[Project Post] Citroen AX SPORT 16v [lots of pics]

Discussion

A Brief History:

The Ax Sport was a LHD spec car only. It visually looks like the GT, sharing the same bodykit, but came with steel wheels as standard, and did not have electric windows or central locking.

The engine was the TU24 series, with a capacity of 1294cc. (Bore of 75mm stroke 73.2mm) In addition it had twin Solex carbs (Yes Solex, unlike the 205 rallye, which used Webbers as apparently the Webbers were too tall and wouldn't fit under the bonnet!).

As a result the standard engine was very revvy making 95bhp at the flywheel at 6800rpm. (The engine actually started life as a modified version of the TU3S version, and was designed in house.

The head from the sport is an entirely different casting than that of the GT. It has much bigger valves 31mm and 39mm compared to 29.4mm and 36.8mm, and has a specific cam and exhaust system.

The gearbox was also different to the already low ratio GT box. The final drive was changed from 18/82 to the 14/60 ratio as later used in the S1 106 rallye.

Combined with a very light weight model of the ax (715kg) this made for lively performance. Top speed was 186km/h and 0-60 the same as the 205 GTi 1.6! At 8.8 secs.

The only original colour was white, later red, black and grey were introduced, along with 14" GT alloys, which incidentally required narrower tyres than the original 13" wheels which the sport was using.

An AX Sport

In 1987 Citroen together with TOTAL and MICHELIN created the 'Challenge Citroen-Michelin-Total Championship'. This would select three drivers for the factory team in the World Rally Championship in 1988.

Now I know that of these 3 cars, one was piloted by Dimi Mavropolous, and I know that car is no more, As a friend has half of it! The rot was excessive, and the car was crushed. Not before he'd managed to get some bits off it first though! This would be around 2000/2001.

It is one of these 3 cars that is my yellow ax sport, the other car is probably out there somewhere in France I should imagine.

And so it began..

So in early 2006, a friend manage to track this 3rd ax sport down, sat in Derbyshire, about to broken. By the time he get down there he found the front suspension had already been sold, and the car is in bits. It had been resprayed recently in yellow, with smooth blue kit. It sat in full Forest spec, despite the car having spent most of its life in tarmac rallies. The shell looks to be in very good condition with absolutely no rust anywhere! There's never been any underseal on the car either so that was a pleasant find! The interior was rough! The paint was shoddy and looked like it had been daubed on with a brush, and possibley was dulex one coat white emulsion! The dash was shattered in many places, the electrics were lying everywhere.

The Pic doesnt do it justice, to just how nasty the paint was

If you look carefully the dash is bowing in the middle under its own weight! It was completley shattered beyond belief!

There would be a lot of work, but the car showed massive potential with a full weld in multipoint cage, seam welding through out, and a good solid shell, with bronze tint Perspex windows already in place!

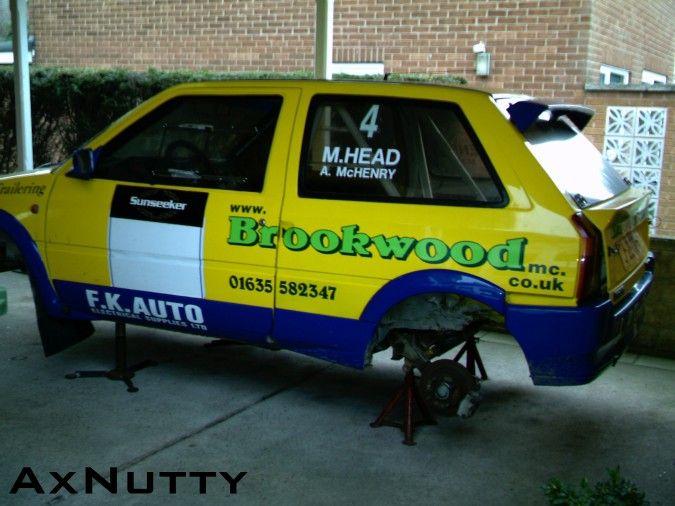

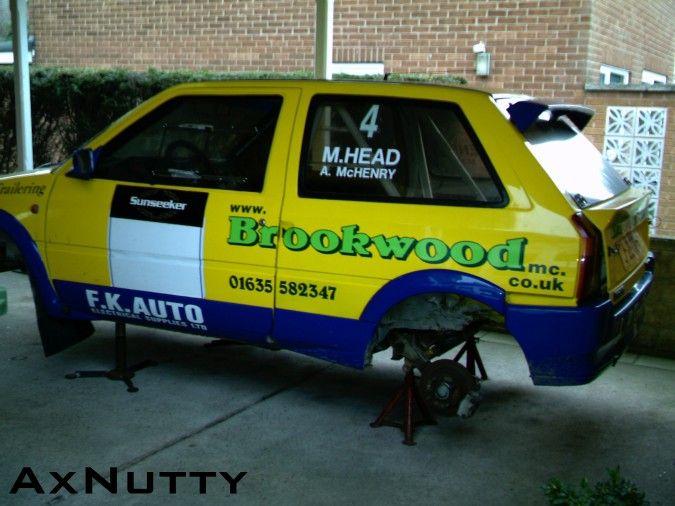

My car in the Rally Sunseeker - its last event

And so 1 week later a shell arrives outside my friends house, and his bank manager phones up to ask what the hell is going on with his bank balance.. lol

Mid dismantling

Now at this point I should point out that my friend had another full race spec ax GTi outside hishouse. This car was prepped by him but would be stripped for parts to build the Sport up.

The Rebuild

The shell as a bit if a tip

The rebuild initially, like all good projects, started with a complete strip down! The interior was pulled out, all wires, switches, etc, all removed to leave just a blank shell.

Now many will argue the point that what he did next was wrong. The car had never seen undersealed, sod that! A can of underseal weighs roughly 1KG, and one can live with that to prevent this car from rusting! So that was painted on all over, apart from the boot area (This area got resprayed white) This shell was absolutely solid! Without a hint of rust anywhere!

The original paint was flatted out, or totally removed using a blow torch where it was too rough to do anything else with.

This was then all masked up and resprayed in celly EWT alpine white. This may not be the exact paint code for the sport, but is for the GT.. so it will do.

Primer

The top coat

The engine bay had the same treatment. There was a lot of staining here, so it took a long time to clean back to the metal in places.

The engine from his old race car was then stripped down and rebuilt in this shell. The bare block had new bearings, and a full rebuild and was then installed to an overhauled GT gearbox. Unfortunately funds hadn't stretched to a LSD at this point.

Note the excessive cut out throught the bulkhead to create a huge airbox space for the side draught carbs.

Note also the engine mounts used. He opted for solid engine mounts from the ax sport competition car. However a note of warning! The car had pulled out of the sunseeker due to the rear engine mount snapping! This was because they were running solid engine mounts all round! Which you are not supposed to do! There was simply no give, and the rear mount broke. So he'd gone for an uprated rubber rear mount on a lengthened bracket to angle the engine slightly...

Ignore the cam pulley, its since been replaced!

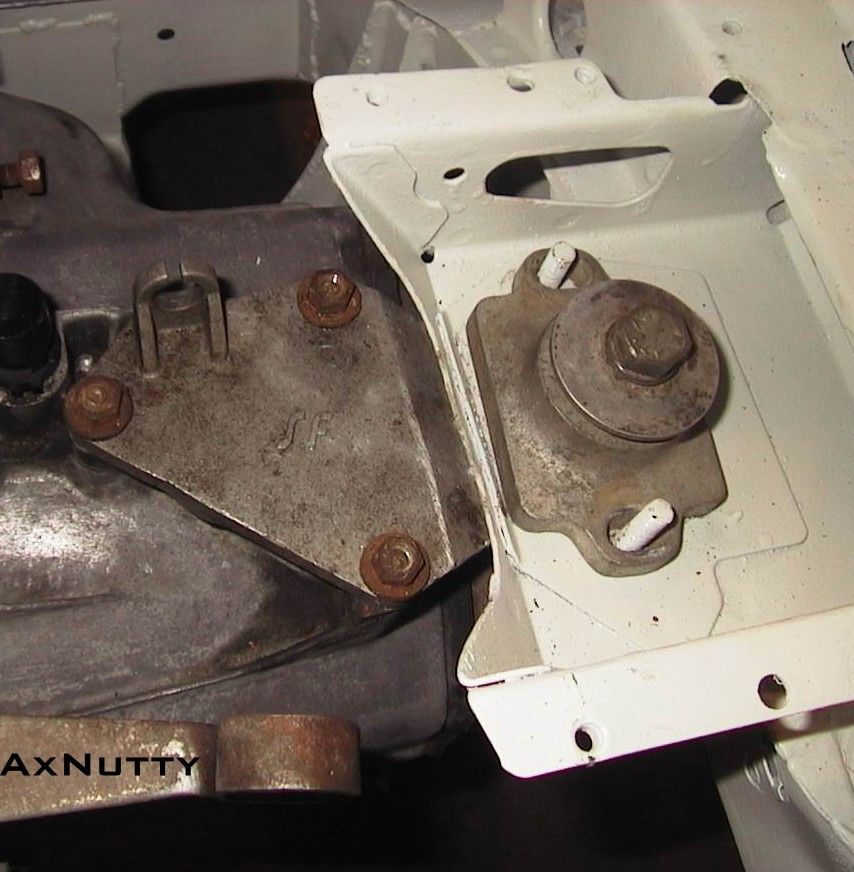

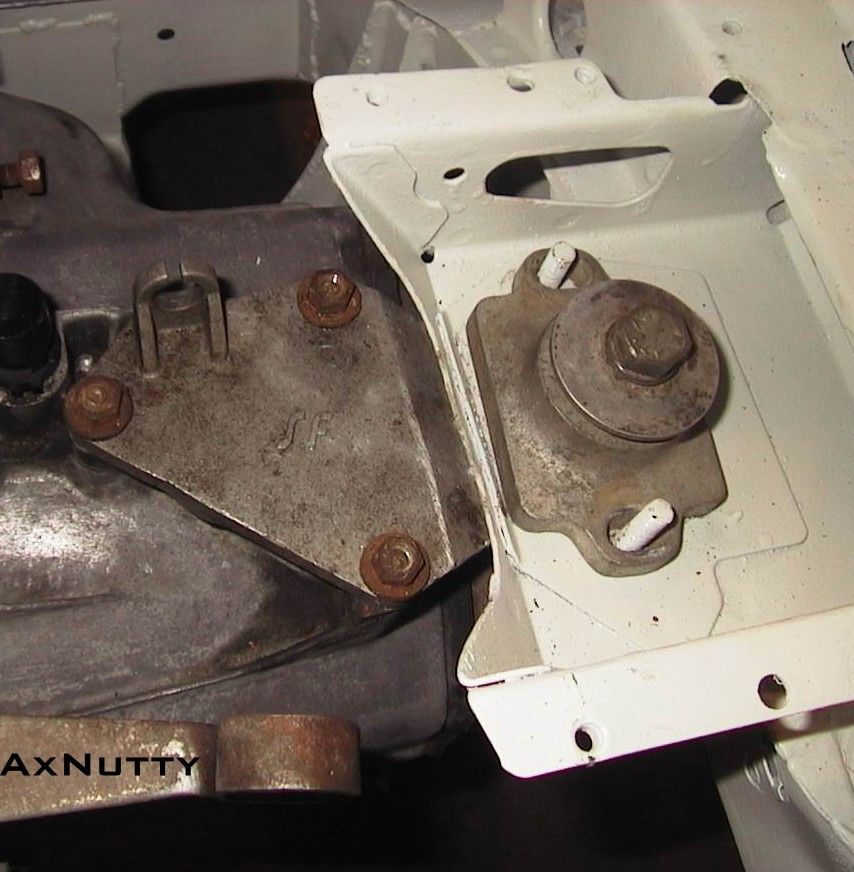

Gearbox side mount.. note the battery tray modifications.

With the engine bay cleaned and painted he started on cleaning and building the twin adjustable pedal box. This is in car controlled. The brake lines are stainless braided all throughout out the car, and obviously run on a front / rear split. He prefered doing it like this rather than running a combination of copper line and stainless flexies.

Pedal box - yes I know the mc's are upside down, but it was just trial run

The steering rack was cleaned up and thus set about the suspension. Up front there are Leda 2 1/4 inch fully adjustables with eccentric top mounts, and negative camber fully adjustable wishbones, with the special Citroen sport wishbone mounts with built in bracketry for the sump guard.

Ledas in place - you can see the fresh underseal and note the small alloy plates over the wishbone mounts.

The rose jointed wishbones

The track rod ends were further modified to use rose joints in the inner joint.

At the rear he rebuilt the Dimi Mavropolous rear beam using a new tube axle (as the original was showing signs of wear). This incorporates solid alloy mounting bushes, 23mm Torsion bars, and a one off custom 26mm Anti Roll bar. The original beam used AP rear callipers and discs. He retained a set of these, but frankly they are an over kill, so the car is currently running VTS rear callipers and discs.

The rear beam showing the Tony Law exhaust and the tank guard

The fuel tank is a standard AX10E item and is foam filled, with twin Facet Red Top fuel pumps. The filler neck is guarded as is the tank itself, and all fuel lines run internally and are stainless steel braided items.

The exhaust is a Tony Law custom built item with single re packable back box. The system is brought up into the recesses of the car, so if used for forest rallying its not the lowest point on the car.

The Exhaust off the car - note the easy spring clip joins

Back to the interior!

Inside after the respray the car needed a replacement LHD dash! There happened to be one on ebay, so that was bought. Fortunatley, he managed to get one from France from a Mk1! Which is a rare thing. Mainly because of the policy the Europeans have on scrap yards. (ie, you squash a car instantly! Hence no AX's, let alone MK1's!)

Another problem lies in that the sun in France being that bit hotter, any of the remaining dash have split due to the heat and are very fragile and brittle.

He modified the dash to fit round the roll cage best he could and set about refitting the myriad of wiring loom from the sport. This loom was all bespoke to the car, and is not standard in any way, and with no way of knowing what goes where this took some time!

The dash in and tackling the wiring loom

Fabrication of a number of panels was in order to make the switch gear. This was all done in thin 0.5mm alloy to good effect, and is just screwed in place. He mounted the fuses and relays in easy access areas, so they can be replaced whilst driving, well that'ss the idea anyway.

Switch gear panels in place

Chequerplate was cut to fit in the footwells, as paint last the whole of 5mins when you have shuffling feet syndrome with your passengers! This was just bolted through the floor in a few places. The passenger footwell was cut in to two pieces as eventually he intended to run a navigators footrest with the plumbed in extinguisher underneath.

This was just bolted through the floor in a few places. The passenger footwell was cut in to two pieces as eventually he intended to run a navigators footrest with the plumbed in extinguisher underneath.

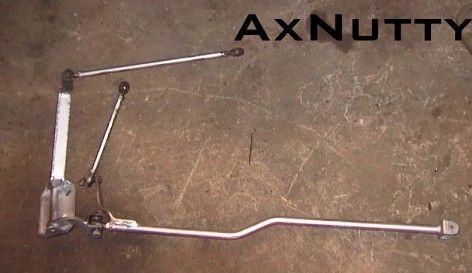

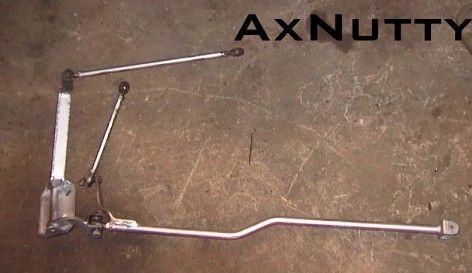

The gear linkage is a combination of the Peugeot Sport rose joint linkage with the TAS quickshift, with extended rod length. This is way over the top, as the synchro's would last all of 10 minutes. This was to be changed by removing to TAS quickshift and just retaining the Peugeot Sport linkage.

Peugeot Sport rose jointed shift

At this point, Handbrake and gauges/dials were still on list of things to do.

The rest

The engine was completed using a standard GT top end with standard carb. This was really to just ensure the car would be driveable first time, and also to help it pass the emissions test come MOT time the first time round.

A set of aircraft 6point Sabelt 3" harnesses were fitted and a set of Corbeau buckets were also fitted.

A hand held extingusher was also been fitted to the drivers foot well.

Wheels Sourced

The car was then fitted with a set of 15" Compomotive MO's. These are to try and cover the Brembo 4pots up front. But they were not doing it!

The compomotive MO's were the wrong offset as they came off a 106 supercup car. They will fit but require a 8mm spacer.... however he managed to source a set of OZ Superleggeras, which JUST fit over the brembos. The lead balence weights just skim them.

Ignore the rusty brakes discs - they were new but thats what a week in the rain does for them!

You can slide a rizler paper through there if your careful.

The brakes were all bled up and worked superbly. With no servo it did require some serious leg exercise, but the feedback was awsome, and once your used to it, its a big improvement.

Cooling

Managed to fit a 106 diesel rad... its sitting behind the panel as the original set up. Space to the alternator is limited but not worrying. About a centimeter at worst. He left space to mount the original 106 fan on (would need to be reversed though). But eventually just left the standard ax fan mounted vertically to prevent fouling the 4 branch manifold.

He quickly sprayed the surround black so the white didnt stand out for when he fitted his black GT bodykit

Morrettes fitted and 106 Diesel radiator fitted.

He couldnt be bothered spending £50 odd quid on an expansion tank so got a brass one instead.

After some time...

He finally got the loom sorted using yet another RHD GT dash loom. It took 3 attempts but he eventually sorted it!

Funny moment with the rear lights as with it being a RHD loom on a LHD car it seemed to recognise the left hand indicator as the right one and vice versa

... That was soon sorted though.

Everything was plumbed in and working. Made some new dash plates... again. Simplicity it seems was everything!

Only issue was the front indicators on one side! With a multimeter it read roughly 8volts. Earth was ok, Electric sockets are ok, But the indicators on the front left werent working! Checked the bulbs/earth/connections/etc.... couldn't see what was wrong! Ran out of ideas on this one.

January 2007..

Electrics were all completed & working.. Finally... !

He took the sport for a test drive and was pretty impressed! It was r unning very flat and not pulling like it should, but it idled fine so it sounds like a carb & dirt problem in a jet somewhere, but he dont care too much because it was all coming off after the MOT emissions test to fit the race head/cam/carbs anyway.

So its was set to be off to be MOT'd soon with some luck before the end of Jan. Then February was set to finish some final tidying up of bits and fitting the race stuff with some track work being penciled into my calender for coming year.

Pictures - Jan 2007'

May 2007' - Makeover

Well with my friend hardly ever doing anything on the sport, and not really liking it, He thought he'd better either finish it, or sell it. Having had a few offers for breaking and even taking it as a whole but all falling through in the end for one reason or another - it left him with two options.

- One: advertise it properly on ebay/Pistonheads/here

- Two: sort it out and keep it.

So like anybody faced in this situation he had one or two beers.. A combination of bordom and car tinkering motivation took hold and he found himself outside, and had a good look round it, curosity got the best of him and found himself idly picking a sponser sticker.... then another.... and another.... eventually he found he'd had ripped the bodykit off it - spoiler, bumpers, bonnet vents, wing mirrors, all the stickers and graphic work. The lot !

..

So he then got himself some Sikaflax 212FC (as this perticular sport has no clips/mounts for the bodykit like the normal 'road going' sports did) and dug out a black GT kit he had knocking about. Have to say I personally think this was a good move, but some of you may diasgree.

It had taken on quite a transformation and doesnt look like the car it did previously. It now looks a lot more mundaine and not so much in your face.

Not the best pics due to shadow, work in progress and lack of polish!

He also added a Laguna front splitter and tinted the side repeaters.

Some slightly better pics "mid clean". Just needed a rear bumper & black roof strips. along with some black Metro vents (which were originally blue when the shell was purchased)

[u] THE REBUILD! [/u]

Ok so now you guys have brief understanding of the history involved in this car, I took it upon myself to replace my current AX Forte' VTS with this AX Sport as it has more potential, plus (as you will see in the following pictures) it really isnt doing much, and if anything will end up like the other works AX Sport which got crushed due to being neglected/unused.

Since i knew the previous owner, and he know's how much effort i put into my current Forte' he gave me the opportunity to take on the challenge of restoring the sport.

It had been sat under a tree for the best part of 2007' and had not moved, therefore wasn't in the best of cosmetic shape. The entire car was covered in thick muck from the tree it had been sat under. the scuttle panel was full of leaves and damp, the engine bay was messy and again, full of leaves due to the open vents in the bonnet which had not been covered on rainy days.

Also, since the car has polycarbonate windows with sliders and rear bootlid window, these are definatley [u]not[/u] the best of seals therefore rainwater had got into the interior and begin to eat away at the floorpan under the alloy plates, and also at the back of the car.

Here's a few pictures of the car before it was trailered to my place.

You can see here the muck that was laying ontop of the paint

You could tell the car hadn't moved for a while. But of no concern as i didnt need these brembo's

You can see the muck in the scuttle here

Not the original SPORT logo, but passable!

On the way back from taking a look at it, i stopped to stretch my legs [cant move much in my current seat!] and take some photo's before the sun went down! [ASW]

And so it begins.. [again]

The Cleandown

After being dropped off at my place, i decided to crack on and get it cleaned. This took some time however.

Pics will do the talking:

You get a good idea of how mucky it was in this pic

Havent yet removed the slider to clean it properly, but you get the idea how how it will look

Undecided weter or not i'll keep the 'Citroën" vinyl on top

The plugs & leads were full of water since the vents havent been covered in the rain etc

Next to my Forte' VTS

The Stripdown

Eventfull day of stripping the car of the major bits so i can see what lies beneath and crack on cleaning everything down and replacing various nuts & bolts so it all looks like new.

[u]Started with the interior:[/u]

As you can see here, the floor pan under the alloy plates has been gethering water and surface rust has set in

Rear of the car wasnt so bad, very light surface rust here n there

Took the car into the garage and then carried on removing bits from the outside of the car.

As mentioned before, very thick deposits of muck

Removed the wiring from the engine bay

Removed the suspension & dropped the struts off the car along with brakes etc.

Dropped the engine

Engine bay looks better already without even cleaning it

I spent a good few hours wet & dry'ing the engine bay removing any muck & grime that was on it and any rust lurking was removed. I then set about removing any traces of rust that my have been there with Kurust, some may say it was a bad idea but quite a few people reccomended this stuff to me. there wasnt rally any on show but rather be safe than sorry and see it creeping back through in a few months time.

Kurust

While that was doing its thing i decided to treat the mild steel tony law exhaust system to the wire brush treatment and a coat of Kurust ready for paint.. along with various other components such as the pedal box, coilovers, fuel tank guard, rad fan bracket etc.

Items now ready for primer & paint to look good as new

Back to the Interior..

The interior required a massive amoung of work to get to the condition i want it to be.

The floorpan wasnt in TOO bad of shape, mainly surface rust. The worst part that worried me was behind the fan, under the grill in the scuttle panel area which has allowed water to seep into the car, onto the arch/bulkhead and rot it though. Since all the arches are reinforced & twin skinned it has not effected both skins, however the inner skin is absolutley rotten and needs replacing.

as it was

Driver side bulkhead corner

Bulkhead

Area concerning me the most. You can see the rot hole on the inner skin of the bulkhead/arch under the vent

At this point i will take the opportunity to note that the bulkhead is structually sound. It looks bad, but its surface rust, besides the rot on the right side of the above picture.

I decided to crack on and see how bad the rot was here.

Peeling the rotten inner skin away

I did take it further than that, and stopped at solid metal, its solid now with the rot gone, but im left with a huge hole where the inner skin should be.. this will be remedied by replacing that section with new metal and seam welded to ensure it does its job properly.

Decided to crack on with the floorpan after this.

Hole in the passenger floorpan, only small. I imagine it was from a dole beign drilled in the wrong place and just left there to rust.

The other hole in the floorpan. The rest is solid other than the holes for the alloy panels

Drivers side floorpan

A rediculous amount of hours wet & drying

Most back to bare metal where possible.

I'd also like to note to anybody else planning to do this. WEAR GLOVES. My fingertips started to bleed after a few days so was forced to, also made it much more difficult to get into the corners like behind the cage mounts and right into the corner of the bulkhead.

Once i was relativley happy with the condition of the metal, proceeded to Kurust.

Kurust turns black on surfaces that have been effected by rust.

Seems that it doesnt effect real bare metal though (see bronze colour on tunnel).

Took the car out of the garage for some snaps outside, however it soon got dark once i put the front struts back on so i could move it.

And that's pretty much it for the moment. It's sat like that for a month or two now since the weather has got rediculously cold and i now need funds to sent it to the bodyshop to do a proper job on the interior & engine bay.

Plans/Spec:

Engine:

Standard VTS Engine. Modified wiring loom with ECU in-dash [for time being]

Raceland 4-2-1 Manifold

Tony Law custom made 'forest spec' exhaust system

ZF Solid engine mounts & Group N/A Rear engine mount

Low pressure 'red top' fuel pump

High pressure external cosworth fuel pump

Brakes:

Hi Spec/Wilwood/Brembo/AP 4 pot front brakes with grooved discs [TBA]

Forodo DS2500 Pads

Pedal box [Independant front/rear master cylinders. sizes TBA]

Braided brake lines

Wilwood bias valve

VTS Rear brakes

Suspension:

Fully adjustable Leda coilovers & Eccentric top mounts, 350lb springs

Peugoet Sport rose-jointed wishbones, with special mounts incl. accomodation for Sump guard

Works spec rear axle:

Modified trailing arms to allow for slight negative camber

23mm peugeot sport torsion bars

26mm custom Anti-Roll bar

Peugeot Sport France rear dampers

Solid mounts

Interior:

Full multi-point works FIA spec roll cage

Corbeau Revolution bucket seat

6-point TRS Magnum 3" harness

OMP Corsica suede steering wheel

Flocked dash

SPA Design 80mm Tacho with LCD speedometer combined

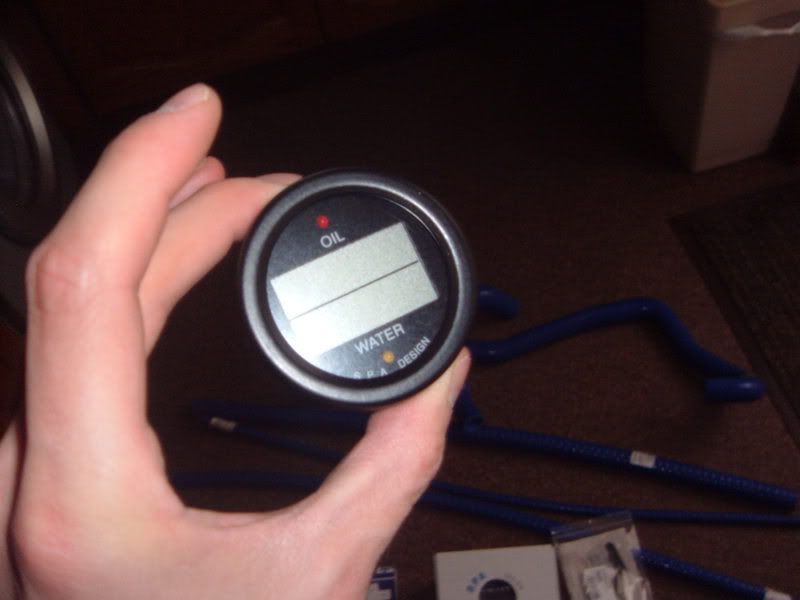

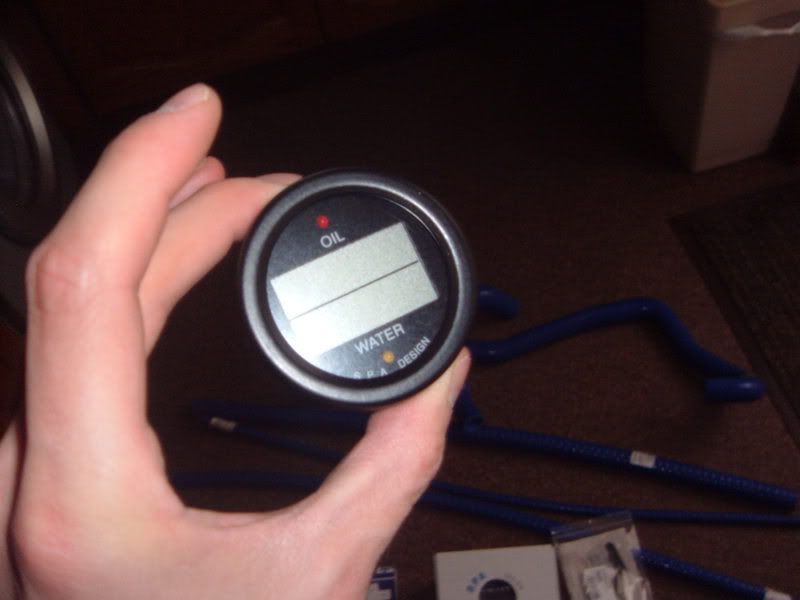

SPA Design dual LCD oil pressure & water temperature 52mm gauge

SPA Design analogue fuel level 52mm gauge

Carbon door cards

Carbon panels on dash

Quife nylon gear knob

Custom 'bespoke' wiring loom

Brake lines & fuel lines mounted inside car

Fire extinguisher

Helmet Hammock

Door 'straps' for handles

Internal fuel 'swirl pot'

Battery relocated inside car

Washer fluid bottle relocated to car interior

Full respray in white

Exterior:

Team Dynamics Pro Race 1.2 in satin black

Toyo Proxy T1-R's

Lowered accordingly

Center-roof mounted ariel

Polycarbonate windows all round with side window sliders

Lockable

'Citroen' vinyl on roof

'Sunseeker rally' vinyl on bonnet/wing

Metro bonnet vents in black

Black GT kit + spoiler

The Ax Sport was a LHD spec car only. It visually looks like the GT, sharing the same bodykit, but came with steel wheels as standard, and did not have electric windows or central locking.

The engine was the TU24 series, with a capacity of 1294cc. (Bore of 75mm stroke 73.2mm) In addition it had twin Solex carbs (Yes Solex, unlike the 205 rallye, which used Webbers as apparently the Webbers were too tall and wouldn't fit under the bonnet!).

As a result the standard engine was very revvy making 95bhp at the flywheel at 6800rpm. (The engine actually started life as a modified version of the TU3S version, and was designed in house.

The head from the sport is an entirely different casting than that of the GT. It has much bigger valves 31mm and 39mm compared to 29.4mm and 36.8mm, and has a specific cam and exhaust system.

The gearbox was also different to the already low ratio GT box. The final drive was changed from 18/82 to the 14/60 ratio as later used in the S1 106 rallye.

Combined with a very light weight model of the ax (715kg) this made for lively performance. Top speed was 186km/h and 0-60 the same as the 205 GTi 1.6! At 8.8 secs.

The only original colour was white, later red, black and grey were introduced, along with 14" GT alloys, which incidentally required narrower tyres than the original 13" wheels which the sport was using.

An AX Sport

In 1987 Citroen together with TOTAL and MICHELIN created the 'Challenge Citroen-Michelin-Total Championship'. This would select three drivers for the factory team in the World Rally Championship in 1988.

Now I know that of these 3 cars, one was piloted by Dimi Mavropolous, and I know that car is no more, As a friend has half of it! The rot was excessive, and the car was crushed. Not before he'd managed to get some bits off it first though! This would be around 2000/2001.

It is one of these 3 cars that is my yellow ax sport, the other car is probably out there somewhere in France I should imagine.

And so it began..

So in early 2006, a friend manage to track this 3rd ax sport down, sat in Derbyshire, about to broken. By the time he get down there he found the front suspension had already been sold, and the car is in bits. It had been resprayed recently in yellow, with smooth blue kit. It sat in full Forest spec, despite the car having spent most of its life in tarmac rallies. The shell looks to be in very good condition with absolutely no rust anywhere! There's never been any underseal on the car either so that was a pleasant find! The interior was rough! The paint was shoddy and looked like it had been daubed on with a brush, and possibley was dulex one coat white emulsion! The dash was shattered in many places, the electrics were lying everywhere.

The Pic doesnt do it justice, to just how nasty the paint was

If you look carefully the dash is bowing in the middle under its own weight! It was completley shattered beyond belief!

There would be a lot of work, but the car showed massive potential with a full weld in multipoint cage, seam welding through out, and a good solid shell, with bronze tint Perspex windows already in place!

My car in the Rally Sunseeker - its last event

And so 1 week later a shell arrives outside my friends house, and his bank manager phones up to ask what the hell is going on with his bank balance.. lol

Mid dismantling

Now at this point I should point out that my friend had another full race spec ax GTi outside hishouse. This car was prepped by him but would be stripped for parts to build the Sport up.

The Rebuild

The shell as a bit if a tip

The rebuild initially, like all good projects, started with a complete strip down! The interior was pulled out, all wires, switches, etc, all removed to leave just a blank shell.

Now many will argue the point that what he did next was wrong. The car had never seen undersealed, sod that! A can of underseal weighs roughly 1KG, and one can live with that to prevent this car from rusting! So that was painted on all over, apart from the boot area (This area got resprayed white) This shell was absolutely solid! Without a hint of rust anywhere!

The original paint was flatted out, or totally removed using a blow torch where it was too rough to do anything else with.

This was then all masked up and resprayed in celly EWT alpine white. This may not be the exact paint code for the sport, but is for the GT.. so it will do.

Primer

The top coat

The engine bay had the same treatment. There was a lot of staining here, so it took a long time to clean back to the metal in places.

The engine from his old race car was then stripped down and rebuilt in this shell. The bare block had new bearings, and a full rebuild and was then installed to an overhauled GT gearbox. Unfortunately funds hadn't stretched to a LSD at this point.

Note the excessive cut out throught the bulkhead to create a huge airbox space for the side draught carbs.

Note also the engine mounts used. He opted for solid engine mounts from the ax sport competition car. However a note of warning! The car had pulled out of the sunseeker due to the rear engine mount snapping! This was because they were running solid engine mounts all round! Which you are not supposed to do! There was simply no give, and the rear mount broke. So he'd gone for an uprated rubber rear mount on a lengthened bracket to angle the engine slightly...

Ignore the cam pulley, its since been replaced!

Gearbox side mount.. note the battery tray modifications.

With the engine bay cleaned and painted he started on cleaning and building the twin adjustable pedal box. This is in car controlled. The brake lines are stainless braided all throughout out the car, and obviously run on a front / rear split. He prefered doing it like this rather than running a combination of copper line and stainless flexies.

Pedal box - yes I know the mc's are upside down, but it was just trial run

The steering rack was cleaned up and thus set about the suspension. Up front there are Leda 2 1/4 inch fully adjustables with eccentric top mounts, and negative camber fully adjustable wishbones, with the special Citroen sport wishbone mounts with built in bracketry for the sump guard.

Ledas in place - you can see the fresh underseal and note the small alloy plates over the wishbone mounts.

The rose jointed wishbones

The track rod ends were further modified to use rose joints in the inner joint.

At the rear he rebuilt the Dimi Mavropolous rear beam using a new tube axle (as the original was showing signs of wear). This incorporates solid alloy mounting bushes, 23mm Torsion bars, and a one off custom 26mm Anti Roll bar. The original beam used AP rear callipers and discs. He retained a set of these, but frankly they are an over kill, so the car is currently running VTS rear callipers and discs.

The rear beam showing the Tony Law exhaust and the tank guard

The fuel tank is a standard AX10E item and is foam filled, with twin Facet Red Top fuel pumps. The filler neck is guarded as is the tank itself, and all fuel lines run internally and are stainless steel braided items.

The exhaust is a Tony Law custom built item with single re packable back box. The system is brought up into the recesses of the car, so if used for forest rallying its not the lowest point on the car.

The Exhaust off the car - note the easy spring clip joins

Back to the interior!

Inside after the respray the car needed a replacement LHD dash! There happened to be one on ebay, so that was bought. Fortunatley, he managed to get one from France from a Mk1! Which is a rare thing. Mainly because of the policy the Europeans have on scrap yards. (ie, you squash a car instantly! Hence no AX's, let alone MK1's!)

Another problem lies in that the sun in France being that bit hotter, any of the remaining dash have split due to the heat and are very fragile and brittle.

He modified the dash to fit round the roll cage best he could and set about refitting the myriad of wiring loom from the sport. This loom was all bespoke to the car, and is not standard in any way, and with no way of knowing what goes where this took some time!

The dash in and tackling the wiring loom

Fabrication of a number of panels was in order to make the switch gear. This was all done in thin 0.5mm alloy to good effect, and is just screwed in place. He mounted the fuses and relays in easy access areas, so they can be replaced whilst driving, well that'ss the idea anyway.

Switch gear panels in place

Chequerplate was cut to fit in the footwells, as paint last the whole of 5mins when you have shuffling feet syndrome with your passengers!

This was just bolted through the floor in a few places. The passenger footwell was cut in to two pieces as eventually he intended to run a navigators footrest with the plumbed in extinguisher underneath.

This was just bolted through the floor in a few places. The passenger footwell was cut in to two pieces as eventually he intended to run a navigators footrest with the plumbed in extinguisher underneath.The gear linkage is a combination of the Peugeot Sport rose joint linkage with the TAS quickshift, with extended rod length. This is way over the top, as the synchro's would last all of 10 minutes. This was to be changed by removing to TAS quickshift and just retaining the Peugeot Sport linkage.

Peugeot Sport rose jointed shift

At this point, Handbrake and gauges/dials were still on list of things to do.

The rest

The engine was completed using a standard GT top end with standard carb. This was really to just ensure the car would be driveable first time, and also to help it pass the emissions test come MOT time the first time round.

A set of aircraft 6point Sabelt 3" harnesses were fitted and a set of Corbeau buckets were also fitted.

A hand held extingusher was also been fitted to the drivers foot well.

Wheels Sourced

The car was then fitted with a set of 15" Compomotive MO's. These are to try and cover the Brembo 4pots up front. But they were not doing it!

The compomotive MO's were the wrong offset as they came off a 106 supercup car. They will fit but require a 8mm spacer.... however he managed to source a set of OZ Superleggeras, which JUST fit over the brembos. The lead balence weights just skim them.

Ignore the rusty brakes discs - they were new but thats what a week in the rain does for them!

You can slide a rizler paper through there if your careful.

The brakes were all bled up and worked superbly. With no servo it did require some serious leg exercise, but the feedback was awsome, and once your used to it, its a big improvement.

Cooling

Managed to fit a 106 diesel rad... its sitting behind the panel as the original set up. Space to the alternator is limited but not worrying. About a centimeter at worst. He left space to mount the original 106 fan on (would need to be reversed though). But eventually just left the standard ax fan mounted vertically to prevent fouling the 4 branch manifold.

He quickly sprayed the surround black so the white didnt stand out for when he fitted his black GT bodykit

Morrettes fitted and 106 Diesel radiator fitted.

He couldnt be bothered spending £50 odd quid on an expansion tank so got a brass one instead.

After some time...

He finally got the loom sorted using yet another RHD GT dash loom. It took 3 attempts but he eventually sorted it!

Funny moment with the rear lights as with it being a RHD loom on a LHD car it seemed to recognise the left hand indicator as the right one and vice versa

... That was soon sorted though.

Everything was plumbed in and working. Made some new dash plates... again. Simplicity it seems was everything!

Only issue was the front indicators on one side! With a multimeter it read roughly 8volts. Earth was ok, Electric sockets are ok, But the indicators on the front left werent working! Checked the bulbs/earth/connections/etc.... couldn't see what was wrong! Ran out of ideas on this one.

January 2007..

Electrics were all completed & working.. Finally... !

He took the sport for a test drive and was pretty impressed! It was r unning very flat and not pulling like it should, but it idled fine so it sounds like a carb & dirt problem in a jet somewhere, but he dont care too much because it was all coming off after the MOT emissions test to fit the race head/cam/carbs anyway.

So its was set to be off to be MOT'd soon with some luck before the end of Jan. Then February was set to finish some final tidying up of bits and fitting the race stuff with some track work being penciled into my calender for coming year.

Pictures - Jan 2007'

May 2007' - Makeover

Well with my friend hardly ever doing anything on the sport, and not really liking it, He thought he'd better either finish it, or sell it. Having had a few offers for breaking and even taking it as a whole but all falling through in the end for one reason or another - it left him with two options.

- One: advertise it properly on ebay/Pistonheads/here

- Two: sort it out and keep it.

So like anybody faced in this situation he had one or two beers.. A combination of bordom and car tinkering motivation took hold and he found himself outside, and had a good look round it, curosity got the best of him and found himself idly picking a sponser sticker.... then another.... and another.... eventually he found he'd had ripped the bodykit off it - spoiler, bumpers, bonnet vents, wing mirrors, all the stickers and graphic work. The lot !

..

So he then got himself some Sikaflax 212FC (as this perticular sport has no clips/mounts for the bodykit like the normal 'road going' sports did) and dug out a black GT kit he had knocking about. Have to say I personally think this was a good move, but some of you may diasgree.

It had taken on quite a transformation and doesnt look like the car it did previously. It now looks a lot more mundaine and not so much in your face.

Not the best pics due to shadow, work in progress and lack of polish!

He also added a Laguna front splitter and tinted the side repeaters.

Some slightly better pics "mid clean". Just needed a rear bumper & black roof strips. along with some black Metro vents (which were originally blue when the shell was purchased)

[u] THE REBUILD! [/u]

Ok so now you guys have brief understanding of the history involved in this car, I took it upon myself to replace my current AX Forte' VTS with this AX Sport as it has more potential, plus (as you will see in the following pictures) it really isnt doing much, and if anything will end up like the other works AX Sport which got crushed due to being neglected/unused.

Since i knew the previous owner, and he know's how much effort i put into my current Forte' he gave me the opportunity to take on the challenge of restoring the sport.

It had been sat under a tree for the best part of 2007' and had not moved, therefore wasn't in the best of cosmetic shape. The entire car was covered in thick muck from the tree it had been sat under. the scuttle panel was full of leaves and damp, the engine bay was messy and again, full of leaves due to the open vents in the bonnet which had not been covered on rainy days.

Also, since the car has polycarbonate windows with sliders and rear bootlid window, these are definatley [u]not[/u] the best of seals therefore rainwater had got into the interior and begin to eat away at the floorpan under the alloy plates, and also at the back of the car.

Here's a few pictures of the car before it was trailered to my place.

You can see here the muck that was laying ontop of the paint

You could tell the car hadn't moved for a while. But of no concern as i didnt need these brembo's

You can see the muck in the scuttle here

Not the original SPORT logo, but passable!

On the way back from taking a look at it, i stopped to stretch my legs [cant move much in my current seat!] and take some photo's before the sun went down! [ASW]

And so it begins.. [again]

The Cleandown

After being dropped off at my place, i decided to crack on and get it cleaned. This took some time however.

Pics will do the talking:

You get a good idea of how mucky it was in this pic

Havent yet removed the slider to clean it properly, but you get the idea how how it will look

Undecided weter or not i'll keep the 'Citroën" vinyl on top

The plugs & leads were full of water since the vents havent been covered in the rain etc

Next to my Forte' VTS

The Stripdown

Eventfull day of stripping the car of the major bits so i can see what lies beneath and crack on cleaning everything down and replacing various nuts & bolts so it all looks like new.

[u]Started with the interior:[/u]

As you can see here, the floor pan under the alloy plates has been gethering water and surface rust has set in

Rear of the car wasnt so bad, very light surface rust here n there

Took the car into the garage and then carried on removing bits from the outside of the car.

As mentioned before, very thick deposits of muck

Removed the wiring from the engine bay

Removed the suspension & dropped the struts off the car along with brakes etc.

Dropped the engine

Engine bay looks better already without even cleaning it

I spent a good few hours wet & dry'ing the engine bay removing any muck & grime that was on it and any rust lurking was removed. I then set about removing any traces of rust that my have been there with Kurust, some may say it was a bad idea but quite a few people reccomended this stuff to me. there wasnt rally any on show but rather be safe than sorry and see it creeping back through in a few months time.

Kurust

While that was doing its thing i decided to treat the mild steel tony law exhaust system to the wire brush treatment and a coat of Kurust ready for paint.. along with various other components such as the pedal box, coilovers, fuel tank guard, rad fan bracket etc.

Items now ready for primer & paint to look good as new

Back to the Interior..

The interior required a massive amoung of work to get to the condition i want it to be.

The floorpan wasnt in TOO bad of shape, mainly surface rust. The worst part that worried me was behind the fan, under the grill in the scuttle panel area which has allowed water to seep into the car, onto the arch/bulkhead and rot it though. Since all the arches are reinforced & twin skinned it has not effected both skins, however the inner skin is absolutley rotten and needs replacing.

as it was

Driver side bulkhead corner

Bulkhead

Area concerning me the most. You can see the rot hole on the inner skin of the bulkhead/arch under the vent

At this point i will take the opportunity to note that the bulkhead is structually sound. It looks bad, but its surface rust, besides the rot on the right side of the above picture.

I decided to crack on and see how bad the rot was here.

Peeling the rotten inner skin away

I did take it further than that, and stopped at solid metal, its solid now with the rot gone, but im left with a huge hole where the inner skin should be.. this will be remedied by replacing that section with new metal and seam welded to ensure it does its job properly.

Decided to crack on with the floorpan after this.

Hole in the passenger floorpan, only small. I imagine it was from a dole beign drilled in the wrong place and just left there to rust.

The other hole in the floorpan. The rest is solid other than the holes for the alloy panels

Drivers side floorpan

A rediculous amount of hours wet & drying

Most back to bare metal where possible.

I'd also like to note to anybody else planning to do this. WEAR GLOVES. My fingertips started to bleed after a few days so was forced to, also made it much more difficult to get into the corners like behind the cage mounts and right into the corner of the bulkhead.

Once i was relativley happy with the condition of the metal, proceeded to Kurust.

Kurust turns black on surfaces that have been effected by rust.

Seems that it doesnt effect real bare metal though (see bronze colour on tunnel).

Took the car out of the garage for some snaps outside, however it soon got dark once i put the front struts back on so i could move it.

And that's pretty much it for the moment. It's sat like that for a month or two now since the weather has got rediculously cold and i now need funds to sent it to the bodyshop to do a proper job on the interior & engine bay.

Plans/Spec:

Engine:

Standard VTS Engine. Modified wiring loom with ECU in-dash [for time being]

Raceland 4-2-1 Manifold

Tony Law custom made 'forest spec' exhaust system

ZF Solid engine mounts & Group N/A Rear engine mount

Low pressure 'red top' fuel pump

High pressure external cosworth fuel pump

Brakes:

Hi Spec/Wilwood/Brembo/AP 4 pot front brakes with grooved discs [TBA]

Forodo DS2500 Pads

Pedal box [Independant front/rear master cylinders. sizes TBA]

Braided brake lines

Wilwood bias valve

VTS Rear brakes

Suspension:

Fully adjustable Leda coilovers & Eccentric top mounts, 350lb springs

Peugoet Sport rose-jointed wishbones, with special mounts incl. accomodation for Sump guard

Works spec rear axle:

Modified trailing arms to allow for slight negative camber

23mm peugeot sport torsion bars

26mm custom Anti-Roll bar

Peugeot Sport France rear dampers

Solid mounts

Interior:

Full multi-point works FIA spec roll cage

Corbeau Revolution bucket seat

6-point TRS Magnum 3" harness

OMP Corsica suede steering wheel

Flocked dash

SPA Design 80mm Tacho with LCD speedometer combined

SPA Design dual LCD oil pressure & water temperature 52mm gauge

SPA Design analogue fuel level 52mm gauge

Carbon door cards

Carbon panels on dash

Quife nylon gear knob

Custom 'bespoke' wiring loom

Brake lines & fuel lines mounted inside car

Fire extinguisher

Helmet Hammock

Door 'straps' for handles

Internal fuel 'swirl pot'

Battery relocated inside car

Washer fluid bottle relocated to car interior

Full respray in white

Exterior:

Team Dynamics Pro Race 1.2 in satin black

Toyo Proxy T1-R's

Lowered accordingly

Center-roof mounted ariel

Polycarbonate windows all round with side window sliders

Lockable

'Citroen' vinyl on roof

'Sunseeker rally' vinyl on bonnet/wing

Metro bonnet vents in black

Black GT kit + spoiler

Some new toys..

Some new bits came through the post last friday, some samco hosing, 106 gti hose kit, only Demon Tweeks messed up the order and sent me the wrong top hose to the rad!!! so been on the blower to them thismorning n they're arranging pickup for the kit and they're sending me the proper one this time but have to wait a week or something to actually get it back, what a messabout!

One of my SPA Design gauges came too, along with a row of warning lights for the dash.

still waiting on the spa design tacho, shift light, fuel level gauge, and cage stiffeners/gussetts though...

Rally Design said the wilwood 4pots, bias valve & one of the switch panels for the dash would be with me soon too!

anyway, some quick pics:

The random wrong samco hose that DT sent me?

Bits that came today

SPA Design Oil Pressure & Water Temp dual gauge

Some new bits came through the post last friday, some samco hosing, 106 gti hose kit, only Demon Tweeks messed up the order and sent me the wrong top hose to the rad!!! so been on the blower to them thismorning n they're arranging pickup for the kit and they're sending me the proper one this time but have to wait a week or something to actually get it back, what a messabout!

One of my SPA Design gauges came too, along with a row of warning lights for the dash.

still waiting on the spa design tacho, shift light, fuel level gauge, and cage stiffeners/gussetts though...

Rally Design said the wilwood 4pots, bias valve & one of the switch panels for the dash would be with me soon too!

anyway, some quick pics:

The random wrong samco hose that DT sent me?

Bits that came today

SPA Design Oil Pressure & Water Temp dual gauge

Little bit of progress...

Had a little tinker with the dash looms for a few hours the other night.. The plan is to fit a mk2 AX poverty spec loom without the leccy window, central locking etc wiring to a mk1 AX dash.. only the mk2s i have are RHD, and the dash is LHD, so ive had to pretty much turn the loom upside down and see how it fits, and its not all that bad really... few wires need extending and a handfull of relays need relocating back to the other side of the dash. the fusebox needs modification too so it sits properly, probably a bracket or something made up to support it but its almost there as it is =]

Heres some pics anyway. Not a huge amount of progress, but ive got 9 days off work coming up soon expect to get all of this done then, hopefully

Quick pic of the size of the gauges compared to the visible dash area is. Should work out alright!

Had a little tinker with the dash looms for a few hours the other night.. The plan is to fit a mk2 AX poverty spec loom without the leccy window, central locking etc wiring to a mk1 AX dash.. only the mk2s i have are RHD, and the dash is LHD, so ive had to pretty much turn the loom upside down and see how it fits, and its not all that bad really... few wires need extending and a handfull of relays need relocating back to the other side of the dash. the fusebox needs modification too so it sits properly, probably a bracket or something made up to support it but its almost there as it is =]

Heres some pics anyway. Not a huge amount of progress, but ive got 9 days off work coming up soon expect to get all of this done then, hopefully

Quick pic of the size of the gauges compared to the visible dash area is. Should work out alright!

new bits turned up yesterday from rally design!

Have to say that the service at rally design is top notch. Scott has left a few notes and a diagram on a piece of paper within the box my order came in about what we discussed when i ordered bits on the phone [without being asked] and his direct number if i have any questions... Was quite impressed really. not a bad word to say about them =]

Switch panel & wilwood bias valve

Plan 285mm discs with wilwood Midilite 4pots

Have to say that the service at rally design is top notch. Scott has left a few notes and a diagram on a piece of paper within the box my order came in about what we discussed when i ordered bits on the phone [without being asked] and his direct number if i have any questions... Was quite impressed really. not a bad word to say about them =]

Switch panel & wilwood bias valve

Plan 285mm discs with wilwood Midilite 4pots

Ive already got an ax vts at the moment which i built last christmas, so this is the second time round which should be easier as i already know what to expect fitting & wiring wise.

The car has never had an 'original' sport engine in. When it rolled out from citroen it would have had a works spec engine which i wouldnt know the spec of unfortuantley, no doubt it would have been pretty revvy. The 8v engine tht was in it when i got my hands on it i gave back to the previous owner as it was no use to me being a race spec bottom end, with a standard ax gt head which he put together for MOT purposes, but never actually finished it so never got mot'd in the end...

The vts engine is the best bang for buck and has more potential anyway.

Next year i'll be running Omex600 and catcams 708's more than likley. Theres a good engine being build at the moment by matt @ QEP for lad on SSC (saxosportsclub) which is producing 202bhp (and more to come) from N/A without running maxi spec pistons or rods. Dave @ Pumaracing did the head work on it on the flow bench etc and its come up with some superb power since he's got his hands on it, so may go down the route of ITB's, omex, 734 catcams, iapel forged high comp pistons, and some good head work. Should see a realistic 185bhp, possibly even more which should result in a pretty quick track setup considering it should go round corners really well with some cut slicks the works spec axle & ledas. (at least thats the plan!)

Heres some pics of my current AX VTS i use daily. (and yes, i wear a suit to work.. haha)

Made some more progress with the sport today anyway. The floorpan and bits of the engine bay are back to bare metal but i ran out of sunlight so i'd imagine when i go back to it in the morning there'll be a bit of surface rust again... No fear though. Hopefully i'll go through a few grades of grit paper tomorrow and zinc primer the engine bay where neccesary.. the floorpan has some holes in it too which were previously used to mount the alloy floor plates and underbody fuel tank guard which is a bit of a pain in the arse really and im not sure how to get about that as i cant weld.. [Ill learn one day!]. Ill go over it with filler primer or something possibly too to try to get rid of the roughness as i dont thinc just zinc primer will do the job effectivley enough.

On another note, my cage stiffeners came from demon tweeks this morning too so that'll be going on in a short while when a friend comes round to do a spot of welding. Maxi style

Heres how it should look once its done though.

Note: The cage stiffeners on A and B pillars!

The car has never had an 'original' sport engine in. When it rolled out from citroen it would have had a works spec engine which i wouldnt know the spec of unfortuantley, no doubt it would have been pretty revvy. The 8v engine tht was in it when i got my hands on it i gave back to the previous owner as it was no use to me being a race spec bottom end, with a standard ax gt head which he put together for MOT purposes, but never actually finished it so never got mot'd in the end...

The vts engine is the best bang for buck and has more potential anyway.

Next year i'll be running Omex600 and catcams 708's more than likley. Theres a good engine being build at the moment by matt @ QEP for lad on SSC (saxosportsclub) which is producing 202bhp (and more to come) from N/A without running maxi spec pistons or rods. Dave @ Pumaracing did the head work on it on the flow bench etc and its come up with some superb power since he's got his hands on it, so may go down the route of ITB's, omex, 734 catcams, iapel forged high comp pistons, and some good head work. Should see a realistic 185bhp, possibly even more which should result in a pretty quick track setup considering it should go round corners really well with some cut slicks the works spec axle & ledas. (at least thats the plan!)

Heres some pics of my current AX VTS i use daily. (and yes, i wear a suit to work.. haha)

Made some more progress with the sport today anyway. The floorpan and bits of the engine bay are back to bare metal but i ran out of sunlight so i'd imagine when i go back to it in the morning there'll be a bit of surface rust again... No fear though. Hopefully i'll go through a few grades of grit paper tomorrow and zinc primer the engine bay where neccesary.. the floorpan has some holes in it too which were previously used to mount the alloy floor plates and underbody fuel tank guard which is a bit of a pain in the arse really and im not sure how to get about that as i cant weld.. [Ill learn one day!]. Ill go over it with filler primer or something possibly too to try to get rid of the roughness as i dont thinc just zinc primer will do the job effectivley enough.

On another note, my cage stiffeners came from demon tweeks this morning too so that'll be going on in a short while when a friend comes round to do a spot of welding. Maxi style

Heres how it should look once its done though.

Note: The cage stiffeners on A and B pillars!

Small update as ive been off the last 2 days.

Spent a little time with a paint remover disc and wire wheel for grinder/drill and decided im bored of trying to prep it, ill leave it for the professionals as im sure they have the knowledge & tools to do the job MUCH more quickly [considering the hours ive spent on it so far! and its not even near 'flat', to the standards im expecting anyway]

Sorted a few components out today too but didnt take any pics yet, need to give them another coat tomorrow =]

Some pics anyway =]

After some debating decided to zinc primer it as didnt want bare metal on show for long, knowing the weather round here on the coast..

3 cattle cans of zinc primer later!

The Floorpan.. is something im not sure what to do with, The holes in the floor from where alloy plates and also where rust has eaten through is going to be a pain in the arse to get somebody to plate over as i dont want the floorpan to have weld seams and random plates all over..

So options are to either:

A: Cut them out and replace with 'new' floorpans but that means starting again with side mount brackets/mounts and 6th eyebolt and the cost of getting somebody to weld one in properly!

B: Cut out a square section where the holes etc are, basically where ones feet would go and weld a steel plate in there so at least it was flat so could maybe giv eme the opportunity to fit a carbon panel over it or something?

C) get it painted anyway and use rubber gromets to plug each of them, which imho will look too dodgy on a white floor!

Random photo:

On a more positive note anyway, i treated myself to a Halfords pro socket set. Can really reccomend it like, only a pain in the arse getting the spanners out if im honest, probably needs a bit of breaking in lol

lol

More to come over the next couple of days while im off work! =]

Spent a little time with a paint remover disc and wire wheel for grinder/drill and decided im bored of trying to prep it, ill leave it for the professionals as im sure they have the knowledge & tools to do the job MUCH more quickly [considering the hours ive spent on it so far! and its not even near 'flat', to the standards im expecting anyway]

Sorted a few components out today too but didnt take any pics yet, need to give them another coat tomorrow =]

Some pics anyway =]

After some debating decided to zinc primer it as didnt want bare metal on show for long, knowing the weather round here on the coast..

3 cattle cans of zinc primer later!

The Floorpan.. is something im not sure what to do with, The holes in the floor from where alloy plates and also where rust has eaten through is going to be a pain in the arse to get somebody to plate over as i dont want the floorpan to have weld seams and random plates all over..

So options are to either:

A: Cut them out and replace with 'new' floorpans but that means starting again with side mount brackets/mounts and 6th eyebolt and the cost of getting somebody to weld one in properly!

B: Cut out a square section where the holes etc are, basically where ones feet would go and weld a steel plate in there so at least it was flat so could maybe giv eme the opportunity to fit a carbon panel over it or something?

C) get it painted anyway and use rubber gromets to plug each of them, which imho will look too dodgy on a white floor!

Random photo:

On a more positive note anyway, i treated myself to a Halfords pro socket set. Can really reccomend it like, only a pain in the arse getting the spanners out if im honest, probably needs a bit of breaking in

lol

lol

More to come over the next couple of days while im off work! =]

Some more pics from yesterday...

Leda coilovers

Get an idea of the size of the calipers here, didnt want to take the discs out of the bags as by the time i get to use them they'd be rusty!

Pedal bias box

Pugsport special rose jointed wishbones

Pugsport rose jointed gear linkage

Tony law custom 'forest spec' exhaust

If it sounds anything like this i'll be chuffing happy!

[size=18]http://www.youtube.com/watch?v=cjFHfjmOSII [/size]

Leda coilovers

Get an idea of the size of the calipers here, didnt want to take the discs out of the bags as by the time i get to use them they'd be rusty!

Pedal bias box

Pugsport special rose jointed wishbones

Pugsport rose jointed gear linkage

Tony law custom 'forest spec' exhaust

If it sounds anything like this i'll be chuffing happy!

[size=18]http://www.youtube.com/watch?v=cjFHfjmOSII [/size]

Fished the engine out of the garage earlier..

but first had to put the struts back onto the car so i could move it =]

pic:

Few of the engine about 30 min ago when i started stripping it.. forgot about the time though and need to go check out the new addition [car] in a few mins, just thought i'd breifly shoot some pics up in the meantime

Handy that stand for moving engines on your own

[img]http://i131.photobucket.com/albums/p307/Jessop_bucket/Project%20Sport/Engine/DSCF3327.jpg/img]

From further inspection it seems that the saxo VTS it was in had a bit of a bump!

More to come..

Intend to strip the engine down then put it on the engine stand i have and crack on cleaning it up, replace the sump etc! Baffled sump anybody?

but first had to put the struts back onto the car so i could move it =]

pic:

Few of the engine about 30 min ago when i started stripping it.. forgot about the time though and need to go check out the new addition [car] in a few mins, just thought i'd breifly shoot some pics up in the meantime

Handy that stand for moving engines on your own

[img]http://i131.photobucket.com/albums/p307/Jessop_bucket/Project%20Sport/Engine/DSCF3327.jpg/img]

From further inspection it seems that the saxo VTS it was in had a bit of a bump!

More to come..

Intend to strip the engine down then put it on the engine stand i have and crack on cleaning it up, replace the sump etc! Baffled sump anybody?

Been slacking over the weekend, really annoyed with myself as wanted to really crack on with the sport again but hey ho, cant change the past can we

Engine's now on engine stand ready for w eage..

eage..

NOTE: The sum was smashed in previous pics, on the OIL PUMP side.. however seems like i have gotten away with a nightmare of a job on an engine ive never actually tested yet..

Does all seem to be looking fine to you guys there?

Engine's now on engine stand ready for w

eage..

eage..

NOTE: The sum was smashed in previous pics, on the OIL PUMP side.. however seems like i have gotten away with a nightmare of a job on an engine ive never actually tested yet..

Does all seem to be looking fine to you guys there?

block has been done gloss black, only i dont want to paint the cylinder head as it only goes crappy after a short while anyway.

Head has got pitted with muck on the front, which is a f king pain in the arse, the back is much better though, typical!

king pain in the arse, the back is much better though, typical!

Might see how the steering columb & arms come out in spray silver like, also the pedalbox looks a bit s t with the brush marks on it. might go over it with another coat to see how it goes though in the meantime! might just be a first coat type of thing.!

t with the brush marks on it. might go over it with another coat to see how it goes though in the meantime! might just be a first coat type of thing.!

Its pissing down here now so cant do any work on the shell, picking up timing belt kit and new water pump in the morning too, been on order since monday. If i get bored later i might get bufty on the rocker covers or something. but more than likley crack on with the dash loom. Need to move the multiplug tht goes through behind the inner wing to the other side of the car since the dash loom has been turned inside out. needs reinforcing too (the dash that is) as its had so much cut away from it.

Heres some quick pics anyway..

Right on queue it begins to piss it down something chronic!

the joys of sharing a garage with the folks... !

NOTE: The wood on the left side, theres about 6 months worth of it there [garage is pretty wide!] for the new wood burner we fitted in the conservatory.. so so nice n warm in there now after a days graft

Anyhow.. stopped raining so took it back outside and painted it up..

Heres how it looked straight after a lick of paint, was a little wet and the cheap camera does it no justice , Looks really good in comparison to what it did. With the white 'minimalistic' engine bay it should look pretty cool in the glossy black!

Pics..

Head has got pitted with muck on the front, which is a f

king pain in the arse, the back is much better though, typical!

king pain in the arse, the back is much better though, typical!Might see how the steering columb & arms come out in spray silver like, also the pedalbox looks a bit s

t with the brush marks on it. might go over it with another coat to see how it goes though in the meantime! might just be a first coat type of thing.!

t with the brush marks on it. might go over it with another coat to see how it goes though in the meantime! might just be a first coat type of thing.!Its pissing down here now so cant do any work on the shell, picking up timing belt kit and new water pump in the morning too, been on order since monday. If i get bored later i might get bufty on the rocker covers or something. but more than likley crack on with the dash loom. Need to move the multiplug tht goes through behind the inner wing to the other side of the car since the dash loom has been turned inside out. needs reinforcing too (the dash that is) as its had so much cut away from it.

Heres some quick pics anyway..

Right on queue it begins to piss it down something chronic!

the joys of sharing a garage with the folks... !

NOTE: The wood on the left side, theres about 6 months worth of it there [garage is pretty wide!] for the new wood burner we fitted in the conservatory.. so so nice n warm in there now after a days graft

Anyhow.. stopped raining so took it back outside and painted it up..

Heres how it looked straight after a lick of paint, was a little wet and the cheap camera does it no justice , Looks really good in comparison to what it did. With the white 'minimalistic' engine bay it should look pretty cool in the glossy black!

Pics..

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff