Escort Mk2 Rally Car Build Modern Spec

Discussion

We have started building a Escort Mk2 rally car at work ( Motorsport-Tools.com) . Quite excited to have to opportunity to be involved in building a car to such a high spec from the chassis up. Over the coming months we will be building up the Escort to tarmac rally specification. Here some pictures of the shell before work starts, currently waiting for the engine to arrive before we can start bolting things on (2.5 N/A Cosworth race engine)

Full Group 4 Modern spec shell, tarmac alloy arched and painted throughout in arctic white.

Steel bonnet and boot, alloy arches. steel bumpers. Full weld in Safety Devices roll cage, sitting on out 20mm Sill Stands

Tarmac 13" spec light weight alloy arches, TIG welded, wire edged and riveted on with countersunk rivets

Alloy rear spoiler, attached with countersunk rivets. The boot lid is fastened down with 'bonnet pins'. The short Group4 alloy front spoiler again fitted with countersunk rivets mates up to the alloy front arches. New Front steel bumpers, re-manufactured to original Ford spec

I'll post any major updates here, but more detailed explanation of things will be added to our blog:

Mk2 Escort Rally Build Blog

Full Group 4 Modern spec shell, tarmac alloy arched and painted throughout in arctic white.

Steel bonnet and boot, alloy arches. steel bumpers. Full weld in Safety Devices roll cage, sitting on out 20mm Sill Stands

Tarmac 13" spec light weight alloy arches, TIG welded, wire edged and riveted on with countersunk rivets

Alloy rear spoiler, attached with countersunk rivets. The boot lid is fastened down with 'bonnet pins'. The short Group4 alloy front spoiler again fitted with countersunk rivets mates up to the alloy front arches. New Front steel bumpers, re-manufactured to original Ford spec

I'll post any major updates here, but more detailed explanation of things will be added to our blog:

Mk2 Escort Rally Build Blog

Edited by Work-Shy-Wanabe on Friday 2nd August 13:33

Ordinary_Chap said:

I'm looking forward to this!

Please post regularly and good luck!

Lee

Thanks Lee, will do.

Please post regularly and good luck!

Lee

Just held up atm tracking down a suitable engine and gearbox! Cant really start without test fitting them first.

We've been playing around test fitting adjustable electric power steering, but it doesn't fit ! :-) So back to the drawing board with that for the time being.

Cant wait for the engine and box to arrive! :-)

m30dus said:

What a waste of time - prepping a rusty old ford escort...

Seriously though, this is my dream car, will follow with great interest!

heheee :-) ThanksSeriously though, this is my dream car, will follow with great interest!

Will be watching your thread too, very interested to see how you get on with the Quaife 69G and Motec M800! I think we'll be doing the same, might have our own custom Tractive style shifter done for the 69G.

Bosshogg76 said:

Gotcha, looks awesome I'm busily trying to pry's my mates MK2 off him, Duratec engine and 6speed MX5 box. The red bug is currently being replaced by a 67 I'm building, no pics of that as beetles seem to be the spawn of satan on here.

Nice!Ive built a bay window camper in the past, so no stranger to air cooled! :-)

Got a bit more on the body shell, engine bay work done:

Fully strengthened strut tops and bulkhead, shaped gussets (for exhaust manifold) and a weld on strut brace, also engine chassis mounts welded in.

Radiator cut out panel added, which allows the radiator to be moved forward and allow extra space for the engine! :-)

Radiator mount support gussets added. Extra vent holes have also been added to improve air flow. (Holes made with these handy punches Hole Punch Tool)

Shaped bulkhead gussets welded in which are designed to strengthen a weak point in the Escort body shell, welds between the bulkhead, inner wing and chassis. The shaped cut out allows extra exhaust manifold clearance.

Thats the front end of the body shell sorted!

Will post up details of the rear end chassis soon, lots of works been done on it.

5potTurbo said:

Wibble!

Wibble!Work-Shy-Wanabe said:

oh and nearly forgot, engine has been ordered and is currently being built to our spec! :-) Hopefully we'll have that within a month.

Which engine have you gone for, a YB, Duratec, BDA/Burton....?2.5 N/A Cosworth YB all alloy race engine, engine builder will be revealed when the engine arrives! :-)

Part three of the body shell:

