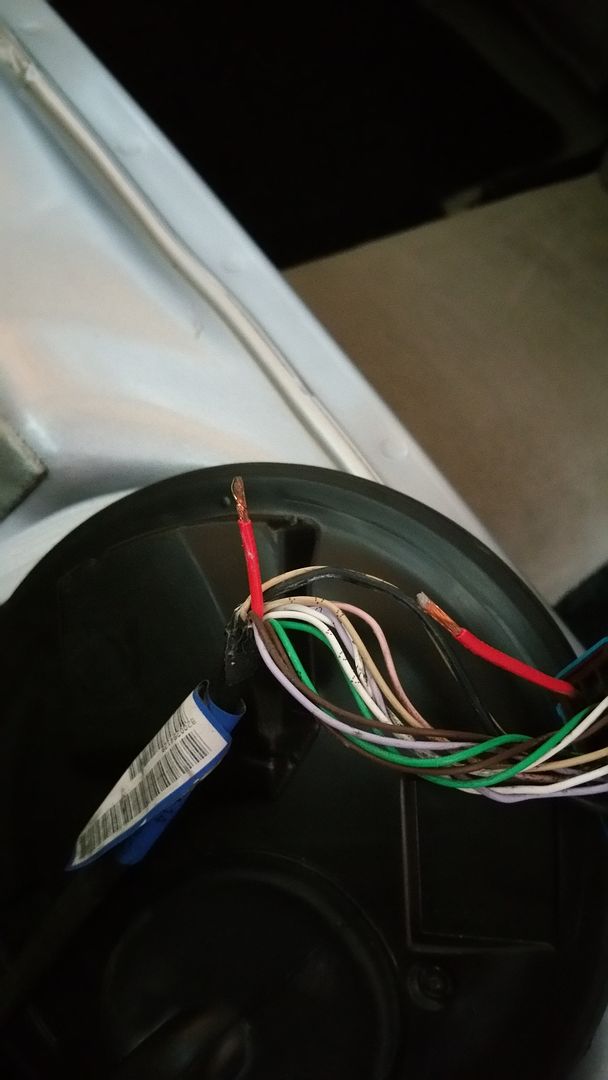

Suggestions for joining these two wires

Discussion

The best option is to cut back to good wire. Anything green is not on the wire; it used to be wire.

Soldering is the best option, with shrink wrap, Self Amalgamating Tape or liquid tape to seal it from the elements. Anything open to air will eventually corrode again. Wire is of course copper, connectors are of course not copper, so corrosion will start the moment you make the join by using connectors.

Soldering is the best option, with shrink wrap, Self Amalgamating Tape or liquid tape to seal it from the elements. Anything open to air will eventually corrode again. Wire is of course copper, connectors are of course not copper, so corrosion will start the moment you make the join by using connectors.

If your not confident with soldering these jobbies work well. As has been said cut back any corroded wire. Is it in an area exposed to the elements?

http://www.ebay.co.uk/itm/Adhesive-Lined-Heat-Shri...

http://www.ebay.co.uk/itm/Adhesive-Lined-Heat-Shri...

This cluster sits alongside the tank sender unit, so its pretty much exposed to all sorts down there.

Looks like it's been chaffing on the sender unit. Eventually enough of the strands were severed, before a bit of current did the rest - it has a 60A fuse, so not unsubstantial.

Soldering is no doubt the best option, but my soldering iron is rubbish. Melts the insulation on the wires before it melts the solder!

Looks like it's been chaffing on the sender unit. Eventually enough of the strands were severed, before a bit of current did the rest - it has a 60A fuse, so not unsubstantial.

Soldering is no doubt the best option, but my soldering iron is rubbish. Melts the insulation on the wires before it melts the solder!

littlebasher said:

This cluster sits alongside the tank sender unit, so its pretty much exposed to all sorts down there.

Looks like it's been chaffing on the sender unit. Eventually enough of the strands were severed, before a bit of current did the rest - it has a 60A fuse, so not unsubstantial.

Soldering is no doubt the best option, but my soldering iron is rubbish. Melts the insulation on the wires before it melts the solder!

If you are melting the insulation, you are doing it wrong.Looks like it's been chaffing on the sender unit. Eventually enough of the strands were severed, before a bit of current did the rest - it has a 60A fuse, so not unsubstantial.

Soldering is no doubt the best option, but my soldering iron is rubbish. Melts the insulation on the wires before it melts the solder!

Make sure the tip is clean & get a good blob of solder on to it.

Add some flux to the wires if you have, then apply the iron, along with feeding in some solder with it.

I work in the aviation industry, avionics. I would second a good crimp and heat shrink over the top. We use them in aircraft fuel tanks.

Just remember to put the heat shrink on first. I once re-terminated a 50 pin plug only to find out I hadn't put the backing shell on. It was three in the morning (good job there was no swear jar around while I was extracting 50 pins).

Just remember to put the heat shrink on first. I once re-terminated a 50 pin plug only to find out I hadn't put the backing shell on. It was three in the morning (good job there was no swear jar around while I was extracting 50 pins).

Markbarry1977 said:

Just remember to put the heat shrink on first. I once re-terminated a 50 pin plug only to find out I hadn't put the backing shell on. It was three in the morning (good job there was no swear jar around while I was extracting 50 pins).

I watched a B2 guy do this once. I said "shouldn't this be on first?" as he pushed the last pin home.B2s? I s

t 'em!

t 'em!Markbarry1977 said:

Just remember to put the heat shrink on first. I once re-terminated a 50 pin plug only to find out I hadn't put the backing shell on. It was three in the morning (good job there was no swear jar around while I was extracting 50 pins).

Have the T-shirt on that one. Also have the forgetting/putting spade connector insulators on the wrong way around before criming the connector to the end of the wire shirts.Gassing Station | Home Mechanics | Top of Page | What's New | My Stuff