CAR PORN ALERT !!!!!! Our trackday kit car.

Discussion

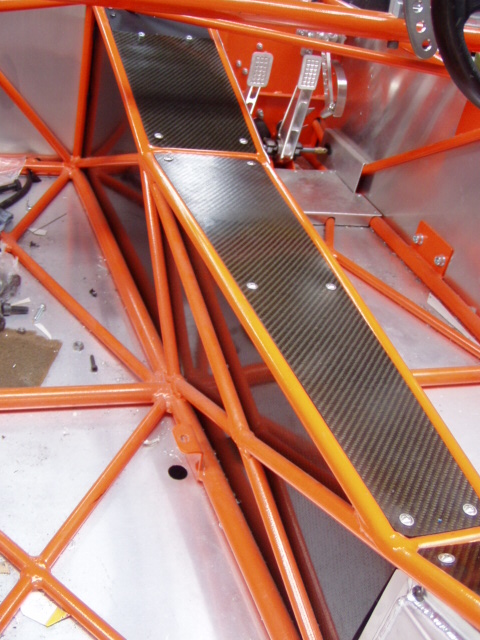

Here are a few pics of our Stuart Taylor Phoenix trackday car,presently under construction.Engine is a Fireblade 929. Loads of one off parts, made by ourselves. Alloy engine cradle, carbon tunnel, billet rack mounts and column mounts,pedals, all our own work.

In the pipeline...

titanium manifold, titanium blade type adjustable anti-roll bar ..

Can't wait to drive it!!

Geoff and Eldon. ,

P1010075 by Geoff Lee, on Flickr

P1010075 by Geoff Lee, on Flickr

P1010076 by Geoff Lee, on Flickr

P1010076 by Geoff Lee, on Flickr

P1010027 by Geoff Lee, on Flickr

P1010027 by Geoff Lee, on Flickr

P1010028 by Geoff Lee, on Flickr

P1010028 by Geoff Lee, on Flickr

5 by Geoff Lee, on Flickr

5 by Geoff Lee, on Flickr

P1010101 by Geoff Lee, on Flickr

P1010101 by Geoff Lee, on Flickr

P1010109 by Geoff Lee, on Flickr

P1010109 by Geoff Lee, on Flickr

P1010081 by Geoff Lee, on Flickr

P1010081 by Geoff Lee, on Flickr

P1010062 by Geoff Lee, on Flickr

P1010062 by Geoff Lee, on Flickr

P1010022 by Geoff Lee, on Flickr

P1010022 by Geoff Lee, on Flickr

e by Geoff Lee, on Flickr

e by Geoff Lee, on Flickr

In the pipeline...

titanium manifold, titanium blade type adjustable anti-roll bar ..

Can't wait to drive it!!

Geoff and Eldon. ,

P1010075 by Geoff Lee, on Flickr

P1010075 by Geoff Lee, on Flickr P1010076 by Geoff Lee, on Flickr

P1010076 by Geoff Lee, on Flickr P1010027 by Geoff Lee, on Flickr

P1010027 by Geoff Lee, on Flickr P1010028 by Geoff Lee, on Flickr

P1010028 by Geoff Lee, on Flickr 5 by Geoff Lee, on Flickr

5 by Geoff Lee, on Flickr P1010101 by Geoff Lee, on Flickr

P1010101 by Geoff Lee, on Flickr P1010109 by Geoff Lee, on Flickr

P1010109 by Geoff Lee, on Flickr P1010081 by Geoff Lee, on Flickr

P1010081 by Geoff Lee, on Flickr P1010062 by Geoff Lee, on Flickr

P1010062 by Geoff Lee, on Flickr P1010022 by Geoff Lee, on Flickr

P1010022 by Geoff Lee, on Flickr e by Geoff Lee, on Flickr

e by Geoff Lee, on FlickrEdited by spyder dryver on Friday 12th February 19:33

Edited by spyder dryver on Friday 12th February 19:36

Edited by spyder dryver on Friday 12th February 19:55

Edited by spyder dryver on Saturday 15th February 17:25

Edited by spyder dryver on Saturday 15th February 17:30

Edited by spyder dryver on Saturday 15th February 20:45

Edited by spyder dryver on Saturday 15th February 20:45

Hi daz! We're very busy as you can see. You're welcome to come and see the car any time. You may be able to help us source some bits of carbon sheet we need.

We are usually in the garage most weekends.

Still loads to do. Eldon is making the fuel tank, header tank, breather tank etc. I'm busy on anti roll bar design and install. And making a complete loom from scratch.

Do you know anywhere local for limited slip diff work?

Geoff.

We are usually in the garage most weekends.

Still loads to do. Eldon is making the fuel tank, header tank, breather tank etc. I'm busy on anti roll bar design and install. And making a complete loom from scratch.

Do you know anywhere local for limited slip diff work?

Geoff.

dugt said:

....won't the pedals feel weird as they will be in different arks?...

P1010109 by Geoff Lee, on Flickr

P1010109 by Geoff Lee, on FlickrFar from it Doug. This arrangement is often seen in race cars. My road going kit car has a similar arrangement. I find it perfectly OK, especially for heel and toeing.

Geoff.

Edited by spyder dryver on Saturday 15th February 17:31

MJO said:

Very nice, love the trick parts.

Not trying to start an argument here, but, do you think the Fireblade motor is powerful enough?

MJO, do yourself a favour and hitch a ride in a "bike engined car", or BEC as they are referred to.Not trying to start an argument here, but, do you think the Fireblade motor is powerful enough?

I didn't believe the performance either, given as you rightly point out, the apparent lack of outright power.

The 929 Blade engine only makes around 140hp or so, but it is the way it is delivered that makes the difference I think.

Bike engines have little or no flywheel type inertia to overcome, so they are very free revving. This, in combination with close gear ratios and overall gearing that runs out at 130mph or so, gives stunning performance. Low vehicle weight of 450kgs also helps. (Although this is mitigated somewhat when two "less than svelte" PHers climb aboard)

60mph is reached in around 4 seconds, 100mph in less than 10. I haven't measured these myself, I am quoting other sources, but these figures are typical. Bigger engined BECs are quicker still.

Acceleration through the gears from 50 to 130 is incredible.

Get yourself to a trackday and blag a ride. You'll be stunned!

Geoff.

P1010113 by Geoff Lee, on Flickr

P1010113 by Geoff Lee, on Flickr P1010115 by Geoff Lee, on Flickr

P1010115 by Geoff Lee, on Flickr P1010117 by Geoff Lee, on Flickr

P1010117 by Geoff Lee, on FlickrEdited by spyder dryver on Saturday 15th February 20:49

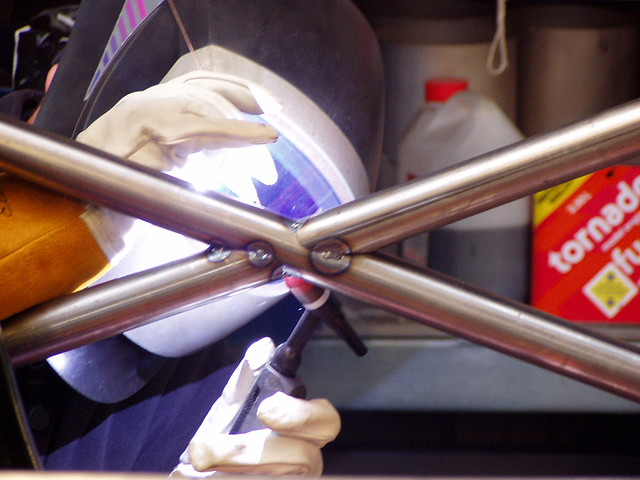

This weekend we are mostly been making...a Titanium exhaust manifold, with Eldon on duty on the TIG set.

Not finished yet but well on the way. Not the easiest of materials to work with worth the effort. Making a collector is going to be fun as Titanium doesn't like being bent. Eldon says its a piece of p155 to weld though.

Not finished yet but well on the way. Not the easiest of materials to work with worth the effort. Making a collector is going to be fun as Titanium doesn't like being bent. Eldon says its a piece of p155 to weld though.

Edited by spyder dryver on Monday 10th March 17:22

Edited by spyder dryver on Friday 12th February 19:44

selnic said:

..... would that be the great Eldon Sellars from Heanor, former bike crasher and pigeon-s te welder ordinaire???

te welder ordinaire???

Would that be his cousin and ex mini clubman owner? te welder ordinaire???

te welder ordinaire???Here is Eldon in action. And I mean inaction!

P1010124 by Geoff Lee, on Flickr

P1010124 by Geoff Lee, on FlickrEdited by spyder dryver on Saturday 15th February 17:17

MJO said:

....... if I was in your position I'd definately consider something with more capacity.

Feel free to tell me to shut up, these are just my thoughts.

I wouldn't dream of telling you to shut up. Your point is a fair one. The 929 engine came along at the right price, especially when compared (price wise) to the zx12 or busa units. Feel free to tell me to shut up, these are just my thoughts.

IF we do get used to it to the point of boredom I have a plan which involves a small turbo, a medium sized intercooler and yet more titanium. This is, hopefully, far into the future.

The 929 is cheaply replaceable too.

And talking of titanium, the system is virtually finished.

Second pic shows the slash cut tailpipe poking through our (very) second hand bodywork.( Tim Gray's old bodywork from his Championship winning Phoenix, hence the no.1 )

Geoff.

Edited by spyder dryver on Friday 12th February 19:47

After a lengthy delay work has re-commenced, featuring Eldon on the TIG set.

The titanium blade front anti-roll bar is coming along nicely. Just the mounts to make. Possibly needle roller? It is probably going to be too stiff, even with both ends at minimum strength, but it is easy to make it less stiff. Just machine some thickness off the blades.

The alloy tank shown contains the original fuel pump for the Blade engine. It is fed from the usual tank at the back via copper fuel pipes which are attached along the chassis using specially made alloy clamp fixings, shaped to fit the pipes and the chassis. A bit OTT but we do it because we can.

Geoff and Eldon.

P1010011 by Geoff Lee, on Flickr

P1010011 by Geoff Lee, on Flickr

P1010037 by Geoff Lee, on Flickr

P1010037 by Geoff Lee, on Flickr

P1010119 by Geoff Lee, on Flickr

P1010119 by Geoff Lee, on Flickr

The titanium blade front anti-roll bar is coming along nicely. Just the mounts to make. Possibly needle roller? It is probably going to be too stiff, even with both ends at minimum strength, but it is easy to make it less stiff. Just machine some thickness off the blades.

The alloy tank shown contains the original fuel pump for the Blade engine. It is fed from the usual tank at the back via copper fuel pipes which are attached along the chassis using specially made alloy clamp fixings, shaped to fit the pipes and the chassis. A bit OTT but we do it because we can.

Geoff and Eldon.

P1010011 by Geoff Lee, on Flickr

P1010011 by Geoff Lee, on Flickr P1010037 by Geoff Lee, on Flickr

P1010037 by Geoff Lee, on Flickr P1010119 by Geoff Lee, on Flickr

P1010119 by Geoff Lee, on FlickrEdited by spyder dryver on Friday 22 August 21:31

Edited by spyder dryver on Saturday 15th February 17:35

Edited by spyder dryver on Saturday 15th February 17:38

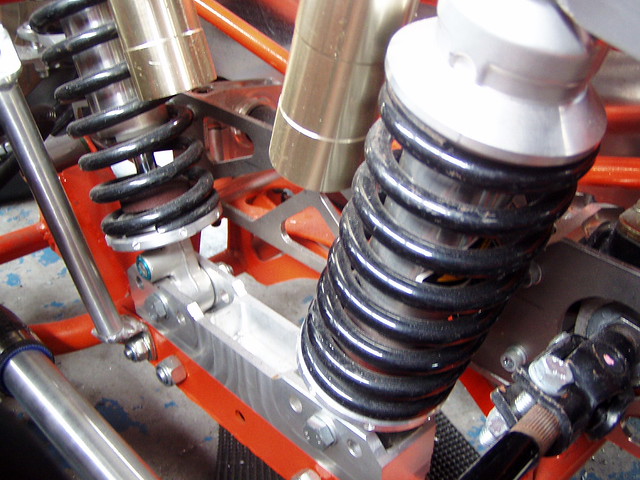

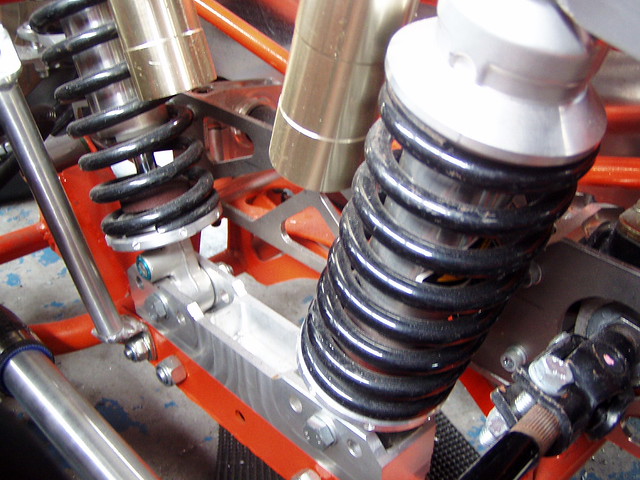

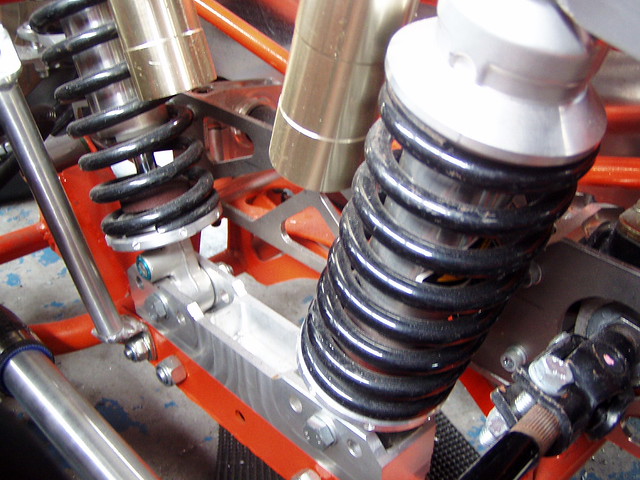

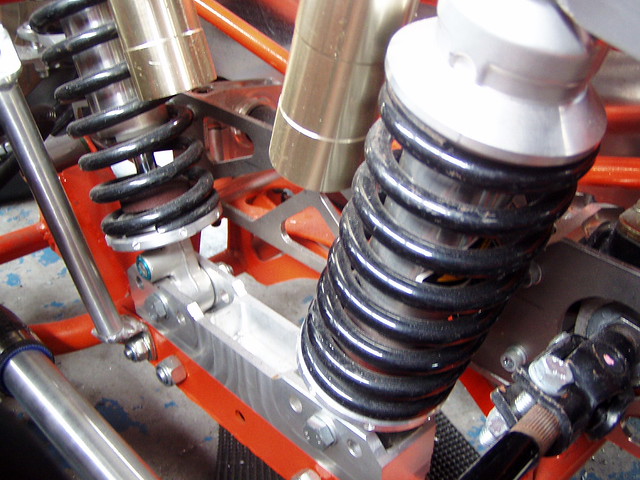

The front suspension is now fitted featuring R1 shocks, suitably resprung.

The rear suspension is coming along nicely, again using R1 units. The next pic shows a mock up of the rear caliper positioning. These are radial mount ZX12 four pots.

Fuel tank is ready. Eldon's TIG welding again.It slots nicely between the alloy rear cage stays.

Geoff and Eldon.

kk by Geoff Lee, on Flickr

kk by Geoff Lee, on Flickr

b by Geoff Lee, on Flickr

b by Geoff Lee, on Flickr

g by Geoff Lee, on Flickr

g by Geoff Lee, on Flickr

h by Geoff Lee, on Flickr

h by Geoff Lee, on Flickr

The rear suspension is coming along nicely, again using R1 units. The next pic shows a mock up of the rear caliper positioning. These are radial mount ZX12 four pots.