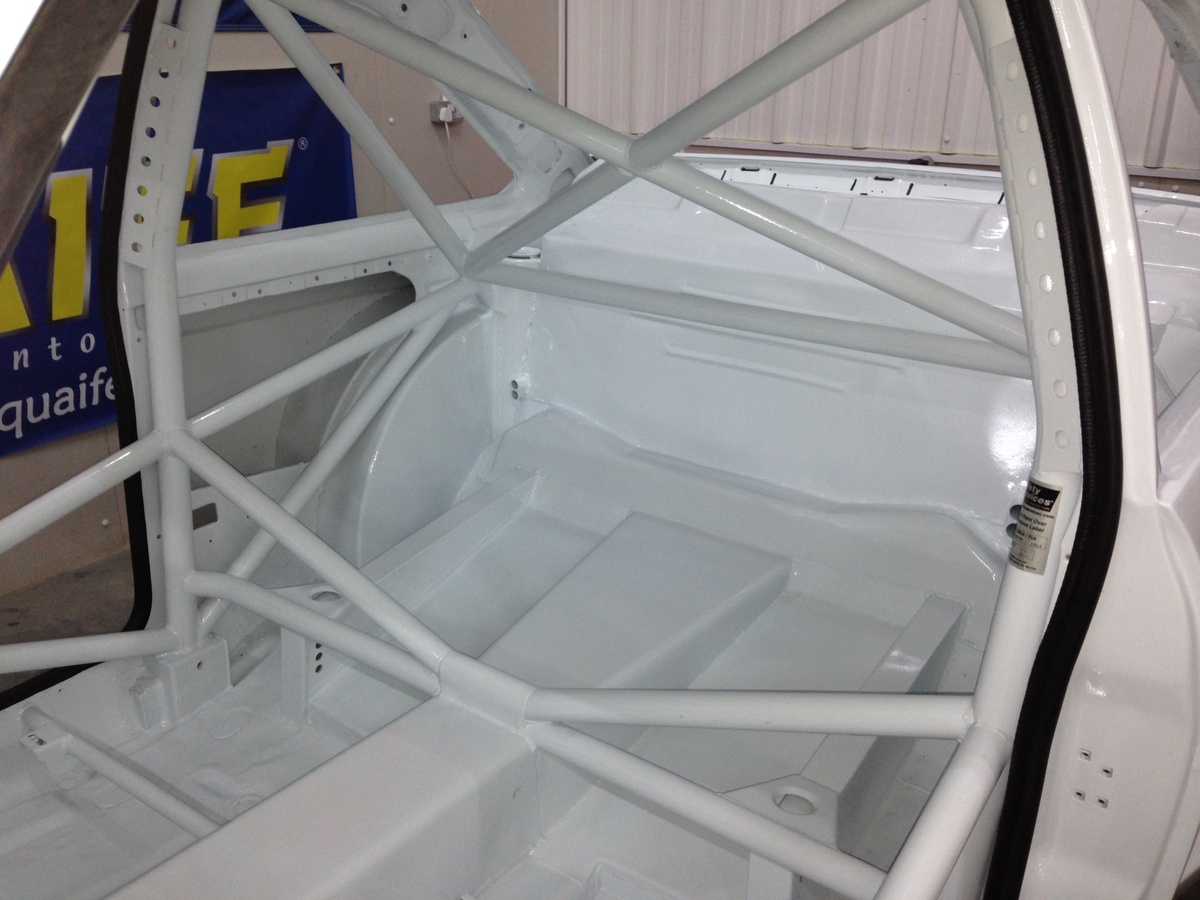

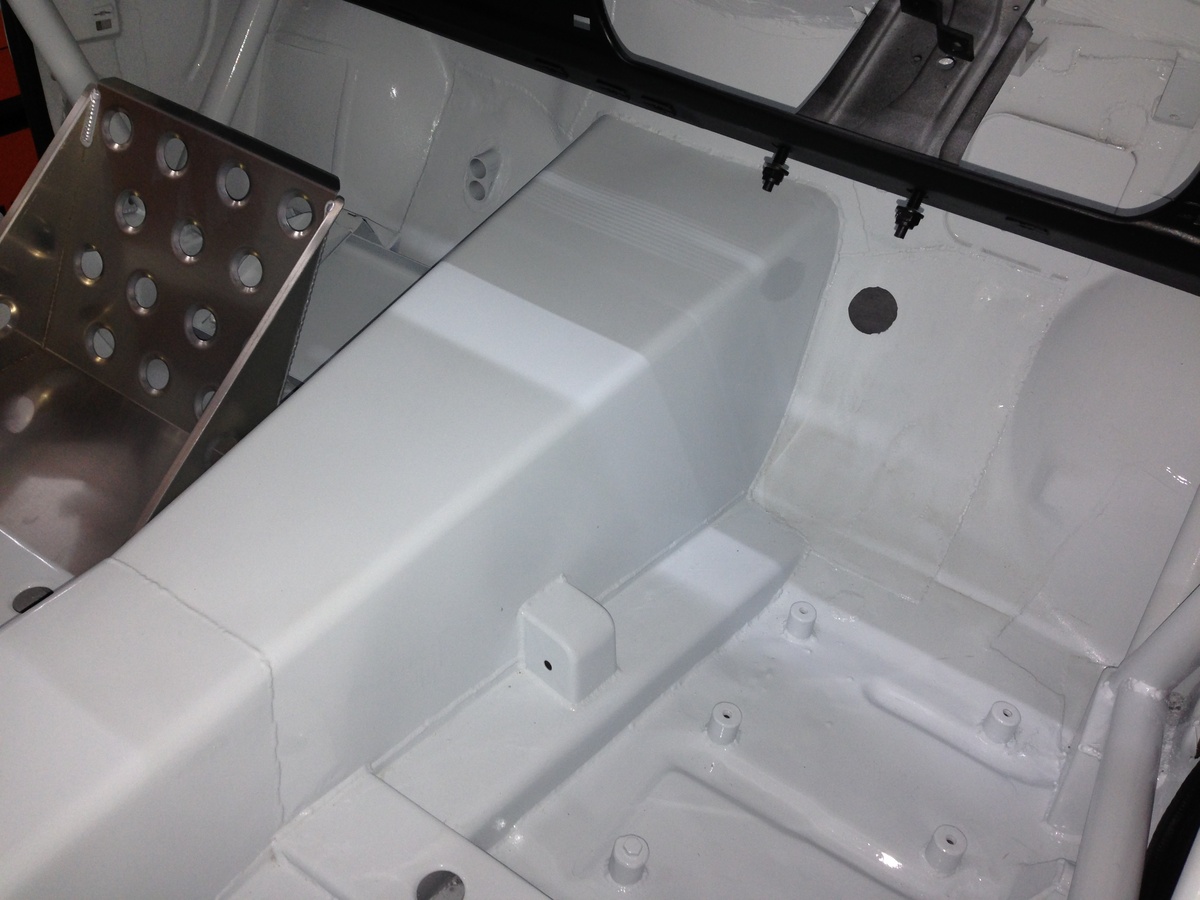

Full Safety devices weld in cage:

Extra gussets added on the door bars:

Turret conversion on the rear:

Bigger wheel arch inner's for....that's right bigger wheels! ;-)

Massive transmission tunnel ready for Quaife 60G Sequential:

A few more details on here: http://www.motorsport-tools.com/blog/a-closer-look...

By the way if your into MotoGp, I went to visit a team at Silverstone and got some brilliant pictures from in the garage here:

http://www.motorsport-tools.com/blog/motorsport-to...

Next to come:

3 way monotube suspension has arrived, looks very complicated :-)

Engine in on the dyno so should be here very soon.

Gearbox is in build at Qauife.

Our own type9 bell housing and hydraulic clutch kit is ready...will be fitted up to an AP Racing twin plate.

