Riley Elf restoration dilemma.......

Discussion

The Story:

Having unexpectedly acquired the car of my boyhood dreams (a Merc fronted mini) due to some boredom initiated Ebay surfing at work one day I’m now stuck with a dilemma and thought I’d canvass opinion….

The Car:

Has obviously been inspired by the old W&P “50MAR” car and other similar ones of its day, the headlight conversion looks like a good job. Despite the awful choice of kit the standard of fitting and paint finish is excellent and clearly done by someone with professional facilities / experience. The roof conversion however is a little more agricultural…….

The strengthening of the shell has been undertaken by welding 1/4 inch plate to the inner sill and first few inches of the floorpan where the door opening is, there is no strengthening at all behind the B pillar. Additionally there is a length of 1 inch box section bolted underneath the car from front to rear on each side of the tunnel midway between the tunnel and the sill.

The rear subframe mounting points have rotted through and on inspection the tin worm has worked its way into the rear pockets and started on the inner sill there as well.

The boot floor appears good up to the “Elf extension panel” and then becomes holier than swiss cheese, to get round this someone has glued a patch panel in place with fibreglass and filled under the boot board supports and any other cavity they could find in the boot with expanding foam then painted the whole lot with underseal (actually a very good cover up job – pity they didn’t spend the time doing it properly!)

So far I have extracted a bin liner full of expanding foam from the boot and rear door pockets and I can also see some round the headlight bowls, rear subframe mounting points and behind the body kit.

The Dilemma:

I love Riley Elfs and my heart really wants to get this one back on the road in time for summer BUT my garage is tiny (there’s 2 inches between the back of the car and the door when the door is closed so I can’t even walk round it!) and I’ve never taken on anything that’s quite as bad as this – Who knows how much other foam is in there!. I’ve got the tools to do the preparation work and am happy to bring in hired help for welding etc but looking at it now it feels like such a huge job I’m not really sure where to start….

Does anyone have any advice / experiences to share?

Having unexpectedly acquired the car of my boyhood dreams (a Merc fronted mini) due to some boredom initiated Ebay surfing at work one day I’m now stuck with a dilemma and thought I’d canvass opinion….

The Car:

Has obviously been inspired by the old W&P “50MAR” car and other similar ones of its day, the headlight conversion looks like a good job. Despite the awful choice of kit the standard of fitting and paint finish is excellent and clearly done by someone with professional facilities / experience. The roof conversion however is a little more agricultural…….

The strengthening of the shell has been undertaken by welding 1/4 inch plate to the inner sill and first few inches of the floorpan where the door opening is, there is no strengthening at all behind the B pillar. Additionally there is a length of 1 inch box section bolted underneath the car from front to rear on each side of the tunnel midway between the tunnel and the sill.

The rear subframe mounting points have rotted through and on inspection the tin worm has worked its way into the rear pockets and started on the inner sill there as well.

The boot floor appears good up to the “Elf extension panel” and then becomes holier than swiss cheese, to get round this someone has glued a patch panel in place with fibreglass and filled under the boot board supports and any other cavity they could find in the boot with expanding foam then painted the whole lot with underseal (actually a very good cover up job – pity they didn’t spend the time doing it properly!)

So far I have extracted a bin liner full of expanding foam from the boot and rear door pockets and I can also see some round the headlight bowls, rear subframe mounting points and behind the body kit.

The Dilemma:

I love Riley Elfs and my heart really wants to get this one back on the road in time for summer BUT my garage is tiny (there’s 2 inches between the back of the car and the door when the door is closed so I can’t even walk round it!) and I’ve never taken on anything that’s quite as bad as this – Who knows how much other foam is in there!. I’ve got the tools to do the preparation work and am happy to bring in hired help for welding etc but looking at it now it feels like such a huge job I’m not really sure where to start….

Does anyone have any advice / experiences to share?

Edited by uksurvivor on Wednesday 10th December 13:47

guru_1071 said:

the worse bits about yours (imho) are the terrible 1980's body kit and the roof. elfs just dont look right with the top chopped as it makes the whole car 'look' longer - the heinz ones got round this by making a 2cv type roof and retaining the side windows.

as for the welding its a case of getting stuck in and measuring twice cutting once!

anything is possible with rotten old minis...........

this ones 'nearly' done now.

Guru - Thanks for the response, are you telepathic? That picture of the bracing may well be the answer to the problem that is bothering me! How to hold the bodyshell square when I remove the rear subframe.as for the welding its a case of getting stuck in and measuring twice cutting once!

anything is possible with rotten old minis...........

this ones 'nearly' done now.

One other problem you may be able to help with - I've never touched a hydro subframe before can you let them down yourself?

Totally agree on the bodykit front but semi afraid to remove it as I'm fearful of what lurks beneath.

MHM said:

No advice other than good luck !

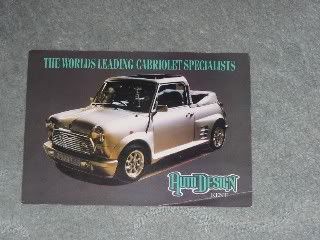

But as a point of interest i reckon that was done by Auto design in paddock wood, kent. That roof and body kit are typical of the cars they turned out back in the day, and it wouldnt surprise me if they did that to the front.

Thanks for the tip, previous owner had no history so I'm investigating all leads....But as a point of interest i reckon that was done by Auto design in paddock wood, kent. That roof and body kit are typical of the cars they turned out back in the day, and it wouldnt surprise me if they did that to the front.

OK so I'm desperate to get going with the subframe removal but still have concerns over the floppy bodyshell I'll be left with when its gone. The bracing idea appeals for 2 reasons:

1. Having read hundreds of the posts on PH/Classic Minis it seems Guru knows his bodyshell reconstruction and if its good enough for him .....

2. I was always going to brace the shell somehow anyway because removing the roof has so obviously weakened the shell (or was it failure to strengthen it elsewhere?)

New dilemma, should I brace the shell as I intended to and add "restoration bracing" on top before removing the subframe or just go for it without the bracing?

FYI I was going to brace like this (cheers for the as never normally seen picture dogfather!) using box section, then go across the back of the seat to brace across the car, this would keep everything out of sight, the disadvantage being the rear pockets would shrink a little and my rear interior panels would probably have to be custom jobs...

also has anyone ever seen the bracing in a real mini cabrio? What is the wierd B piller extension for? Presumably I could do worse than copy whatever strengthening they were designed with....?

1. Having read hundreds of the posts on PH/Classic Minis it seems Guru knows his bodyshell reconstruction and if its good enough for him .....

2. I was always going to brace the shell somehow anyway because removing the roof has so obviously weakened the shell (or was it failure to strengthen it elsewhere?)

New dilemma, should I brace the shell as I intended to and add "restoration bracing" on top before removing the subframe or just go for it without the bracing?

FYI I was going to brace like this (cheers for the as never normally seen picture dogfather!) using box section, then go across the back of the seat to brace across the car, this would keep everything out of sight, the disadvantage being the rear pockets would shrink a little and my rear interior panels would probably have to be custom jobs...

also has anyone ever seen the bracing in a real mini cabrio? What is the wierd B piller extension for? Presumably I could do worse than copy whatever strengthening they were designed with....?

Edited by uksurvivor on Monday 8th December 16:45

Edited by uksurvivor on Wednesday 10th December 13:44

Might have to rethink that plan! I thought I'd make a start on clearing my minimalist garage today ready for the work to begin in earnest.... Pushed the car out with great difficulty and jacked her up ready for the first 'proper' look underneath. Whilst she was up in the air I removed the shoes from the nearside rear drums as the slave is siezed on (hence the less than easy pushing task!) full renovation can take place off the car later (not todays priority).

As I expected the subframe mounting panel is fully shot and the floorpans have also been repaired by Stevie Wonder at some stage , The agricultural shell strengthening can also be seen complete with MOT failure chalk!

, The agricultural shell strengthening can also be seen complete with MOT failure chalk!

Having already cleared the nearside bin of expanding foam I knew what to expect from the offside but even I was shocked with what I came across next.

Nearside

Offside

As you can see the offside bin looks substantially smaller......

so I ground away the two 1 inch welds on either side of the plate and hey presto.... A tyre

The only other weld was two inches long and across the wheelarch - I just find it amazing that someone bodged it that badly to get it through an MOT that little plate is literally all that is preventing the rear subframe from coming through the floor! Imagine what would have happened in an accident - doesn't bear thinking about!

that little plate is literally all that is preventing the rear subframe from coming through the floor! Imagine what would have happened in an accident - doesn't bear thinking about!

Oh and the shiny thing was a 50p that dropped out of the inner sill so at least the value of my investment has increased

You can't really see it from the pictures but there are also 3 lots of sills welded one on top of the other so as well as the subframe mounting panel and boot floor I'm now looking at sills and floorpans too. Can't wait to see what tomorrow will bring!

As I expected the subframe mounting panel is fully shot and the floorpans have also been repaired by Stevie Wonder at some stage

, The agricultural shell strengthening can also be seen complete with MOT failure chalk!

, The agricultural shell strengthening can also be seen complete with MOT failure chalk!

Having already cleared the nearside bin of expanding foam I knew what to expect from the offside but even I was shocked with what I came across next.

Nearside

Offside

As you can see the offside bin looks substantially smaller......

so I ground away the two 1 inch welds on either side of the plate and hey presto.... A tyre

The only other weld was two inches long and across the wheelarch - I just find it amazing that someone bodged it that badly to get it through an MOT

that little plate is literally all that is preventing the rear subframe from coming through the floor! Imagine what would have happened in an accident - doesn't bear thinking about!

that little plate is literally all that is preventing the rear subframe from coming through the floor! Imagine what would have happened in an accident - doesn't bear thinking about!

Oh and the shiny thing was a 50p that dropped out of the inner sill so at least the value of my investment has increased

You can't really see it from the pictures but there are also 3 lots of sills welded one on top of the other so as well as the subframe mounting panel and boot floor I'm now looking at sills and floorpans too. Can't wait to see what tomorrow will bring!

Edited by uksurvivor on Thursday 11th December 10:52

guru_1071 said:

whilst youve got that out its easy to do inside the companion box (id chop them out and put new ones in) and do the heel board and the small closer panels.

I'm starting back to front (section 2 first) - When you say companion box do you mean the rear bins next to the seat? I did notice you'd done that on your picture above but just assumed it was a race shell and you were looking to loose precious kilos...That approach makes a lot of sense, my only concern with that is that the B pillars don't seem to come into contact with anything apart from the doorstep, rear quarter and the rear bins ie. they don't touch the inner sill at all, there's a rough finish to the end of both of them and I'm not sure if it left the factory like that or someone has chopped through them? Can you confirm that I should / shouldn't be able to get my fingers between the bottom of the B pillar and the inner sill?

And thanks for taking the time out to respond to my other questions - much appreciated.

guru_1071 said:

it might be worth hunting down info in the old kieths convertables kits as they where self build.

Internet searches have resulted in the opinion (from theminiforum) that they were floppy shells too... I did find a "Keiths" on Ebay Another Topless project? but the B pillars, door frames and sections of the roof have been retained so a different approach to mine.MHM said:

I reckon that was done by Auto design in paddock wood, kent. That roof and body kit are typical of the cars they turned out back in the day, and it wouldnt surprise me if they did that to the front.

Similarly internet searches have resulted in the elimination of Autodesign....  although the similarities are striking! Still can't believe anyone would choose to buy that kit!

although the similarities are striking! Still can't believe anyone would choose to buy that kit! (apologies if any of you have it on your cars....)

(apologies if any of you have it on your cars....)Edited by uksurvivor on Wednesday 10th December 13:51

Bin day today and limited "garage time" available due to work  so I thought I'd clear out all the useless rubbish that is going anyway, like hessian backed carpet etc....

so I thought I'd clear out all the useless rubbish that is going anyway, like hessian backed carpet etc....

Today's surprise

Where are the front subframe mounting bolts??????

Oh there they are! three tiny self tappers and mounting plate on the right.....

Also got a better look at the offside crossmember today - not pretty but at least I knew about that!

so I thought I'd clear out all the useless rubbish that is going anyway, like hessian backed carpet etc....

so I thought I'd clear out all the useless rubbish that is going anyway, like hessian backed carpet etc....Today's surprise

Where are the front subframe mounting bolts??????

Oh there they are! three tiny self tappers and mounting plate on the right.....

Also got a better look at the offside crossmember today - not pretty but at least I knew about that!

guru_1071 said:

I will take some photos at the weekend of what yours 'should' look like around the b post / inner sill area (as std), a photo will speak a thousand words i guess!

Thanks guru much appreciatedEdited by uksurvivor on Wednesday 10th December 13:53

Preparation for the big event today (rear subframe removal) Restricted space means the car must still move under "Andy power" afterwards so I've rigged up a scavenged pallet with 100mm castors ready to replace the backend with when I'm ready.

Liberally coated all the subframe retaining bolts with penetrating fluid from underneath before I started then set about loosening the bolts right off ready to go.

Finally cleared the last of the remaining expanding foam from the boot

Leaving a lovely fiberglass coloured area arount the subframe mount, the only upside being at least the glass held the head of the bolts in place while I undid the nut!

Once again there's no real strength of metal holding the subframe on....

The nearside was hardly surprising either, I knew there was fiberglass there so expected more of the same but....

A plate had been welded over the top of the nut (and corrosion surrounding the subframe mount)

So I'm thinking now I might as well replace the boot floor in its entirety (if such a panel exists?)

The question is now if I'm replacing: boot floor, heelboard panel, and complete floors what do I weld to what as I go????? Here's hoping the rear quarters are made of metal!

Having looked at the price of box section yesterday bracing is going to be constructed of 13mm studding which I can aquire in ample supply from a mate in the air conditioning trade - I'm saving my pennies for panels!

Liberally coated all the subframe retaining bolts with penetrating fluid from underneath before I started then set about loosening the bolts right off ready to go.

Finally cleared the last of the remaining expanding foam from the boot

Leaving a lovely fiberglass coloured area arount the subframe mount, the only upside being at least the glass held the head of the bolts in place while I undid the nut!

Once again there's no real strength of metal holding the subframe on....

The nearside was hardly surprising either, I knew there was fiberglass there so expected more of the same but....

A plate had been welded over the top of the nut (and corrosion surrounding the subframe mount)

So I'm thinking now I might as well replace the boot floor in its entirety (if such a panel exists?)

The question is now if I'm replacing: boot floor, heelboard panel, and complete floors what do I weld to what as I go????? Here's hoping the rear quarters are made of metal!

Having looked at the price of box section yesterday bracing is going to be constructed of 13mm studding which I can aquire in ample supply from a mate in the air conditioning trade - I'm saving my pennies for panels!

Limited garage time again today due to work  so taking into account the realisation that every panel I've looked at so far needs major work I thought I'd brave body kit removal....

so taking into account the realisation that every panel I've looked at so far needs major work I thought I'd brave body kit removal....

Already looking a million times better although I had some concerns about standard of workmanship on the deseamed front end (given everything else I've seen so far!) so thought I'd get the electric wire brush and dig through the filler....

Although the toeboard patch panel below had some "alignment issues"

Also had a dig about in the usual rust havens to see how bad things were and am generally happy'ish that the project is still worth doing.

I'll do the other side tomorrow and then hopefully my consignment of illicit studding will arrive so I can start bracing - gave the MIG a quick test drive today and surprisingly after a new tip and general service it was welding ok after at least 10 years of inactivity! On the downside forgot to turn off the compressor last night and it fired up at 3:30am - wifey not best pleased as the garage backs on to the bedroom in our bungalow!

so taking into account the realisation that every panel I've looked at so far needs major work I thought I'd brave body kit removal....

so taking into account the realisation that every panel I've looked at so far needs major work I thought I'd brave body kit removal....

Already looking a million times better although I had some concerns about standard of workmanship on the deseamed front end (given everything else I've seen so far!) so thought I'd get the electric wire brush and dig through the filler....

Although the toeboard patch panel below had some "alignment issues"

Also had a dig about in the usual rust havens to see how bad things were and am generally happy'ish that the project is still worth doing.

I'll do the other side tomorrow and then hopefully my consignment of illicit studding will arrive so I can start bracing - gave the MIG a quick test drive today and surprisingly after a new tip and general service it was welding ok after at least 10 years of inactivity! On the downside forgot to turn off the compressor last night and it fired up at 3:30am - wifey not best pleased as the garage backs on to the bedroom in our bungalow!

robminiman said:

just strip it toa bare shell ad bracing were required and have it shot blasted to remove all the rust filler and foam.

Has anyone ever done this? How much does it cost and what are the drawbacks?Just been quoted £300 for a shell blast (no doors, bonnet or boot) and immediate paint in '2 pack holding primer' providing it is a completely bare shell. Seems like a good deal but means I need to hire a trailer as I only have an a frame and I'm not sure my pallet and casters set up is road legal!

I've convinced myself overnight that blasting is the only option in the long run and so all thoughts of correcting anything have been overtaken by stripping the car ready to go, removed the nearside kit today

and the Merc front end...

looks wierd without the lights!

Have also been thinking about the things I can be getting on with whilst the car is at the blasters (estimated 2 days).

Never having fiddled with 4 stroke engines (as a motorbike rider in my late teens I could take a 2 stroke engine apart, replace the broken part and put it back together as I found it but thats it) I'm slightly reluctant to touch it but then again it seems a shame to miss an oppertunity to at least smarten things up. I have no idea on the history of the engine whatsoever and haven't even heard it run so I know I need to spend some time on it but it also feels a tad premature.... On the other hand it would be a shame to get everything else ready to go and not have an engine waiting.

My mind has also wondered to colourschemes based on my thoughts I'd repaint the block but what colour - wouldn't want it to clash with the shell

Also having looked at the cost of heritage panels I'm thinking pattern parts are the way to go! My local panel supplier is a Hadrians distributor has anyone got any experiences of the quality of fit etc?

I'm thinking pattern parts are the way to go! My local panel supplier is a Hadrians distributor has anyone got any experiences of the quality of fit etc?

bargain number one ..... 08-01-341 a bit cheaper than Hadrians £85.33! even with my hastily brokered P&P deal!

and the Merc front end...

looks wierd without the lights!

Have also been thinking about the things I can be getting on with whilst the car is at the blasters (estimated 2 days).

Never having fiddled with 4 stroke engines (as a motorbike rider in my late teens I could take a 2 stroke engine apart, replace the broken part and put it back together as I found it but thats it) I'm slightly reluctant to touch it but then again it seems a shame to miss an oppertunity to at least smarten things up. I have no idea on the history of the engine whatsoever and haven't even heard it run so I know I need to spend some time on it but it also feels a tad premature.... On the other hand it would be a shame to get everything else ready to go and not have an engine waiting.

My mind has also wondered to colourschemes based on my thoughts I'd repaint the block but what colour - wouldn't want it to clash with the shell

Also having looked at the cost of heritage panels

I'm thinking pattern parts are the way to go! My local panel supplier is a Hadrians distributor has anyone got any experiences of the quality of fit etc?

I'm thinking pattern parts are the way to go! My local panel supplier is a Hadrians distributor has anyone got any experiences of the quality of fit etc?bargain number one ..... 08-01-341 a bit cheaper than Hadrians £85.33! even with my hastily brokered P&P deal!

Edited by uksurvivor on Friday 12th December 13:24

Just so nobody thinks I've stopped I thought I'd update you. A new client has meant I'm spending more time away from home than usual (normally I work from home) but on the plus side its doubled my reach in terms of Ebay items! I've sourced a heritage boot floor as well as a selection of other panels, an original Elf engine and a "spit" for the car to help with floorpan removal/refitting. The spit was a bargain at £40!

Rest assured I still pop in the garage evey time I come home but nowadays its to add something new to the pile of bits awaiting attachment!

Rest assured I still pop in the garage evey time I come home but nowadays its to add something new to the pile of bits awaiting attachment!

Its been a while..... The job lasted longer than expected and I've moved house so the work on the Elf stopped around the same time as the last post and she's now tucked up in the garage under so many other bits that got relegated from the old house when I moved that there's little chance of progress indoors this winter.

By chance I was searching Ebay and came across a Stimson mini bug for sale and put a speculative bid on it figuring I could work on that outdoors without fear of the dreaded tin worm undoing all my good work. Anyway I won! I picked up the car a few weeks ago and returned to pick up the engines and paperwork for the Stimson this weekend and got chatting with the guy I'd bought it off about minis in general. He'd owned a few and offered to show me some of his pictures of previous cars... as we walked we got chatting about my "special elf" and it turns out he built it! He's got pictures of it being built and the finished article in its heyday...

Small world!

By chance I was searching Ebay and came across a Stimson mini bug for sale and put a speculative bid on it figuring I could work on that outdoors without fear of the dreaded tin worm undoing all my good work. Anyway I won! I picked up the car a few weeks ago and returned to pick up the engines and paperwork for the Stimson this weekend and got chatting with the guy I'd bought it off about minis in general. He'd owned a few and offered to show me some of his pictures of previous cars... as we walked we got chatting about my "special elf" and it turns out he built it! He's got pictures of it being built and the finished article in its heyday...

Small world!

Latest update... Its been a while but after securing a new job in difficult times I thought I'd best not take the mickey and put in too much time in the garage. My plans have now changed and rather than wait 10 years for me to restore the car I've handed it back to its original creators! We have agreed a good price (in my mind) and although I don't get the pleasure of saying "I did that" at least I'll get to drive the car before I'm too old to have a licence

The guys are 62 and 77 respectively and are two of the nicest blokes I'm ever likely to meet - progress updates have been plentiful (as has the list of parts required) and whilst its a long way from being completed the pace they're working at astounds me! In less than a week they've achieved more than the bloke restoring my 68 Hornet has managed in 18 months. The shell is now on the £40 spit in their workshop andx they both seem happy it'll reduce their need to bend down

I'm excited, slightly dissapointed but reassuring myself it'll be worth it in the end and am forgoing a holiday to make myself feel better about the cost. I'll get some piccys next time I'm there and provide a photographic update.

The guys are 62 and 77 respectively and are two of the nicest blokes I'm ever likely to meet - progress updates have been plentiful (as has the list of parts required) and whilst its a long way from being completed the pace they're working at astounds me! In less than a week they've achieved more than the bloke restoring my 68 Hornet has managed in 18 months. The shell is now on the £40 spit in their workshop andx they both seem happy it'll reduce their need to bend down

I'm excited, slightly dissapointed but reassuring myself it'll be worth it in the end and am forgoing a holiday to make myself feel better about the cost. I'll get some piccys next time I'm there and provide a photographic update.

Minor update as I've finally made it down the workshop for a look at progress.... Slightly gutted I won't be able to drive it this summer but totally chuffed with how things are going. Sadly by the time we worked out exactly how much metal needed to come out there was nothing left to hold the shell rigid (as the roof has already gone) so the original plan to replace the entire floor with the mini machine floor panel has gone by the wayside and I've ended up with a patchwork quilt (albeit with full floorpan sections).

Budget is still semi under control but probably 25% over my first thoughts, if its worth doing its worth doing properly!

Budget is still semi under control but probably 25% over my first thoughts, if its worth doing its worth doing properly!

Edited by uksurvivor on Thursday 23 September 23:39

GingerWizard said:

guru_1071 said:

looks good, and credit to you for been man enough to 'wallet up' to save this beast!

+1 massive respect.Gwiz

I very much doubt it'll be worth what its cost, but it'll be unique and designed exactly as I wanted it as its basically my dream car from 20 years ago and a little treat for myself as I approach the big 40....

The only problem is that the quirky car collection seems to be growing

Gassing Station | Classic Minis | Top of Page | What's New | My Stuff