the first layer height correctly, all good after that.

I genuinely can't fault the Prusa i3 Mk3. 580 quid, or 800 with the multi material upgrade, as a kit.

The kit is a few evenings entertainment in itself and has all the features you'd want; self leveling, heated bed, flexible build plate so no faffing around with glue or tape, all the software you need to get started, in one nice bundle.

Well regarded, good support, etc.

The kit is a few evenings entertainment in itself and has all the features you'd want; self leveling, heated bed, flexible build plate so no faffing around with glue or tape, all the software you need to get started, in one nice bundle.

Well regarded, good support, etc.

jimmyjimjim said:

I genuinely can't fault the Prusa i3 Mk3. 580 quid, or 800 with the multi material upgrade, as a kit.

The kit is a few evenings entertainment in itself and has all the features you'd want; self leveling, heated bed, flexible build plate so no faffing around with glue or tape, all the software you need to get started, in one nice bundle.

Well regarded, good support, etc.

I might argue the glue bit but yes, interesting to assemble. The large number of printed components offer some good insights into 3dp component design...The kit is a few evenings entertainment in itself and has all the features you'd want; self leveling, heated bed, flexible build plate so no faffing around with glue or tape, all the software you need to get started, in one nice bundle.

Well regarded, good support, etc.

Gassing Station | Computers, Gadgets & Stuff | Top of Page | What's New | My Stuff