Cross member is being powder coated.

Cant really get stuck in without all the main parts here!

firemunki said:

On the top pic why does the plate between the cage and the shell not have one long weld instead of lots of little ones?

I've see it on lots of pics but with yours painted I'd though nows the time to ask.

Is that to allow for any slight flexing? Lighter if a full one not required? In case of a crash to absorb energy?

I think you've hit the nail on the head there.I've see it on lots of pics but with yours painted I'd though nows the time to ask.

Is that to allow for any slight flexing? Lighter if a full one not required? In case of a crash to absorb energy?

A lot of the car has been seam welded, but the roof inner isnt at all! I told thats how its done with Escort's......Some movement is left in it in places.

Im not 100% sure why though tbh, I think its for handling. I'll ask the boss who knows a lot more about them.

Update:

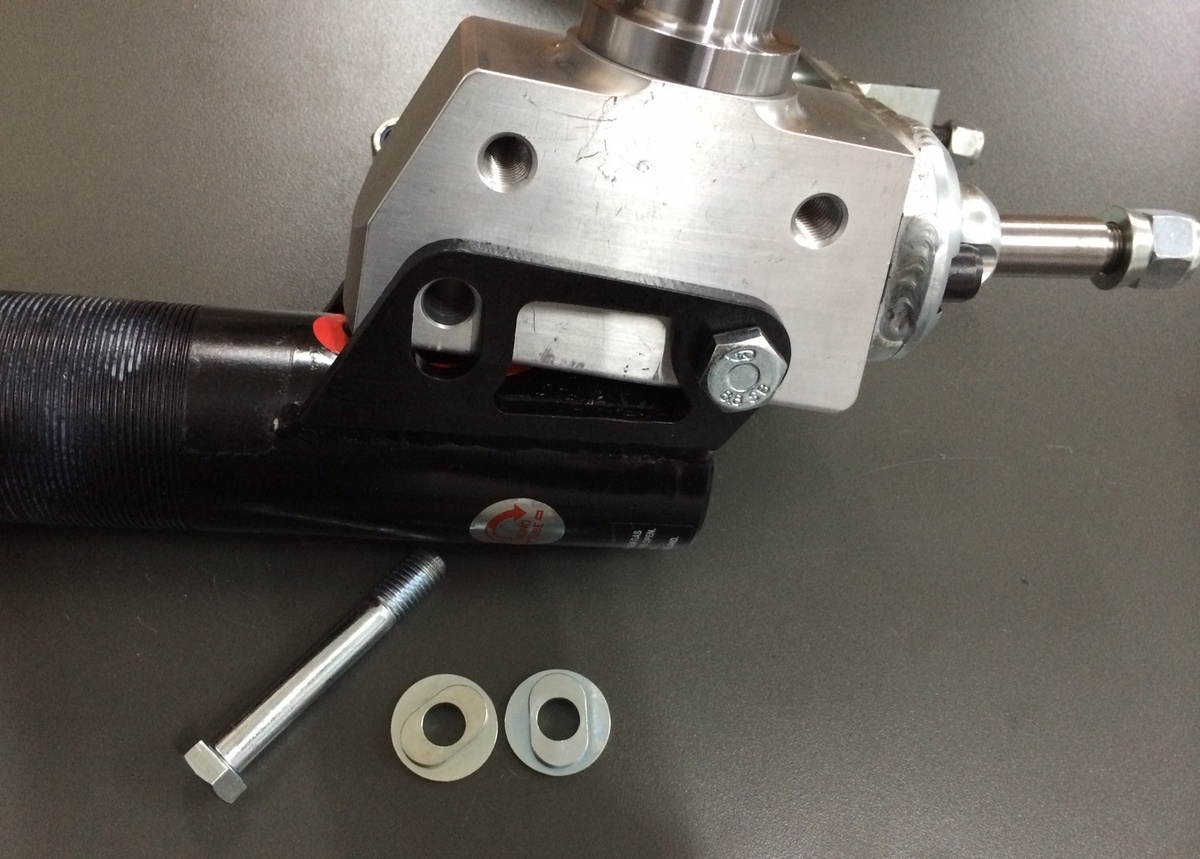

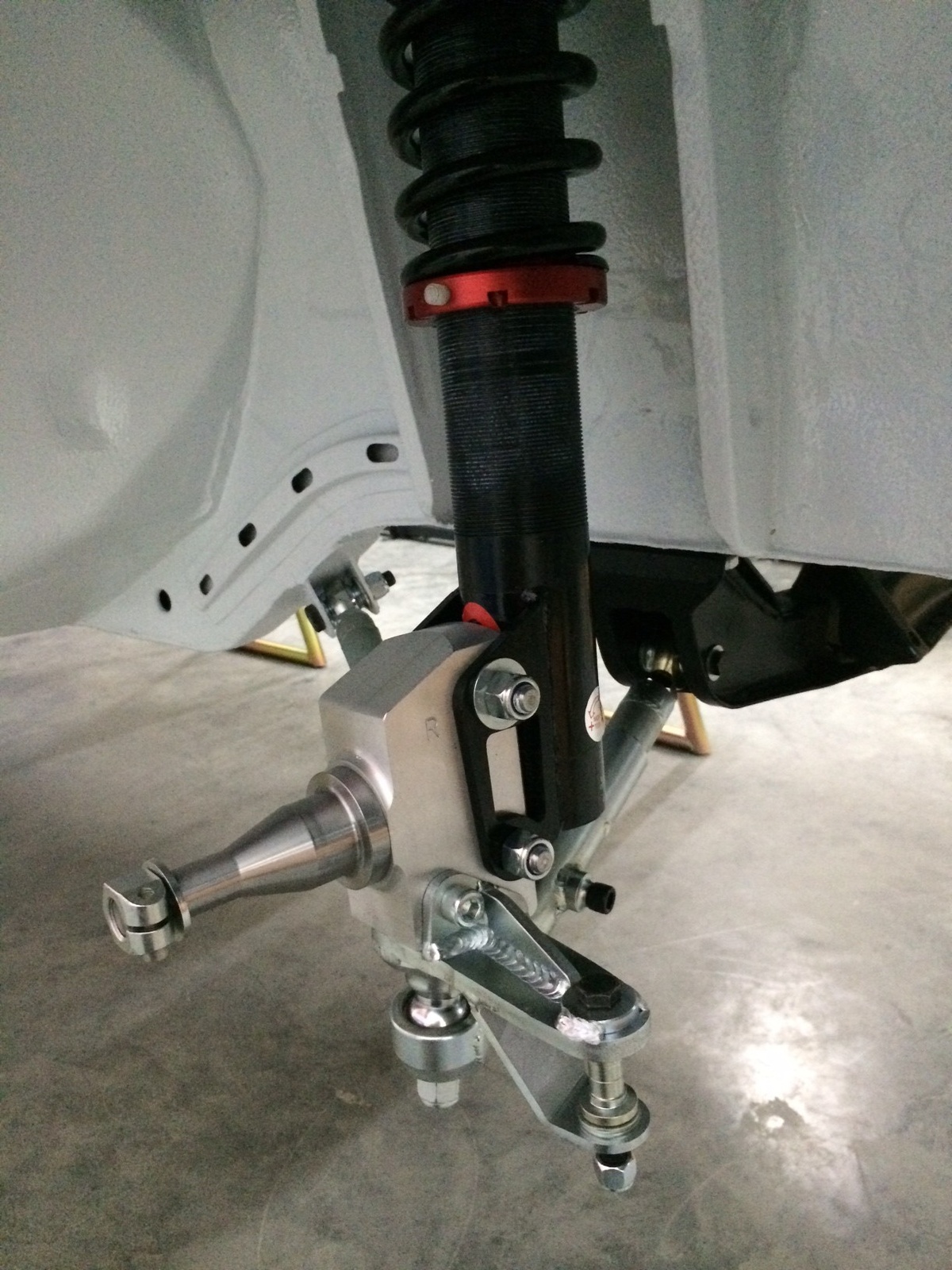

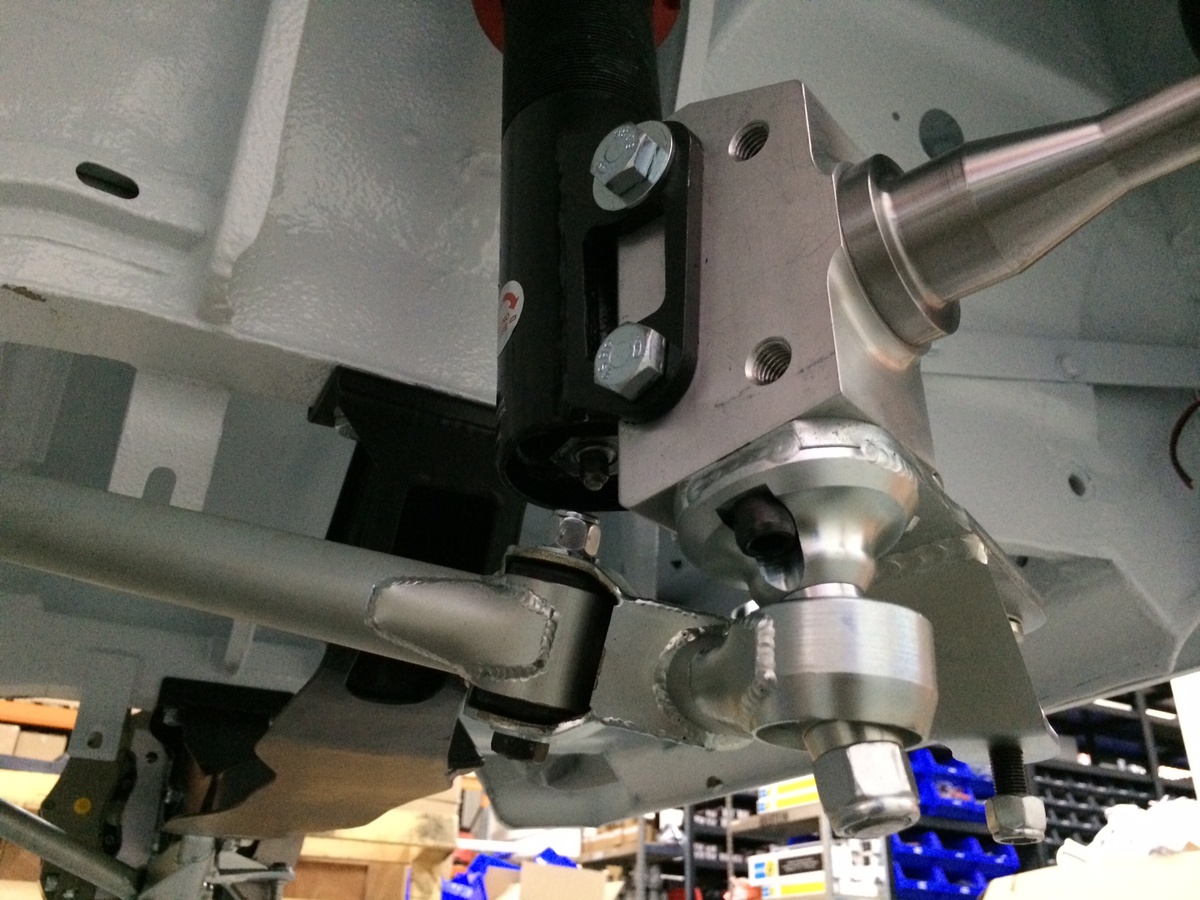

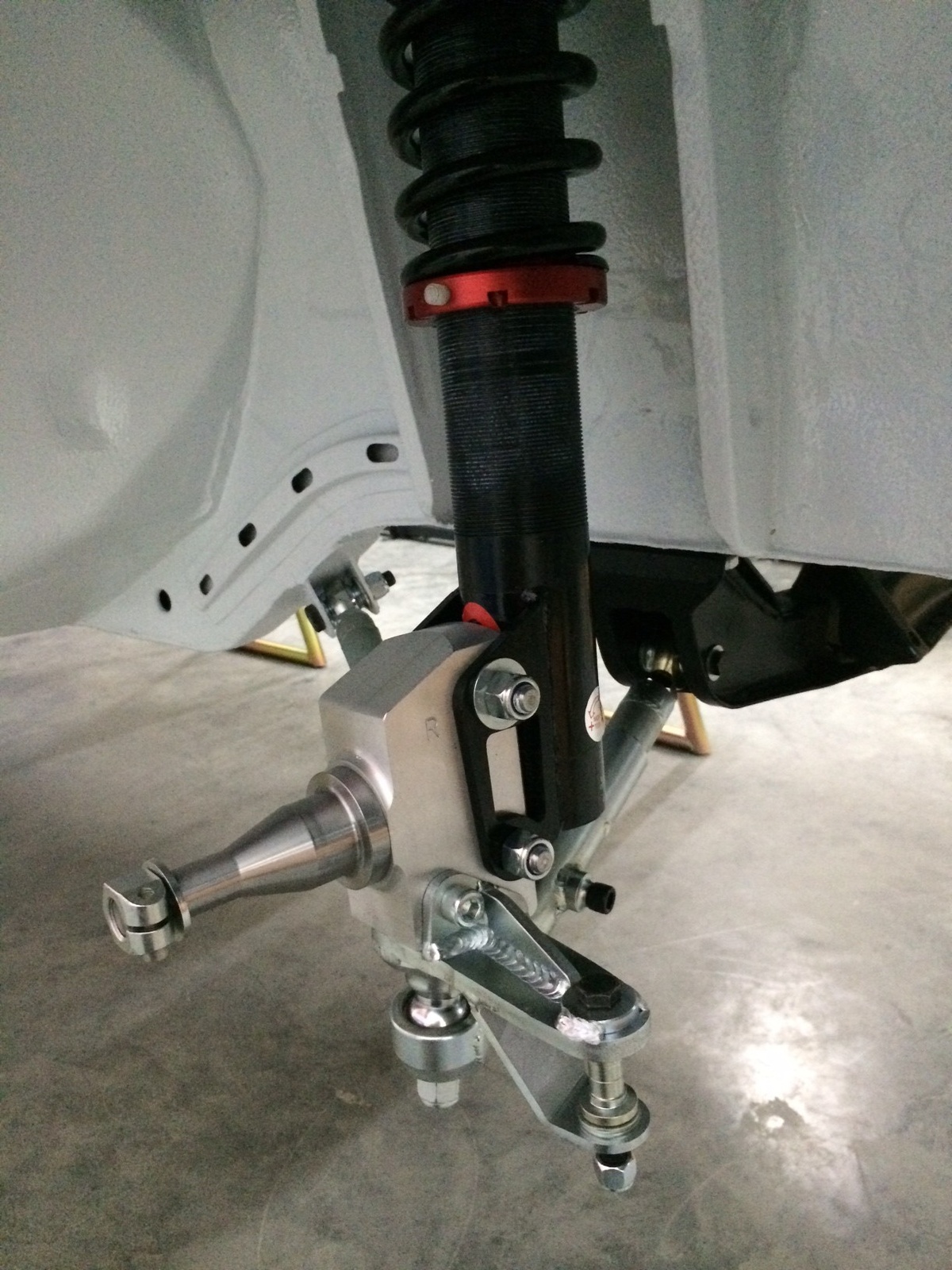

The first few bits for our Escort Mk2 project are now coming together, this week we have been putting together the front suspension. We are using AVO 3 way adjustable monotubes all round with the RIX Engineering front assembly which will be fully adjustable.