Fuel tank is ready. Eldon's TIG welding again.It slots nicely between the alloy rear cage stays.

Geoff and Eldon.

kk by Geoff Lee, on Flickr

kk by Geoff Lee, on Flickr b by Geoff Lee, on Flickr

b by Geoff Lee, on Flickr g by Geoff Lee, on Flickr

g by Geoff Lee, on Flickr h by Geoff Lee, on Flickr

h by Geoff Lee, on FlickrEdited by spyder dryver on Saturday 15th February 17:43

rhinochopig said:

Looks great and very impressed by the level of bespoke engineering. However, you say this going to be a track car so I will add a voice of caution. I would be amazed that your exhaust set-up will get you anywhere near the noise restrictions for most UK circuits. You really should look at having the option of fitting a second can for low noise circuits.

As a comparison, my 'Bird westy had a massive can, heavily baffled, and yet still measured 101dBA on the shuftyscope. It'd be a shame to make a lovely Ti system that you can't use on a track.

Good job though

Thanks everyone for your positive reactions. As regarding the exhaust, the can is a bog standard ZX12 Titanium unit. It is not at all "straight through".As a comparison, my 'Bird westy had a massive can, heavily baffled, and yet still measured 101dBA on the shuftyscope. It'd be a shame to make a lovely Ti system that you can't use on a track.

Good job though

We are hoping that it will be quiet enough for trackday use. It should, after all, be no louder than a standard bike. We will find out shortly as we are hoping to fire it up soon. We could fit a larger diameter can if necessary. We are retaining the standard airbox.

Here is a pic of the APRILIA RSV fan setup. They are made by SPAL and are silly cheap to buy.

In answer to a previous post, titanium is cheap enough when retrieved from the scrap bin! Airbox support will be titanium.

Front splitter will be composite construction, again from the bin.

And the paddles don't go round with the wheel! ( as per previous posts)

Geoff and Eldon.

P1010061 by Geoff Lee, on Flickr

P1010061 by Geoff Lee, on FlickrEdited by spyder dryver on Saturday 15th February 17:48

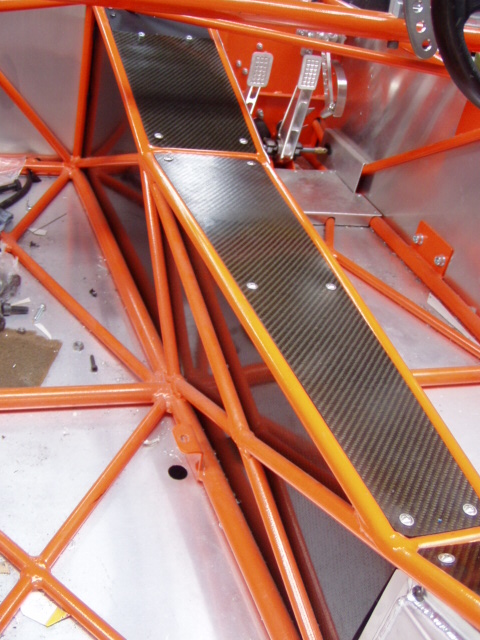

After yet more delay ( due in the main to health reasons) we have got a few more jobs out of the way.

The propshaft is fitted and the tunnel clothed in lovely carbon fibre.

The front mounted auxiliary fuel tank/ swirl pot is now properly mounted.

Next jobs are cooling system and then the body to be fitted.

Geoff & Eldon.

P1010041 by Geoff Lee, on Flickr

P1010041 by Geoff Lee, on Flickr

P1010035 by Geoff Lee, on Flickr

P1010035 by Geoff Lee, on Flickr

P1010034 by Geoff Lee, on Flickr

P1010034 by Geoff Lee, on Flickr

P1010031 by Geoff Lee, on Flickr

P1010031 by Geoff Lee, on Flickr

The propshaft is fitted and the tunnel clothed in lovely carbon fibre.

The front mounted auxiliary fuel tank/ swirl pot is now properly mounted.

Next jobs are cooling system and then the body to be fitted.

Geoff & Eldon.

P1010041 by Geoff Lee, on Flickr

P1010041 by Geoff Lee, on Flickr P1010035 by Geoff Lee, on Flickr

P1010035 by Geoff Lee, on Flickr P1010034 by Geoff Lee, on Flickr

P1010034 by Geoff Lee, on Flickr P1010031 by Geoff Lee, on Flickr

P1010031 by Geoff Lee, on FlickrEdited by spyder dryver on Tuesday 3rd November 19:37

Edited by spyder dryver on Saturday 15th February 17:52

Work has started again in earnest. This could be the last big push!

I have been doing the wiring whilst Eldon has knocked up the header and breather tanks pictured.

Bulkhead area is nearly finished with ECU and battery located.

Eldon is now making an instrument pod followed by various infill panels.

Fuel and water next weekend methinks.

More pics to follow....

Geoff & Eldon.

mm by Geoff Lee, on Flickr

mm by Geoff Lee, on Flickr

P1010132 by Geoff Lee, on Flickr

P1010132 by Geoff Lee, on Flickr

kk by Geoff Lee, on Flickr

kk by Geoff Lee, on Flickr

I have been doing the wiring whilst Eldon has knocked up the header and breather tanks pictured.

Bulkhead area is nearly finished with ECU and battery located.

Eldon is now making an instrument pod followed by various infill panels.

Fuel and water next weekend methinks.

More pics to follow....

Geoff & Eldon.

mm by Geoff Lee, on Flickr

mm by Geoff Lee, on Flickr P1010132 by Geoff Lee, on Flickr

P1010132 by Geoff Lee, on Flickr kk by Geoff Lee, on Flickr

kk by Geoff Lee, on FlickrEdited by spyder dryver on Tuesday 3rd November 19:35

Edited by spyder dryver on Saturday 15th February 17:54

Edited by spyder dryver on Saturday 15th February 20:53

Another day in the garage, slaving over a hot wiring loom!

Anyway, she starts and she runs. No dramas, only one minor water leak.

Eldon has nearly finished the instrument pod to house the tacho and digidash. Still a work in progress at this stage. It will be sprayed wrinkle finish black.

It mounts onto the steering column via the CNC clamp to which it will be welded.

Just the rear lights and gear position indicator to wire up now. Then airbox to fit, inner wheelarches to make...........

Geoff & Eldon.

P1010065 by Geoff Lee, on Flickr

P1010065 by Geoff Lee, on Flickr

uu by Geoff Lee, on Flickr

uu by Geoff Lee, on Flickr

Anyway, she starts and she runs. No dramas, only one minor water leak.

Eldon has nearly finished the instrument pod to house the tacho and digidash. Still a work in progress at this stage. It will be sprayed wrinkle finish black.

It mounts onto the steering column via the CNC clamp to which it will be welded.

Just the rear lights and gear position indicator to wire up now. Then airbox to fit, inner wheelarches to make...........

Geoff & Eldon.

P1010065 by Geoff Lee, on Flickr

P1010065 by Geoff Lee, on Flickr uu by Geoff Lee, on Flickr

uu by Geoff Lee, on FlickrEdited by spyder dryver on Tuesday 3rd November 19:36

Edited by spyder dryver on Saturday 15th February 17:57

Furyous said:

Some very nice fabbing going on there.

Im interested in the use of R1 shocks. Do you think the damping will be valved up ok to work on the car ?

I can understand changing the springs, but even if they have adjustable damping,how do you know they will work ?

Hi there. The simple answer is that we don't know for sure. The use of R1 shocks is a little bit of a stab in the dark.Im interested in the use of R1 shocks. Do you think the damping will be valved up ok to work on the car ?

I can understand changing the springs, but even if they have adjustable damping,how do you know they will work ?

On the plus side they are light, double adjustable, have needle rollers at one end and cheap.

We have changed the springs to 250 lb/inch. This is around half the value of the original R1 spring. We removed the preload gubbins and made new ally top and bottom caps.

The car is, as yet, untested but when we (un)scientifically bounced on the rear of the car I can report that the damping felt under-damped on low setting and maybe over-damped on full setting. The difference between the two extremes of setting is vast, far more than I expected. If the rebound is set at full the car takes ages to come up to rest. Well, about two seconds. Our good friend Tim Gray, the multiple RGB champion, has performed this test on the car and according to his calibrated spidey-sense he says it feels OK in comparison to his car.

The proof of the pudding...etc. etc.

Am I right in thinking that if the standard damping controls full deflection movement on a 500lb spring that it should be more than adequate with half the springrate?

We are hoping to go on a trackday soon, just as a shakedown session initially. The car has a few.. how shall I put it..unusual features which may or may not cause problems.

The R1 shocks, the bike rear calipers, the titanium anti roll bar...

People have said in the past " why don't you just buy proven stuff off the shelf, like everyone else?" The answer lies in the second part of the question.

Well, we like to be different, despite the inevitable headaches. We make everything we can.

The end result will almost certainly be more capable as a trackday car than we are as drivers. Neither of us could drive a greasy stick up a dogs arse!

We were hoping to take the car to Stafford kit car show but Eldon is on holiday. Bah.

Thanks for your interest anyway and for raising a (hopefully) not too valid point.

Geoff & Eldon.

Edited by spyder dryver on Tuesday 3rd November 19:36

Busy day today, Eldon has fabbed and fitted the inner rear wheelarches whilst I have finished the wiring and fitted the seats and harnesses amongst other things. The instrument pods are fitted and looking good. The STACK temp gauge is a nice piece of kit.

The car is nearly ready for it's baptism. We are looking for a suitable trackday venue to perform a shakedown test.

Only a few more jobs to sort, we are leaving the front and rear diffusers until winter time.

Pics are not up to usual standard. They were taken in a hurry.

We'll wheel the car outside next week and take some better pics.

If Steve is reading this, Hi Steve!!

Geoff.

S4010023 by Geoff Lee, on Flickr

S4010023 by Geoff Lee, on Flickr

S4010024 by Geoff Lee, on Flickr

S4010024 by Geoff Lee, on Flickr

S4010020 by Geoff Lee, on Flickr

S4010020 by Geoff Lee, on Flickr

The car is nearly ready for it's baptism. We are looking for a suitable trackday venue to perform a shakedown test.

Only a few more jobs to sort, we are leaving the front and rear diffusers until winter time.

Pics are not up to usual standard. They were taken in a hurry.

We'll wheel the car outside next week and take some better pics.

If Steve is reading this, Hi Steve!!

Geoff.

S4010023 by Geoff Lee, on Flickr

S4010023 by Geoff Lee, on Flickr S4010024 by Geoff Lee, on Flickr

S4010024 by Geoff Lee, on Flickr S4010020 by Geoff Lee, on Flickr

S4010020 by Geoff Lee, on FlickrEdited by spyder dryver on Saturday 15th February 20:15

AlexVTR said:

Love your Pedal Set !

Will you have Bias Brake control on the dash/switch panel ?

Hi Alex. The bias control is near the drivers right knee. It can be seen three pictures up.

Will you have Bias Brake control on the dash/switch panel ?

I love the pedal set too! One of my better creations!

Both seats are now fitted and roll cage padding added. The car needs a basic alignment check, mirrors fitting, bonnet catches, a few other small jobs... nothing major. We are leaving some jobs till winter and hoping to get a trackday in soon. Probably Teeside.

I'll post some more pics tomorrow.

Geoff.

Here is the result of some of Sundays labours. The roll cage padding is the proper FIA spec stuff and is fixed using concealed tywraps. We like the finished result. The two small triangular openings in the top of the cage will be receiving carbon infill panels.

It's getting so close now, I can smell it! Really should lay off the radishes.

Geoff & Eldon.

It's getting so close now, I can smell it! Really should lay off the radishes.

Geoff & Eldon.

Edited by spyder dryver on Tuesday 3rd November 19:34

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff