Lawnmower engine upgrade/replacement

Discussion

Thought this little project might be of interest

Our old Qualcast Commodore motor mower has been getting hard to start so I decided to replace the old wheezy old 75cc Suffolk engine with something more reliable.

After browsing ebay I found a Honda GX120, was hoping to find a electric start GX390 but they are quite expensive and upgrading from 75cc to 390cc might be a bit excessive.

I removed the old engine and placed it next to the GX120, and could see the engine shaft height was different between the two engines.

I knew it wouldn’t be a direct fit and some engineering would be required.

On the plus side the clutch flange fits

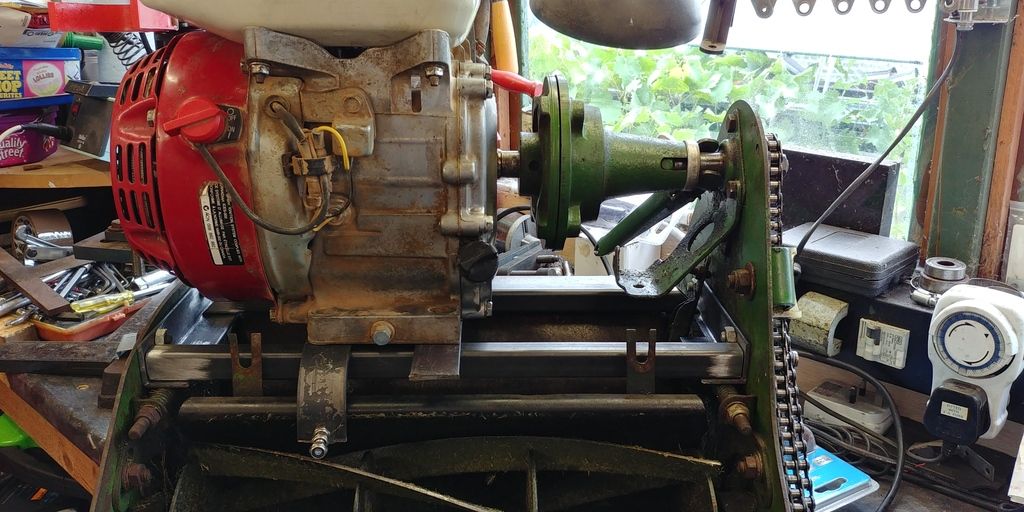

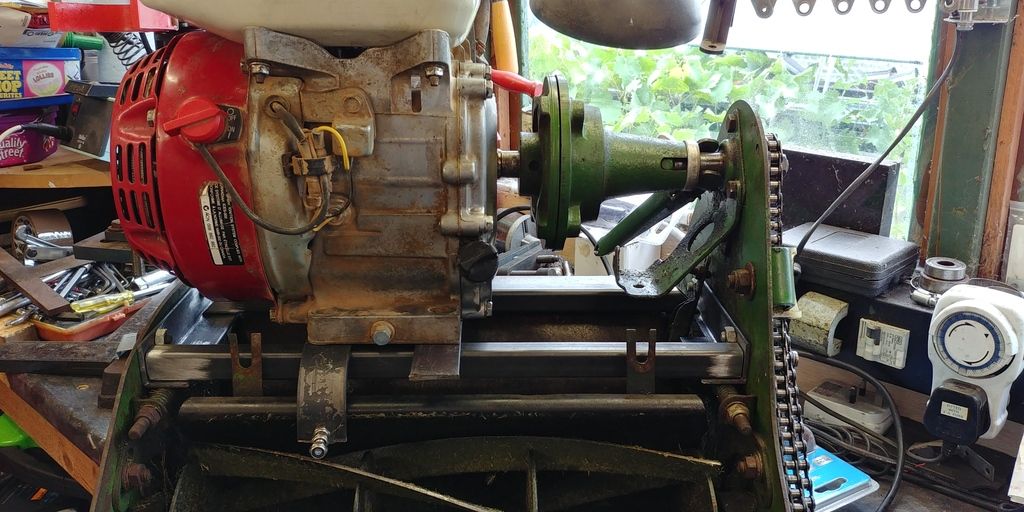

Honda engine on Qualcast chassis

I removed the original engine support and made a frame from some angle and box section steel

Trial fit with engine, starting to look like it will work

Slight adjustment needed to get the engine to sit level

After a bit more fettling I got it all to line up

Next step is to weld it together, so cleaned up the ends of the box tube ready for welding

Had to notch part of the angle steel for the drive clutch arm, this end will be held together with bolts as if I weld it, I won’t be able to get I back in

With any luck I should be able to get I finished I the next day or so

Our old Qualcast Commodore motor mower has been getting hard to start so I decided to replace the old wheezy old 75cc Suffolk engine with something more reliable.

After browsing ebay I found a Honda GX120, was hoping to find a electric start GX390 but they are quite expensive and upgrading from 75cc to 390cc might be a bit excessive.

I removed the old engine and placed it next to the GX120, and could see the engine shaft height was different between the two engines.

I knew it wouldn’t be a direct fit and some engineering would be required.

On the plus side the clutch flange fits

Honda engine on Qualcast chassis

I removed the original engine support and made a frame from some angle and box section steel

Trial fit with engine, starting to look like it will work

Slight adjustment needed to get the engine to sit level

After a bit more fettling I got it all to line up

Next step is to weld it together, so cleaned up the ends of the box tube ready for welding

Had to notch part of the angle steel for the drive clutch arm, this end will be held together with bolts as if I weld it, I won’t be able to get I back in

With any luck I should be able to get I finished I the next day or so

Arif110 said:

Most excellent!!

Will the replacement engine's rev's be appropriate - both for clutch engagement, & running speed? Its top end will be about 3000 rpm, & I think they idle at about 1000rpm.

Thanks Will the replacement engine's rev's be appropriate - both for clutch engagement, & running speed? Its top end will be about 3000 rpm, & I think they idle at about 1000rpm.

Should be ok, I plan to lower the engine speed by adjusting the governor spring, can also reduce the idle speed by adjusting the carburettor.

Hopefully it shouldn’t need much more above idle to run the mower as the GX120 is a lot more powerful than the old Suffolk engine, 1HP ish vs 5hp.

Got some more done today, started with couple of tack welds to hold the frame together.

Welding all done, had some issues as didn’t have the current high enough so the welds are a bit rough. Also probably didn't get the metal clean enough.

Bolt holding the drive clutch end

Finished for today

Next step is to make the mounts for the engine.

Excellent job there sir! I'm following with interest. A humble project maybe - but for me this is very much a great example of the type of amateur engineering which for some reason I associate with being British. This is how Colin Furzes come into being!

There will simply be no feeling like the one of running that mower! Best-of-British meets best-of-Japan!

There will simply be no feeling like the one of running that mower! Best-of-British meets best-of-Japan!

To mount the engine I cut some strips of steel and welded to the frame

I made a template for the base of engine so I could mark the fixing points. I found a method on a DIY gocart forum, where the base of the engine is given a light coat of oil. The engine is then sat on some cardboard, the oil transfers a imprint of the engine base.

I drew around the inside of the oil marks and cut the template to size.

Using the template I was able to mark and drill the holes for the bolts to secure the engine (sorry forgot to take photo)

Engine bolted down, everything lined up

It works

The finished mower (post cutting the rest of the lawn)

As I hoped the engine speed at idle was perfect, it had enough power to cut the grass and drive the roller. I could probably slow it down a bit, but I don’t want to fiddle with the carburettor as the engine runs perfectly.

It’s soooooo much better than the old engine, starts on a single pull, doesn’t smoke or leak oil. It just works like a Honda should

So should I paint the engine green to match the original or leave it in it’s Honda livery?

I made a template for the base of engine so I could mark the fixing points. I found a method on a DIY gocart forum, where the base of the engine is given a light coat of oil. The engine is then sat on some cardboard, the oil transfers a imprint of the engine base.

I drew around the inside of the oil marks and cut the template to size.

Using the template I was able to mark and drill the holes for the bolts to secure the engine (sorry forgot to take photo)

Engine bolted down, everything lined up

It works

The finished mower (post cutting the rest of the lawn)

As I hoped the engine speed at idle was perfect, it had enough power to cut the grass and drive the roller. I could probably slow it down a bit, but I don’t want to fiddle with the carburettor as the engine runs perfectly.

It’s soooooo much better than the old engine, starts on a single pull, doesn’t smoke or leak oil. It just works like a Honda should

So should I paint the engine green to match the original or leave it in it’s Honda livery?

Gassing Station | Homes, Gardens and DIY | Top of Page | What's New | My Stuff