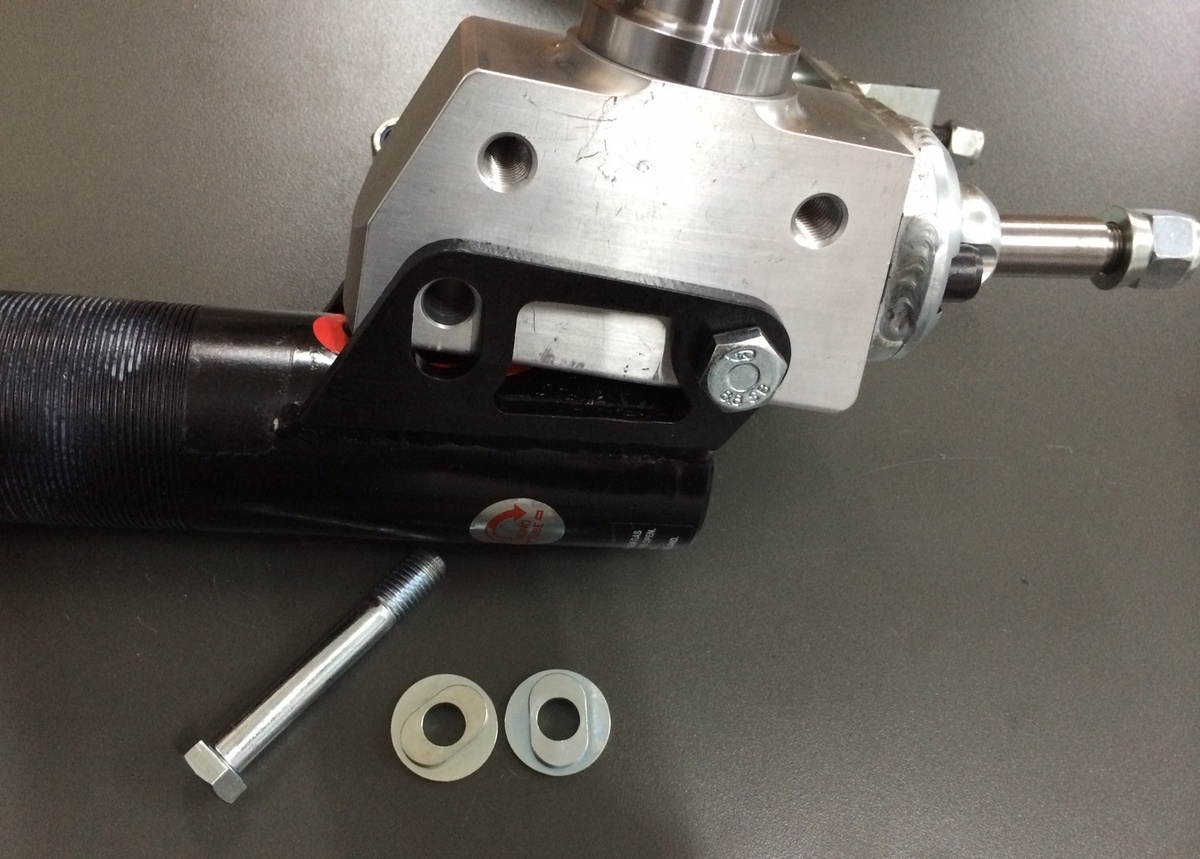

The AVO front leg with remote canister, adjustable ride height:

Mono tube, 50mm OD inserts, supplied with 250lb coilover springs and alloy top mounts:

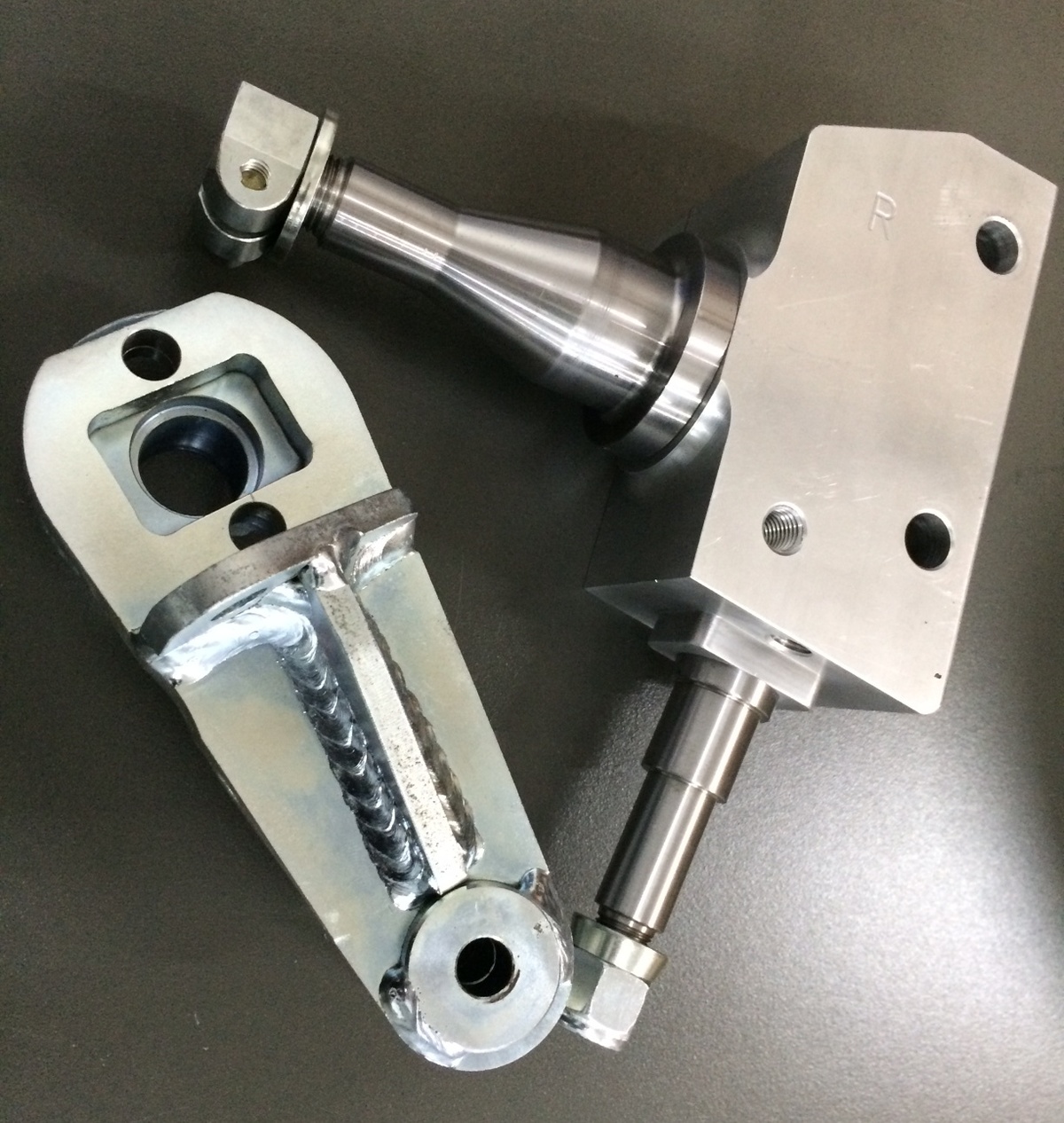

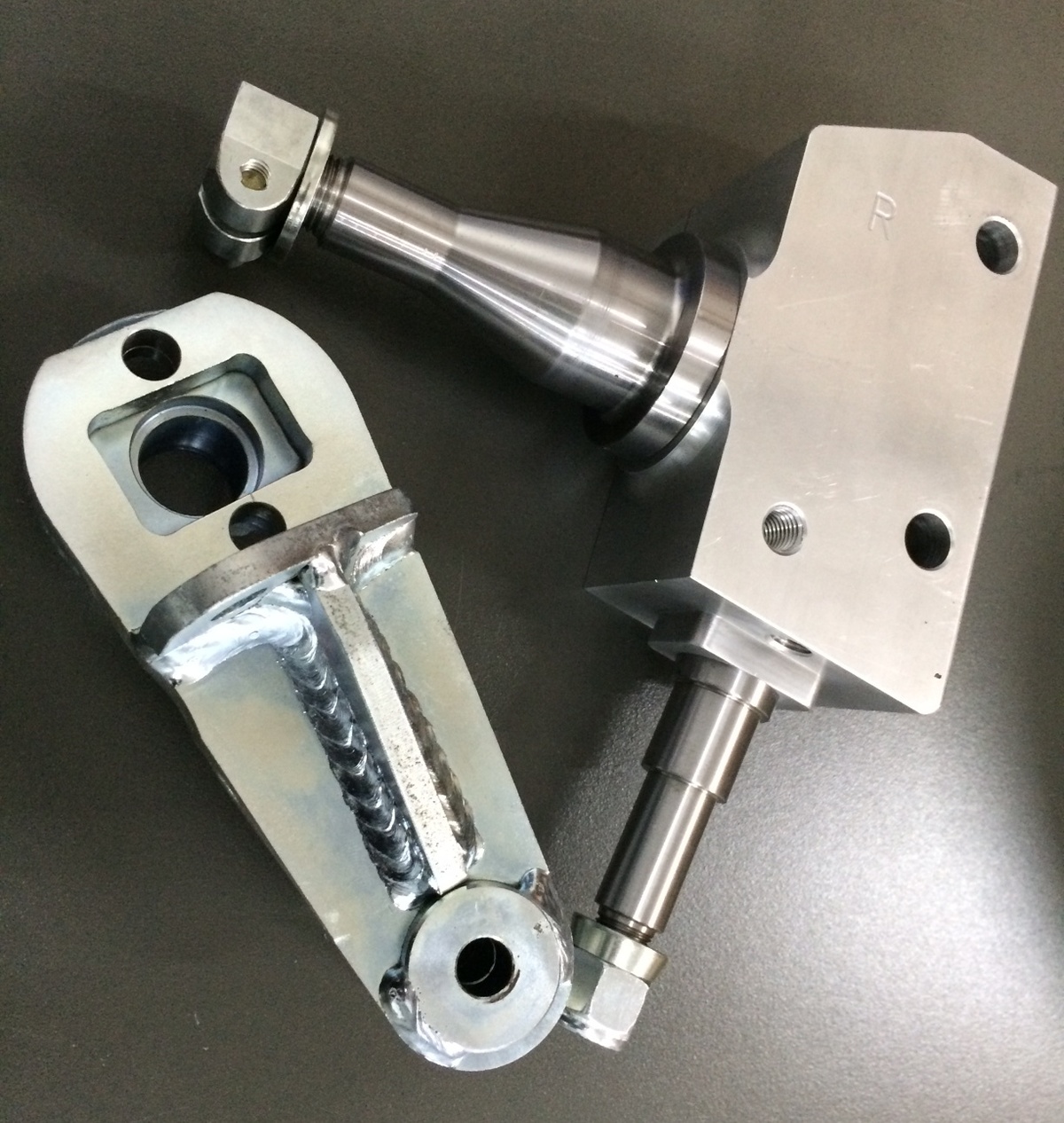

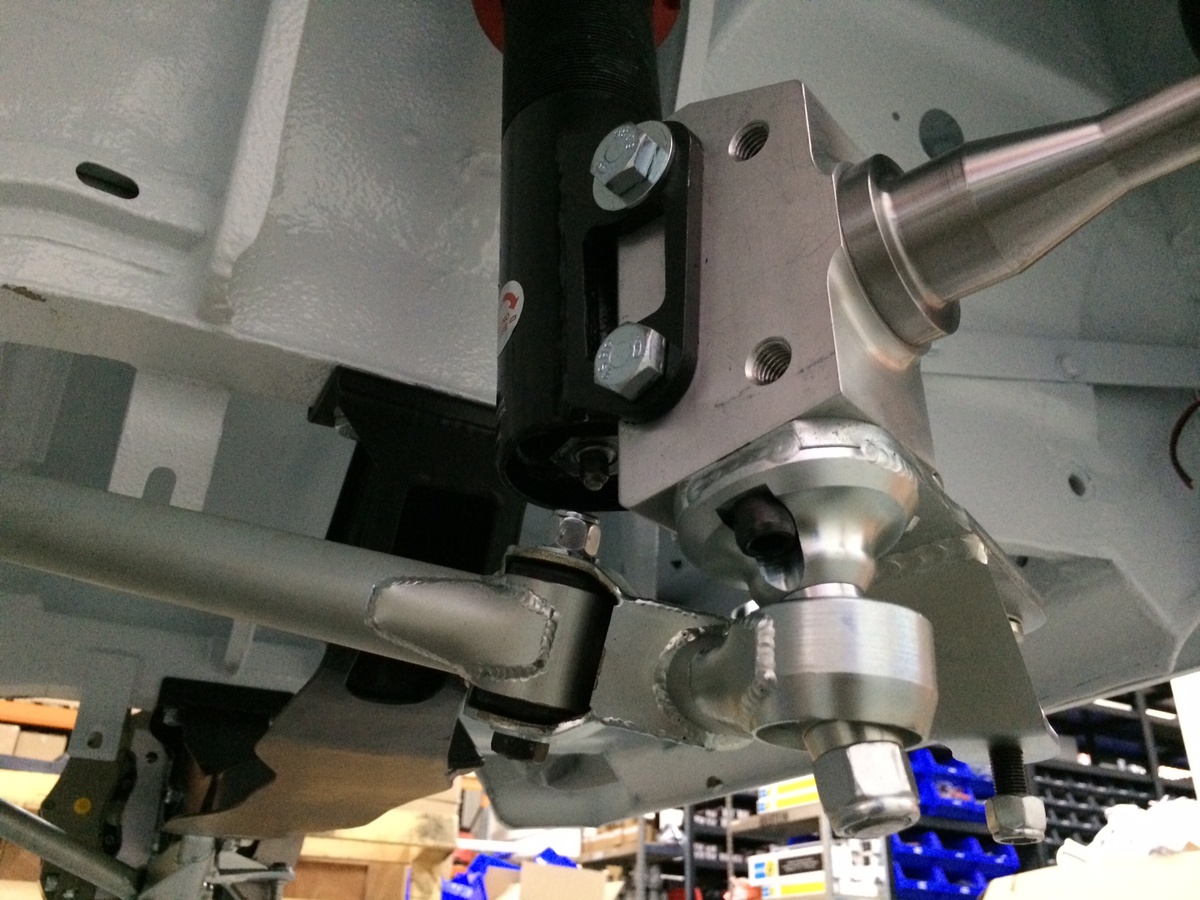

Rix Engineering alloy stub axles with special fabricated steering arms. These are precision fabricated and CNC machined for maximum strength and durability whilst keeping weight to the minimum. :-)

The steering arm attaches under the alloy upright block and over the lower TCA pin. The alloy block then bolts on the the AVO leg, these are specially designed for the RIX setup. The kit is supplied with 4 types of special camper adjustment shims, giving 7 camper adjustments by simply undoing the bolt and replacing the shims.

Tig welded TCAs and compressioin struts complete with heavy duty Aurora rod ends, all part of the Rix Engineering kit.

Also notice the billet caliper mounitng bracket, we will be using the AP Racing CP5219 4 pot calipers. (very very light weight).

Assembly pictures:

Finally bolted up to the shell, ready to fit the wheel hubs and brakes. The main advantage of this set up is the scrub radius position over the standard setup, giving less tyre resistance and more grip. The tyre wear rate will be lower so softer tyres can be used. :-)

Still waiting on an engine.....

Taken from:

http://www.motorsport-tools.com/blog/avo-3-way-adj...

The first few bits for our Escort Mk2 project are now coming together, this week we have been putting together the front suspension. We are using AVO 3 way adjustable monotubes all round with the RIX Engineering front assembly which will be fully adjustable.

The AVO front leg with remote canister, adjustable ride height:

Mono tube, 50mm OD inserts, supplied with 250lb coilover springs and alloy top mounts:

Rix Engineering alloy stub axles with special fabricated steering arms. These are precision fabricated and CNC machined for maximum strength and durability whilst keeping weight to the minimum. :-)

The steering arm attaches under the alloy upright block and over the lower TCA pin. The alloy block then bolts on the the AVO leg, these are specially designed for the RIX setup. The kit is supplied with 4 types of special camper adjustment shims, giving 7 camper adjustments by simply undoing the bolt and replacing the shims.

Tig welded TCAs and compressioin struts complete with heavy duty Aurora rod ends, all part of the Rix Engineering kit.

Also notice the billet caliper mounitng bracket, we will be using the AP Racing CP5219 4 pot calipers. (very very light weight).

Assembly pictures:

Finally bolted up to the shell, ready to fit the wheel hubs and brakes. The main advantage of this set up is the scrub radius position over the standard setup, giving less tyre resistance and more grip. The tyre wear rate will be lower so softer tyres can be used. :-)

Still waiting on an engine.....

Taken from:

http://www.motorsport-tools.com/blog/avo-3-way-adj...

Futuramic said:

firemunki said:

On the top pic why does the plate between the cage and the shell not have one long weld instead of lots of little ones?

I've see it on lots of pics but with yours painted I'd though nows the time to ask.

Is that to allow for any slight flexing? Lighter if a full one not required? In case of a crash to absorb energy?

I can't actually work out which picture you're referring to but I would imagine it's a point where the car's shell is thin, or perhaps the middle of a lesser supported section. Electric welding is usually done in long seams, it's quicker and looks better, however this can introduce a lot of heat into a particular area - which leads to distortion. I've see it on lots of pics but with yours painted I'd though nows the time to ask.

Is that to allow for any slight flexing? Lighter if a full one not required? In case of a crash to absorb energy?

One way round this is to do lots of little welds, letting the metal cool between each. Sometimes called stitch welding, for obvious reasons. I've never welded an Escort but would guess that region is prone to distortion so the fabricator has used a different technique to minimise it.

mighty kitten said:

Vauxhall agila column is much more compact than the corsa and is clutch drive so no drag if you don't use any assistance , I've done a few conversions but they work best if you ditch the eBay box of tricks and feed a proper speed signal in to get proper speed sensitive assistance . The agila has the same Mitsubishi ecu so will work with the eBay signal generator .

Thanks for the info! :-)

Got a few updates:

Done a bit of work on the rear axle, mounts for the canisters, brakes lines, etc.

Fitted the front fog for no real reason apart from board waiting for the engine!

Drum roll! First the gearbox is here:

AND THE ENGINE!!

Test fitted with the gearbox, Millington 2.5 Series 1 and Quaife 60G sequential.

Got a Tony Law manifold to go on and then can sort out the engine mounts.

A little behind on the technical write ups on the website, busy with Christmas coming up. But will have a detailed write up on the axle on Motorsport Parts - Motorsport-Tools.com soon.

Edited by Work-Shy-Wanabe on Friday 6th December 10:02

joe_90 said:

Fantastic... one question.

is the shock basically the top pivot? So when you turn the shock turns each time? What are the benefits of this and how come more 'modern' cars have a hub system? I assume/guess as you can take it to bits quickly and treat it as a replaceable/serviceable part it doesn't matter.

Its a common MacPherson strut setup, http://en.wikipedia.org/wiki/MacPherson_strutis the shock basically the top pivot? So when you turn the shock turns each time? What are the benefits of this and how come more 'modern' cars have a hub system? I assume/guess as you can take it to bits quickly and treat it as a replaceable/serviceable part it doesn't matter.

Lordbenny said:

I probably shouldn't be asking this but.....how is this being funded? What is the estimated build cost?

Centurion07 said:

I'm going to take a punt and guess that the lucky guy won't be seeing much change out of £80k. That gearbox alone must be close, if not well into five figures on it's own I would've thought.

It the demo car for http://www.motorsport-tools.com/ so we sell pretty much every part that going on it. :-) That helps with the costs! It will be rallied for many years once complete. But if you added it up, it'd make your eyes water!It mounts up pretty quick on things you might not budget for, this setup for example:

http://www.motorsport-tools.com/escort-mk1-mk2-rix...

Pretty close on the Quaife 60G

http://www.motorsport-tools.com/catalogsearch/resu...

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff