Spigot bearing

Discussion

Anyone got the dimensions please ?

15mm ID x 21mm OD seems to be common to a lot of Fords ?

ETA, just thought, I've got a spare gearbox, just had a measure of first motion shaft and the 15mm bit is looking good.

Did I see someone on here a while back had made a removal tool from a Rawlbolt?

Edited by phillpot on Tuesday 25th January 22:15

Probably no help whatsoever but I had an old 2.3 Grandad years back - I changed the engine for another one and the opening in the end of the crank was a different diameter. I can't be sure but the original engine was 21mm I think - and the replacement was 19mm, as you said I think the gearbox input shaft was 15mm. I ended up having to use a bronze bush instead of a bearing but it seemed to work till I part exchanged it

I think the replacement engine I fitted may have been from an older 4 speed box grandad but don't know for sure.

I think the replacement engine I fitted may have been from an older 4 speed box grandad but don't know for sure.

lou4010 said:

Hello Tony

Nice to meet you at SCH,glad to hear the box is out and the puller worked.

The clutch came as a three part kit,

QH

QKT 2030AF

Other numbers/letters on the box were Eqiv MHK 52030.

The spigot bearing is

Still not quite sure how I did get the box out on my own,but I think my adjustable beer belly helped

Good luck getting it all back together. Just make sure you compare clutches the first two offered to me were slightly different to the one I had.

Cheers Andy

Nice to meet you at SCH,glad to hear the box is out and the puller worked.

The clutch came as a three part kit,

QH

QKT 2030AF

Other numbers/letters on the box were Eqiv MHK 52030.

The spigot bearing is

Still not quite sure how I did get the box out on my own,but I think my adjustable beer belly helped

Good luck getting it all back together. Just make sure you compare clutches the first two offered to me were slightly different to the one I had.

Cheers Andy

lou4010 said:

Gearbox back in and all running fine just in time for SCH

I found this post most informative and have remade the end of slave cylinder pushrod,sits snugly now in the thrust plate.

http://www.pistonheads.com/xforums/topic.asp?h=0&a...

Here are a few pics.

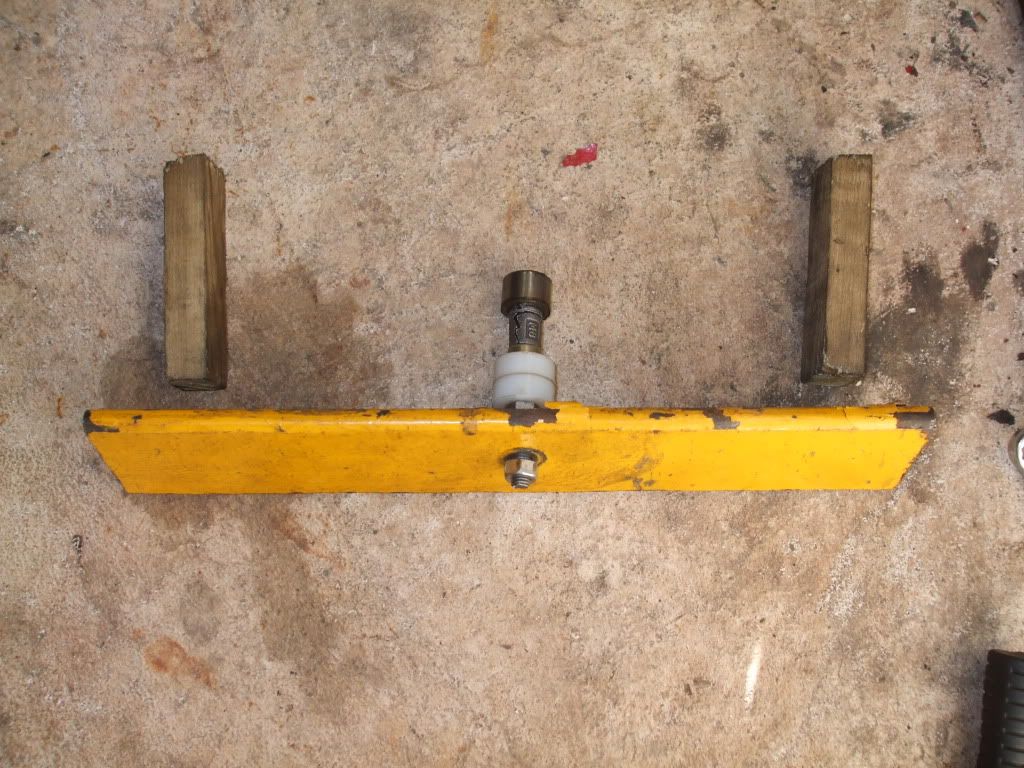

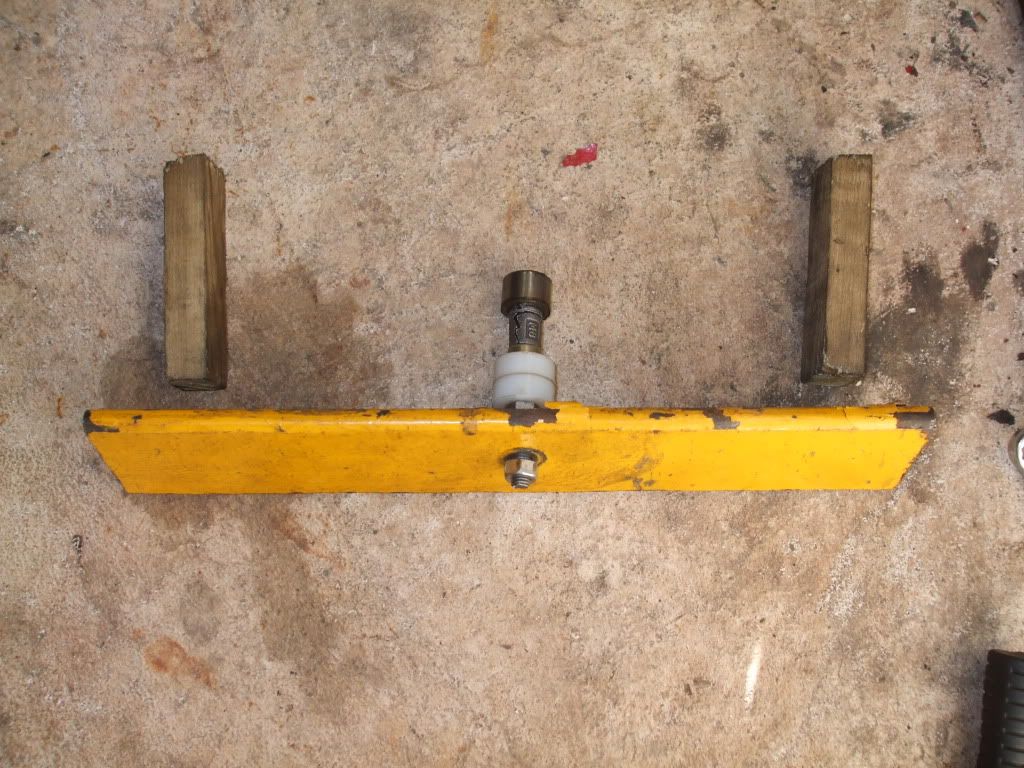

I made spigot bearing puller,worked a treat (thanks Mark)

sorry none of the gearbox etc going back in but if your at SCH tommorrow I will tell you all about it

HTH

I found this post most informative and have remade the end of slave cylinder pushrod,sits snugly now in the thrust plate.

http://www.pistonheads.com/xforums/topic.asp?h=0&a...

Here are a few pics.

I made spigot bearing puller,worked a treat (thanks Mark)

sorry none of the gearbox etc going back in but if your at SCH tommorrow I will tell you all about it

Mike, don't know if this will help but when I worked on Rover V8 engines we used to 'Hydraulic' the spigot bearings out to change them.

Fill the hole in the end of the crank as much as you can with some form of grease. Then find a piece of bar which matches the spigot bush internal diameter (15mm from what you say).

Place the bar into the spigot bush, won't go in too far as the grease will stop it. Then tap the end of the bar with a medium sized persuading tool (or a hammer if you have one).

The pressure built up in the grease will force the spigot bush out, onto the bar.

I thought the guy who showed me this was having a laugh (I was only an apprentice). but it actually works a treat.

HTH Bob

Fill the hole in the end of the crank as much as you can with some form of grease. Then find a piece of bar which matches the spigot bush internal diameter (15mm from what you say).

Place the bar into the spigot bush, won't go in too far as the grease will stop it. Then tap the end of the bar with a medium sized persuading tool (or a hammer if you have one).

The pressure built up in the grease will force the spigot bush out, onto the bar.

I thought the guy who showed me this was having a laugh (I was only an apprentice). but it actually works a treat.

HTH Bob

phillpot said:

Thanks Bob, never seen it done, but was also told that way many years ago.

The Rawlblot and bracket looks a bit less messy so (when I get around to it) will try that first but have the grease and big hammer in reserve

Hello Mike,The Rawlblot and bracket looks a bit less messy so (when I get around to it) will try that first but have the grease and big hammer in reserve

I tried the hydraulic method but gave up after being splatted in grease a couple of times.

I found that the spigot bearing needed pulling out as it was stuck fast.

Edited by DeadSpider on Thursday 27th January 19:52

Bobhon said:

Mike, don't know if this will help but when I worked on Rover V8 engines we used to 'Hydraulic' the spigot bearings out to change them.

Fill the hole in the end of the crank as much as you can with some form of grease. Then find a piece of bar which matches the spigot bush internal diameter (15mm from what you say).

Place the bar into the spigot bush, won't go in too far as the grease will stop it. Then tap the end of the bar with a medium sized persuading tool (or a hammer if you have one).

The pressure built up in the grease will force the spigot bush out, onto the bar.

I thought the guy who showed me this was having a laugh (I was only an apprentice). but it actually works a treat.

HTH Bob

I tried this numerous times with no success before I made the rawl bolt puller that Lou copied. The full make up is on my website hereFill the hole in the end of the crank as much as you can with some form of grease. Then find a piece of bar which matches the spigot bush internal diameter (15mm from what you say).

Place the bar into the spigot bush, won't go in too far as the grease will stop it. Then tap the end of the bar with a medium sized persuading tool (or a hammer if you have one).

The pressure built up in the grease will force the spigot bush out, onto the bar.

I thought the guy who showed me this was having a laugh (I was only an apprentice). but it actually works a treat.

HTH Bob

Has anyone ever has a spigot bearing fail?

I've never heard of one failing, at the end of the day it doesn't get much load most of the time, and when you are driving along normally it isn't even spinning.

Just curious I can't disagree that its good practice to change it although the little bugger sounds like fun.

I've never heard of one failing, at the end of the day it doesn't get much load most of the time, and when you are driving along normally it isn't even spinning.

Just curious I can't disagree that its good practice to change it although the little bugger sounds like fun.

Barkychoc said:

Has anyone ever has a spigot bearing fail?

I've never heard of one failing, at the end of the day it doesn't get much load most of the time, and when you are driving along normally it isn't even spinning.

Just curious I can't disagree that its good practice to change it although the little bugger sounds like fun.

There was a thread on this a while back, it gave a similar effect to a clutch failure IIRC and it occurred in France to the poor unfortunateI've never heard of one failing, at the end of the day it doesn't get much load most of the time, and when you are driving along normally it isn't even spinning.

Just curious I can't disagree that its good practice to change it although the little bugger sounds like fun.

Gassing Station | S Series | Top of Page | What's New | My Stuff