Tamiya Caterham 1/12 - modified

Discussion

Ok - as I have started the work on these again, I thought I'd open a thread on here.

I'll post a few pictures from when I started these *cough* about 10 years ago.

Brief history: I was made redundant, and before starting back at a design consultancy I had previously worked at, I occupied a corner of their workshop,and started these models. The idea was to make some money in between jobs..

I tapped the Lotus 7 Club community, and got a few 'commissions' to make peoples cars, based on the Tamiya 1/12 kit.

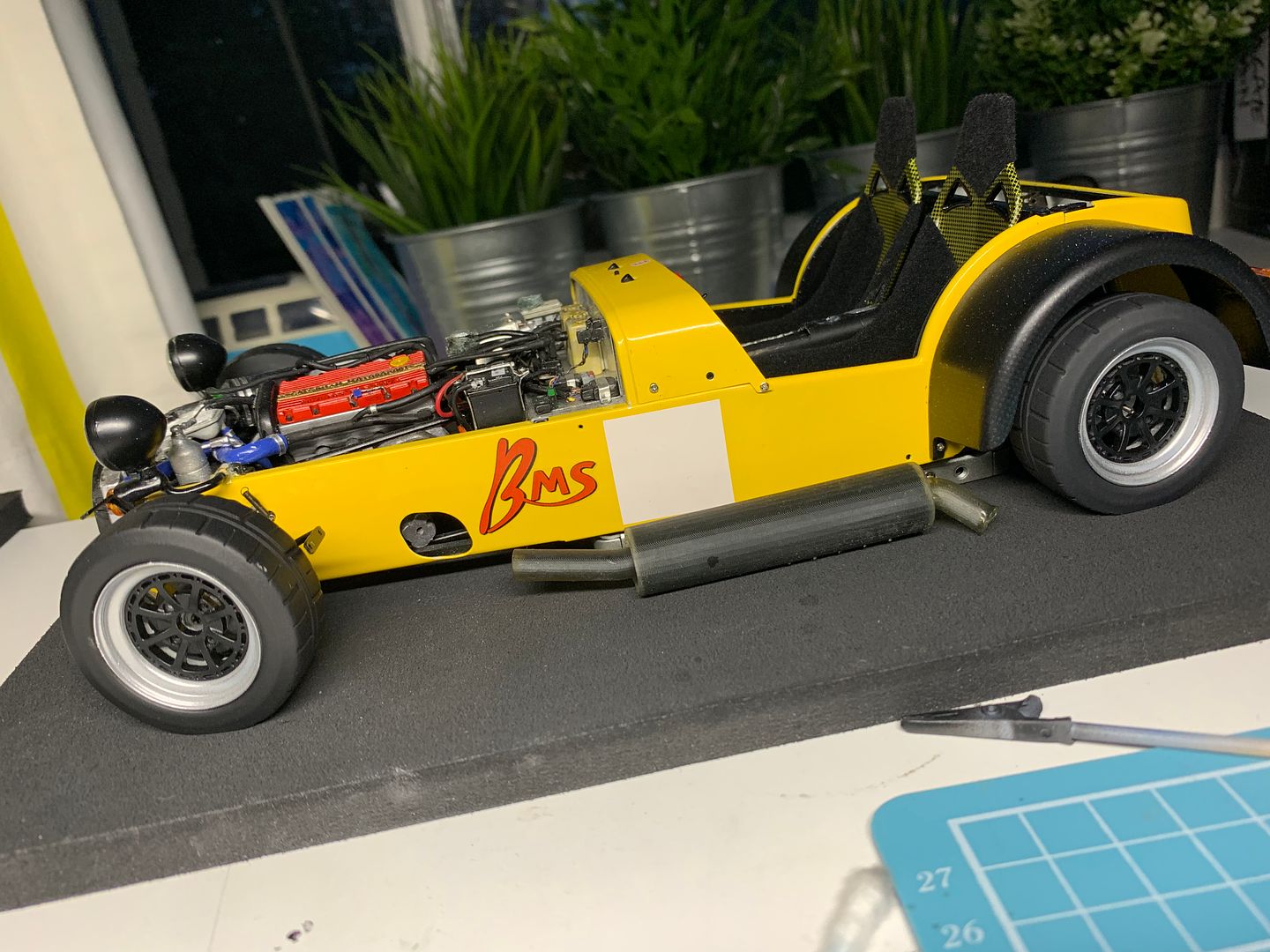

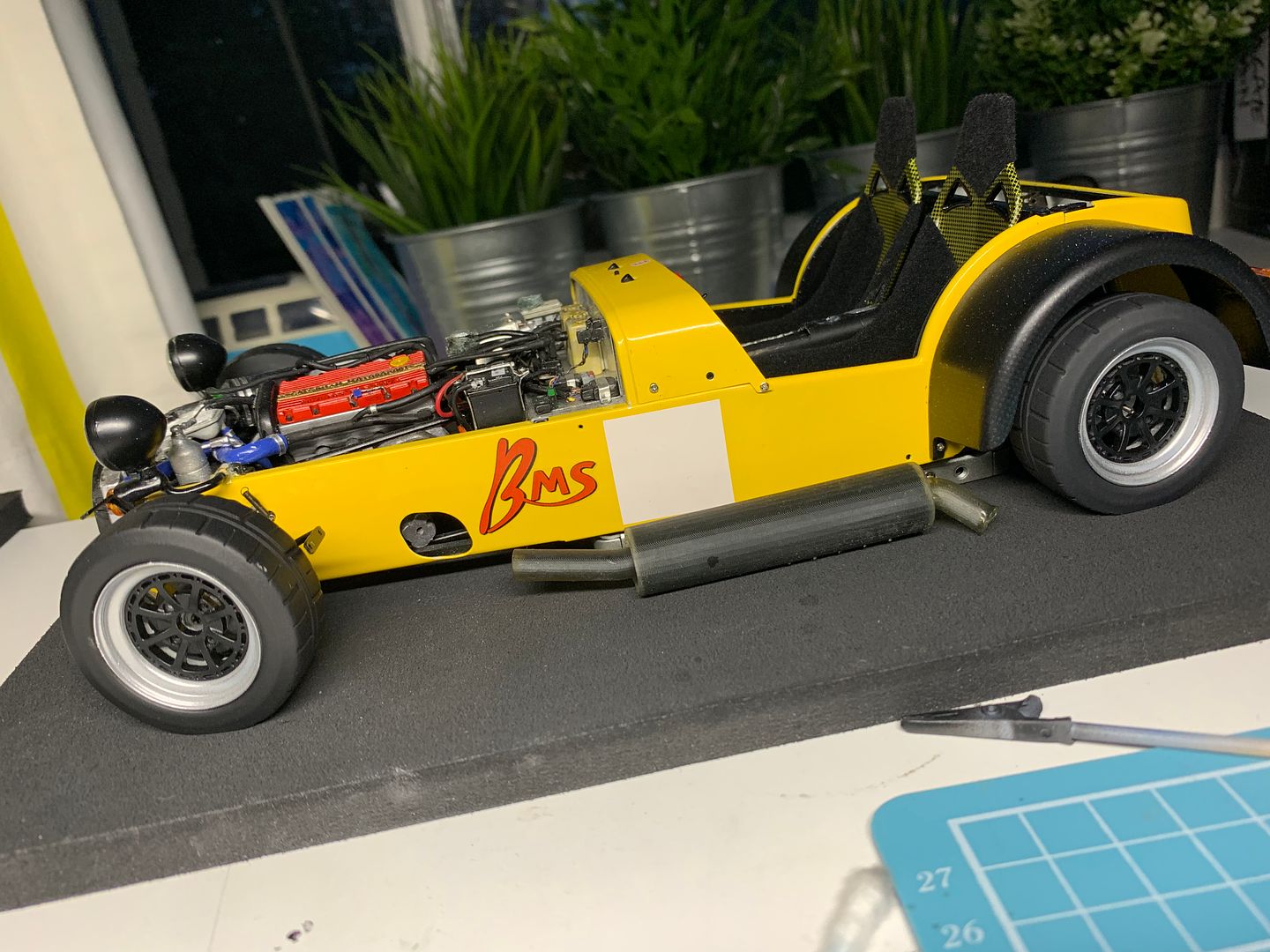

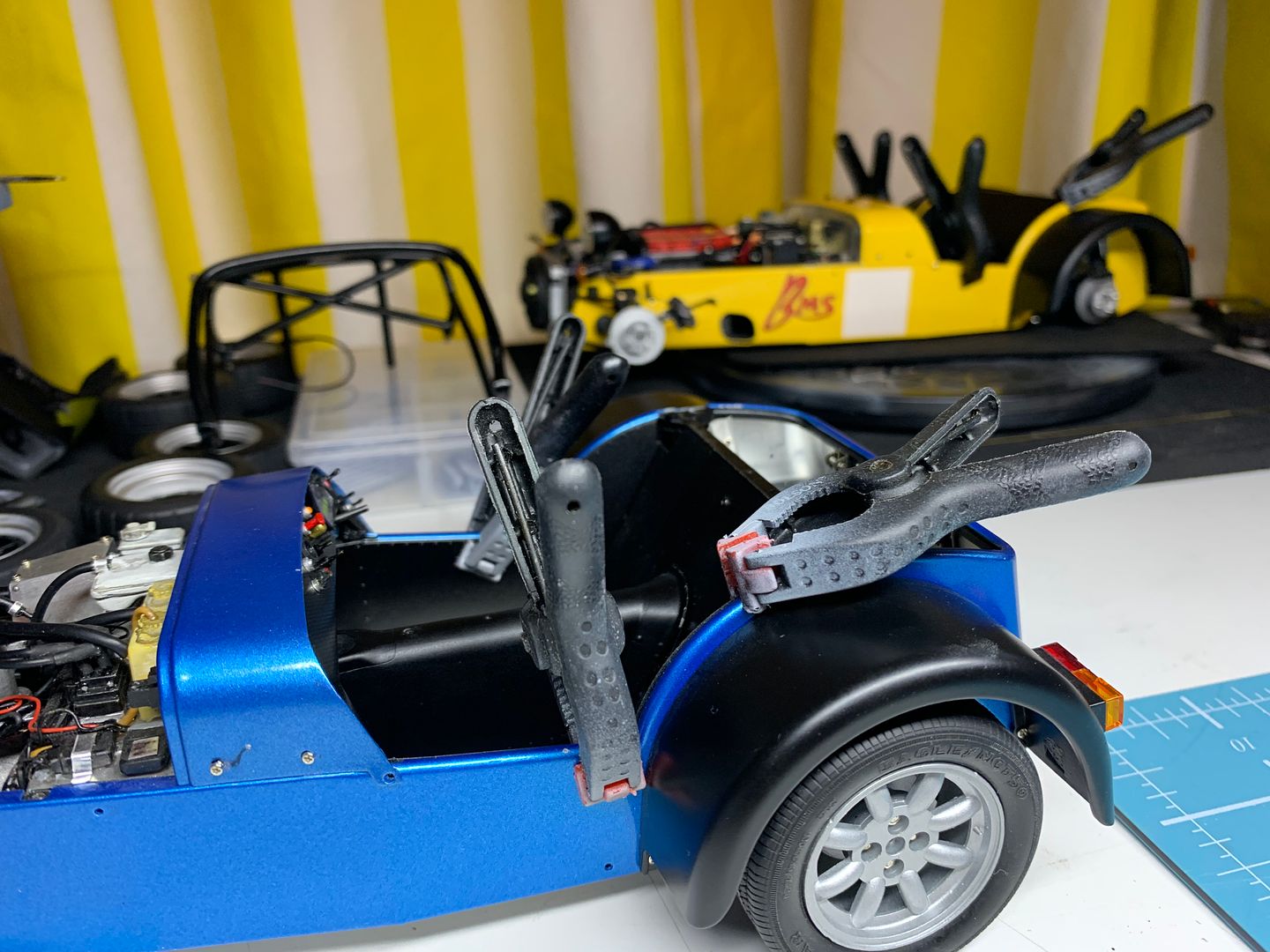

These two models were owned by the same chap - both R500's that he race, before moving on to Radicals. The yellow car was the star of a very early 'Ring lap video...

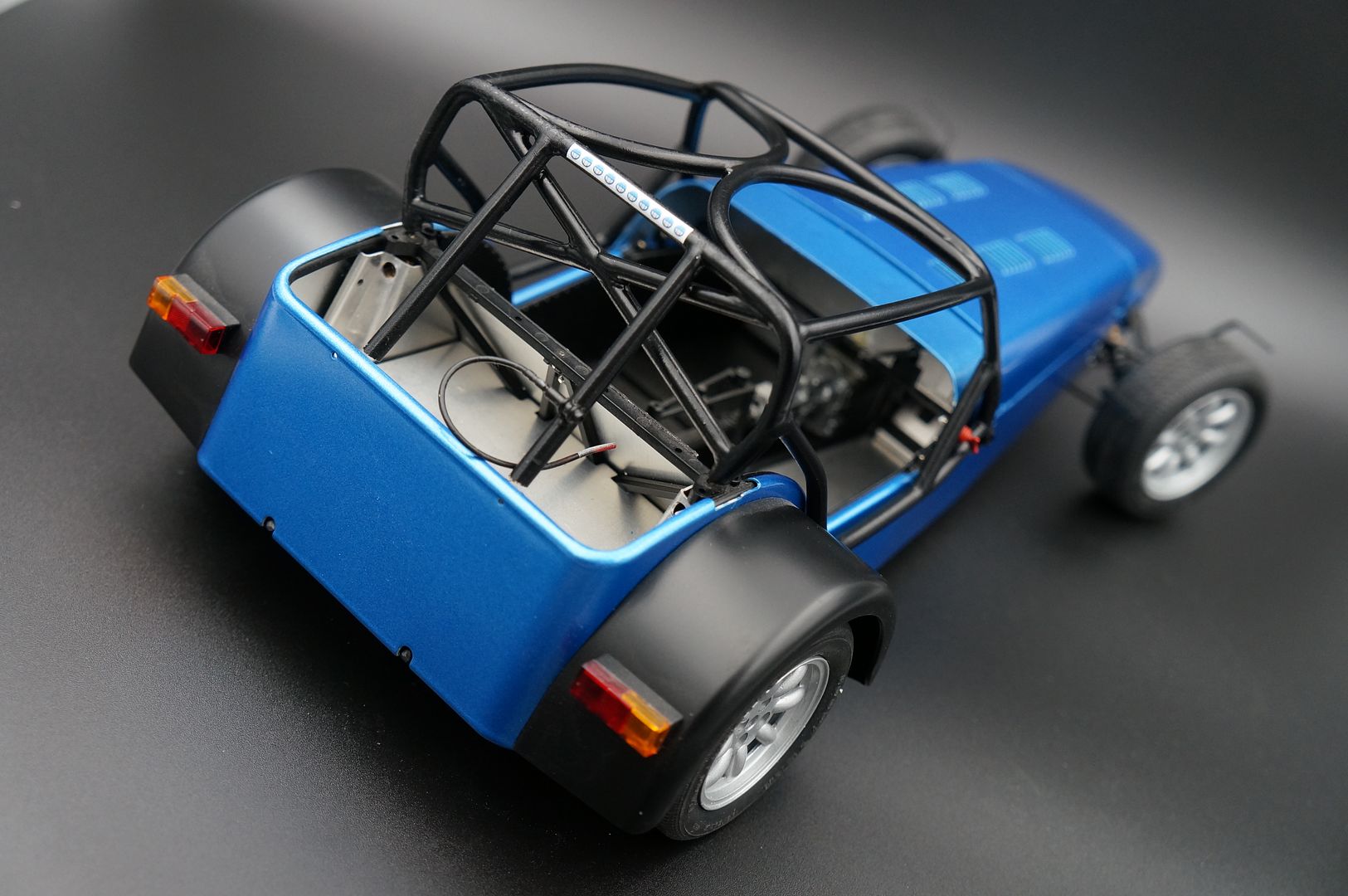

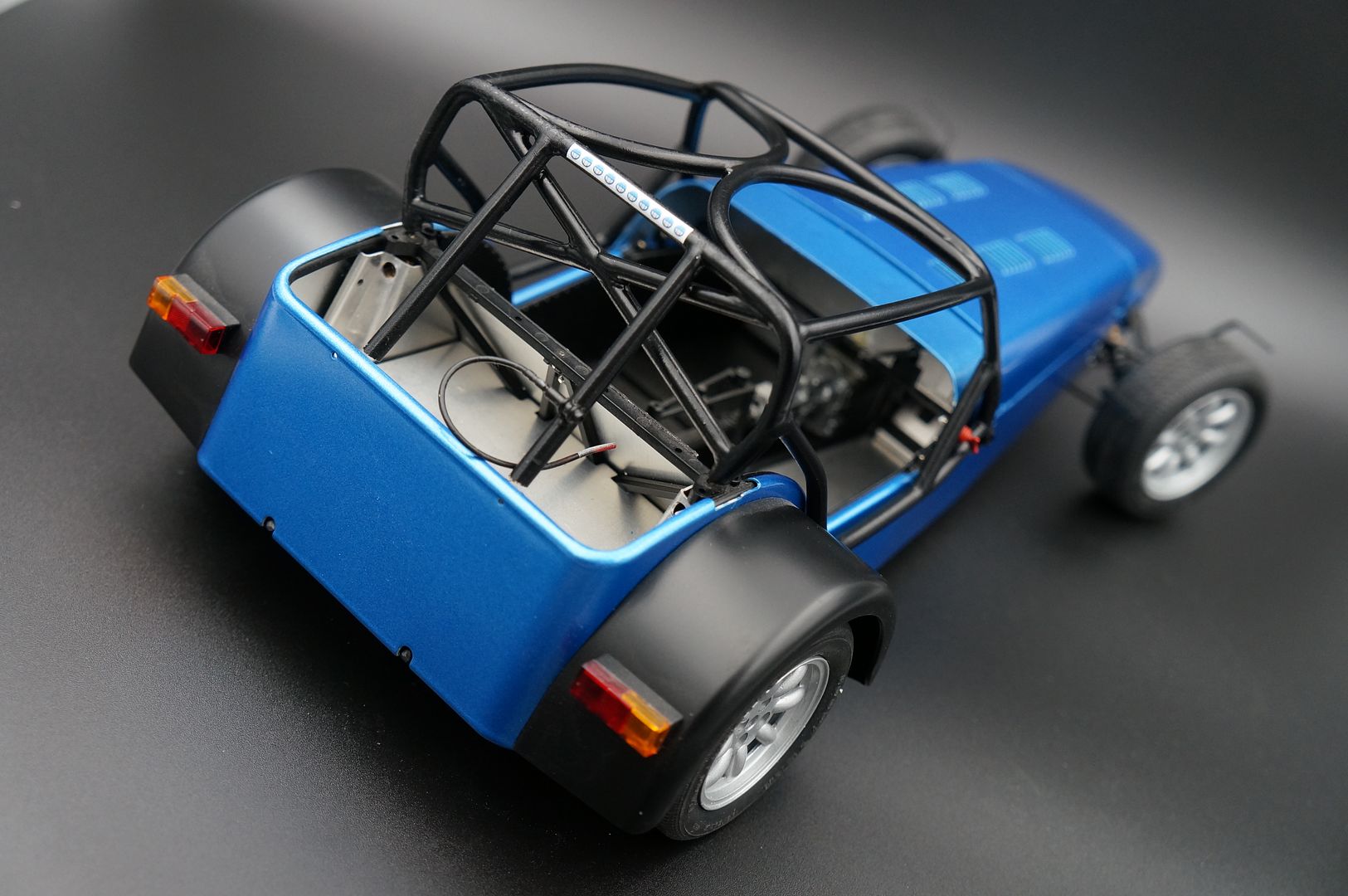

Anyway - I took loads of source pictures of the cars up at Snetterton, and started the cars. I was making them as close to the actual cars as I could. This included changing the engine from a BDR to a 'K-series', adding a full cage, tillet seats etc etc.

I started with crazy detail (same wiring etc!) and of course once you have started, you have to carry on with that level of detail! As any of you who do this to a far higher standard know - this stuff takes a HUGE amount of time...real life took over, I got a new 'proper' job, and the model making took a back seat. I was also stuck at a certain point where I could not make what I had to make - particularly the Tillet seats and a few other details such as rims and tyres....this is not my profession and I did (and don't) have access to mini lathes etc - the shop did vacuum casting, but 3D printing did not exist like it does now. I had to learn software to draw stuff etc etc...

Throughout this, my 'customer' exhibited massive patience...I think he probably gave up. But I was always going to finish the models, and now the time is right, for various reasons. 3D printing is more accessible, as is the supply of modelling supplies via the web! I have an airbrush now!! (everything was hand painted up to now - halfords spray cans for the bodywork!

These models are a bit different from the ultra-detail plastic/diecast kits you can see elsewhere - I'm scratch building by hand, so nothing is measured to 'nth degree etc -

These Tamiya kits are amazing - I rebuilt my 'real' Caterham and it is exactly the same! They have shot up in price though. Wish I had had the funds to buy more 10 years ago - they have doubled now.

I posted more pictures years ago on my website, so you can see them here:

http://mycaterham.com/17619/15191.html

I'll repeat a few here then move onto the recent stuff of the last week...

The Real Car!

There are other threads on here showing the construction of the Tamiya kit, so I'll bypass that - you can see it on my website link above...

'K series' cam cover

Real!

The 'old' R500 exhaust (and induction!) were a nightmare of curves to fit in a small engine bay - even harder this size!

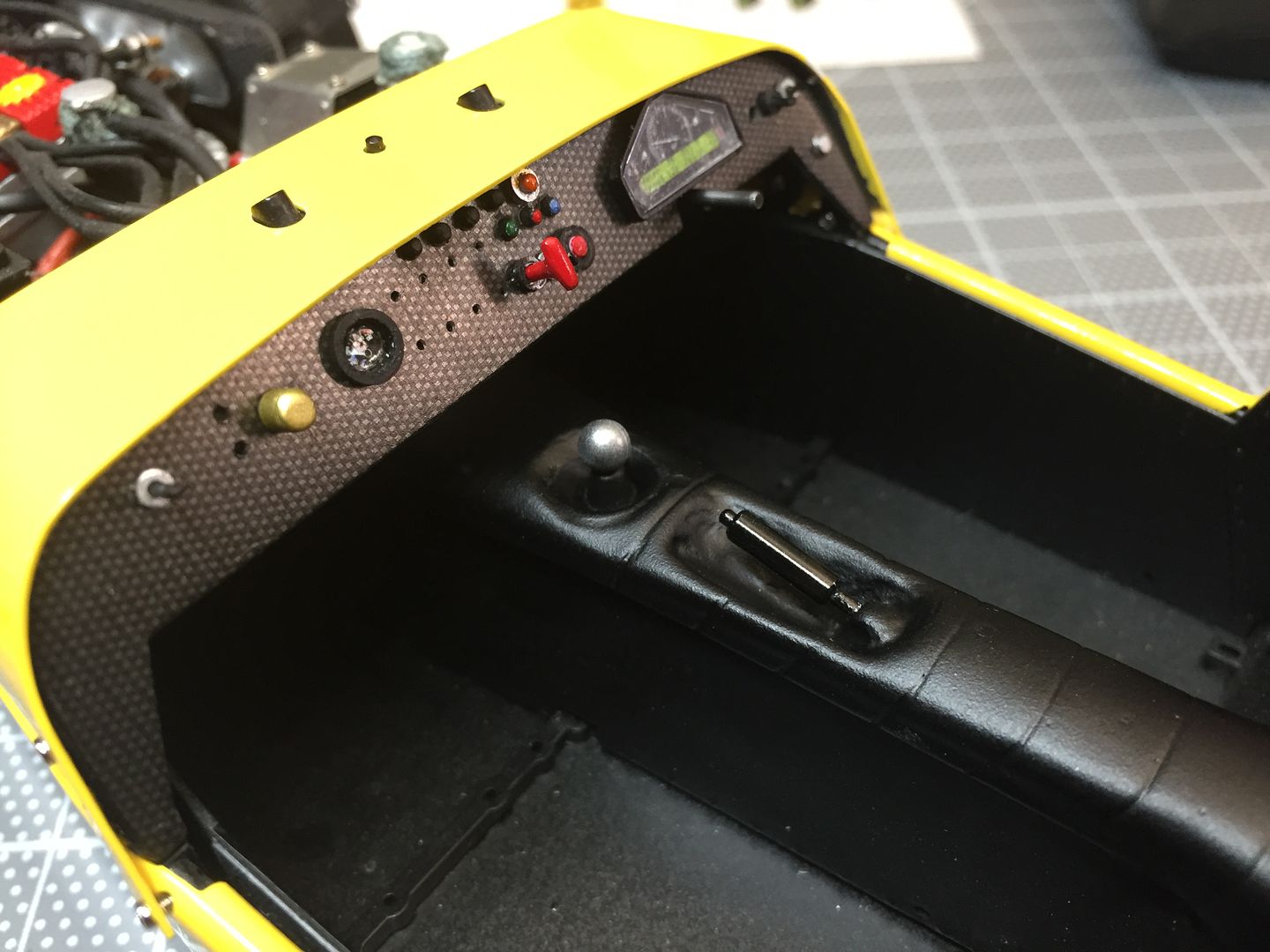

Only things carried over from the kit are the brake fluid reservoir, the coolant tank and pedal box - everything else is scratch built...

Engine bay was complete - except of course there are 2 cars - and the engine bays are subtly different...

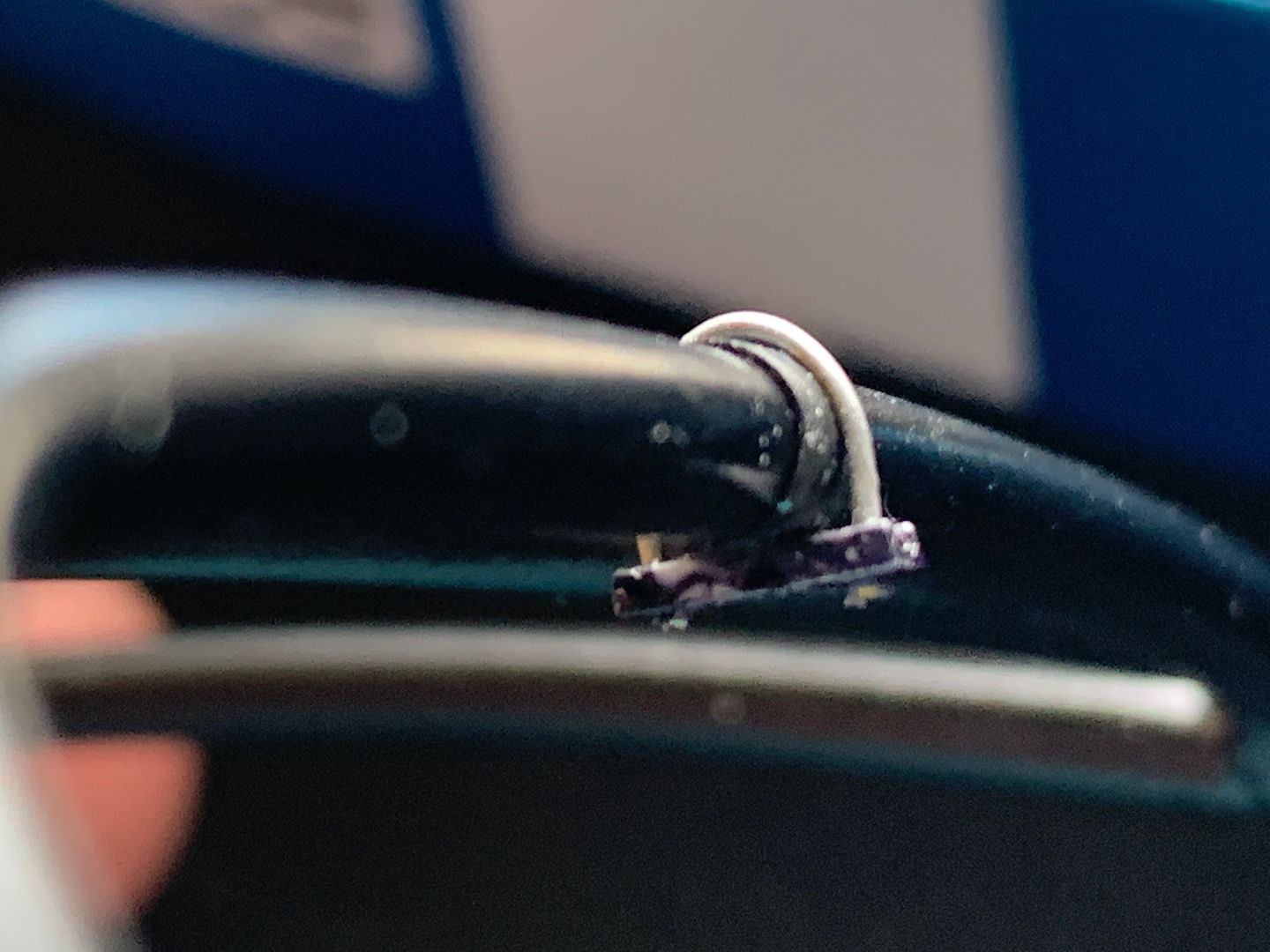

FIA cut-off keys!

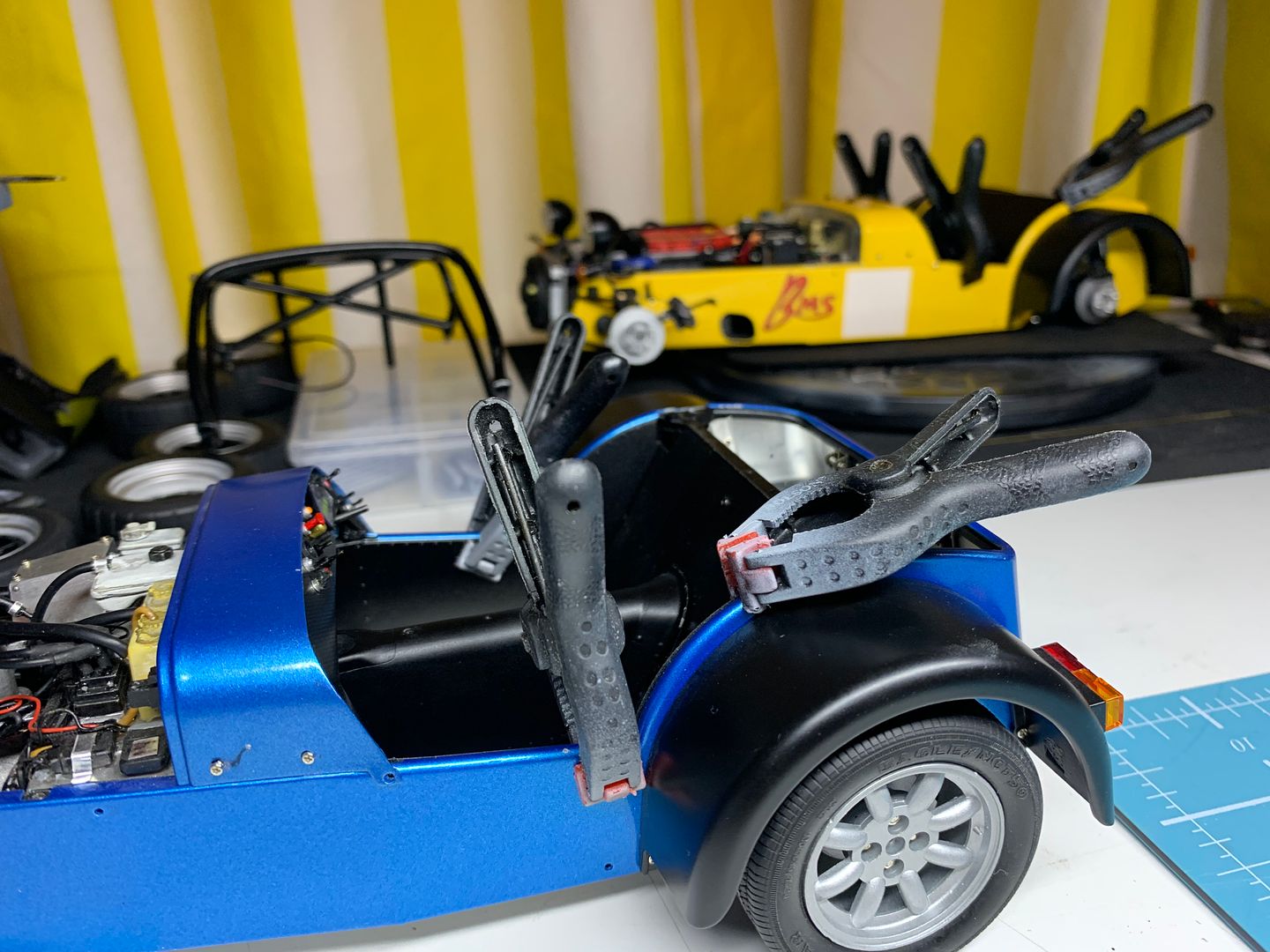

I'm actually most proud of the SLR roll cages I had to scratch make. Scaled from photos, I put coat-hanger wire inside black plastic tube, made some formers and bent the wire. They came out really well, and look amazing on the models - IMO!

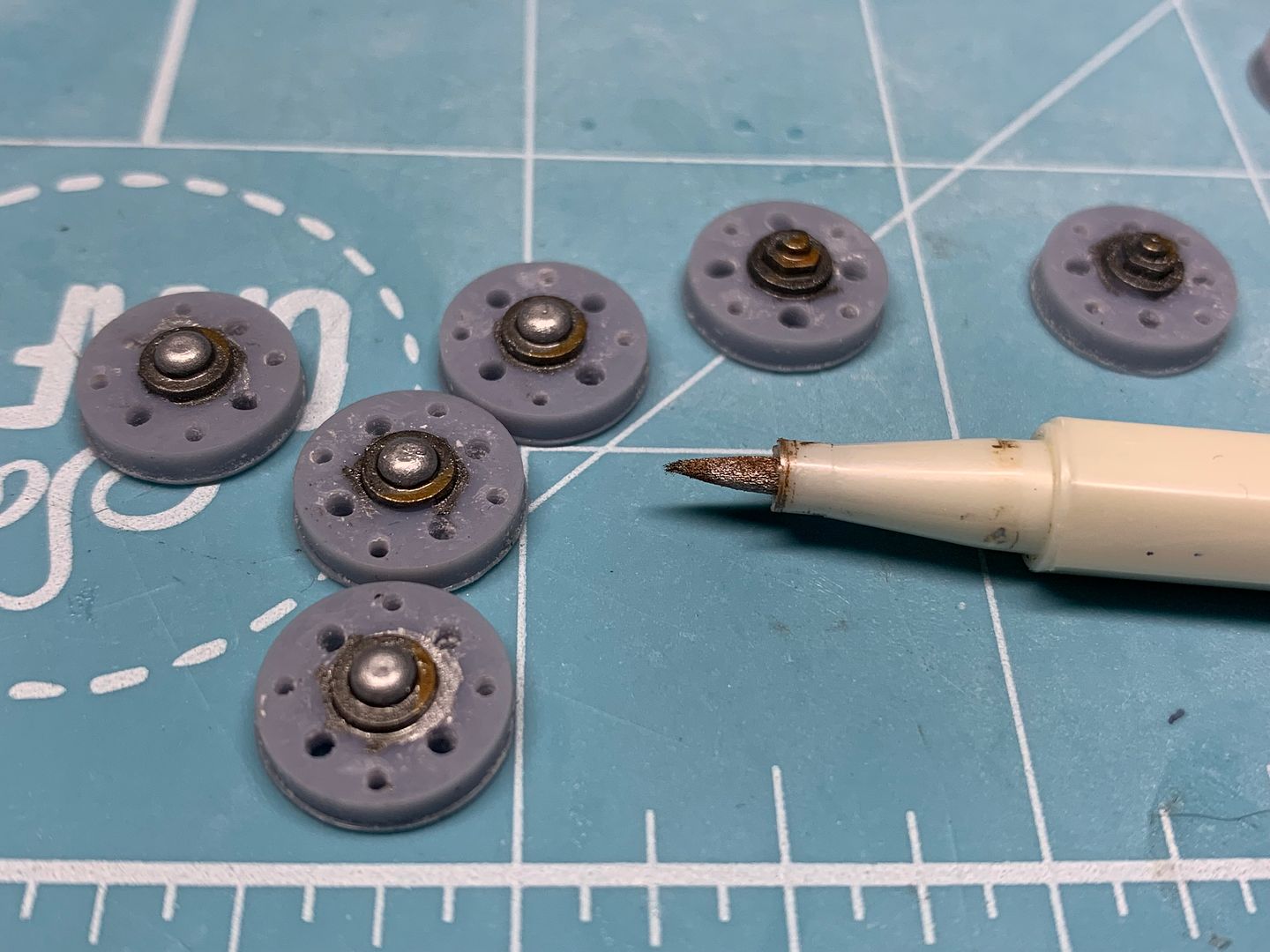

I drew up the Mike Barnby mag wheel hubs in Pro E (back then!) and the only CAD CAM bit so far was milling these hubs out of plastic (after testing using aluminium) - I'll make a cast of these for future!

...and that is pretty much where everything stayed for 10 years!!

When I came out to NYC to work, I gradually carried all the kits over here to force myself to get on with the damn things!

So - another few years later -I am!

List of things to do:

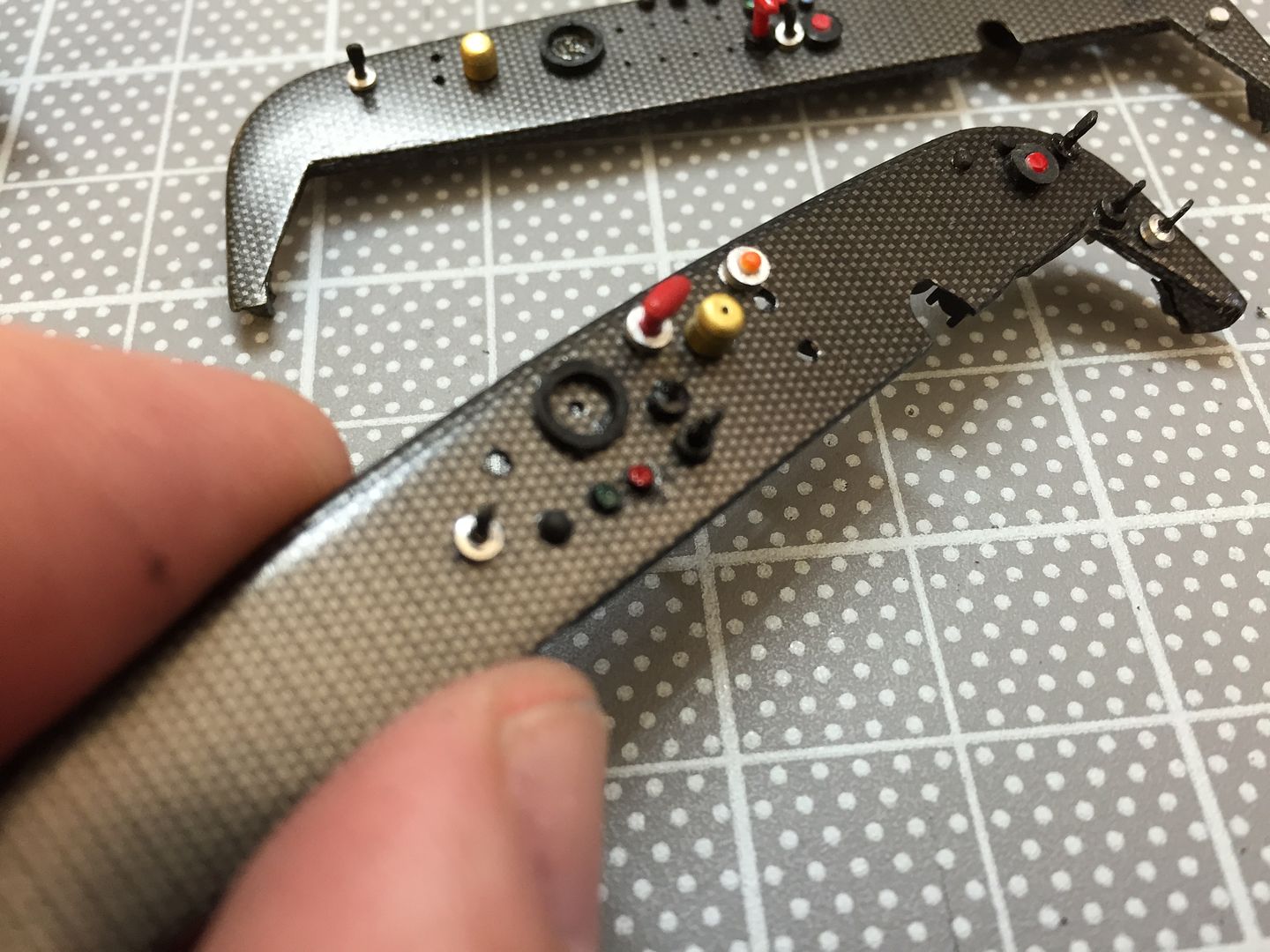

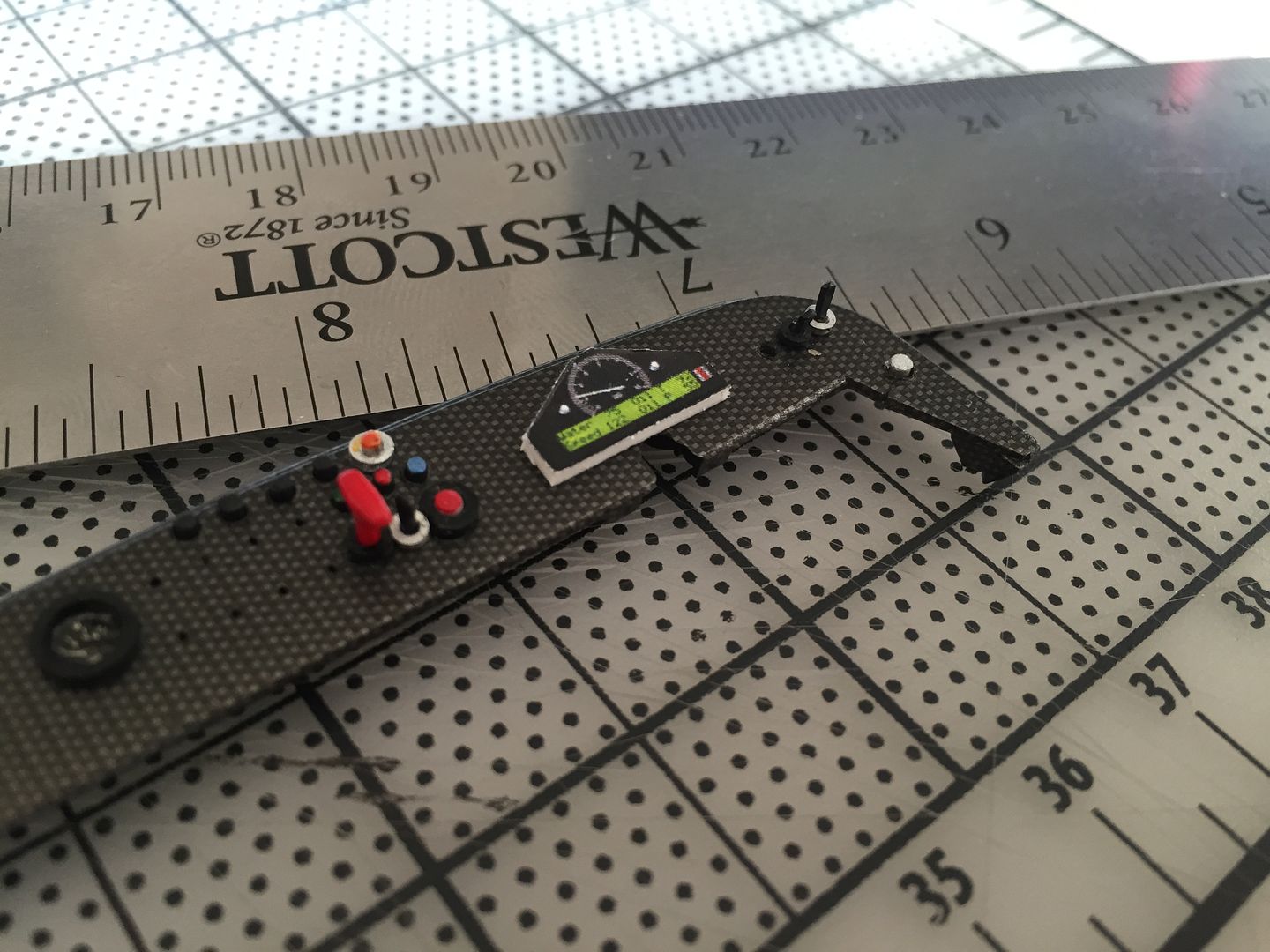

Dash boards

Tillet seats - biggest job!

Wheels - rims and tyres

Exhaust system

Find the Blue model!!

Interior (tunnels, seatbelts etc)

Decals! Another sticking point years ago...

Half 'Doors'

Screens

Fog lights etc, number plates

and loads of little wiring details...

So everything from now on is from the 'present'!

I'll post a few pictures from when I started these *cough* about 10 years ago.

Brief history: I was made redundant, and before starting back at a design consultancy I had previously worked at, I occupied a corner of their workshop,and started these models. The idea was to make some money in between jobs..

I tapped the Lotus 7 Club community, and got a few 'commissions' to make peoples cars, based on the Tamiya 1/12 kit.

These two models were owned by the same chap - both R500's that he race, before moving on to Radicals. The yellow car was the star of a very early 'Ring lap video...

Anyway - I took loads of source pictures of the cars up at Snetterton, and started the cars. I was making them as close to the actual cars as I could. This included changing the engine from a BDR to a 'K-series', adding a full cage, tillet seats etc etc.

I started with crazy detail (same wiring etc!) and of course once you have started, you have to carry on with that level of detail! As any of you who do this to a far higher standard know - this stuff takes a HUGE amount of time...real life took over, I got a new 'proper' job, and the model making took a back seat. I was also stuck at a certain point where I could not make what I had to make - particularly the Tillet seats and a few other details such as rims and tyres....this is not my profession and I did (and don't) have access to mini lathes etc - the shop did vacuum casting, but 3D printing did not exist like it does now. I had to learn software to draw stuff etc etc...

Throughout this, my 'customer' exhibited massive patience...I think he probably gave up. But I was always going to finish the models, and now the time is right, for various reasons. 3D printing is more accessible, as is the supply of modelling supplies via the web! I have an airbrush now!! (everything was hand painted up to now - halfords spray cans for the bodywork!

These models are a bit different from the ultra-detail plastic/diecast kits you can see elsewhere - I'm scratch building by hand, so nothing is measured to 'nth degree etc -

These Tamiya kits are amazing - I rebuilt my 'real' Caterham and it is exactly the same! They have shot up in price though. Wish I had had the funds to buy more 10 years ago - they have doubled now.

I posted more pictures years ago on my website, so you can see them here:

http://mycaterham.com/17619/15191.html

I'll repeat a few here then move onto the recent stuff of the last week...

The Real Car!

There are other threads on here showing the construction of the Tamiya kit, so I'll bypass that - you can see it on my website link above...

'K series' cam cover

Real!

The 'old' R500 exhaust (and induction!) were a nightmare of curves to fit in a small engine bay - even harder this size!

Only things carried over from the kit are the brake fluid reservoir, the coolant tank and pedal box - everything else is scratch built...

Engine bay was complete - except of course there are 2 cars - and the engine bays are subtly different...

FIA cut-off keys!

I'm actually most proud of the SLR roll cages I had to scratch make. Scaled from photos, I put coat-hanger wire inside black plastic tube, made some formers and bent the wire. They came out really well, and look amazing on the models - IMO!

I drew up the Mike Barnby mag wheel hubs in Pro E (back then!) and the only CAD CAM bit so far was milling these hubs out of plastic (after testing using aluminium) - I'll make a cast of these for future!

...and that is pretty much where everything stayed for 10 years!!

When I came out to NYC to work, I gradually carried all the kits over here to force myself to get on with the damn things!

So - another few years later -I am!

List of things to do:

Dash boards

Tillet seats - biggest job!

Wheels - rims and tyres

Exhaust system

Find the Blue model!!

Interior (tunnels, seatbelts etc)

Decals! Another sticking point years ago...

Half 'Doors'

Screens

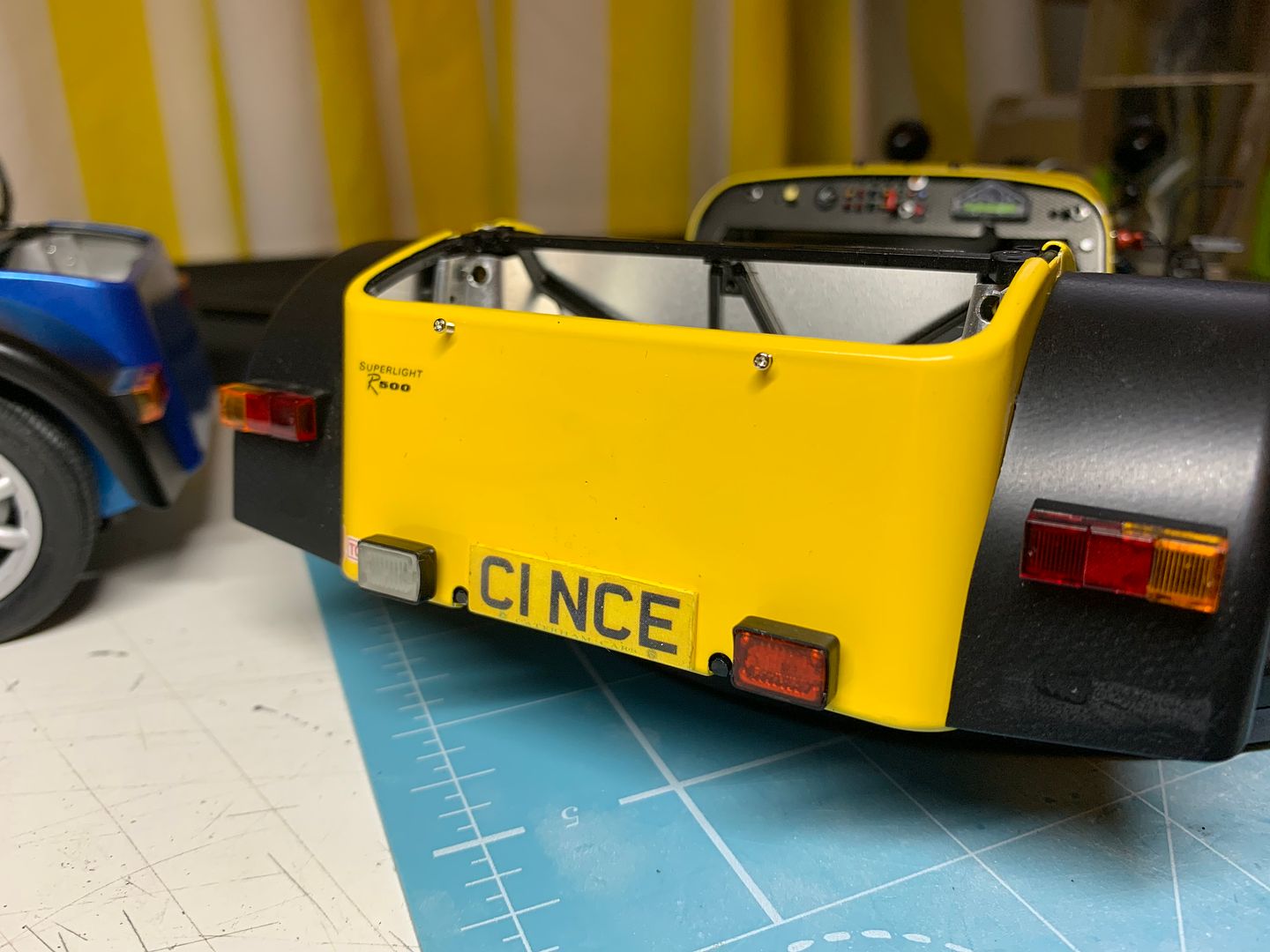

Fog lights etc, number plates

and loads of little wiring details...

So everything from now on is from the 'present'!

Edited by caterhamnut on Saturday 11th July 00:32

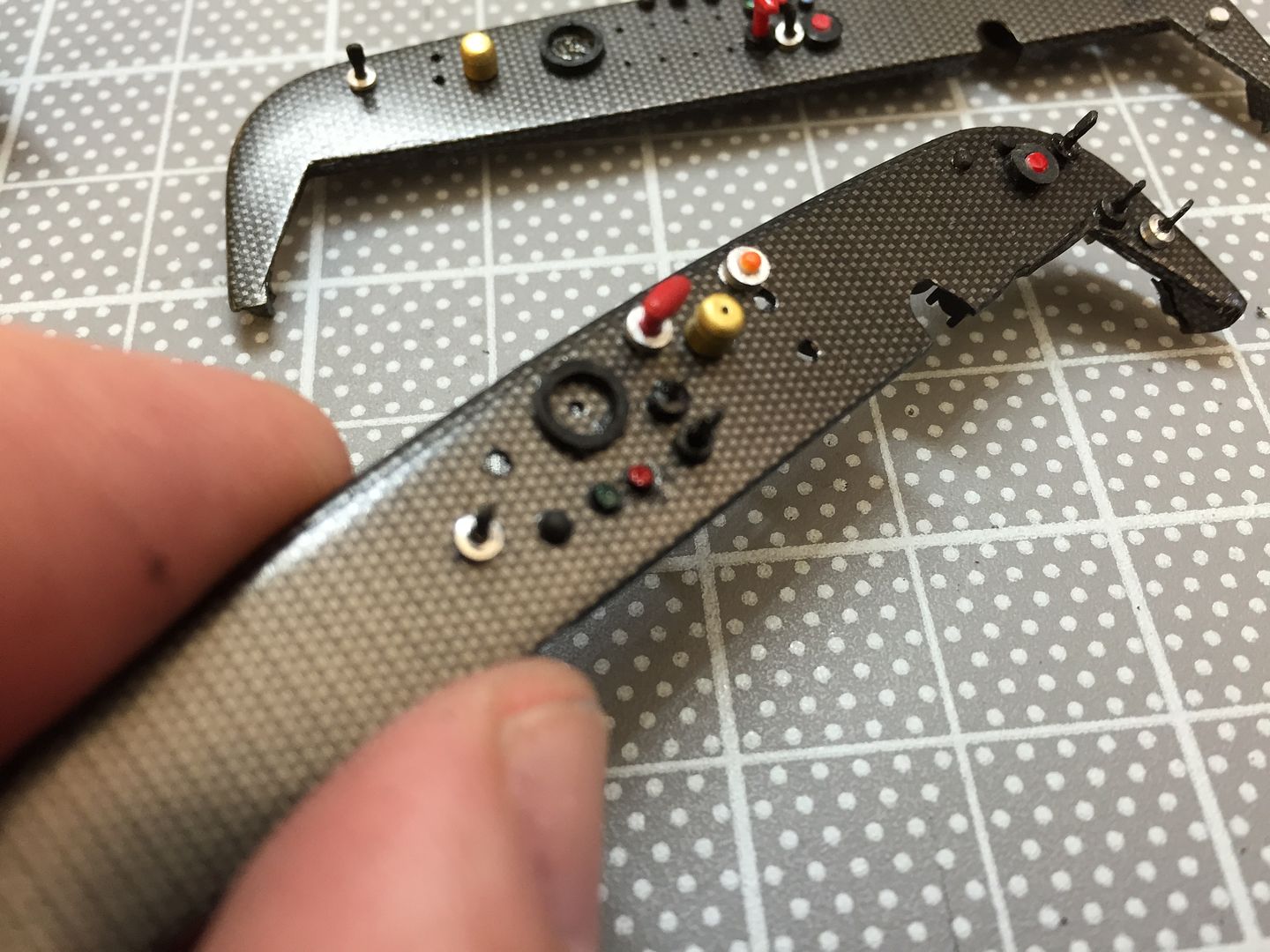

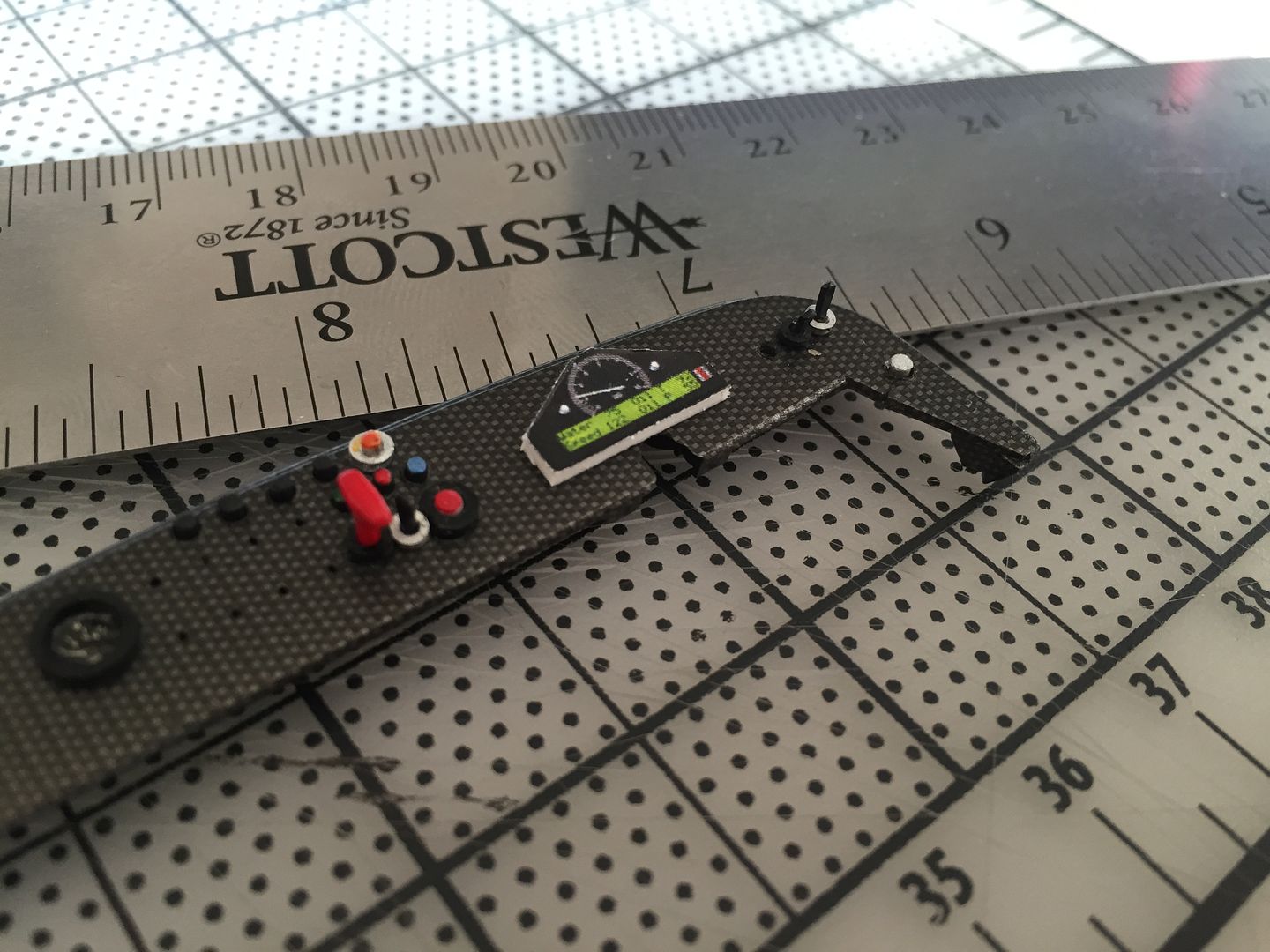

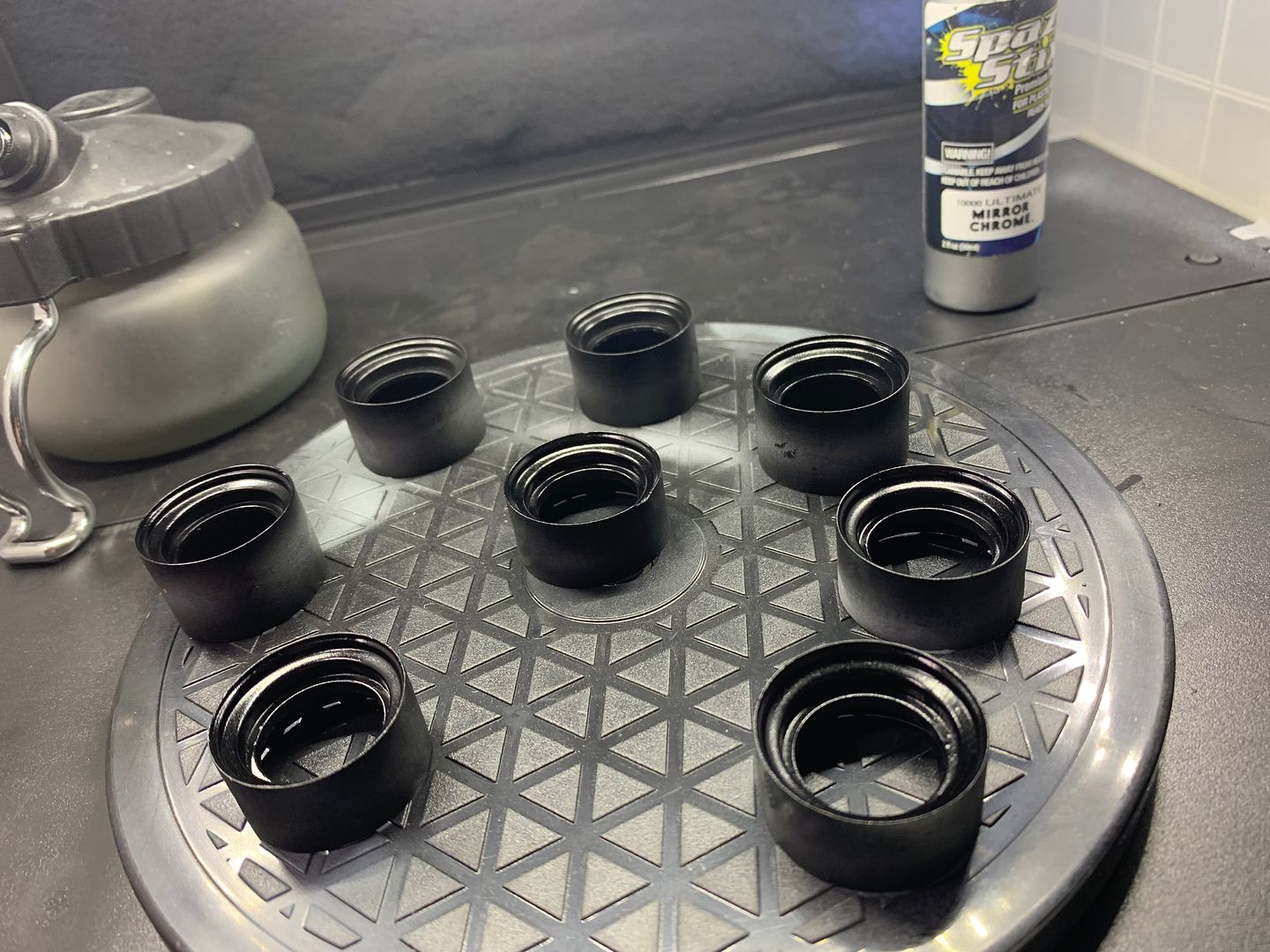

ok - so tried some of those decal sheets. Used one for the laser printer. Had to use clear and white for various decals. Pretty pleased with the results. Had to recreate all the graphics myself. Need to resize a few. Fun cutting them out (they are tiny!) but using the decal solution works well...

Made lots of spares! (also - two cars!)

Incidentally - if you look at the rear wing on this shot, you can see my 'carbon' effect.

Back then, I didn't know you could get carbon scale decals (used a lot in the F1 models) so I made mine by holding a fine brass mesh over the model piece and lightly spraying primer. This gave a nice subtle effect, which I sprayed lightly again with black (all spray cans) to tone it down. I like the effect.

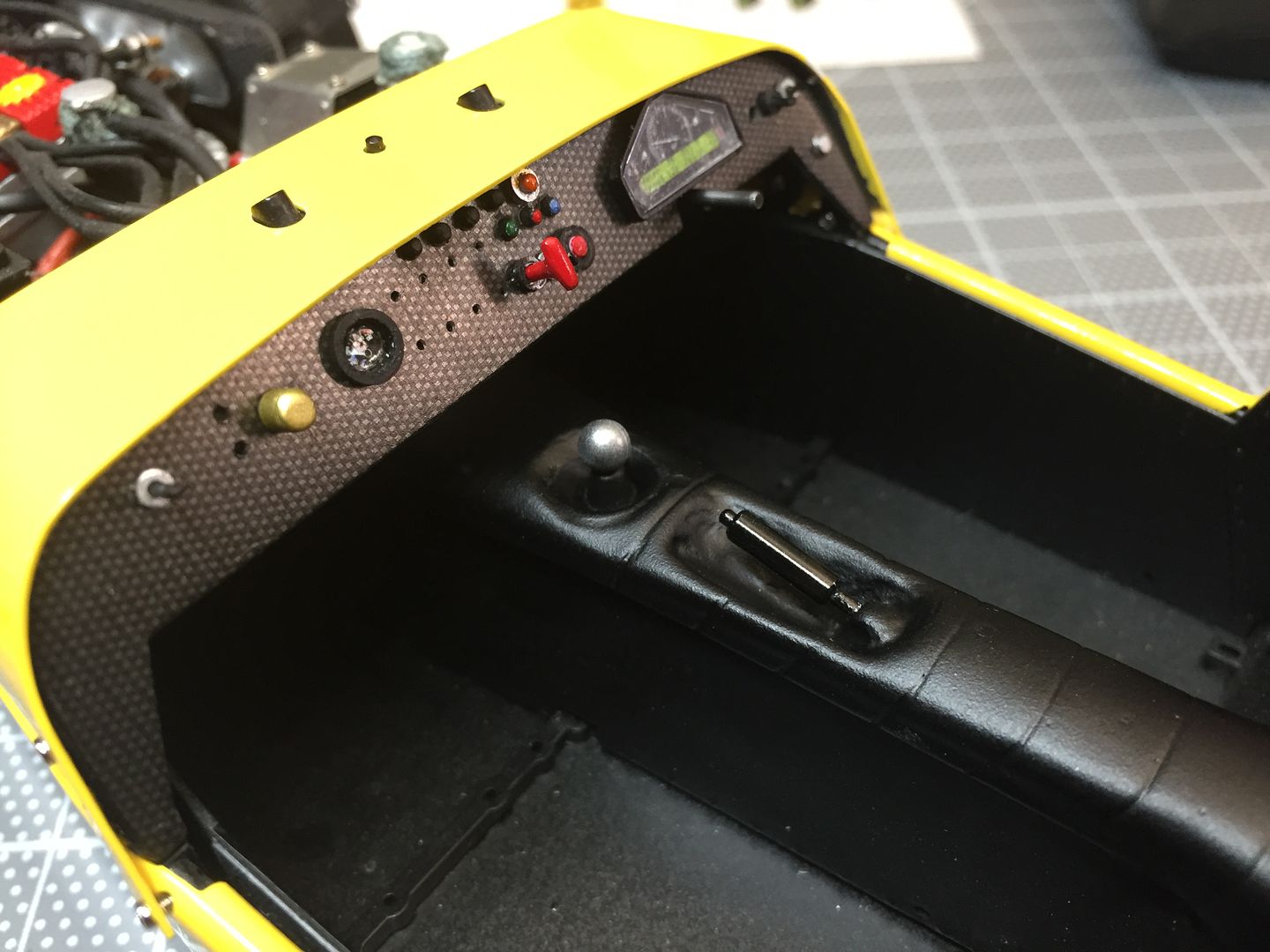

I actually find the carbon decals too 'strong' on some models, so I am leaving these as-is. However, I have used some carbon decals on the dash boards (next set of pictures!) where they work ok...

Note the timing equipment sensor on the roll cage.

Made lots of spares! (also - two cars!)

Incidentally - if you look at the rear wing on this shot, you can see my 'carbon' effect.

Back then, I didn't know you could get carbon scale decals (used a lot in the F1 models) so I made mine by holding a fine brass mesh over the model piece and lightly spraying primer. This gave a nice subtle effect, which I sprayed lightly again with black (all spray cans) to tone it down. I like the effect.

I actually find the carbon decals too 'strong' on some models, so I am leaving these as-is. However, I have used some carbon decals on the dash boards (next set of pictures!) where they work ok...

Note the timing equipment sensor on the roll cage.

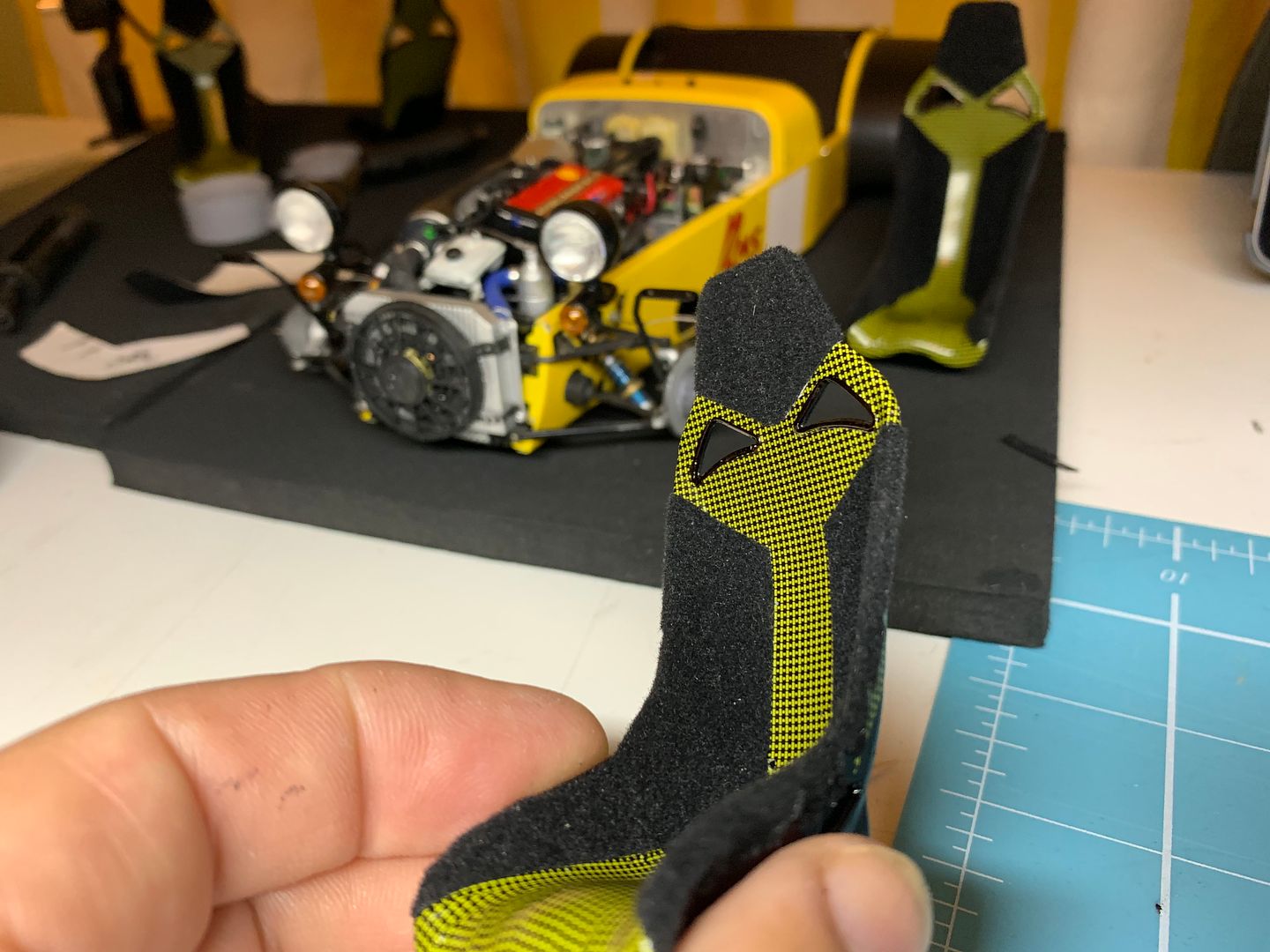

This seat has to become a carbon Tillet Race seat...

The Tamiya kit comes with an ali central tunnel (over the driveshaft) that is covered in flocking sheet to replicate carpet. The JPE version comes with a 'leather' cover molding, which has a gear lever boot molded in...the handbrake appears under the scuttle, as on the cars of that period.

Of course, I need the 'leather' version, but with a hand brake as well - this only appeared on Caterhams after the tamiya model was tooled - (*Interesting fact* - my car was the first chassis with the handbrake mounted on the central tunnel - it was the 1995 British Car show car)

- so I had to scratch build (10 years ago!) - I then took a cast so I can make more...bottom version is the one I have just finished for this model...

Ali tunnel on the kit, with piece cut away to allow the scratch built hand brake to fit...

The Tamiya kit comes with an ali central tunnel (over the driveshaft) that is covered in flocking sheet to replicate carpet. The JPE version comes with a 'leather' cover molding, which has a gear lever boot molded in...the handbrake appears under the scuttle, as on the cars of that period.

Of course, I need the 'leather' version, but with a hand brake as well - this only appeared on Caterhams after the tamiya model was tooled - (*Interesting fact* - my car was the first chassis with the handbrake mounted on the central tunnel - it was the 1995 British Car show car)

- so I had to scratch build (10 years ago!) - I then took a cast so I can make more...bottom version is the one I have just finished for this model...

Ali tunnel on the kit, with piece cut away to allow the scratch built hand brake to fit...

Hi Eric - yep, hardly go there now. Can't explain why - new website/blatchat was a pain (wouldn't let me log on etc for ages) and lack of interesting chat...plus a lot of people I chat with are elsewhere more, on more 'accessible' sites - use FB a lot, simply because it is so easy to post pictures!

Anyway - getting back into modelling a bit now - had an ebay fit a few weeks ago and suddenly have a cupboard (or 3) full of kits - mainly all the 1/12 Tamiya F1 kits (but also a lot of the 1/20 versions) and a few oddities - really fancy that new large scale Mosquito one day....

Anyway - getting back into modelling a bit now - had an ebay fit a few weeks ago and suddenly have a cupboard (or 3) full of kits - mainly all the 1/12 Tamiya F1 kits (but also a lot of the 1/20 versions) and a few oddities - really fancy that new large scale Mosquito one day....

Right - major update time!! These models were started about 2002 - all the pictures above are from that era, apart from the last bunch with decals etc, which were taken in New York 4 years ago...its time to finish these cars!

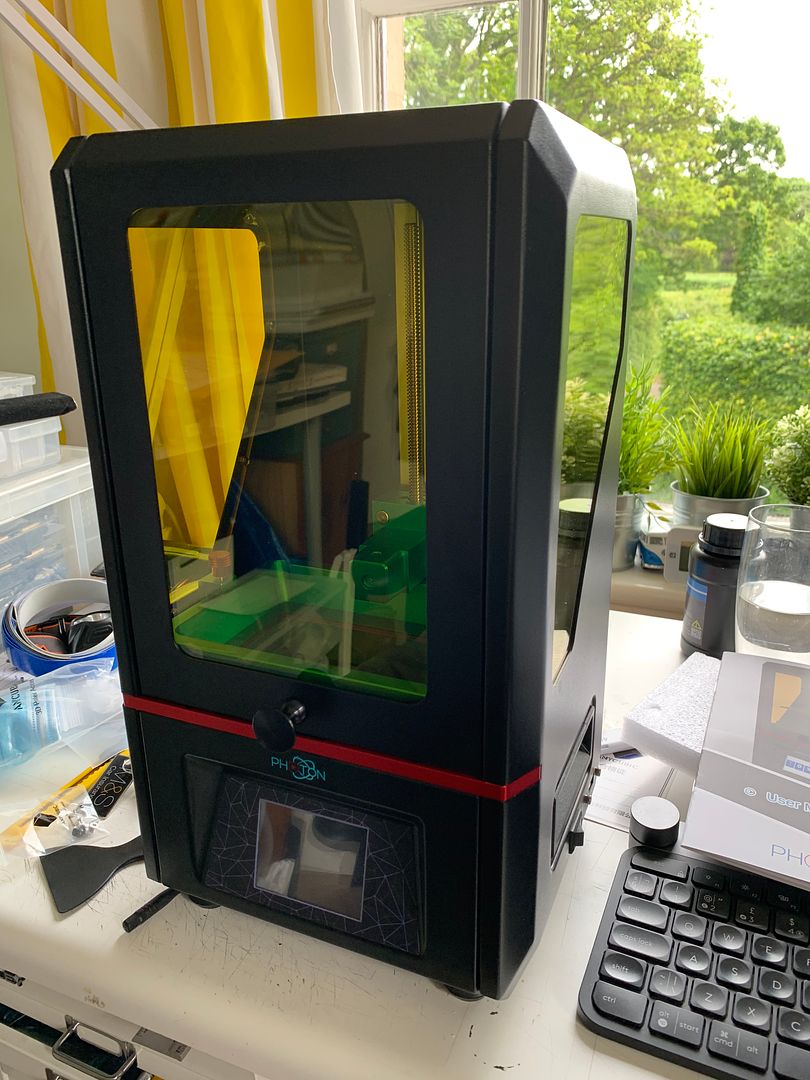

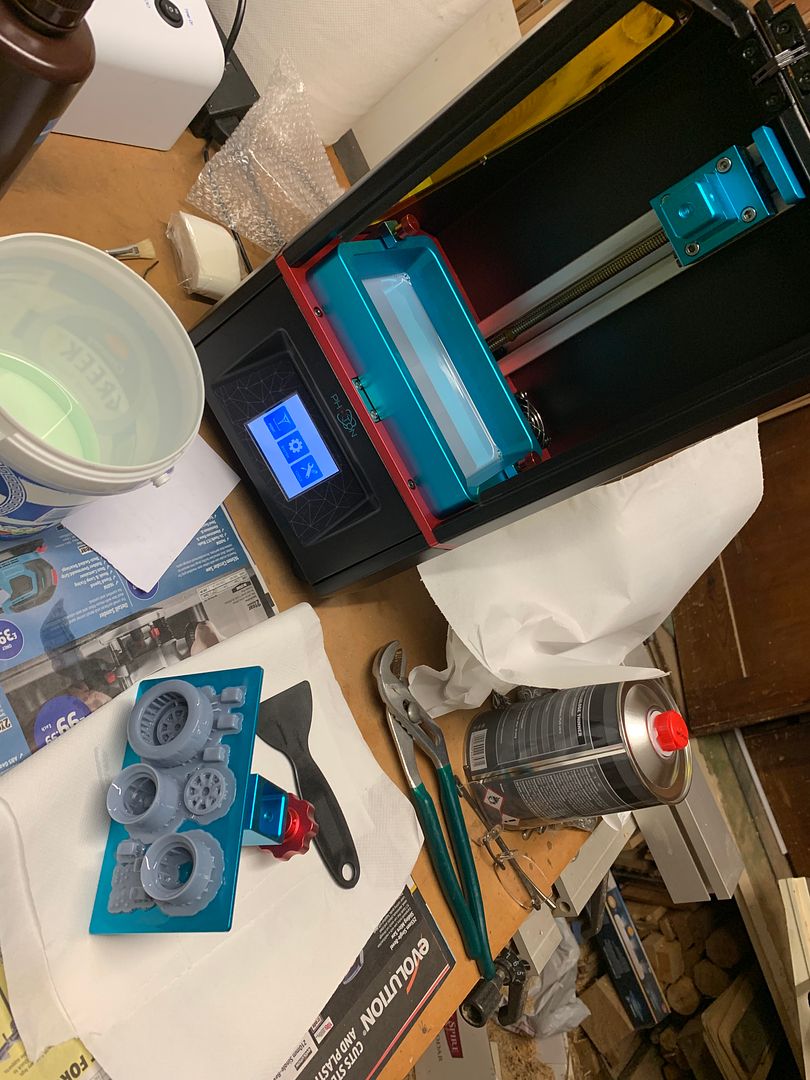

The break-through is the purchase of a resin 3D printer - but more of that later - I'd better get up tp speed with the New York work first, which apart from the decals mainly consisted of finishing the dash and stack display....so a few quick photos of that process...

So that is pretty much where I was at when I came back to the UK - biggest challenge to finish the cars was the Tillet carbon race seats and the wheels and tyres - plus lots of little details...

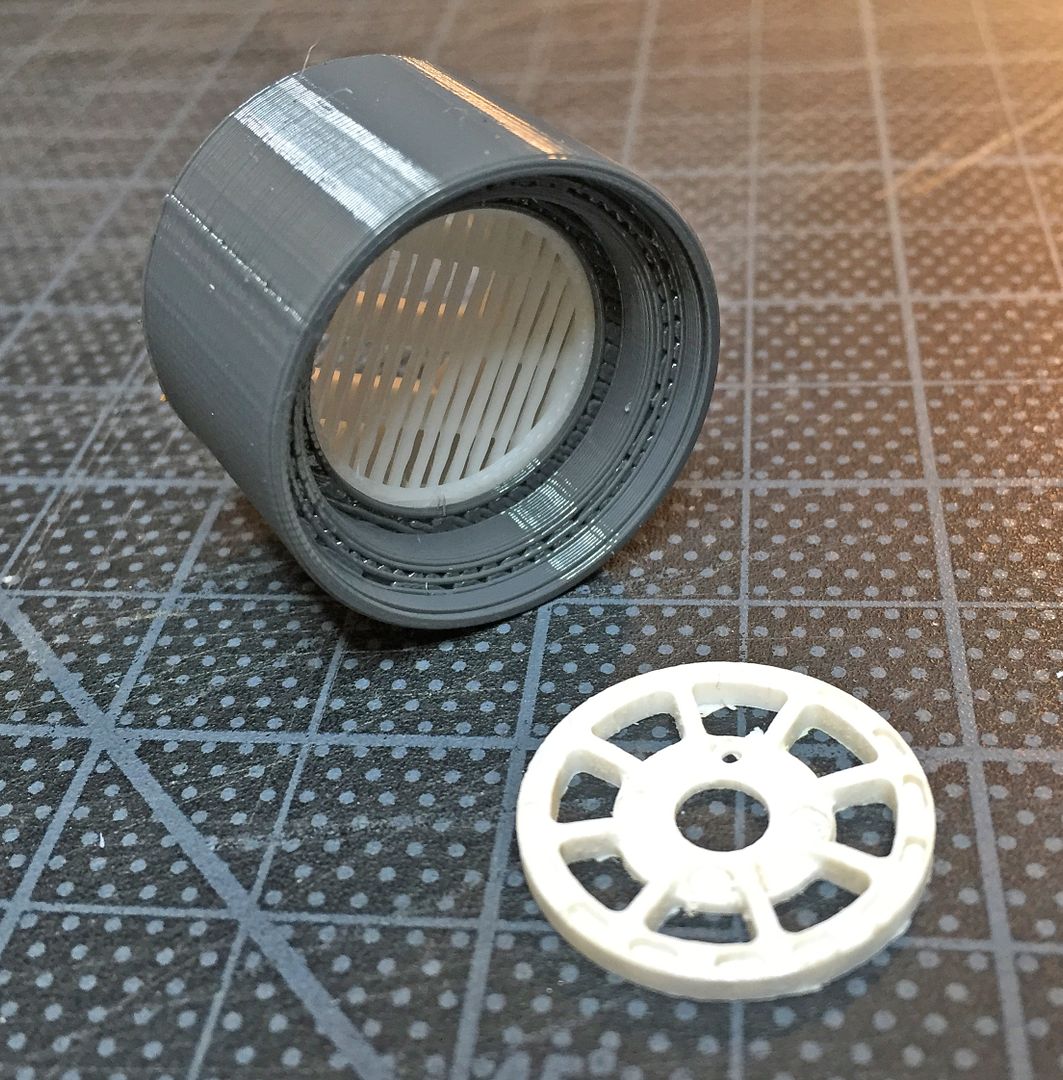

While I was there, I thought I'd try the office 3D printer - a $13k machine, but as you can see - no where good enough for model making of this type - I needed a full-on resin printer - as seen in most F1 design studios!

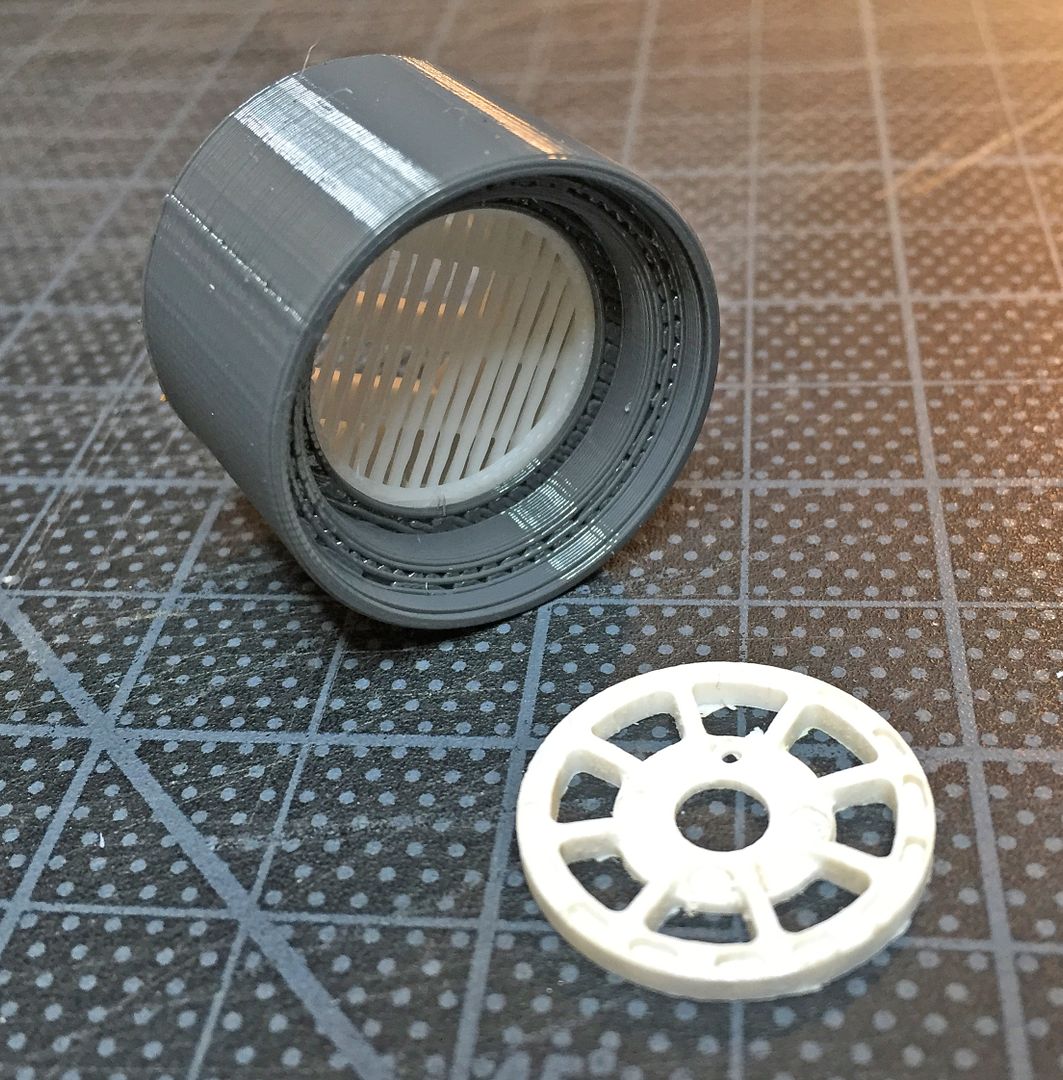

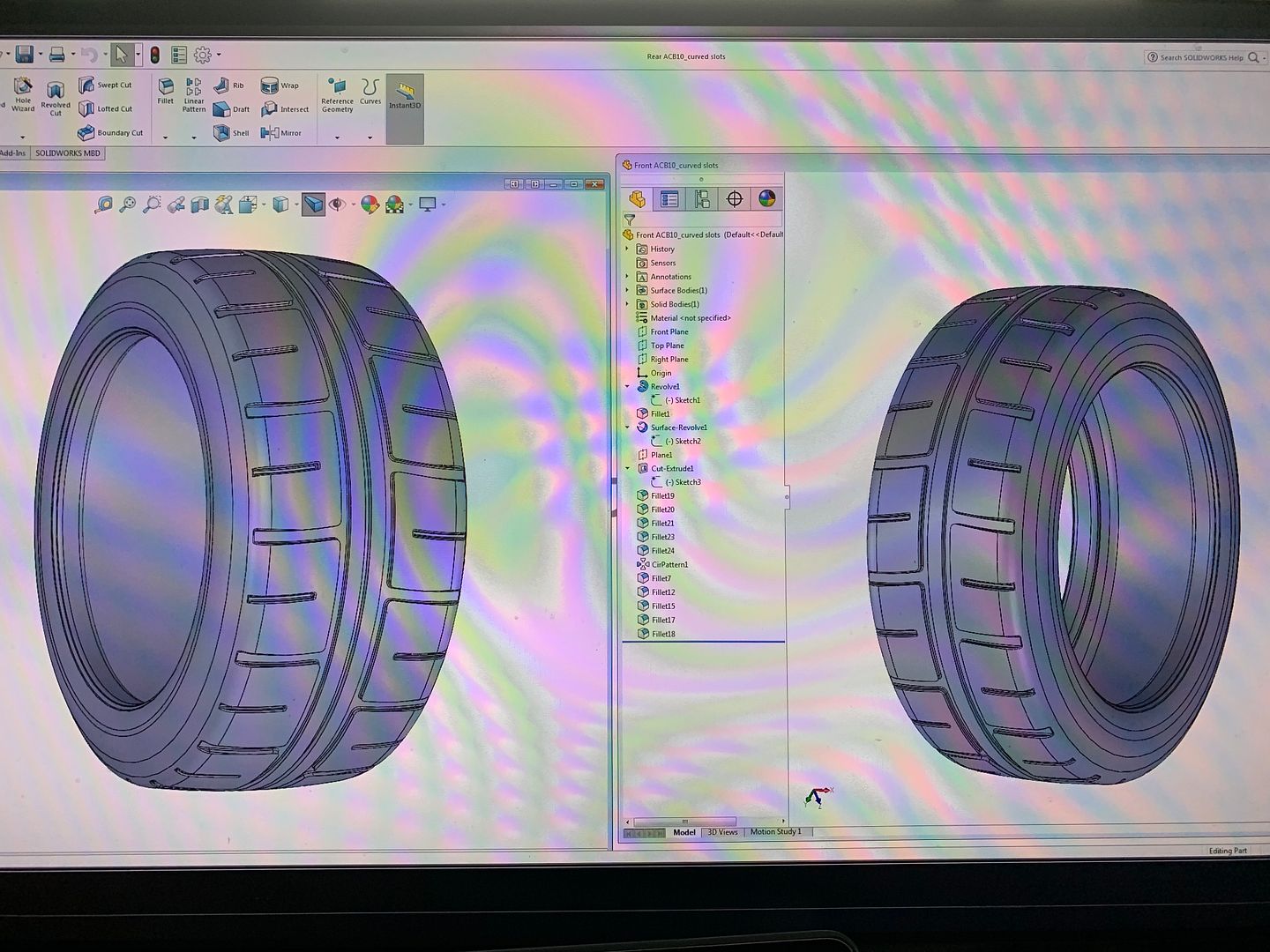

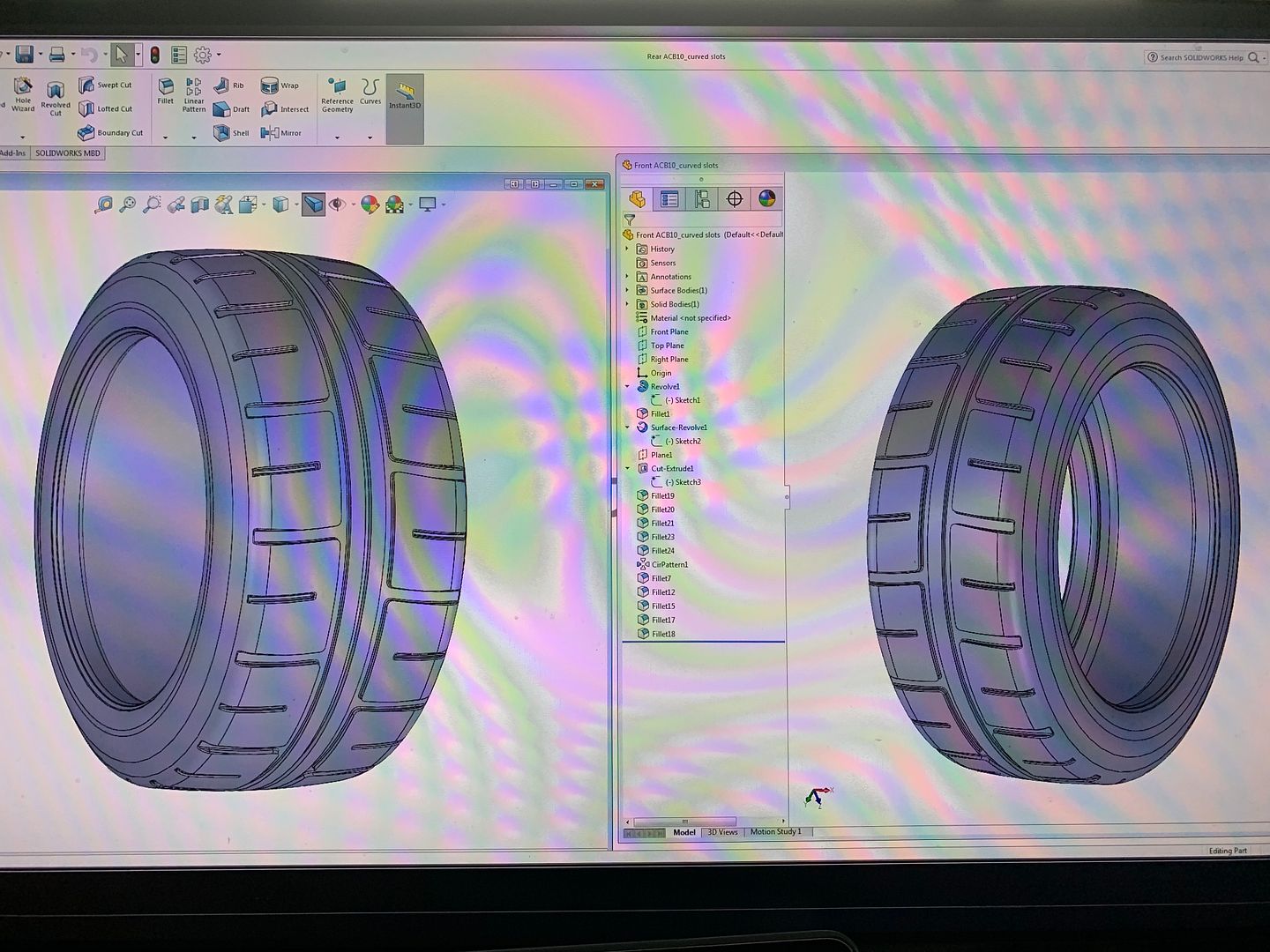

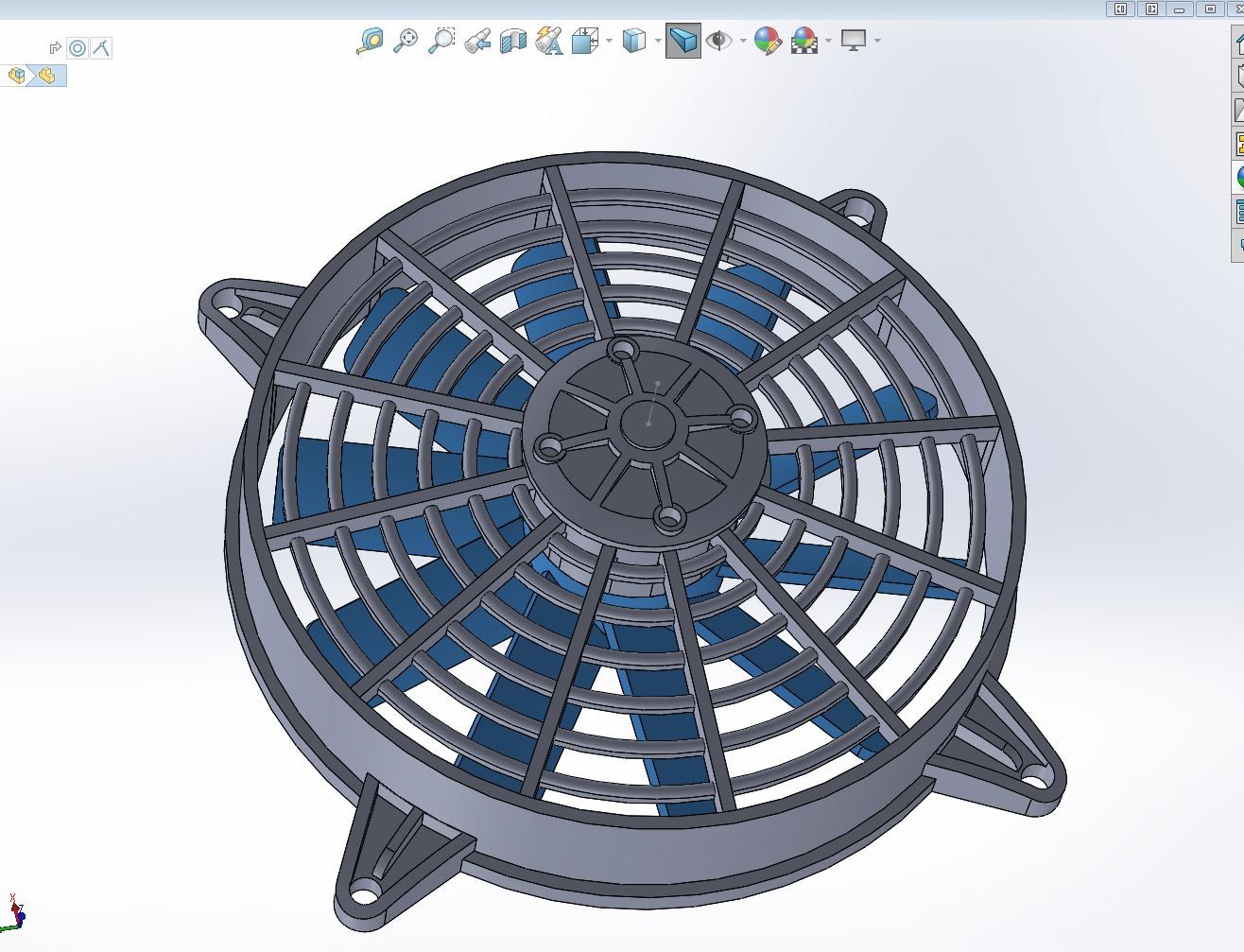

The white centers are the ones I had machined on a CAD milling machine back in 2003...I have to make the rims and the tyres...the CAD files look nice!

....but I need real ones, 1/12 scale...

I took some nice piccies in the photo cube while I tried to figure out how to make them!

Sooooooo - on to 2019!!

The break-through is the purchase of a resin 3D printer - but more of that later - I'd better get up tp speed with the New York work first, which apart from the decals mainly consisted of finishing the dash and stack display....so a few quick photos of that process...

So that is pretty much where I was at when I came back to the UK - biggest challenge to finish the cars was the Tillet carbon race seats and the wheels and tyres - plus lots of little details...

While I was there, I thought I'd try the office 3D printer - a $13k machine, but as you can see - no where good enough for model making of this type - I needed a full-on resin printer - as seen in most F1 design studios!

The white centers are the ones I had machined on a CAD milling machine back in 2003...I have to make the rims and the tyres...the CAD files look nice!

....but I need real ones, 1/12 scale...

I took some nice piccies in the photo cube while I tried to figure out how to make them!

Sooooooo - on to 2019!!

In the mean time I had taken up model making again in the States. New skills and techniques mean that I just know I am not going to be able to resist going back and adding more detail to these kits - particularly when it comes to paint finished and washes/panel wash etc.

But the biggest issue was the damn seats.

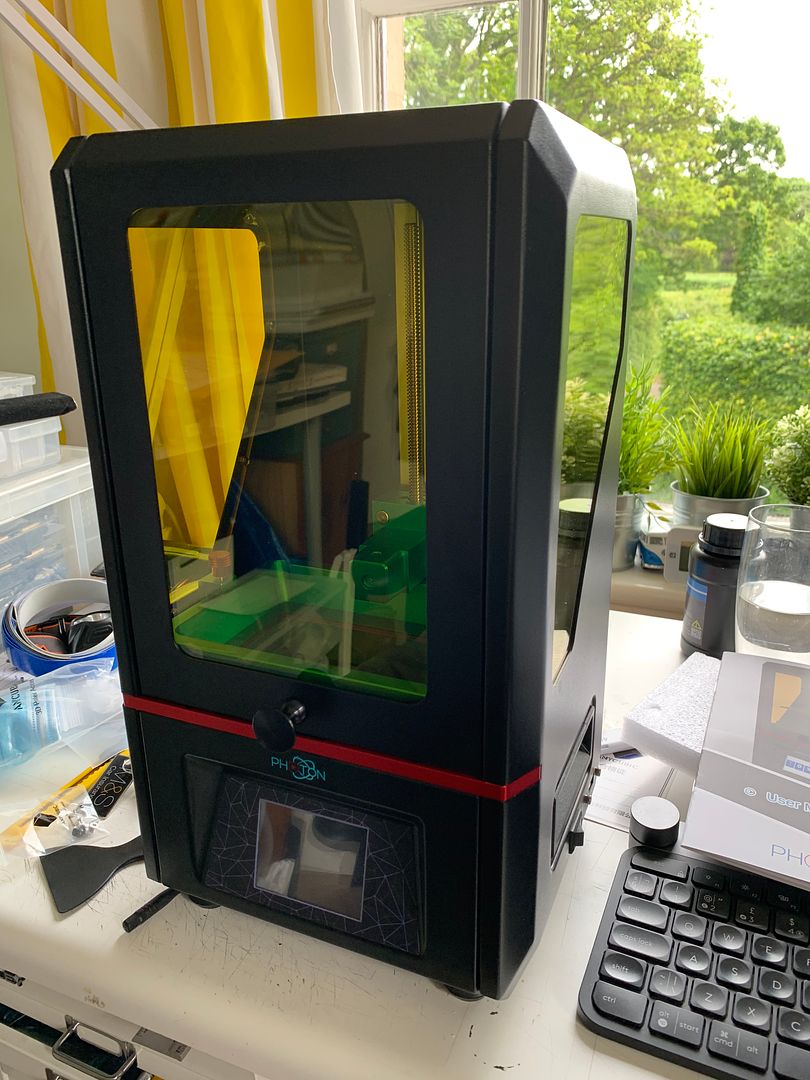

I've kept up to date with the 'home' 3D printer market, but the FDM printers (the ones that swqeeze molten plastic out of a tube - think toothpaste - and build up layers) simply don't have the resolution required. Cheap though - you can pick up a descent kit for £150 - good enough for learning and 'rough' stuff - although actually they are still pretty good now! - and clean...as soon as you start to use resin you have mess, smell, clear-up everytime etc etc..

Resin printers, that use a laser to 'set' UV sensitive resin in very thin layers, are a different level of cost!

You are looking at £2-3k for a good, small model....

....until now! There are now a handful of small printers available for less than £350.

These use a UV emitting LCD screen to 'set' each layer - the resolution (thickness of the layers!) is way higher than any FDM printer - in fact you can even see the pixels of the 2K LCD screen being printed if you really zoom in.

So last week I invested in an Anycubic Photon - a very popular Chinese printer you can get from Amazon. It produces stunning results....

It has a small print area, but for the size of parts I want to make, it is fine.

DO NOT READ AHEAD IF YOU DON'T WANT TO BE TEMPTED - THE RESULTS YOU CAN GET FROM THIS PRINTER ARE AMAZING!

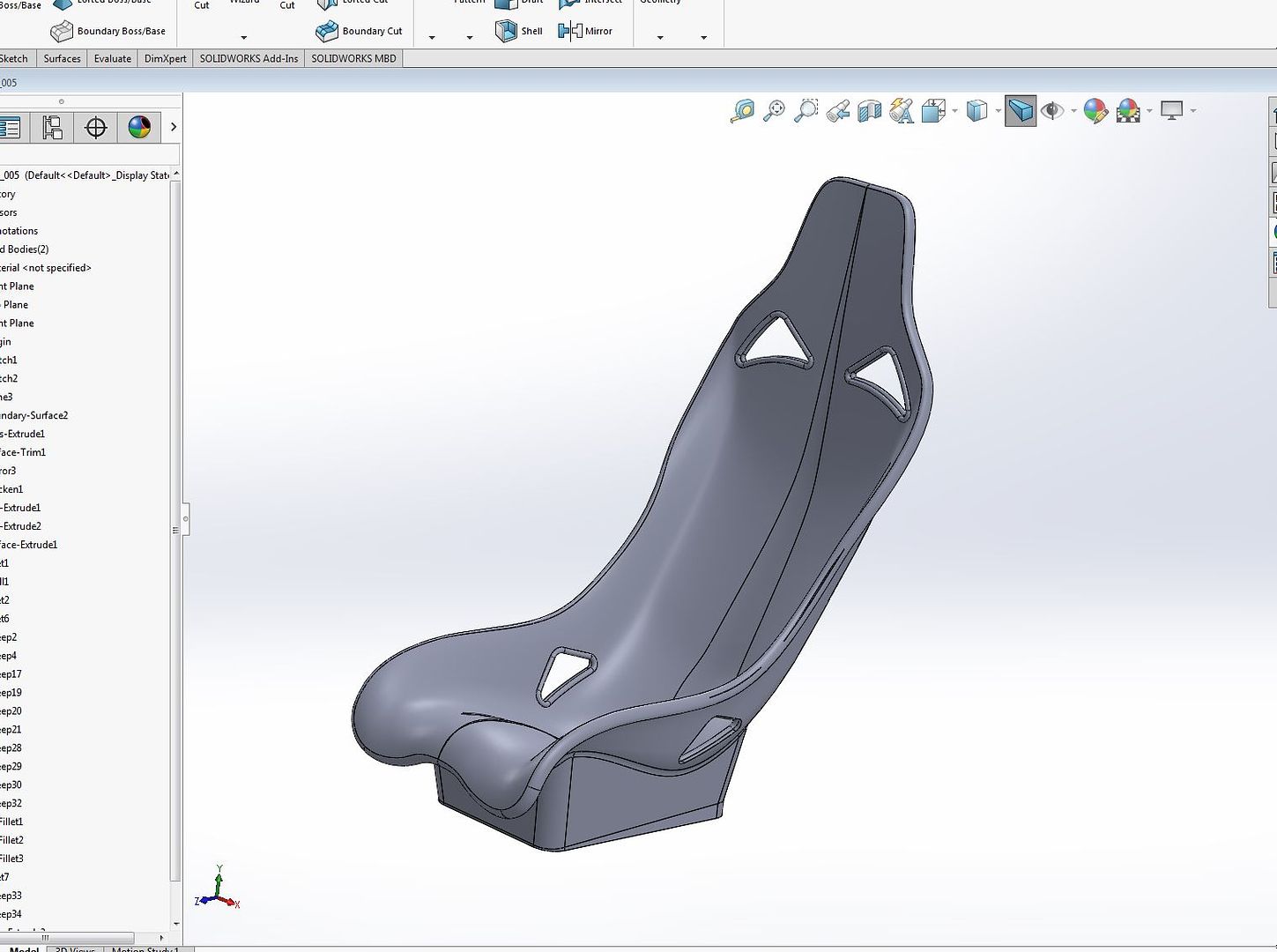

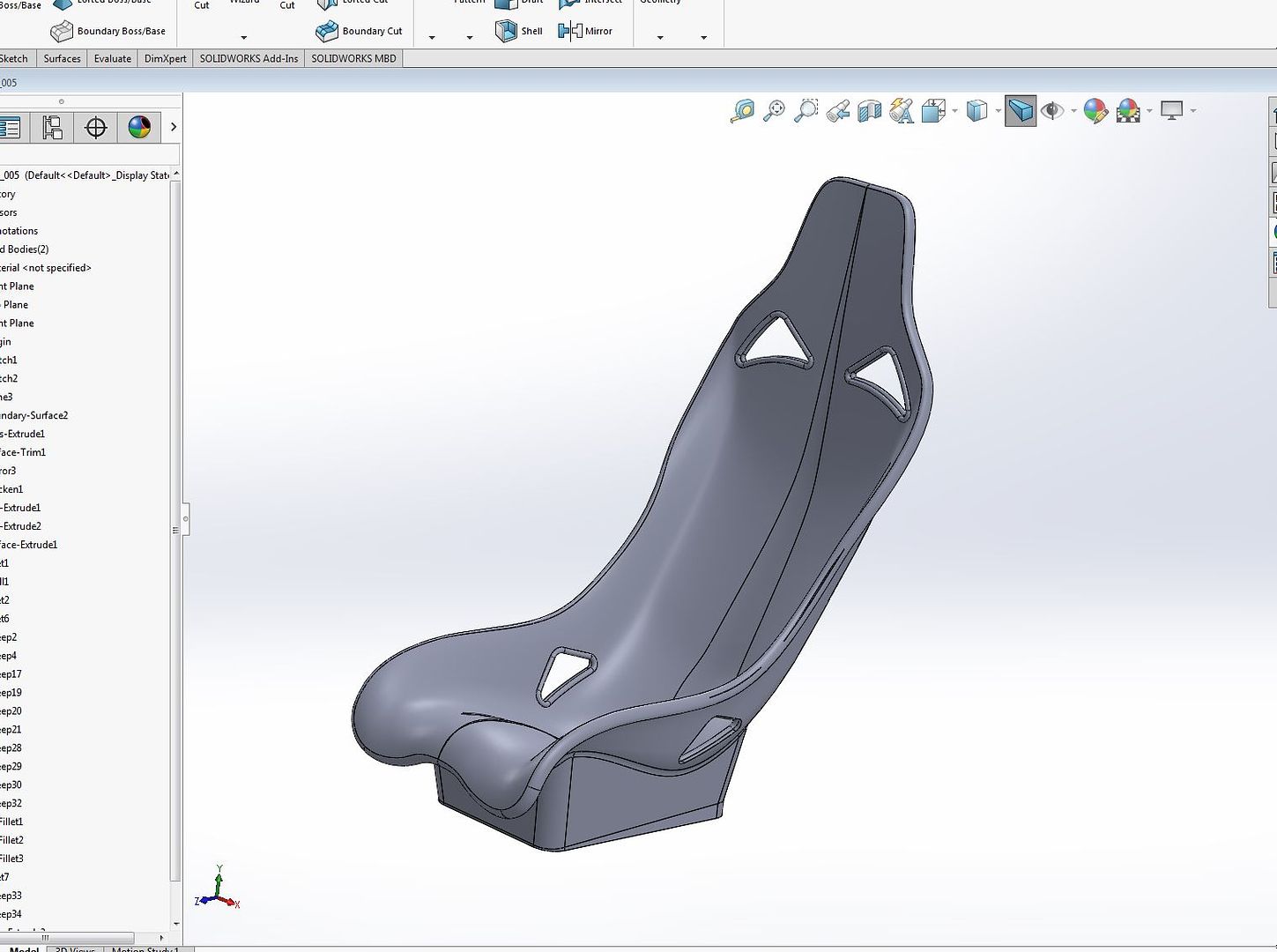

Of course you have to draw the 3D cad files to print - I have access to Solidworks, which I have used in work - but I am not an expert user by any means - I have been drawing boxes and shelves in NYC - so the learning curve to draw a complex shape like a Tillet seat is large!

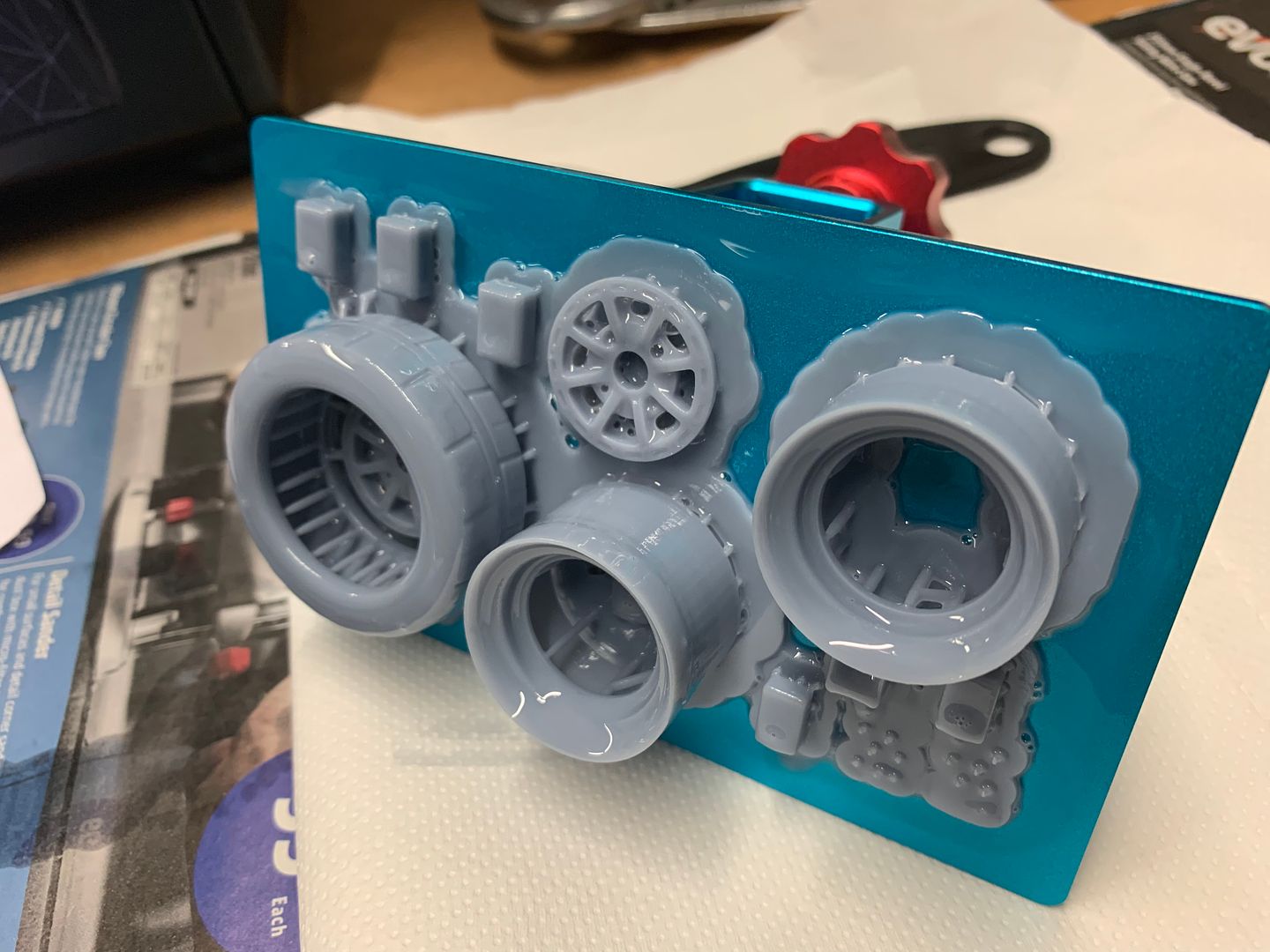

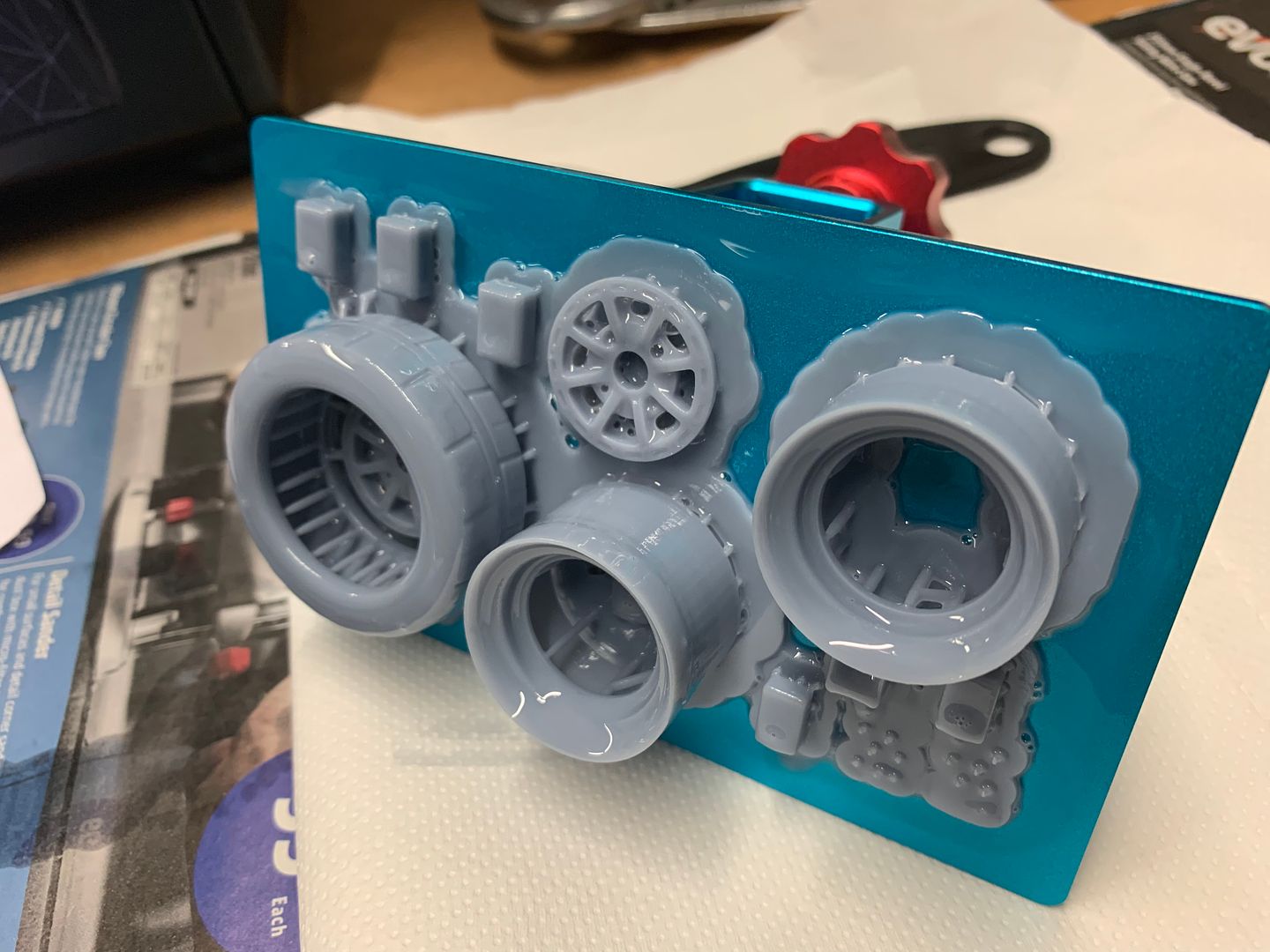

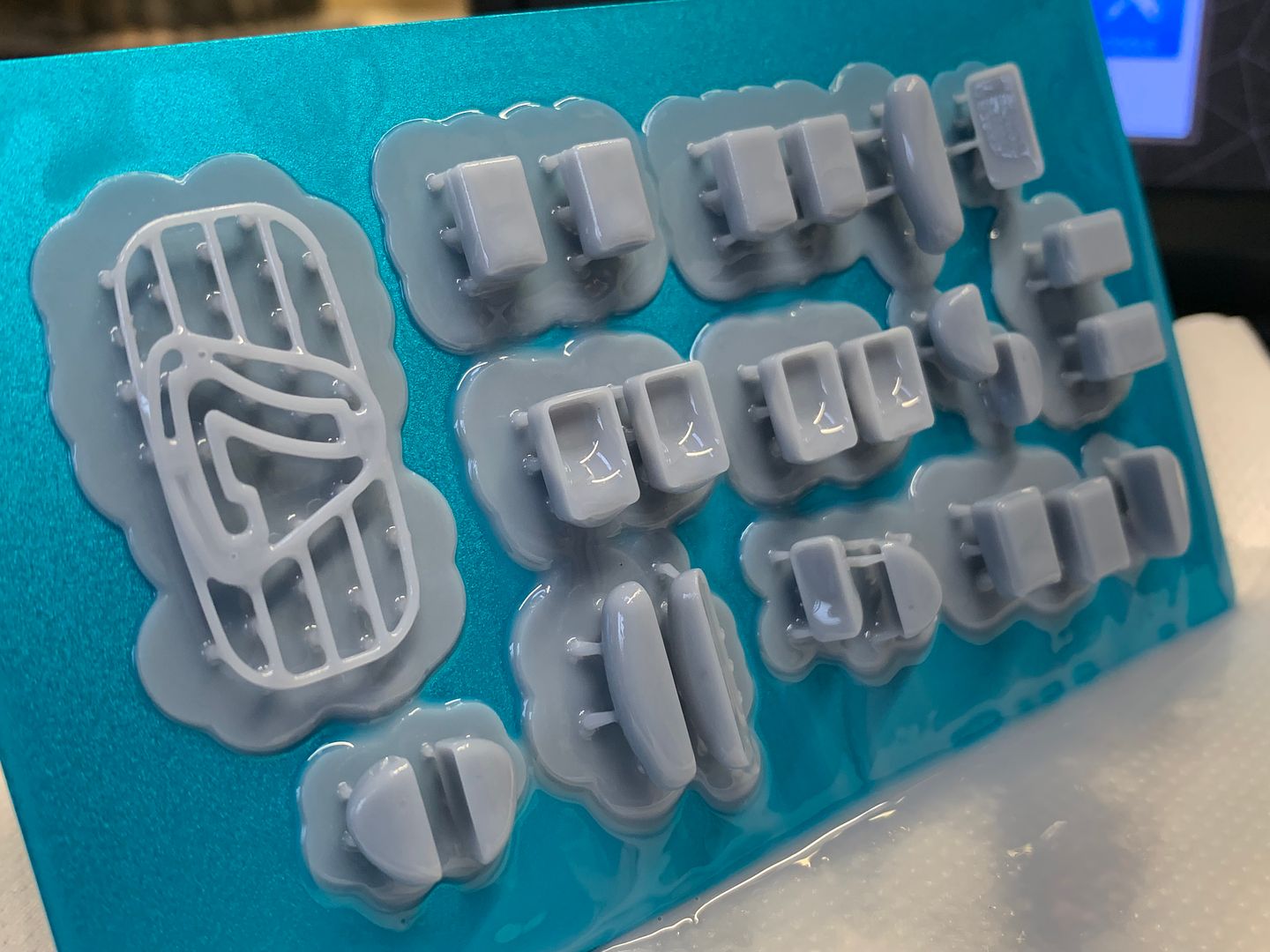

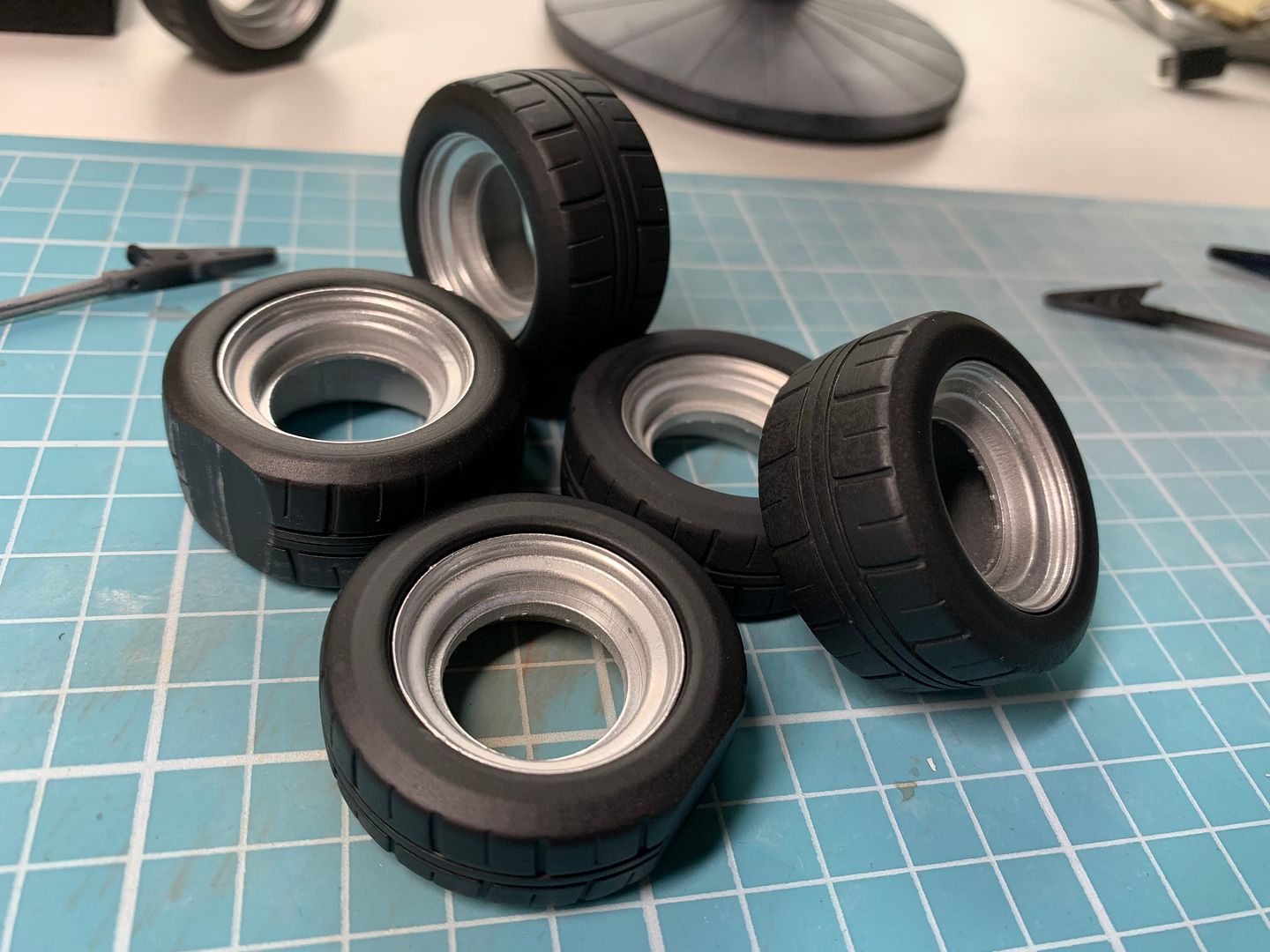

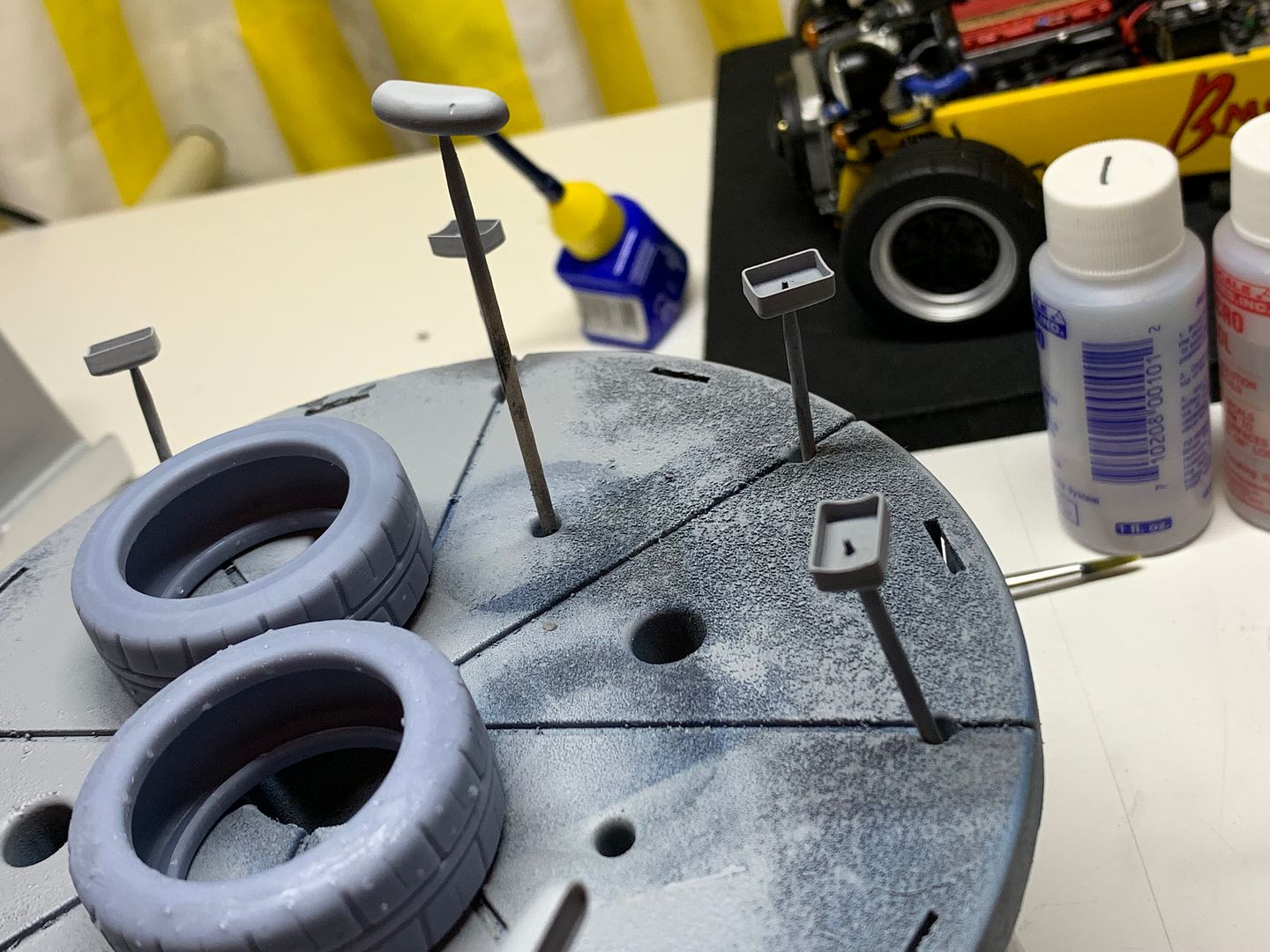

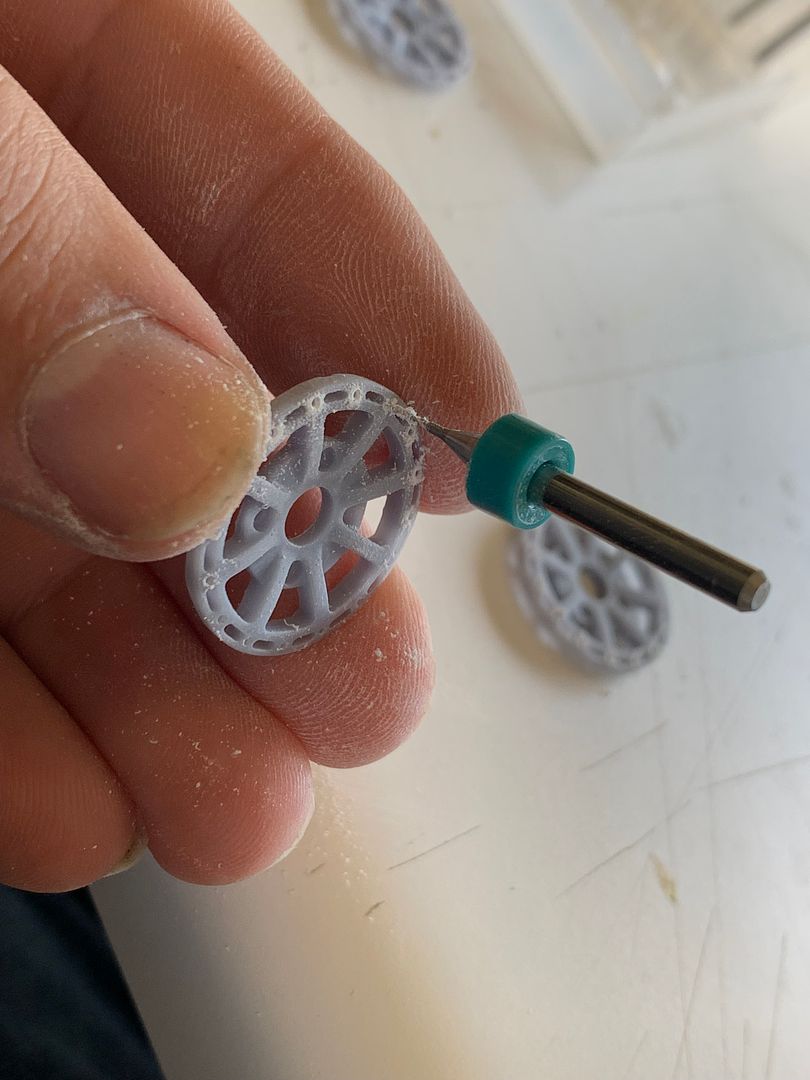

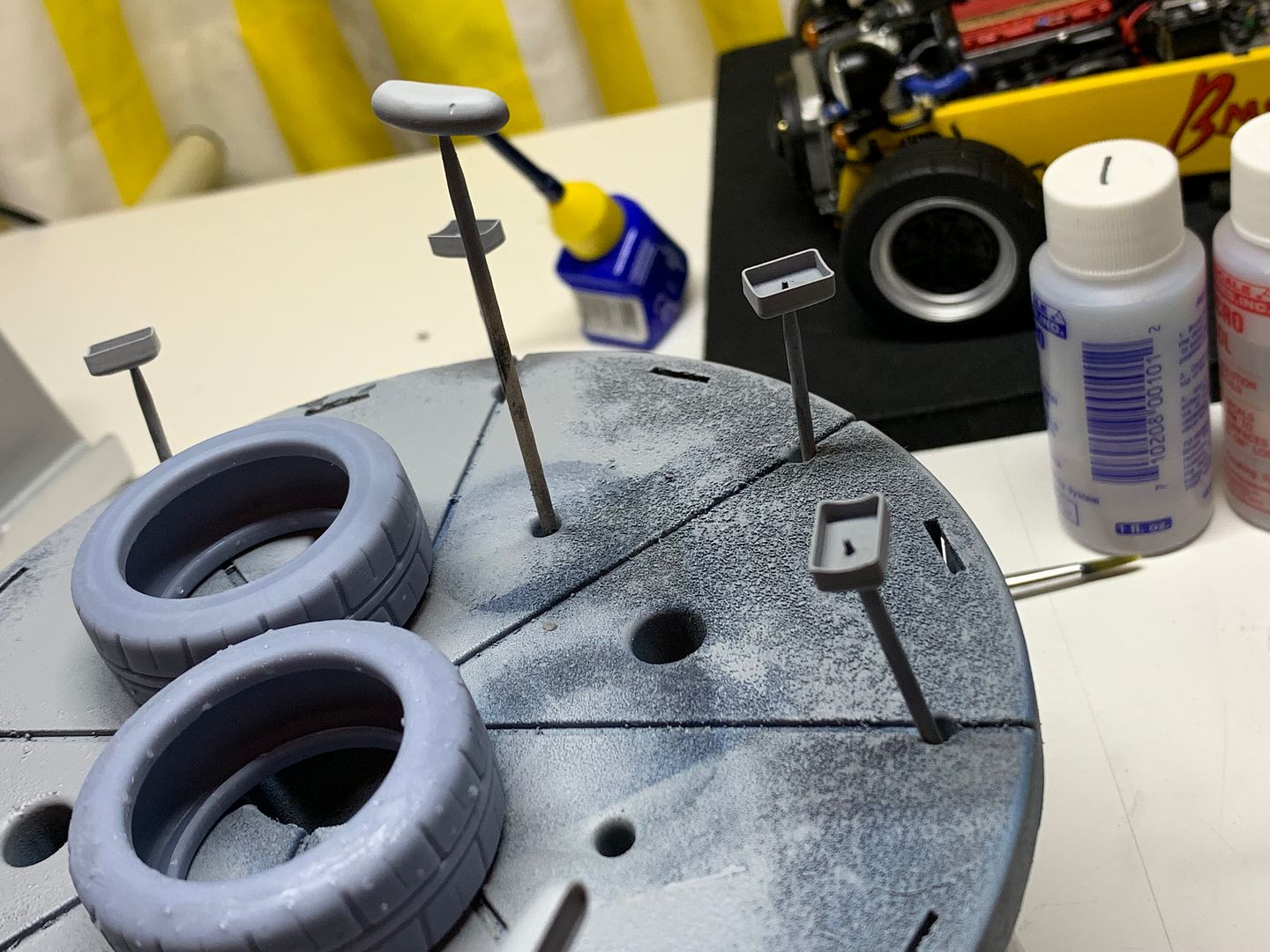

I thought I'd start with some wheels and tyres - these models have ACB 10 tyres, which have to be the simplest tread to try and draw up as well - result!!

So - I worked through some tutorials, and...

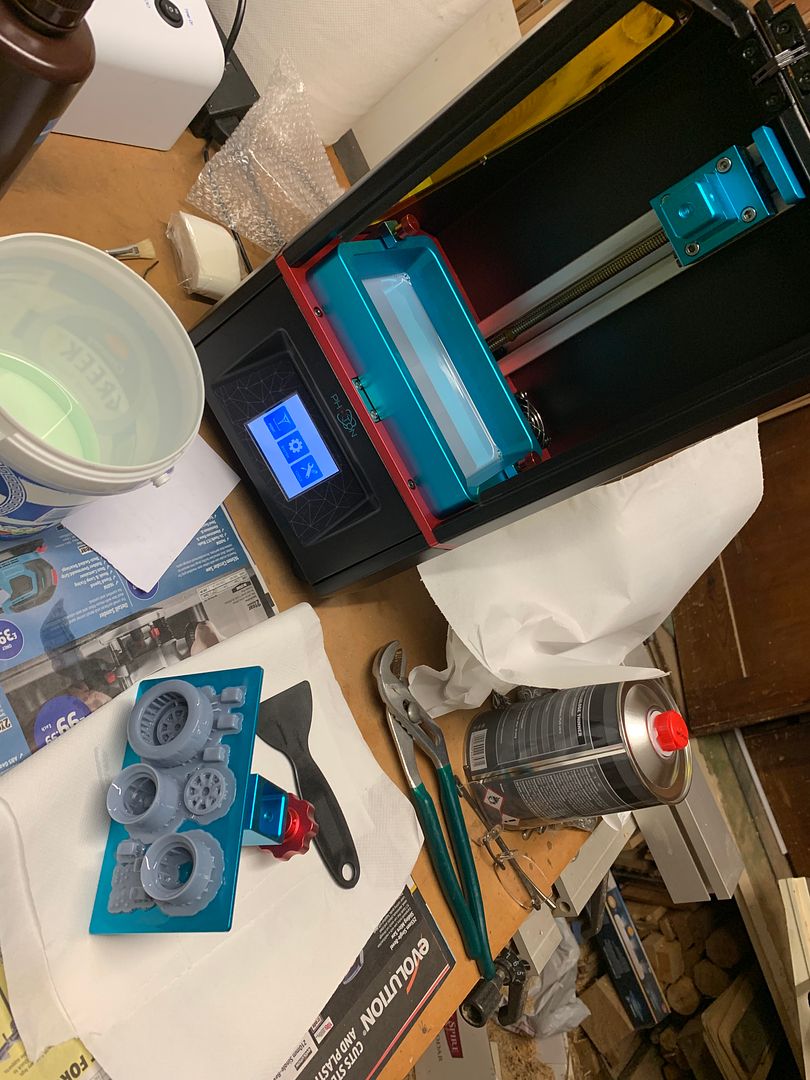

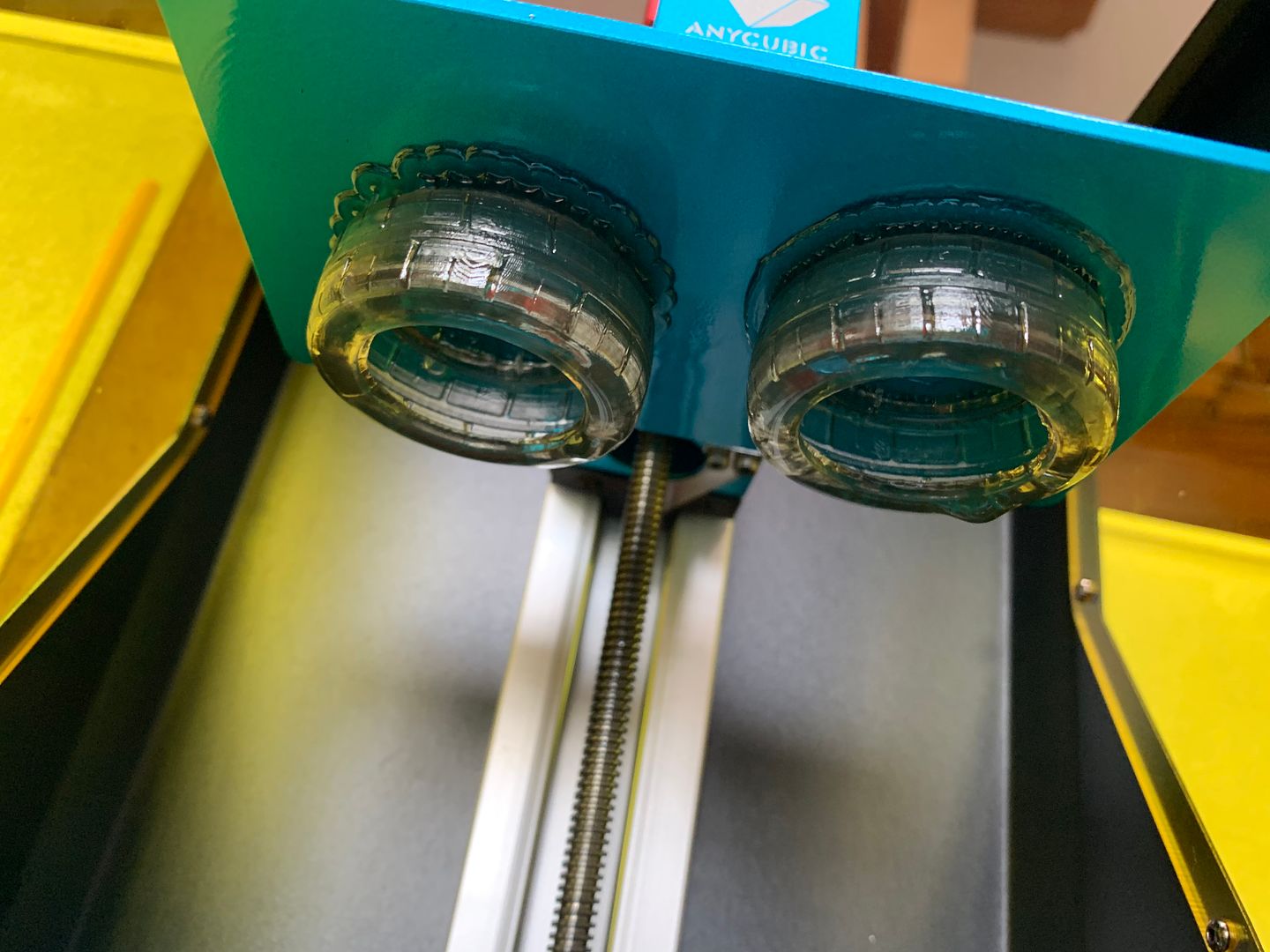

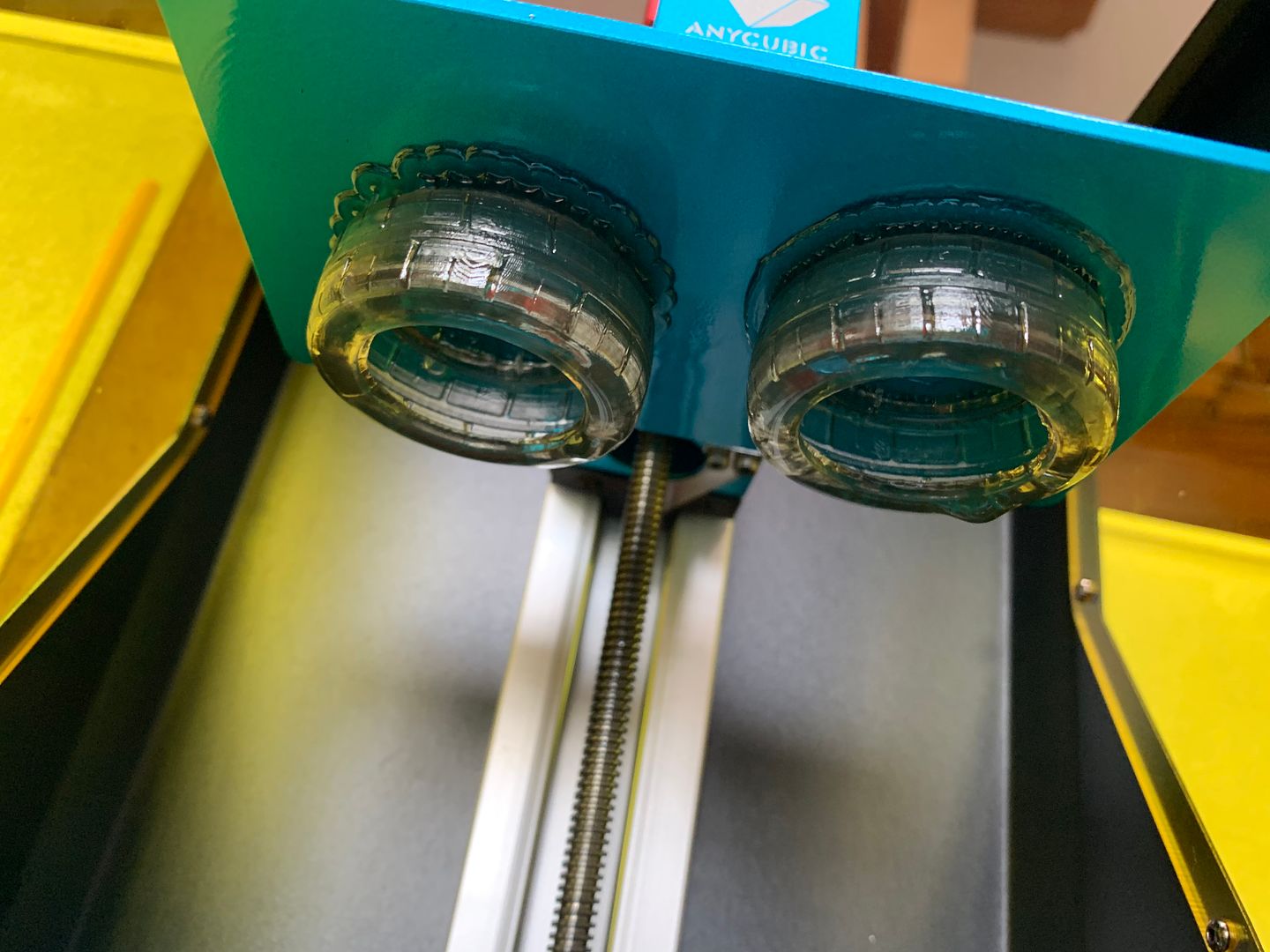

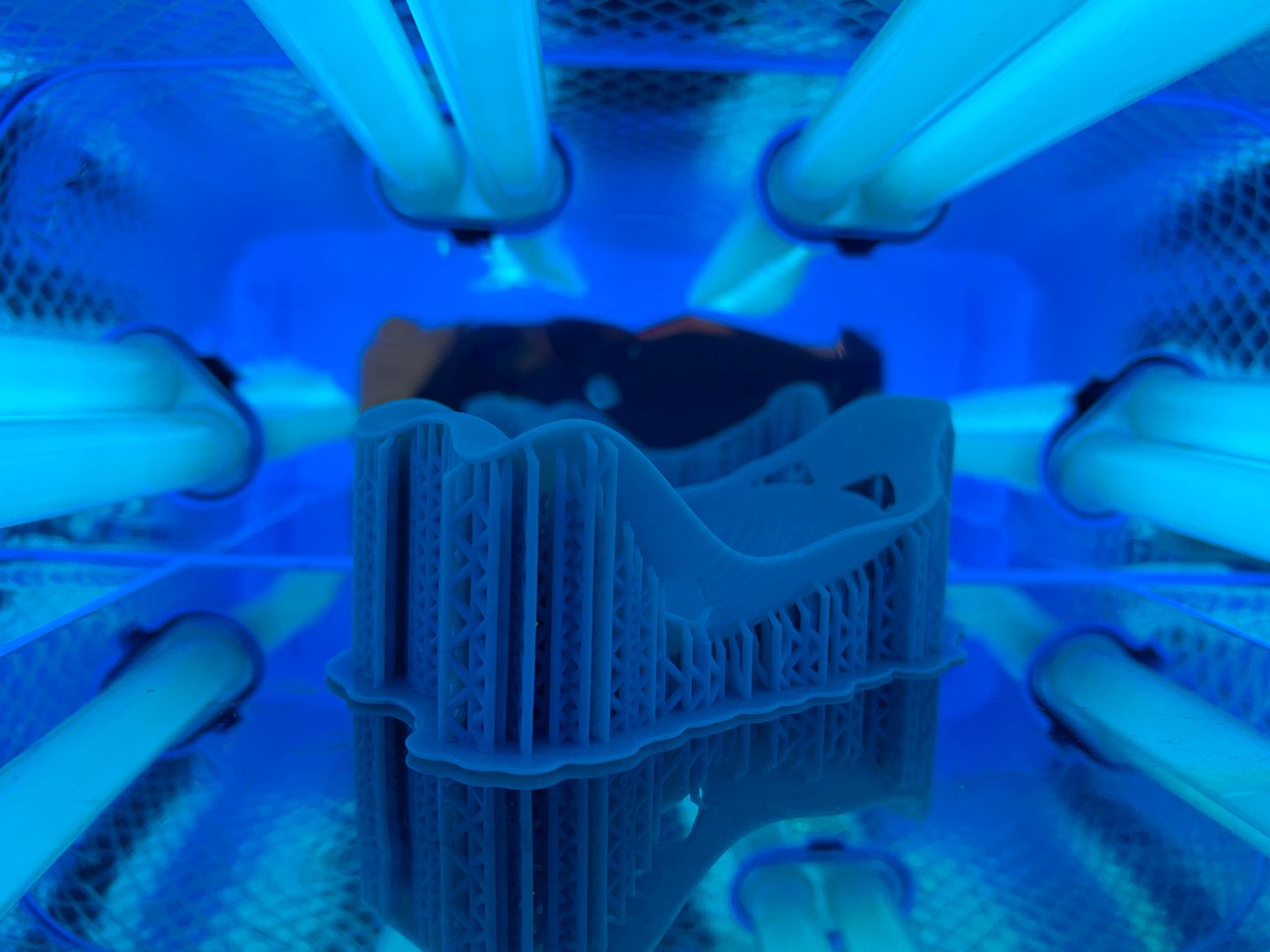

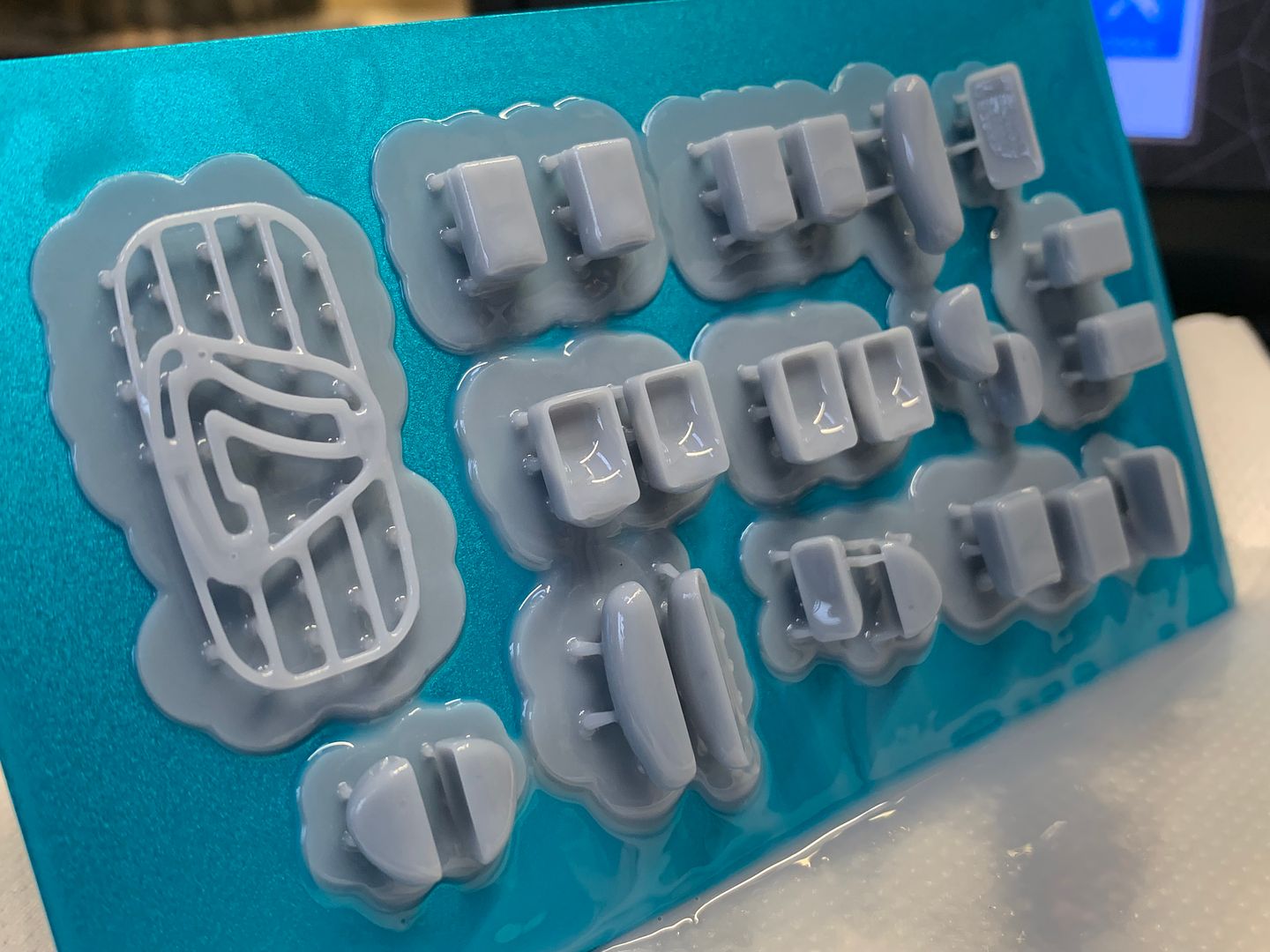

So on to the first print - the printer comes with some resin to try - in this case, translucent green...out to Dads workshop....

BOOM! I was amazed at the results...and please note, these are not at the highest resolution I can print, so you can see some layers - if you go finer the prints take much longer - these are already at about 4hrs plus...

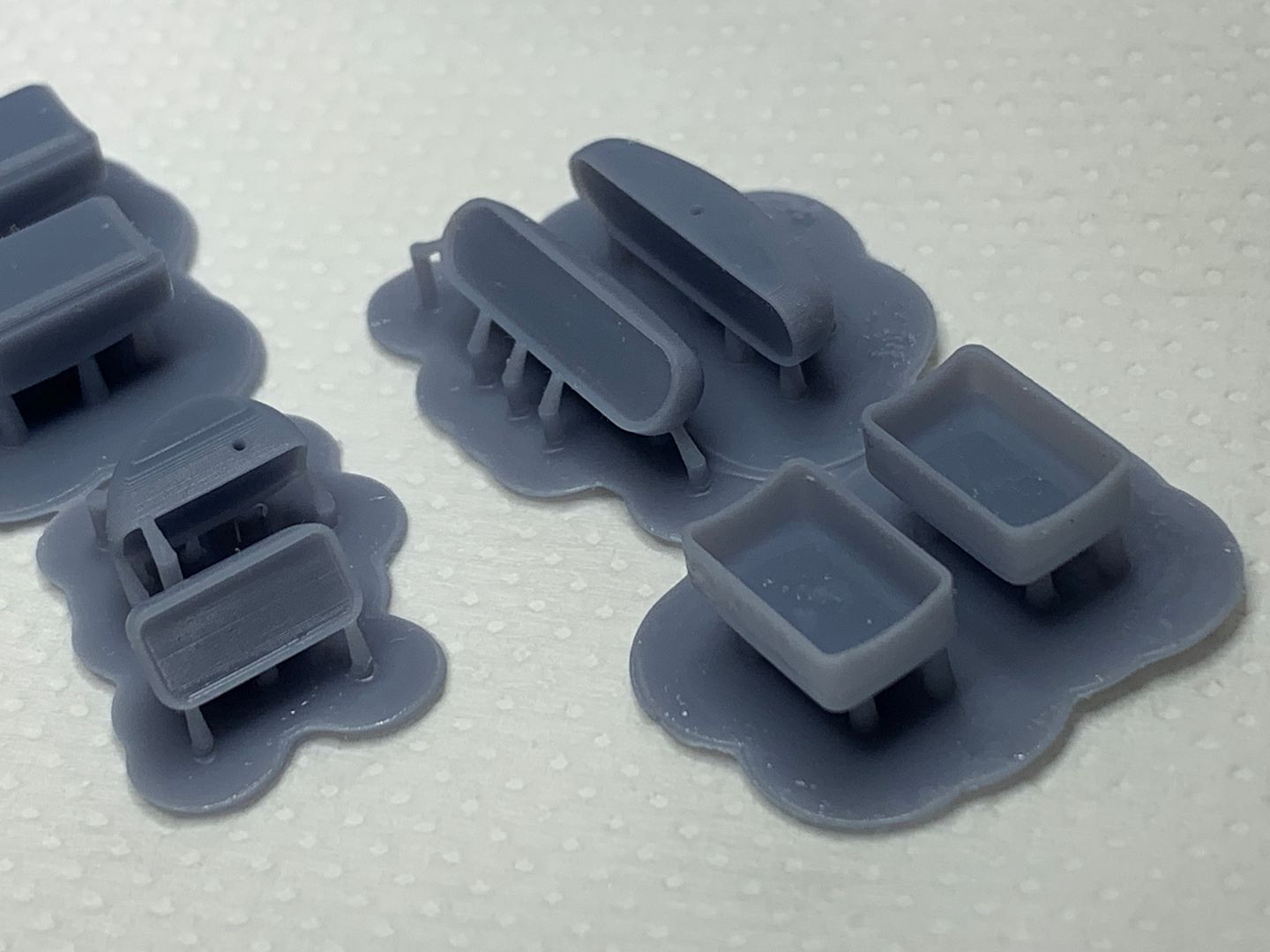

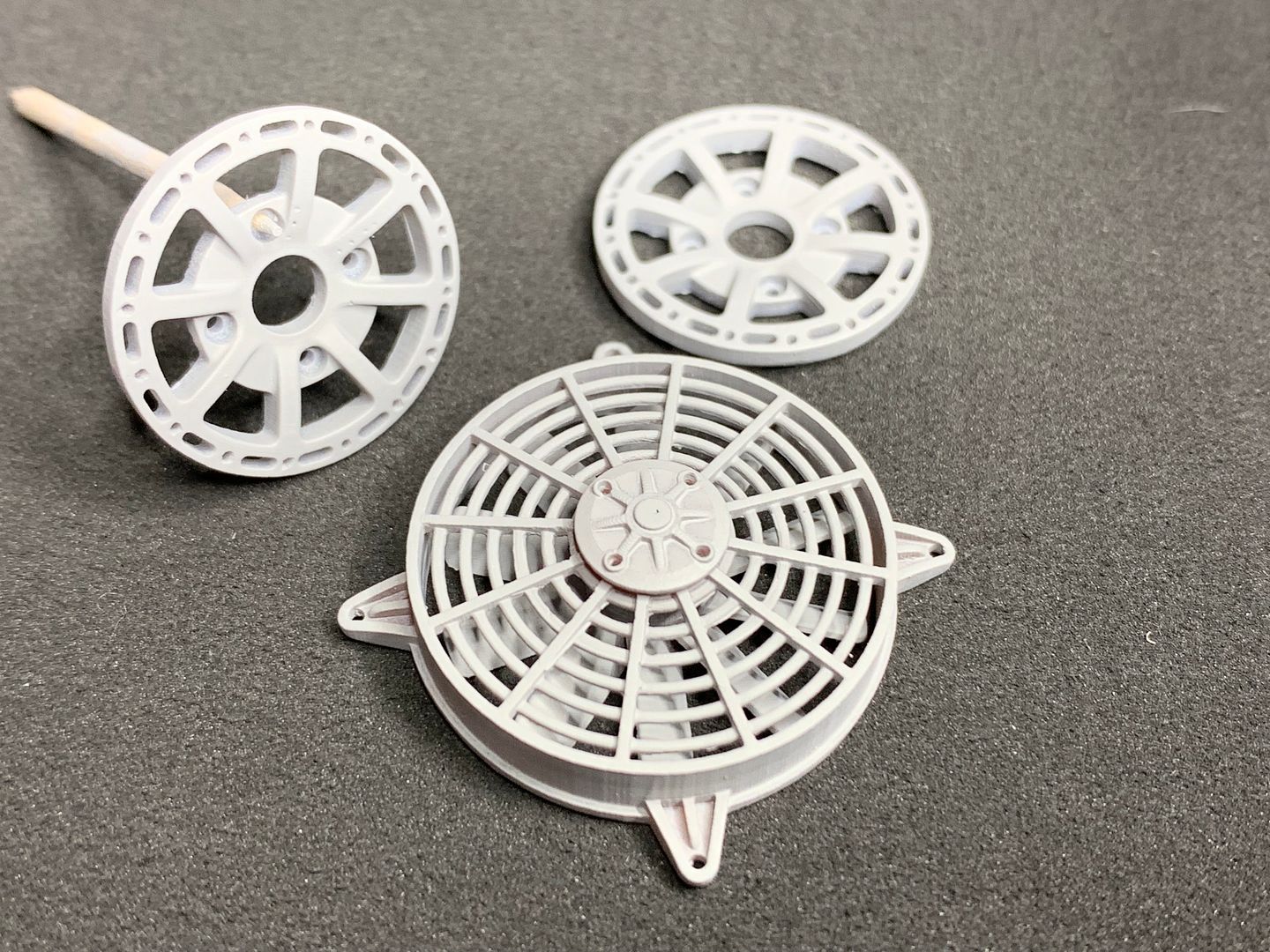

Moved on to some grey resin...

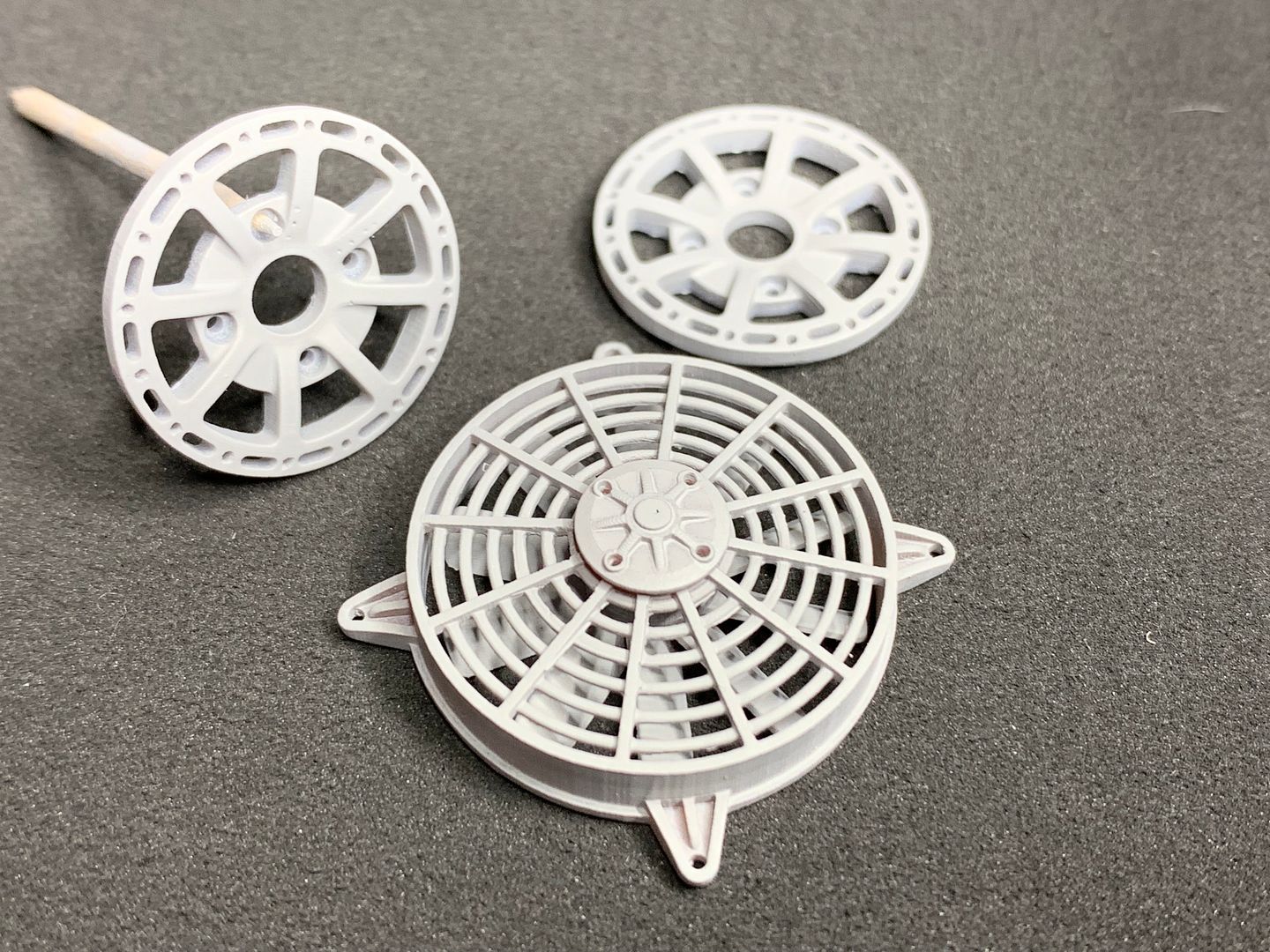

...as I had the file for the central cast hub, I am able to reproduce those as well - lucky as I can't find the plastic sheet with 8 hubs machined onto it from 2003!

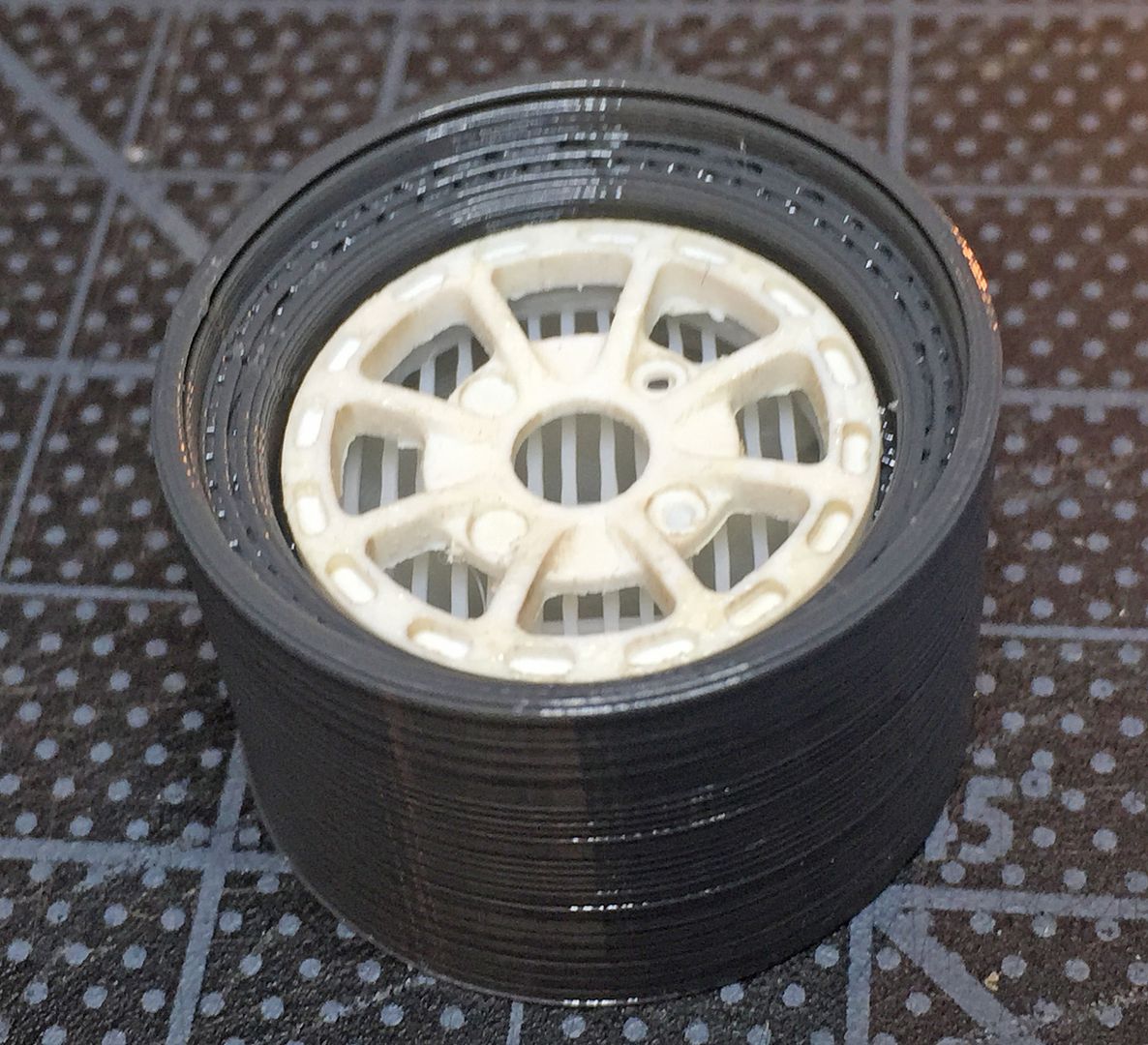

So this is a 3 piece wheel:

I have to play around with sizes to allow for paint clearance etc - but it works brilliantly.

You can get different types of resin - so I have got some flexible resin to try and make 'real' tyres - I'll have to reduce the wall thickness right down, and make sure I can use pigment on the resin to make it black - as the flex resin is clear - but that is to come. I'l probably use the grey hard resin and spray for now...

More updates tomorrow - I'm staying up waaaay too late every night working on this - but it is good to get the modelling MOJO back after 18 mths....

But the biggest issue was the damn seats.

I've kept up to date with the 'home' 3D printer market, but the FDM printers (the ones that swqeeze molten plastic out of a tube - think toothpaste - and build up layers) simply don't have the resolution required. Cheap though - you can pick up a descent kit for £150 - good enough for learning and 'rough' stuff - although actually they are still pretty good now! - and clean...as soon as you start to use resin you have mess, smell, clear-up everytime etc etc..

Resin printers, that use a laser to 'set' UV sensitive resin in very thin layers, are a different level of cost!

You are looking at £2-3k for a good, small model....

....until now! There are now a handful of small printers available for less than £350.

These use a UV emitting LCD screen to 'set' each layer - the resolution (thickness of the layers!) is way higher than any FDM printer - in fact you can even see the pixels of the 2K LCD screen being printed if you really zoom in.

So last week I invested in an Anycubic Photon - a very popular Chinese printer you can get from Amazon. It produces stunning results....

It has a small print area, but for the size of parts I want to make, it is fine.

DO NOT READ AHEAD IF YOU DON'T WANT TO BE TEMPTED - THE RESULTS YOU CAN GET FROM THIS PRINTER ARE AMAZING!

Of course you have to draw the 3D cad files to print - I have access to Solidworks, which I have used in work - but I am not an expert user by any means - I have been drawing boxes and shelves in NYC - so the learning curve to draw a complex shape like a Tillet seat is large!

I thought I'd start with some wheels and tyres - these models have ACB 10 tyres, which have to be the simplest tread to try and draw up as well - result!!

So - I worked through some tutorials, and...

So on to the first print - the printer comes with some resin to try - in this case, translucent green...out to Dads workshop....

BOOM! I was amazed at the results...and please note, these are not at the highest resolution I can print, so you can see some layers - if you go finer the prints take much longer - these are already at about 4hrs plus...

Moved on to some grey resin...

...as I had the file for the central cast hub, I am able to reproduce those as well - lucky as I can't find the plastic sheet with 8 hubs machined onto it from 2003!

So this is a 3 piece wheel:

I have to play around with sizes to allow for paint clearance etc - but it works brilliantly.

You can get different types of resin - so I have got some flexible resin to try and make 'real' tyres - I'll have to reduce the wall thickness right down, and make sure I can use pigment on the resin to make it black - as the flex resin is clear - but that is to come. I'l probably use the grey hard resin and spray for now...

More updates tomorrow - I'm staying up waaaay too late every night working on this - but it is good to get the modelling MOJO back after 18 mths....

4321go said:

That’s very cool.

Now, here’s a challenge...... Although a Caterham doesn’t weigh very much, do your new-found CAD skills go as far as being able to squash and bulge the tyres to replicate the weight of a real car (rather than a featherweight plastic kit) bearing down on them?

- they do flexible resin Now, here’s a challenge...... Although a Caterham doesn’t weigh very much, do your new-found CAD skills go as far as being able to squash and bulge the tyres to replicate the weight of a real car (rather than a featherweight plastic kit) bearing down on them?

- so I'm playing with wall thickness to see if I can get exactlythat to work - the issue is painting, the flexi resin is clear, and paint will crack - so you have to use pigment...

- so I'm playing with wall thickness to see if I can get exactlythat to work - the issue is painting, the flexi resin is clear, and paint will crack - so you have to use pigment...dr_gn said:

Oh. My. God.

I know, right!!Thought of you when I said 'warning', because you WILL end up with one lol - I did wonder if you used them 'at work' - the resin is UV cured as it prints, and then you use a UV light source to cure it once finished - £12 nail varnish curer from amazon!

after washing with IPA - all very simple, if a little messy....

after washing with IPA - all very simple, if a little messy....dr_gn said:

Any chance you could give one of the wheels a quick coat of Tamiya Grey primer to get rid of the reflections? Ta.

ETA - and post an image, obviously

which ones Doc? ETA - and post an image, obviously

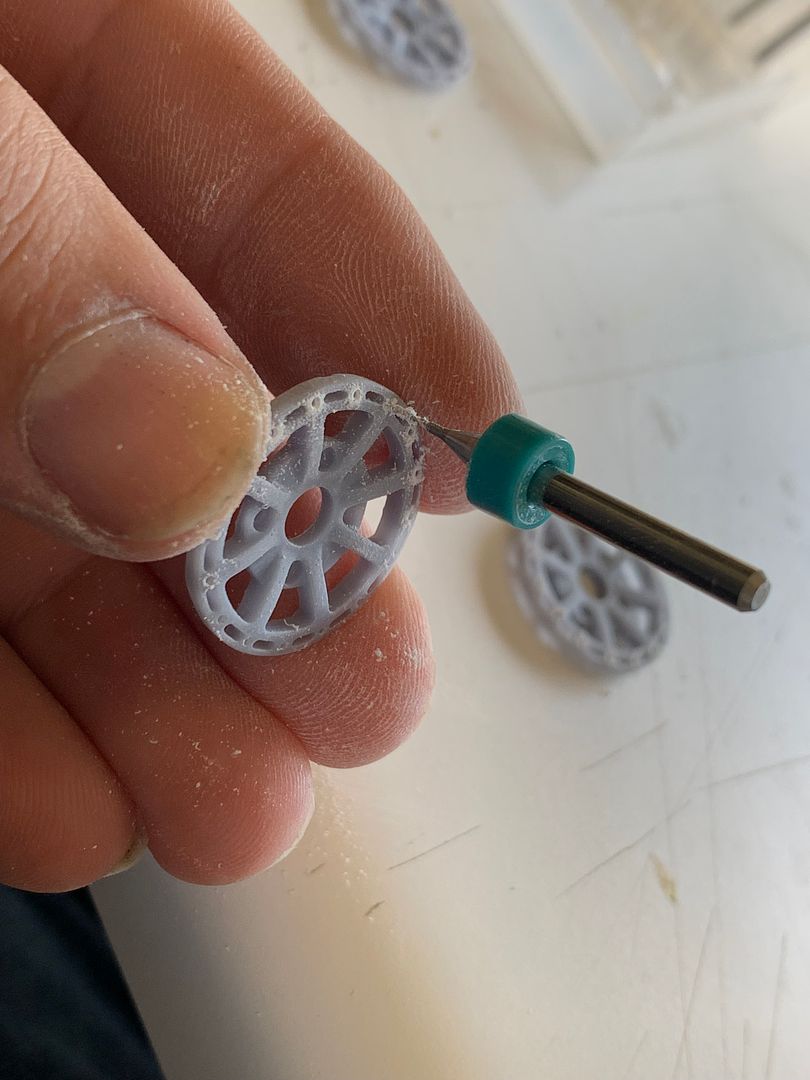

The green ones were first ever tests - so not representative of the quality....and in fact I haven't gone full-blown detail yet because it significantly increases print time! I'm doing some more now for the actual models - I'll show those 'in progress' (before any sanding etc)

It is a bit smelly, yes - one of the disadvantages. My machine is in the workshop - I tried upstairs in the house with the window open, but with prints taking many hours sometimes, It just wasn't going to work.

However, plenty of people put them in cabinets with extractor hoses and carbon filters - just like a spray booth....and some resins are no or low odour...

Next job was the tillet seats - carbon fibre race seats which are only about 4mm thick in 1/1, and are very curvy.

Now I had the tool to print them, I still had to create the 3D file - youtube solidworks tutorials to the rescure:

Not perfect in terms of 3D drawing, but good enough for my use!

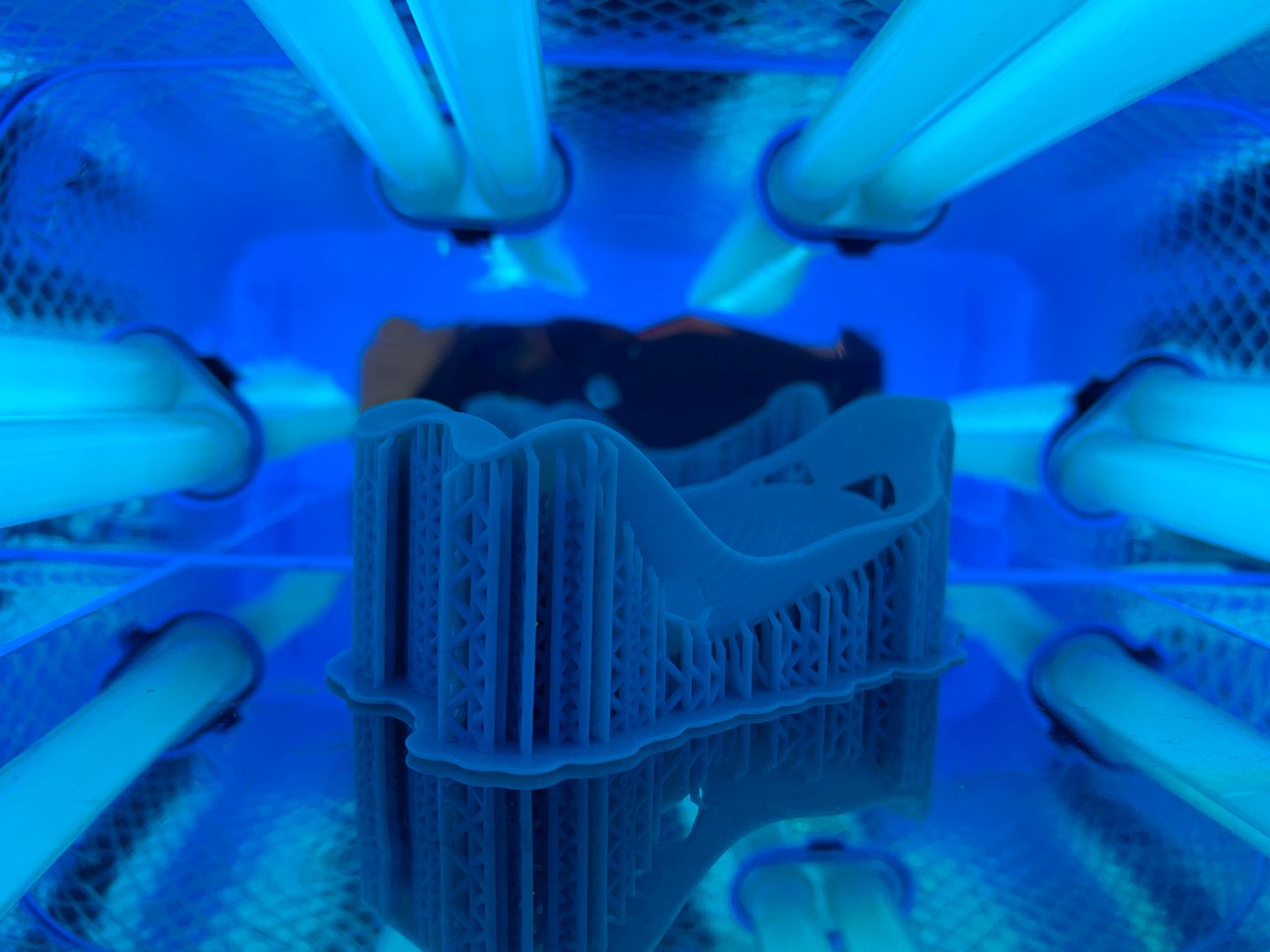

UV curing:

Had to get the scale right, and played around trying to get the shoulder 'bulge' correct - this had to fit in the model...

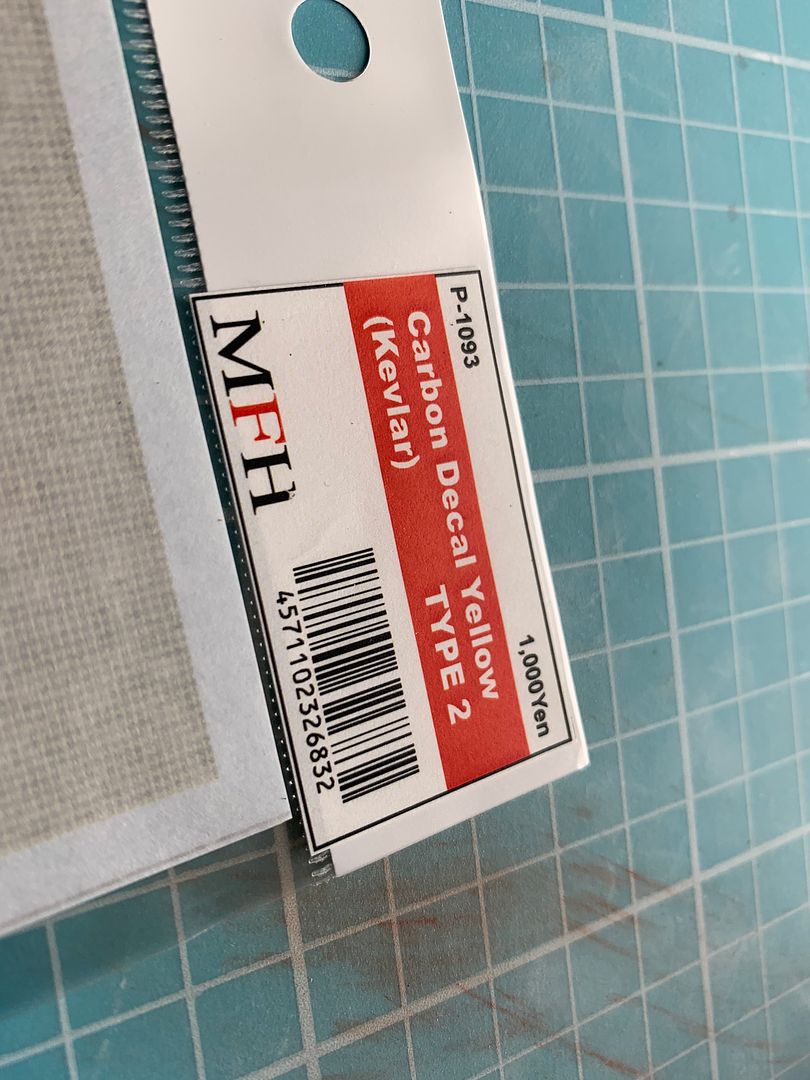

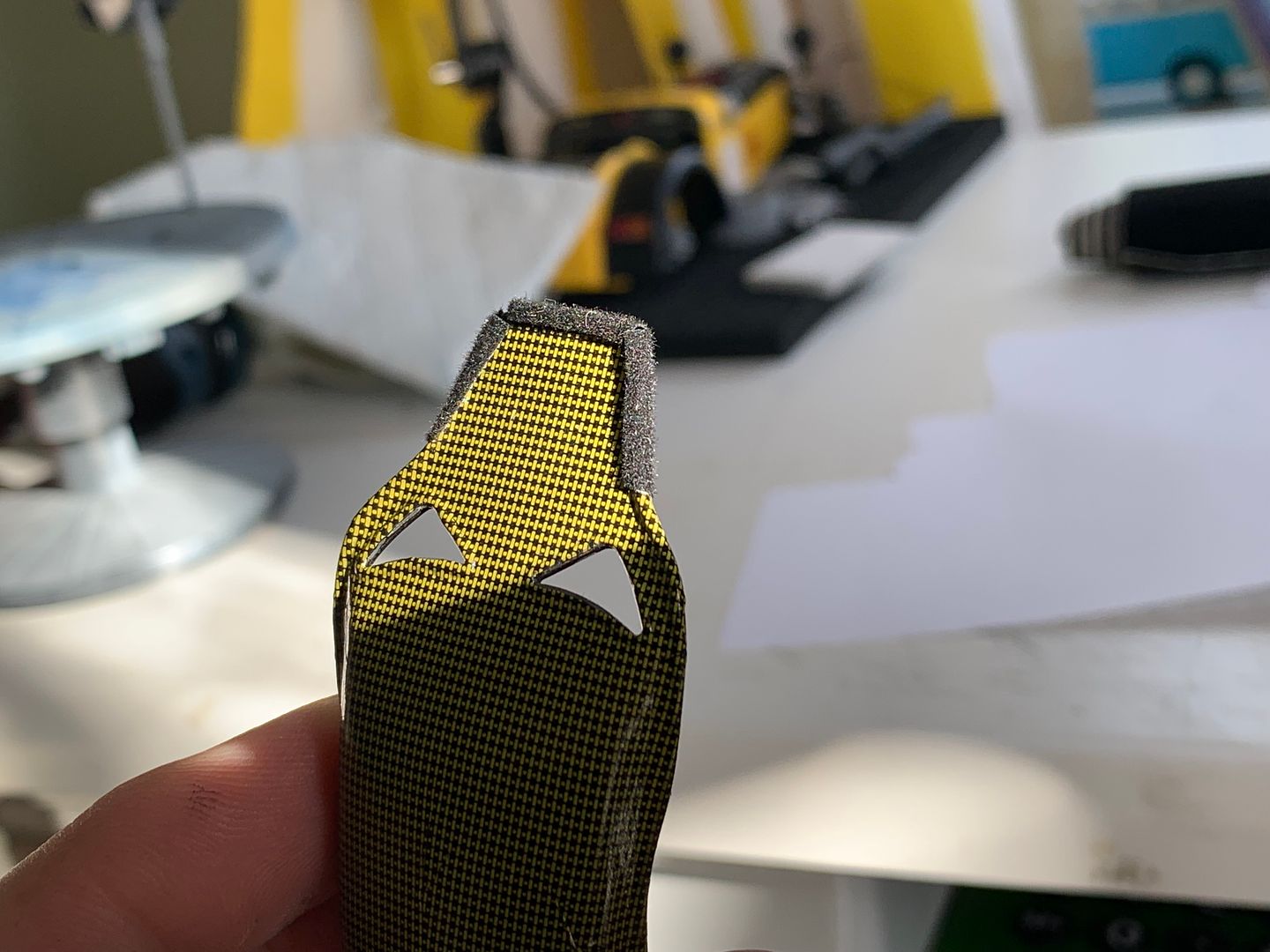

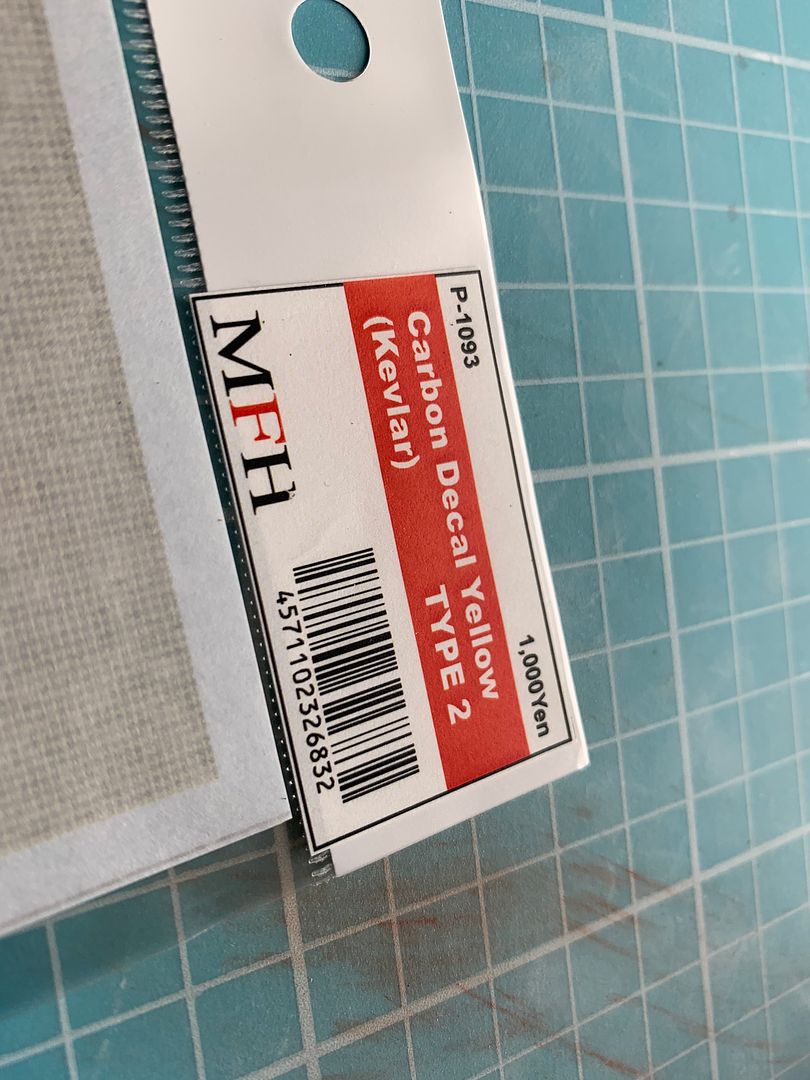

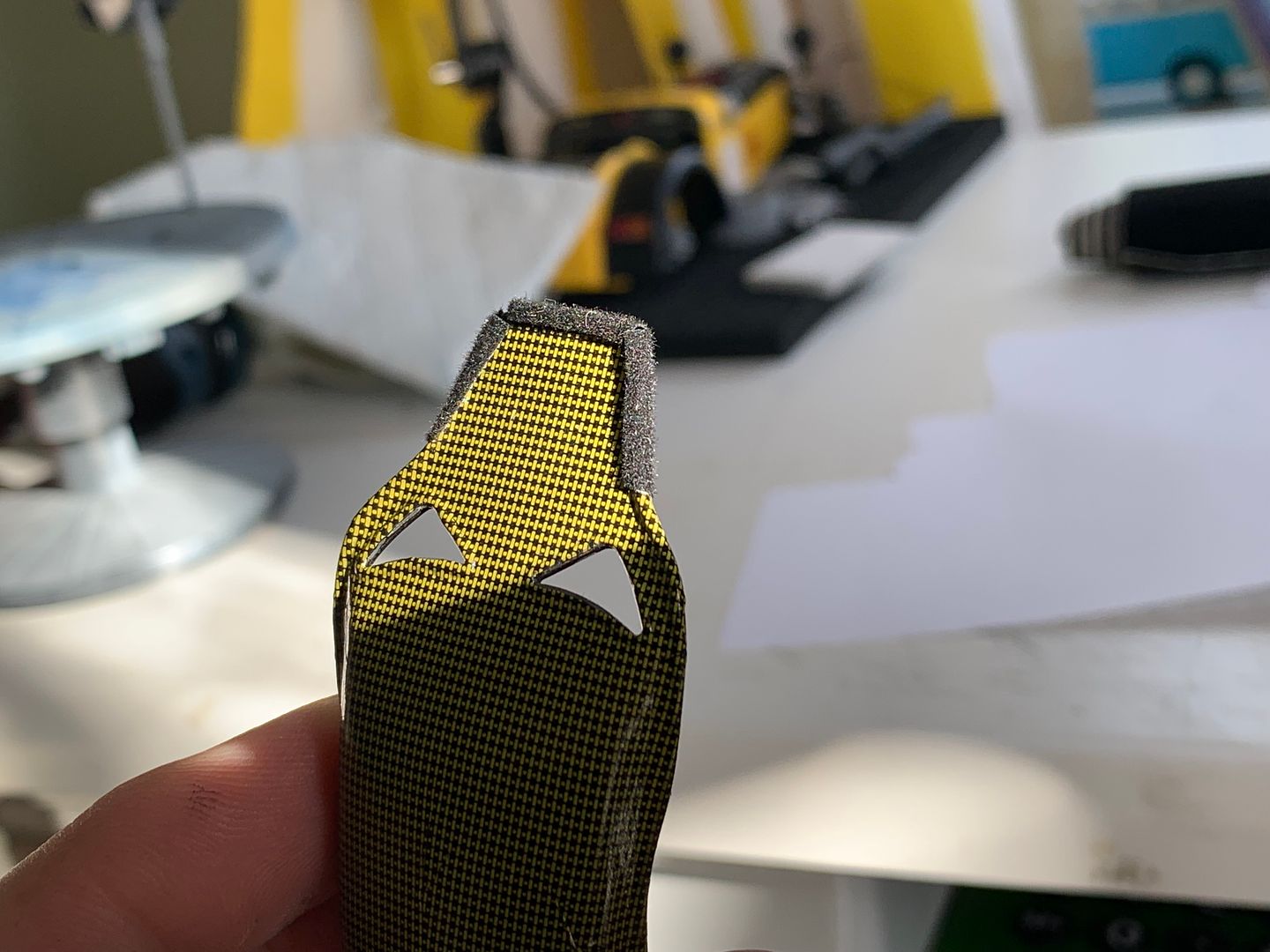

Once I was happy with the size and shape I primed and sprayed black - although the seat was kevlar, so it would be covered with decal and also some fine flocked sheet to represent the fabric on the real thing...

Fun shape to try and cover!

The rears would not be seen, so ignore those creases...

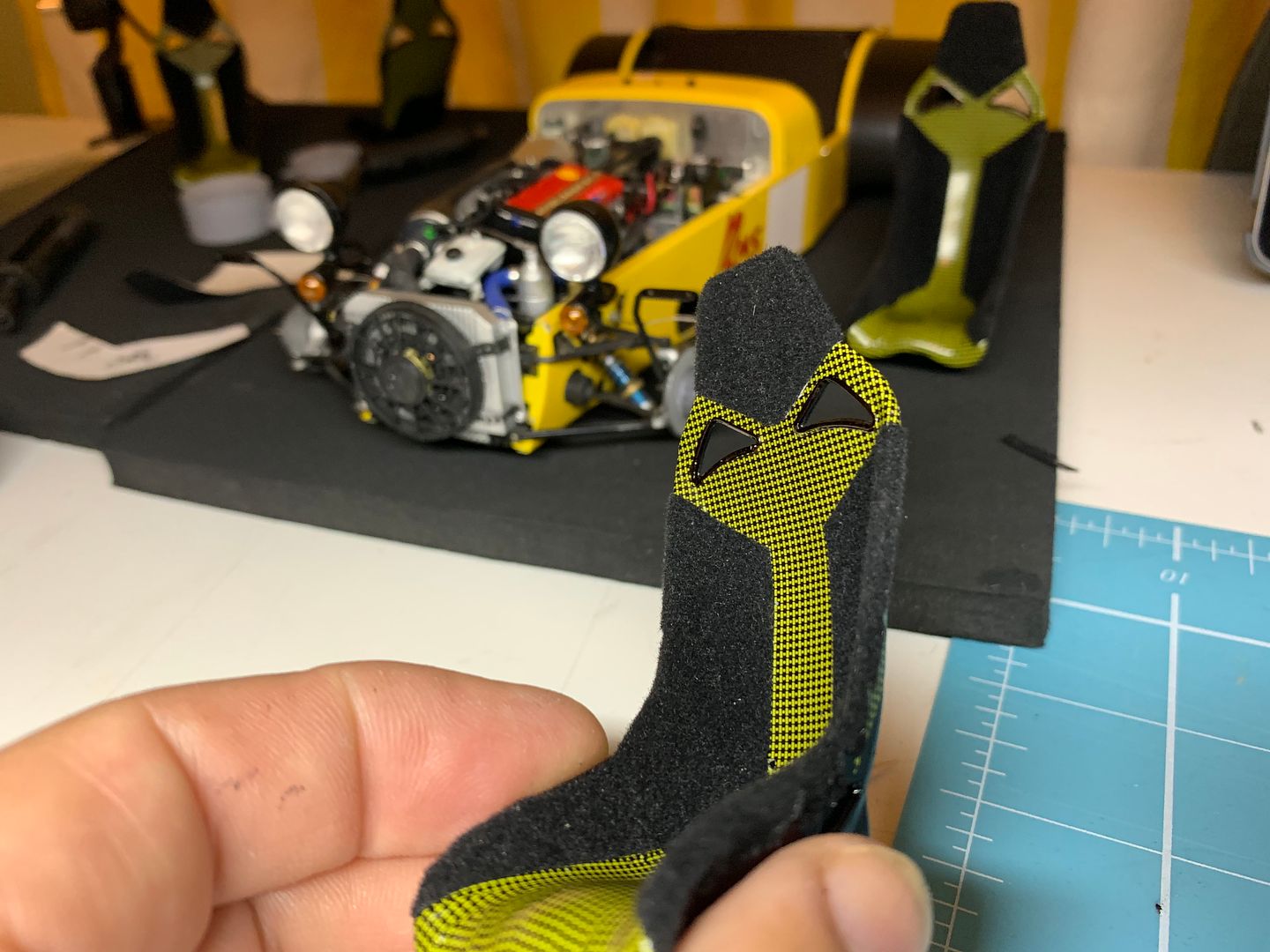

Once I had added the kevlar, I thought it looked a bit too yellow, so I sprayed a few layers of Tamiya 'smoke' to darken it a little...much better. Quick coat of satin clear to seal it all up.

Then the self-adhesive flocking material - bugger to get the shape right for the side pieces...some of these pictures are when testing shapes, so the finished result is neater...

Most of the rear and lower sides of the seat would not be seen, so I saved materials...still have a few bits to patch up, but overall - done!

These seats were the biggest issue to figure out - its only taken 15 years lol

Now I had the tool to print them, I still had to create the 3D file - youtube solidworks tutorials to the rescure:

Not perfect in terms of 3D drawing, but good enough for my use!

UV curing:

Had to get the scale right, and played around trying to get the shoulder 'bulge' correct - this had to fit in the model...

Once I was happy with the size and shape I primed and sprayed black - although the seat was kevlar, so it would be covered with decal and also some fine flocked sheet to represent the fabric on the real thing...

Fun shape to try and cover!

The rears would not be seen, so ignore those creases...

Once I had added the kevlar, I thought it looked a bit too yellow, so I sprayed a few layers of Tamiya 'smoke' to darken it a little...much better. Quick coat of satin clear to seal it all up.

Then the self-adhesive flocking material - bugger to get the shape right for the side pieces...some of these pictures are when testing shapes, so the finished result is neater...

Most of the rear and lower sides of the seat would not be seen, so I saved materials...still have a few bits to patch up, but overall - done!

These seats were the biggest issue to figure out - its only taken 15 years lol

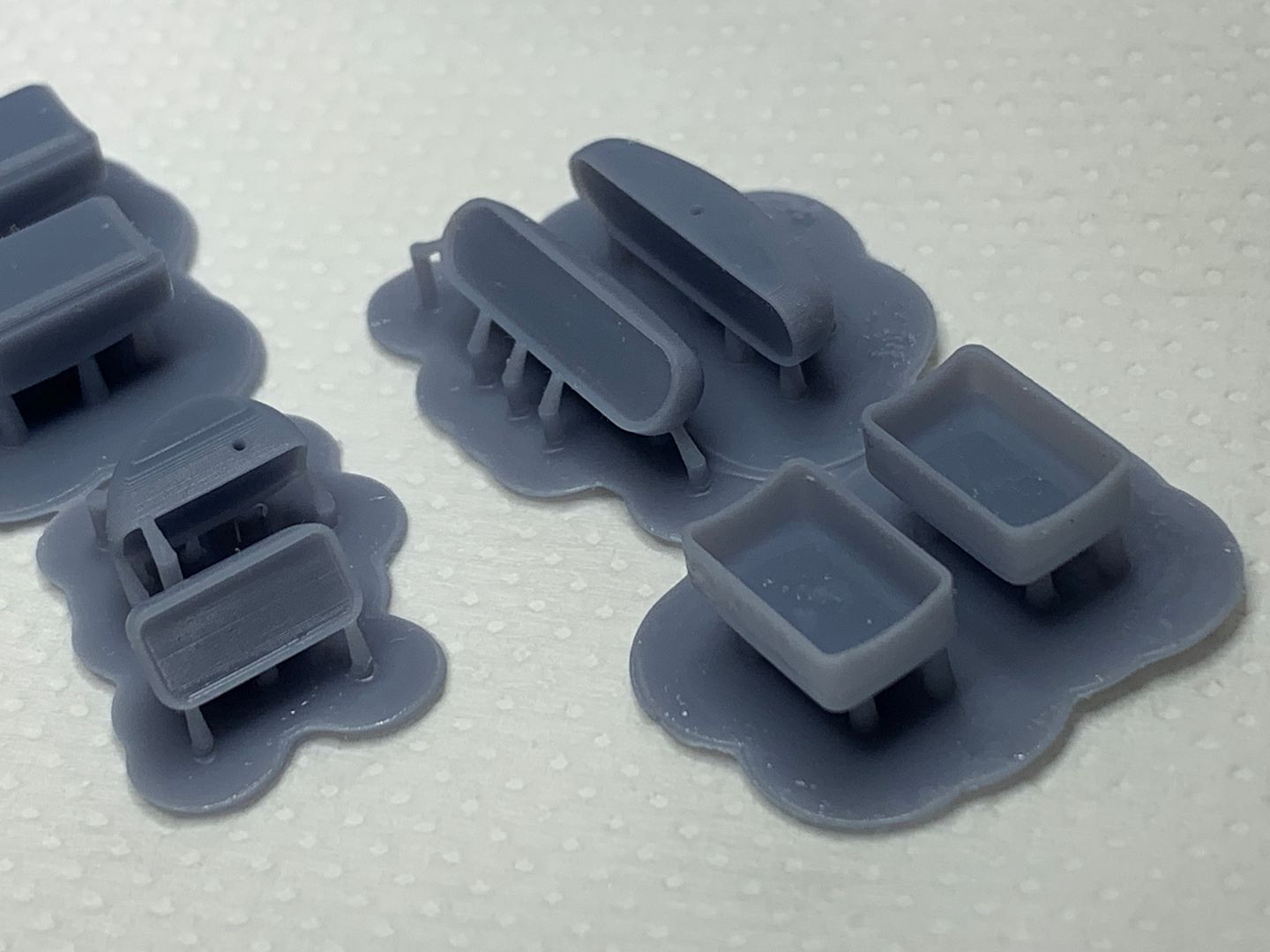

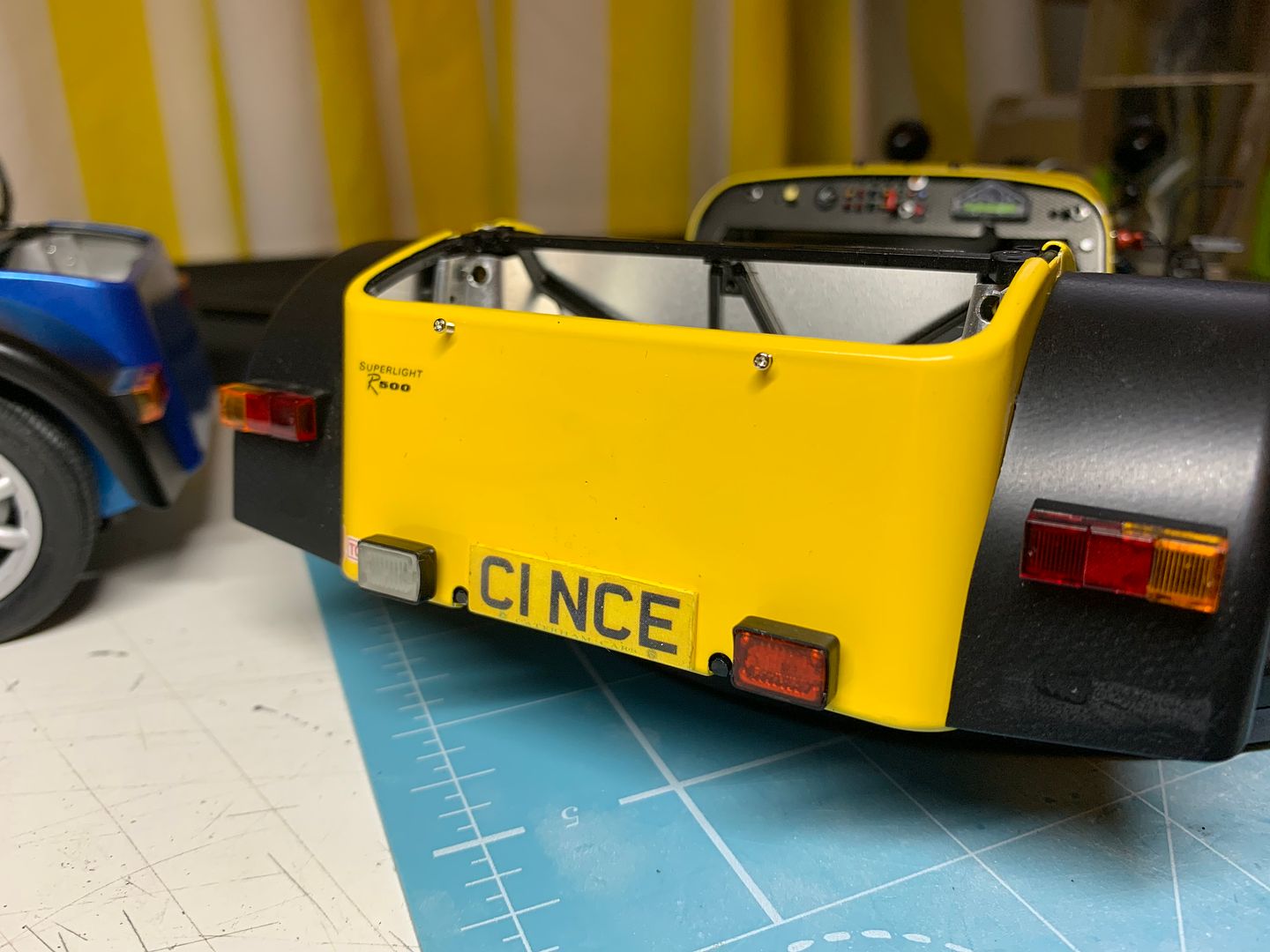

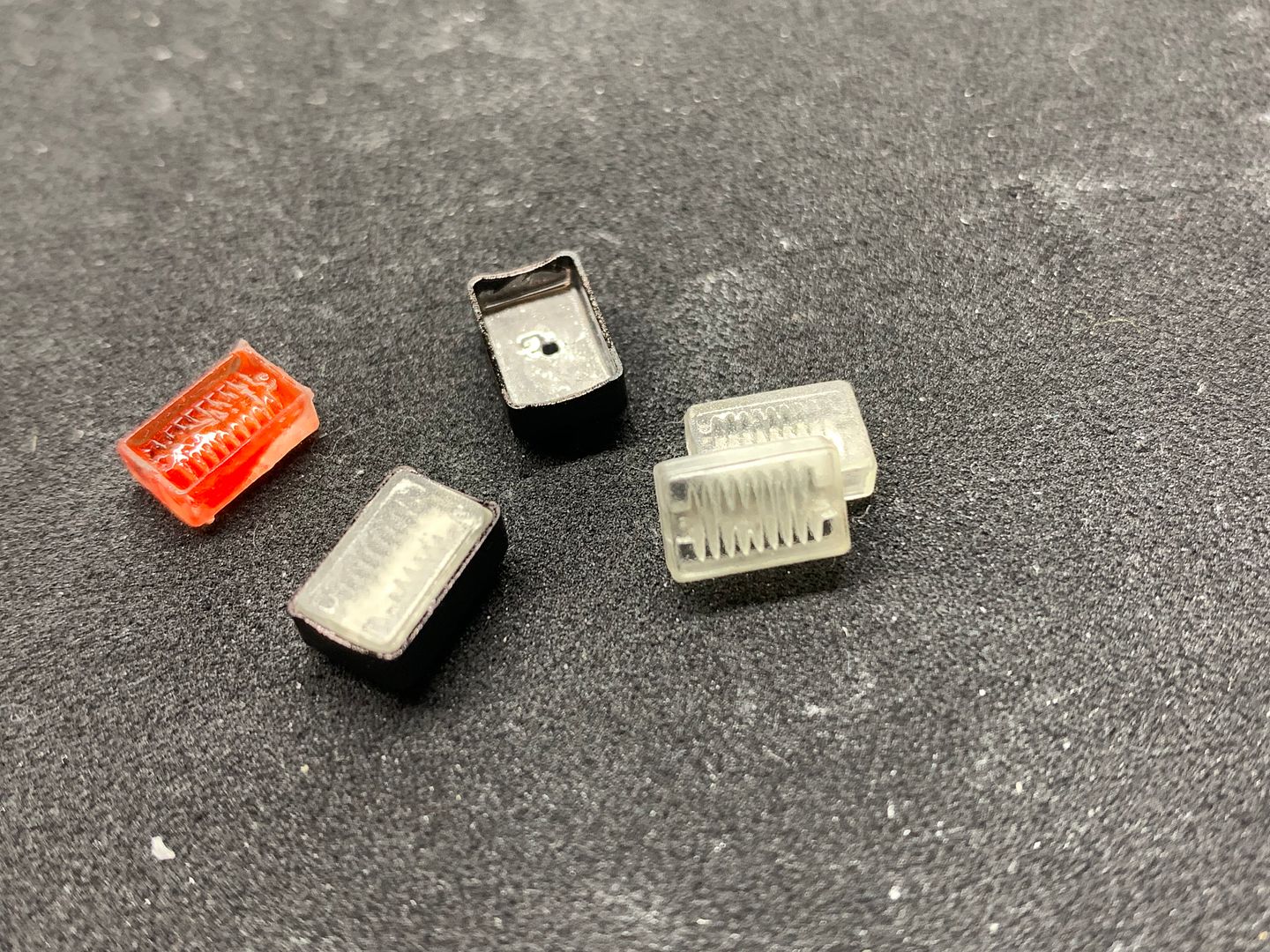

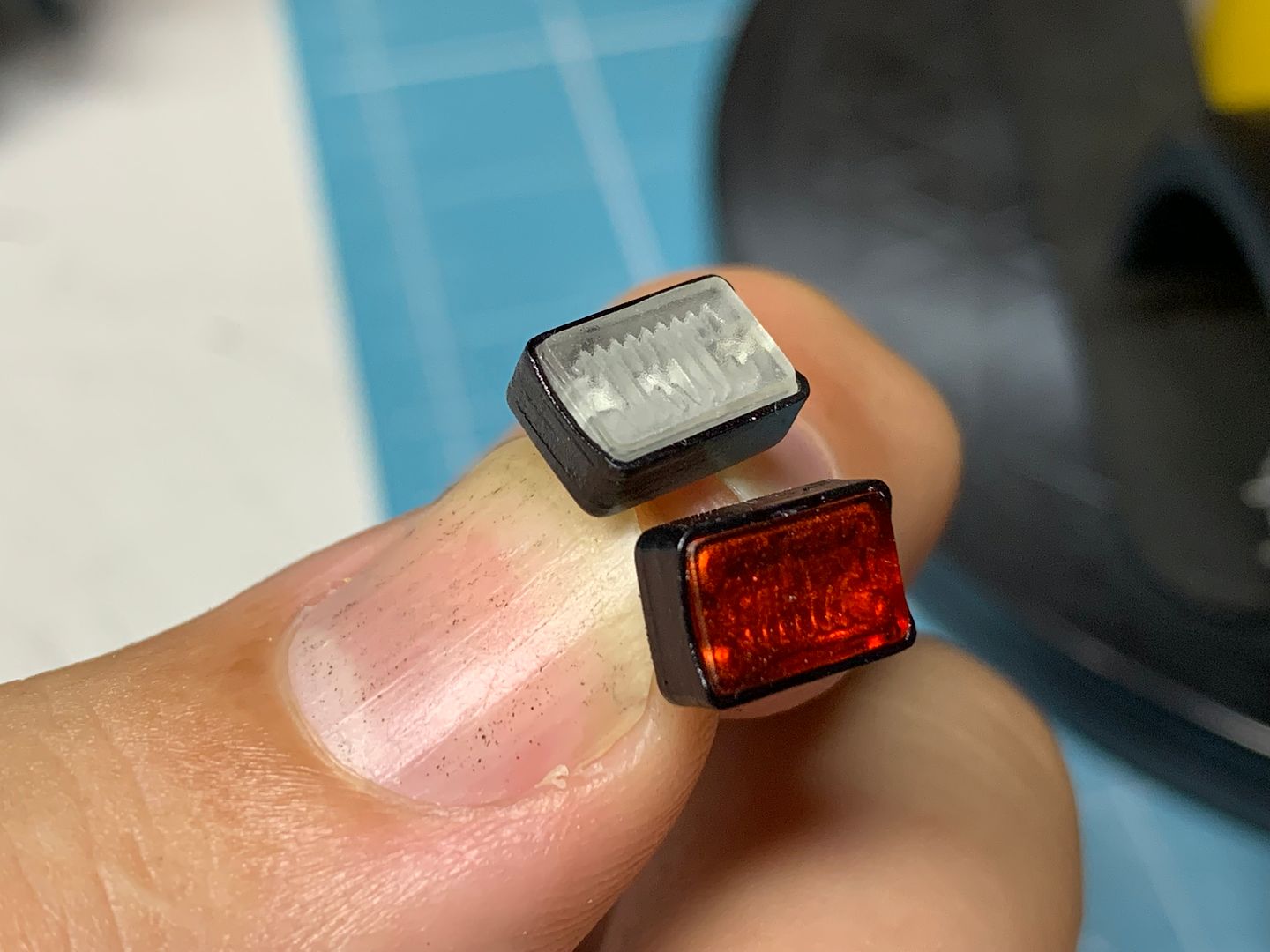

On a mission now, so I also drew up some other parts - the tiny ones like fog lights, rear view race mirrors etc - none of which are correct in the kit for what I need. I also drew up the '7' grill, which printed amazingly - years ago I had tried to resin cast the original wire one that came in one of the Tamiya kits (The VX powered JPE) as I needed more than one, but it was impossible - not now!

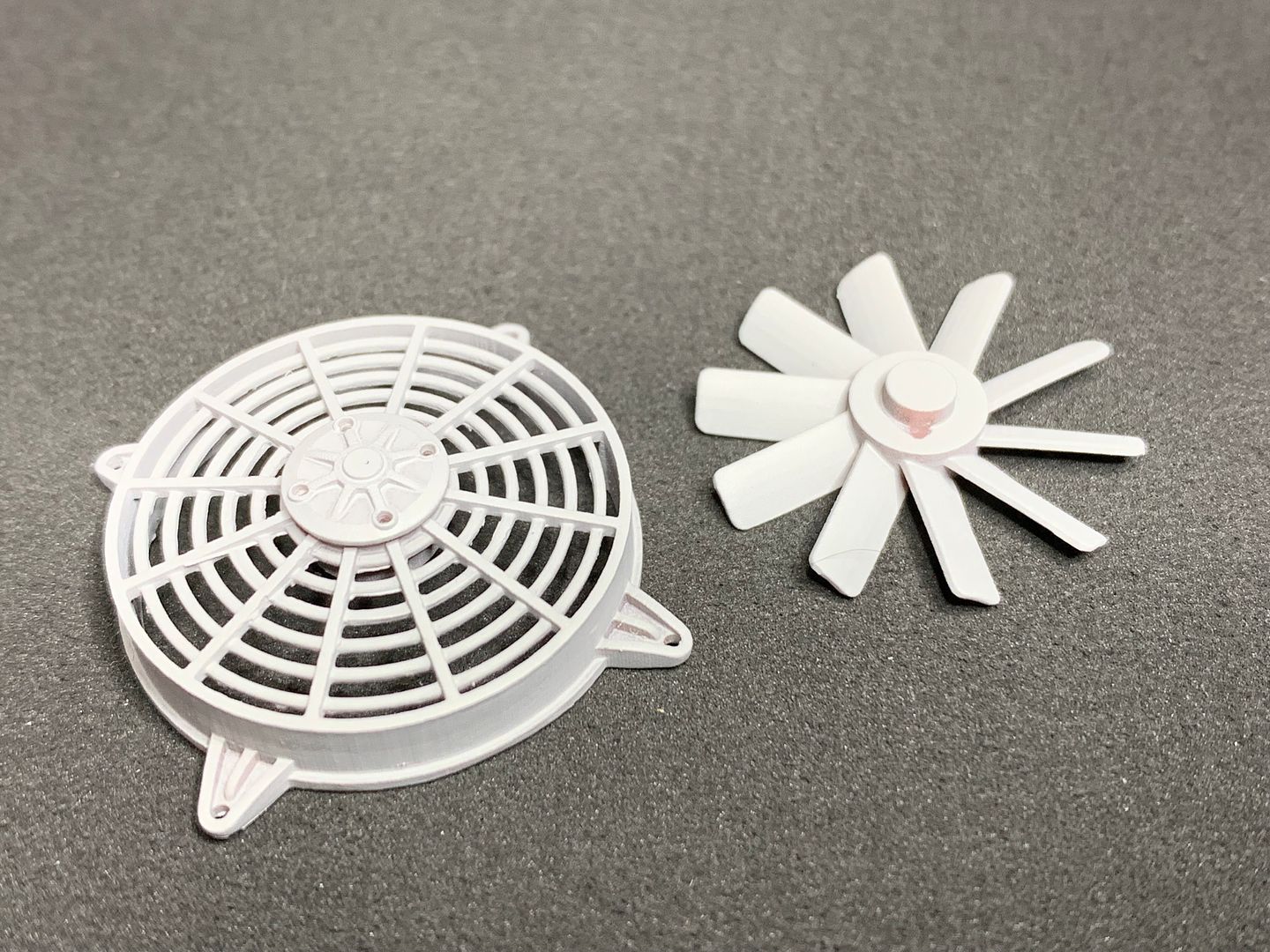

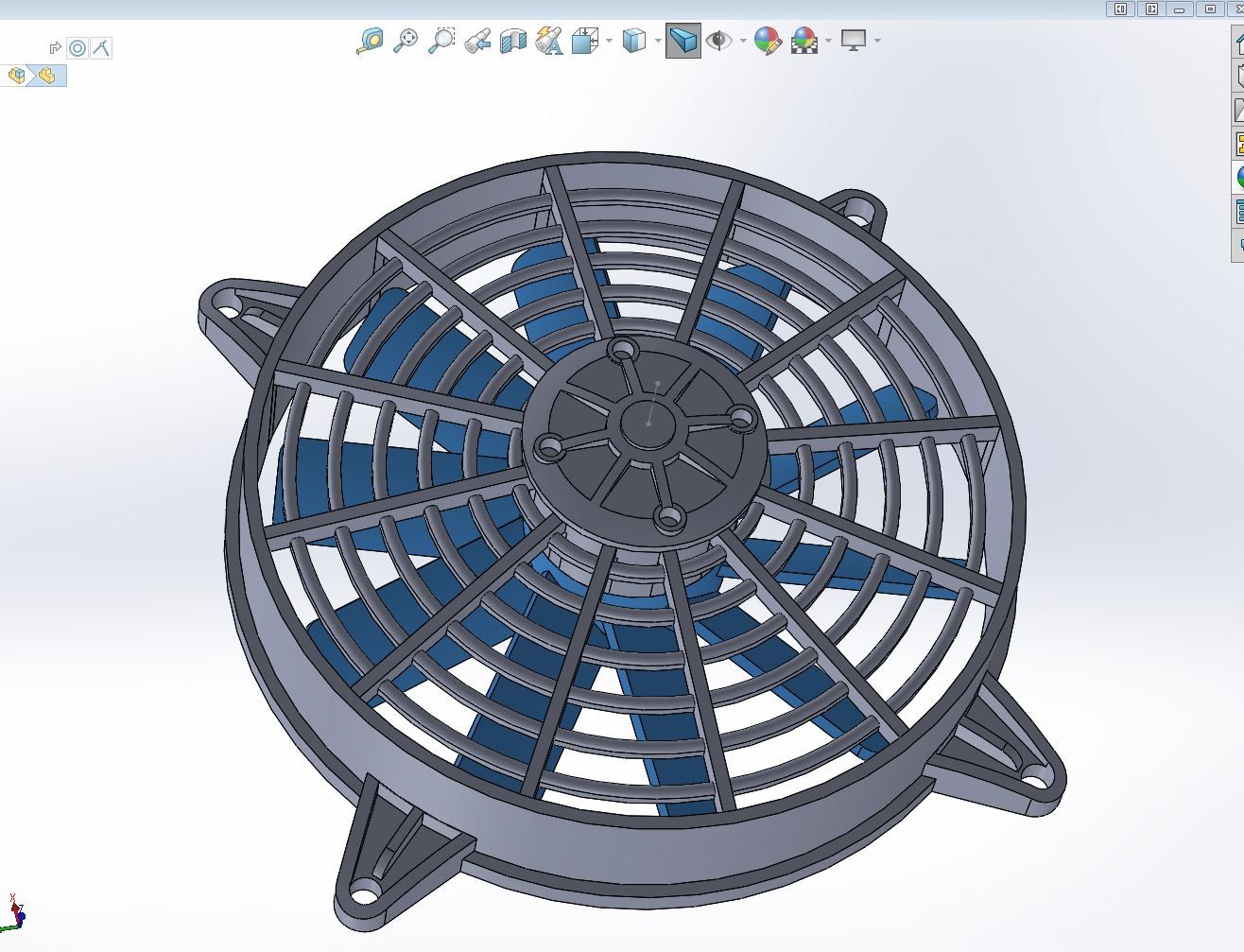

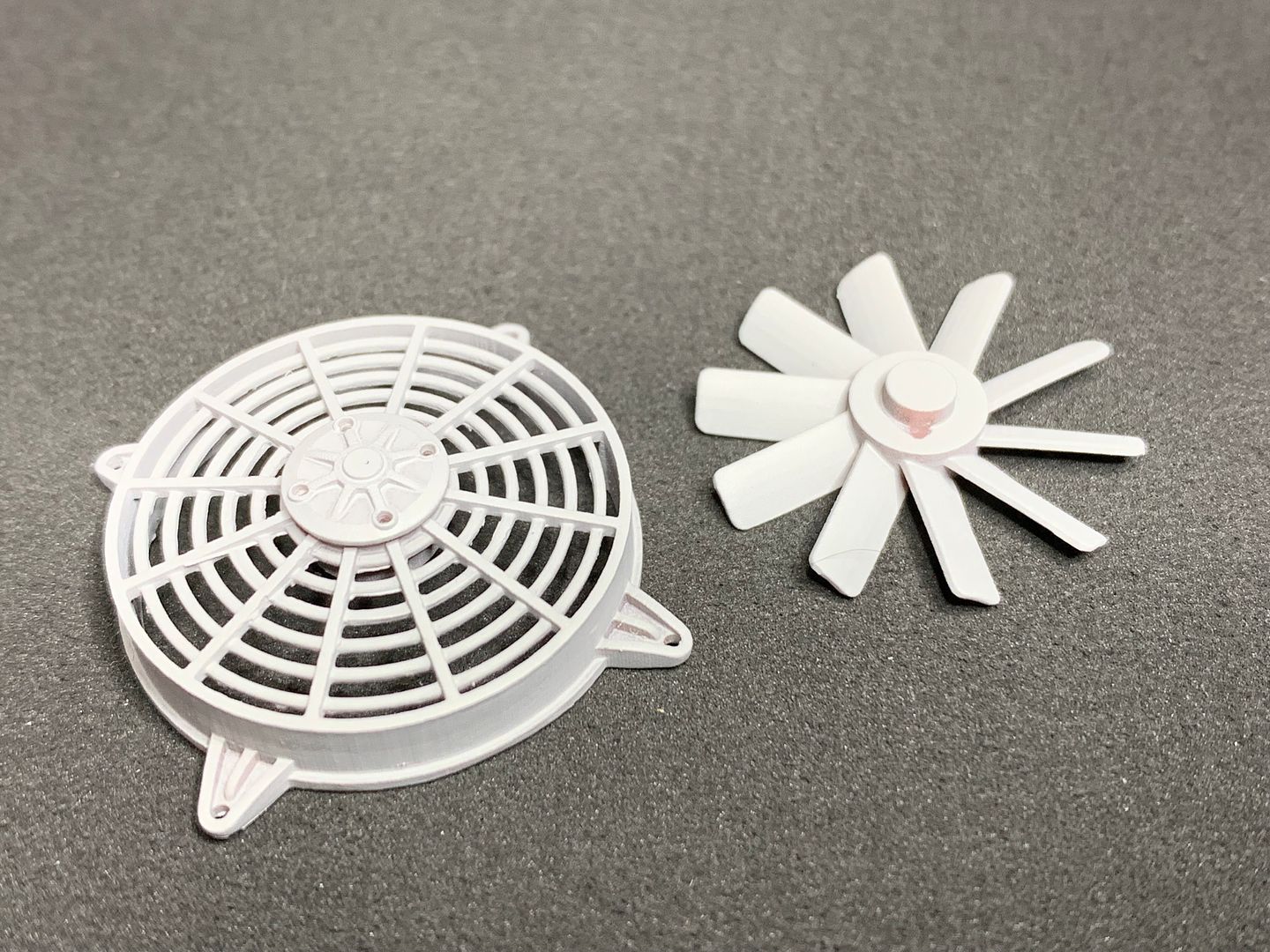

I had to make another cooling fan for the radiator of the blue car - the yellow one consisted of part of a camera film case, carefully bent wire, carved fan blades etc etc - huge amount of labour. I drew up this one, made the fan separately so I could paint more easily,.

I'm currently trying to get the wheel/tyre sizes spot on so I can manufacture those, and am about to start finishing and painting all those parts to assemble...

I had to make another cooling fan for the radiator of the blue car - the yellow one consisted of part of a camera film case, carefully bent wire, carved fan blades etc etc - huge amount of labour. I drew up this one, made the fan separately so I could paint more easily,.

I'm currently trying to get the wheel/tyre sizes spot on so I can manufacture those, and am about to start finishing and painting all those parts to assemble...

Nice - I am sure I'll get an FDM printer sometime for 'bigger' stuff - more structural things...

The bubbling' you are seeing is probably just the mark left by the supports when they are snapped off - light sanding gets rid of them - as I say, a lot of the pics I have posted have been 'quick' test shots...

Some parts require no finishing - depends on print angle, what etc etc....but a very light sand is all that I am doing - finish is superb.

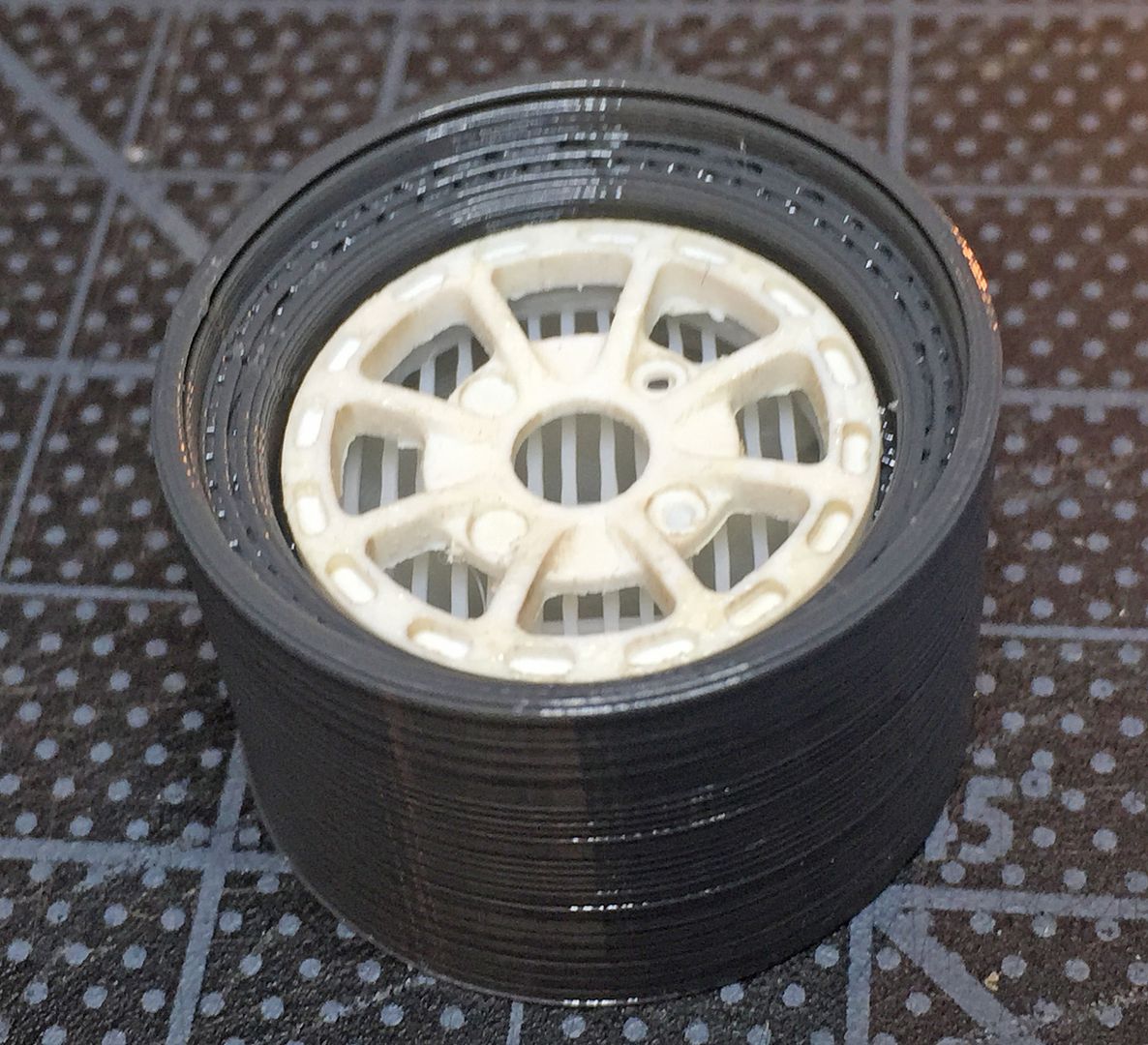

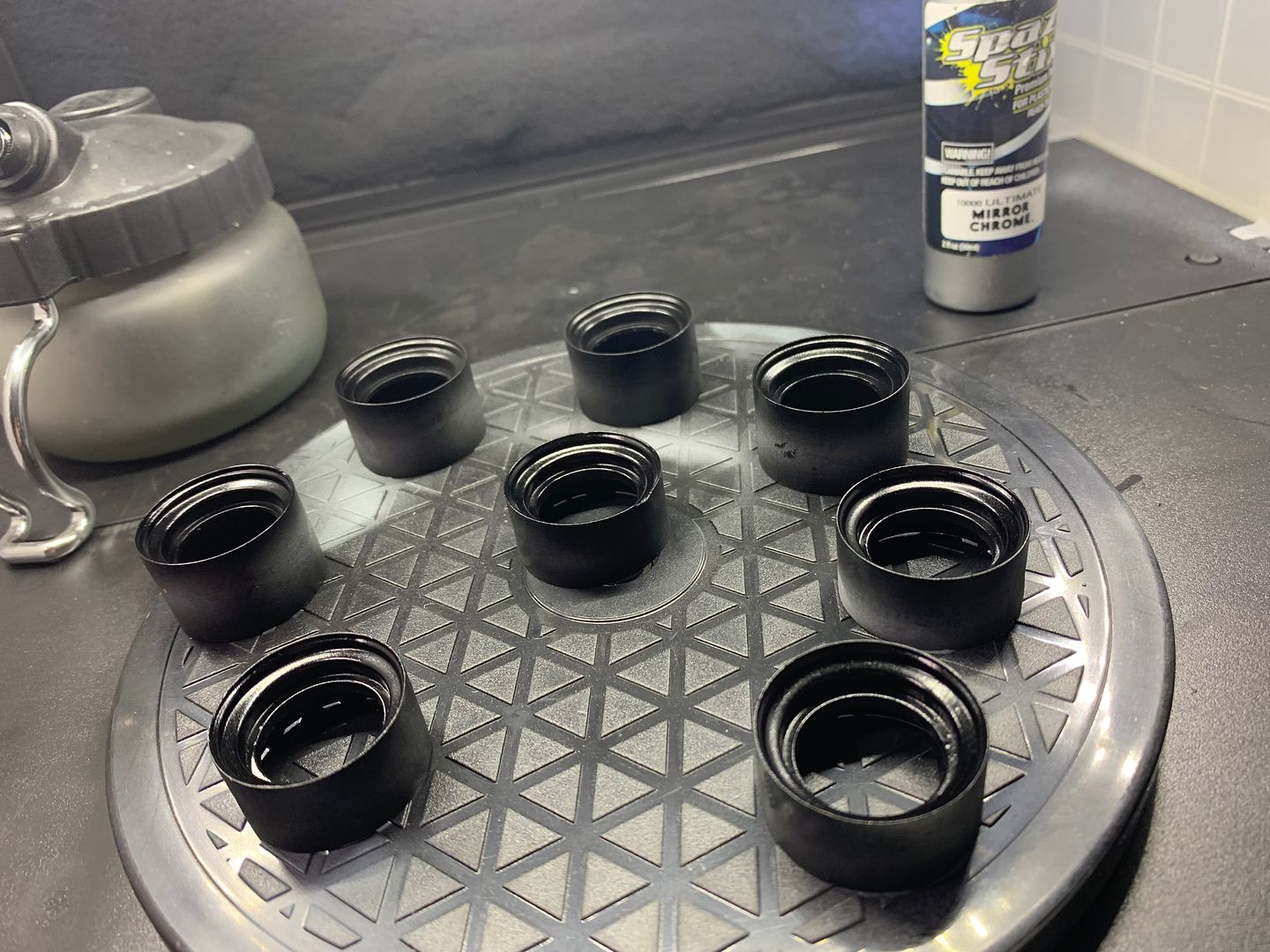

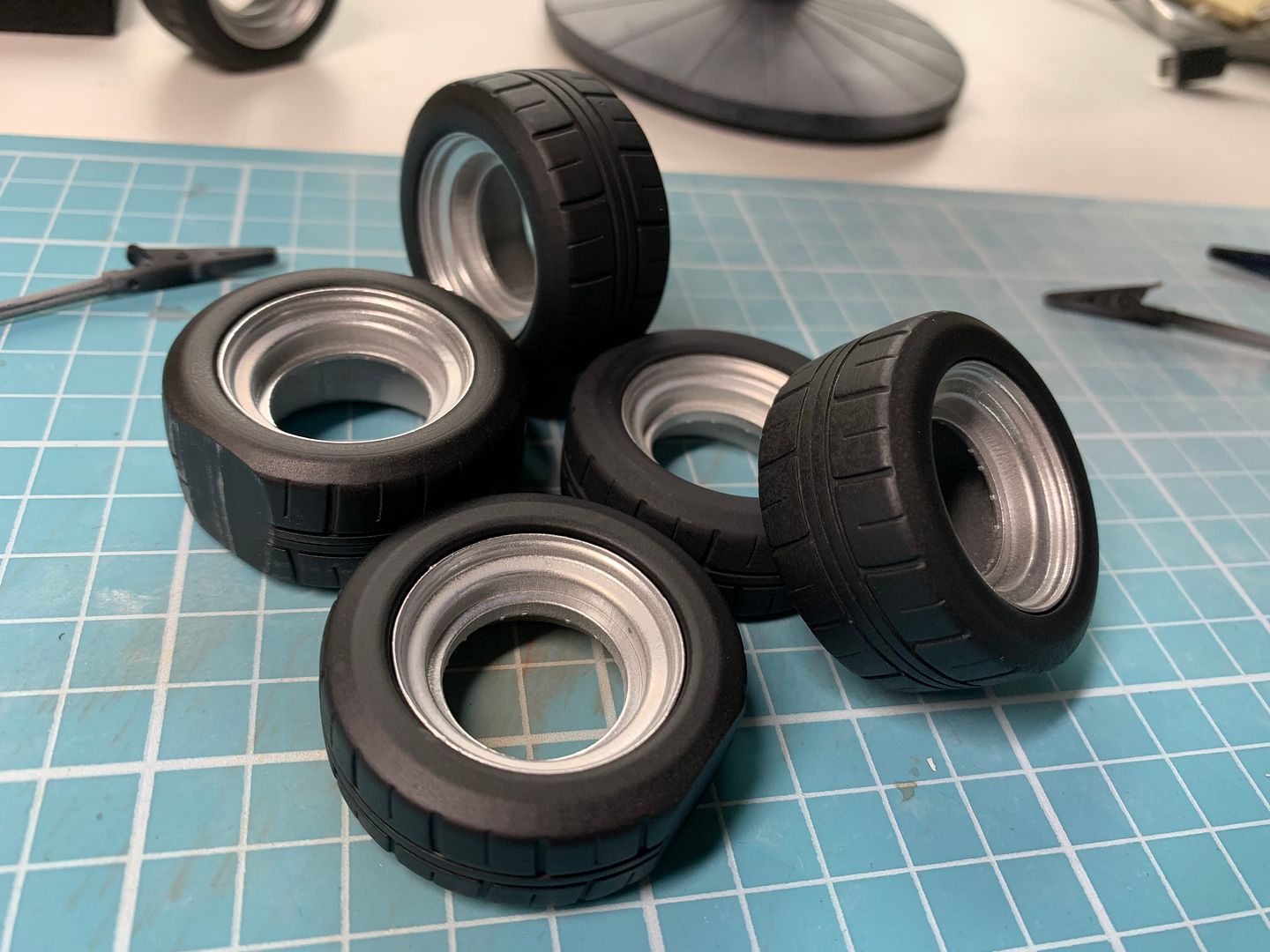

Finished the wheels (or at least the main parts - need to add the air valves etc!)

Printing the tyres was a pain - teied different angles etc, sometimes they would 'sag' as they printed due to the number of supports - still learning all that!

Had a few flats!

But once done, and cleaned off - I primed and sprayed with Tamiya Rubber Black (or tyre black - can't remember) - I am going to print a mask to spray 'AVON' on the tyres.

I ended up using Alclad Chrome on the rims - but not to full 'shine' effect - just enough to glint a little bit. I did try the Spaz chrome you can see, but wasn't impressed - far more to do with prep. and not fiddling with the airbrush - alclad gave me a 'hint' of chrome over the top of the other...

Nothing fixed or attached yet...

Lots of small bits next - mirrors, fog/reverse lights mainly...

Getting pretty close to assembling these parts to the cars and....finishing!!

Not THAT close - obviously...

The bubbling' you are seeing is probably just the mark left by the supports when they are snapped off - light sanding gets rid of them - as I say, a lot of the pics I have posted have been 'quick' test shots...

Some parts require no finishing - depends on print angle, what etc etc....but a very light sand is all that I am doing - finish is superb.

Finished the wheels (or at least the main parts - need to add the air valves etc!)

Printing the tyres was a pain - teied different angles etc, sometimes they would 'sag' as they printed due to the number of supports - still learning all that!

Had a few flats!

But once done, and cleaned off - I primed and sprayed with Tamiya Rubber Black (or tyre black - can't remember) - I am going to print a mask to spray 'AVON' on the tyres.

I ended up using Alclad Chrome on the rims - but not to full 'shine' effect - just enough to glint a little bit. I did try the Spaz chrome you can see, but wasn't impressed - far more to do with prep. and not fiddling with the airbrush - alclad gave me a 'hint' of chrome over the top of the other...

Nothing fixed or attached yet...

Lots of small bits next - mirrors, fog/reverse lights mainly...

Getting pretty close to assembling these parts to the cars and....finishing!!

Not THAT close - obviously...

Right - back on it after a trip to France and marshaling at the British F1 GP!

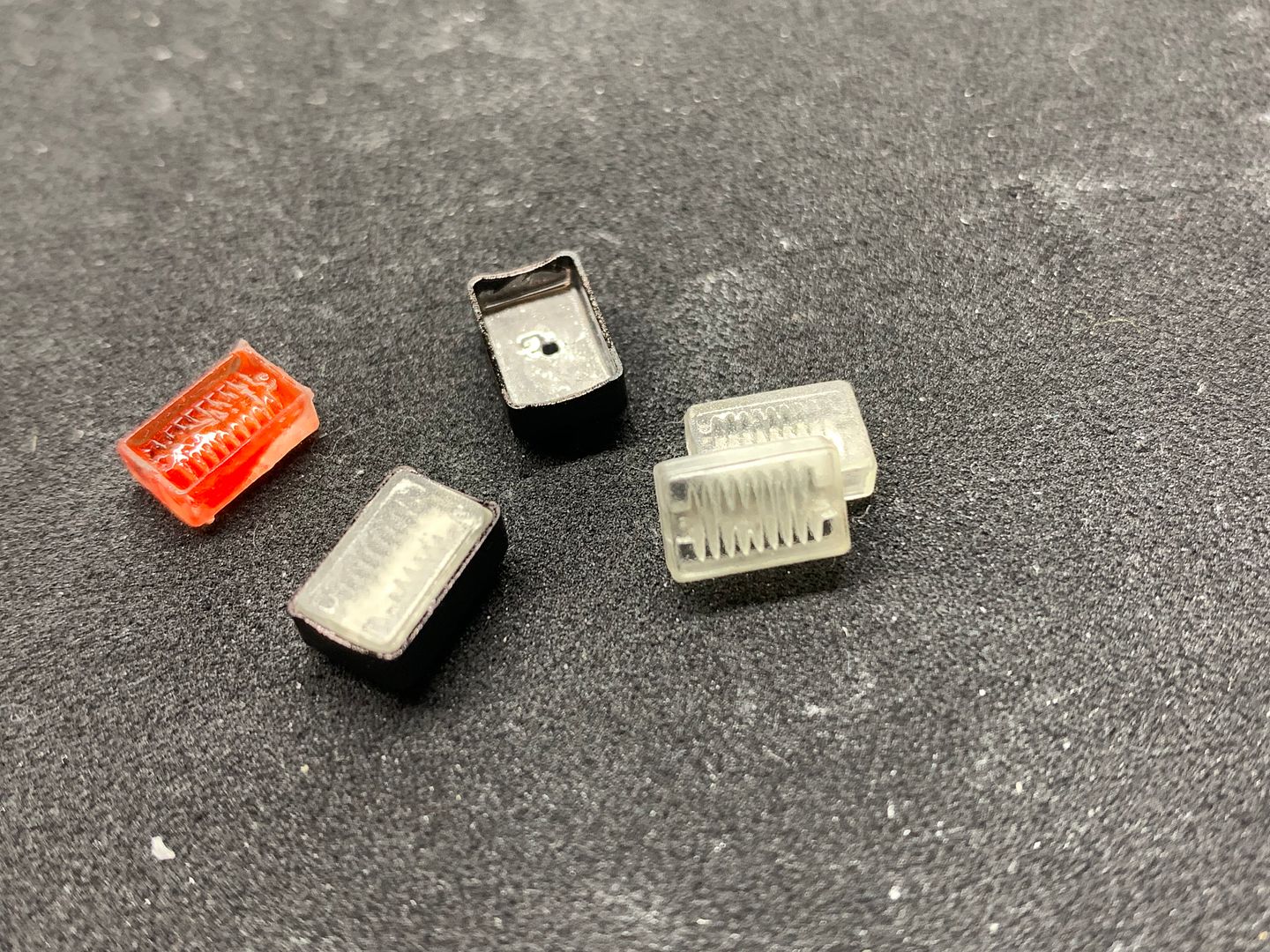

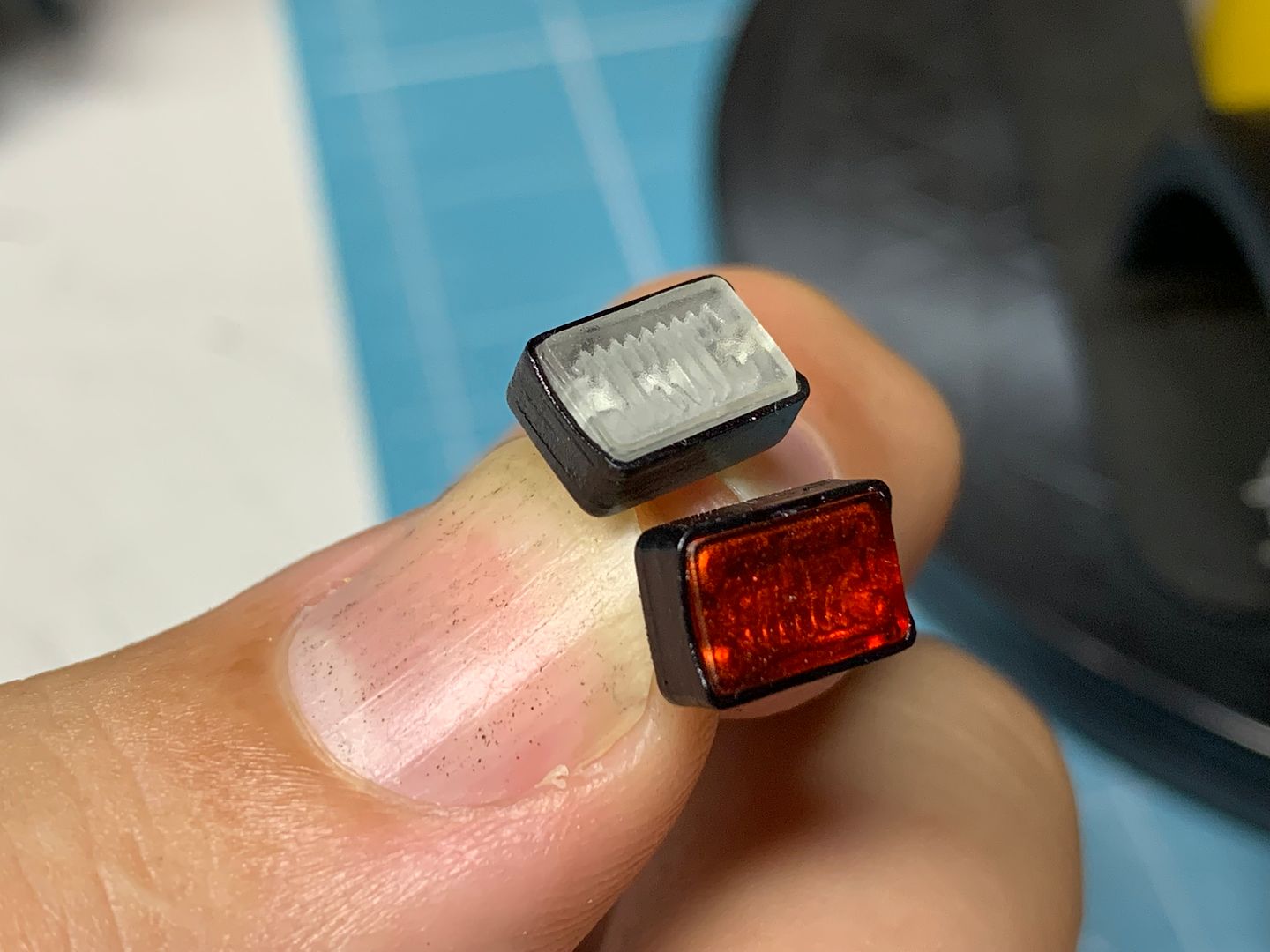

I tried a bit of clear resin to make the rear fog and reverse lights - I'd made the casing already, so made the 'lens' to fit inside. I thought I'd try a few details inside in the lens to see if it showed when painted (with clear red) - it actually worked quite well! I used a bit of silver paint inside the lens to help, especially with the reverse light. I'll add some screw details later...

I had a back-up plan using some clear red reflectors cut up, but the printed clear worked well...

...although I did have some weird artifacting with some of the prints - I think what happened was that the first few layers stuck to the FEP film, not the plate - then it stuck, and then i was getting some refraction of the UVA light through the clear resin - no idea, but I managed to get a few pieces that worked for what I needed.

I needed to find a way to fit my wheels - the bolt holes did not quite line up - I think the file was scaled slightly over the years, but I wanted something stronger anyway...

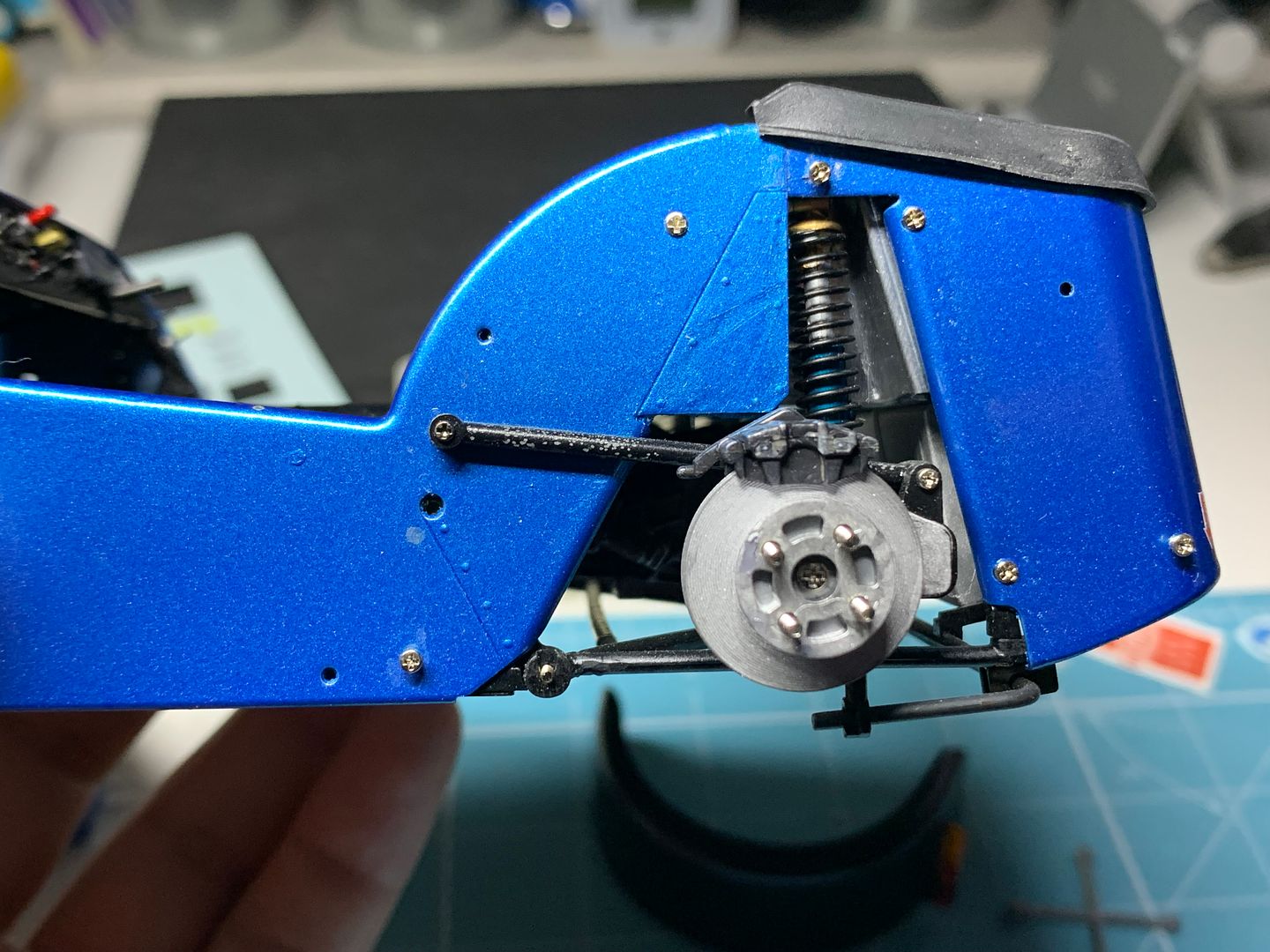

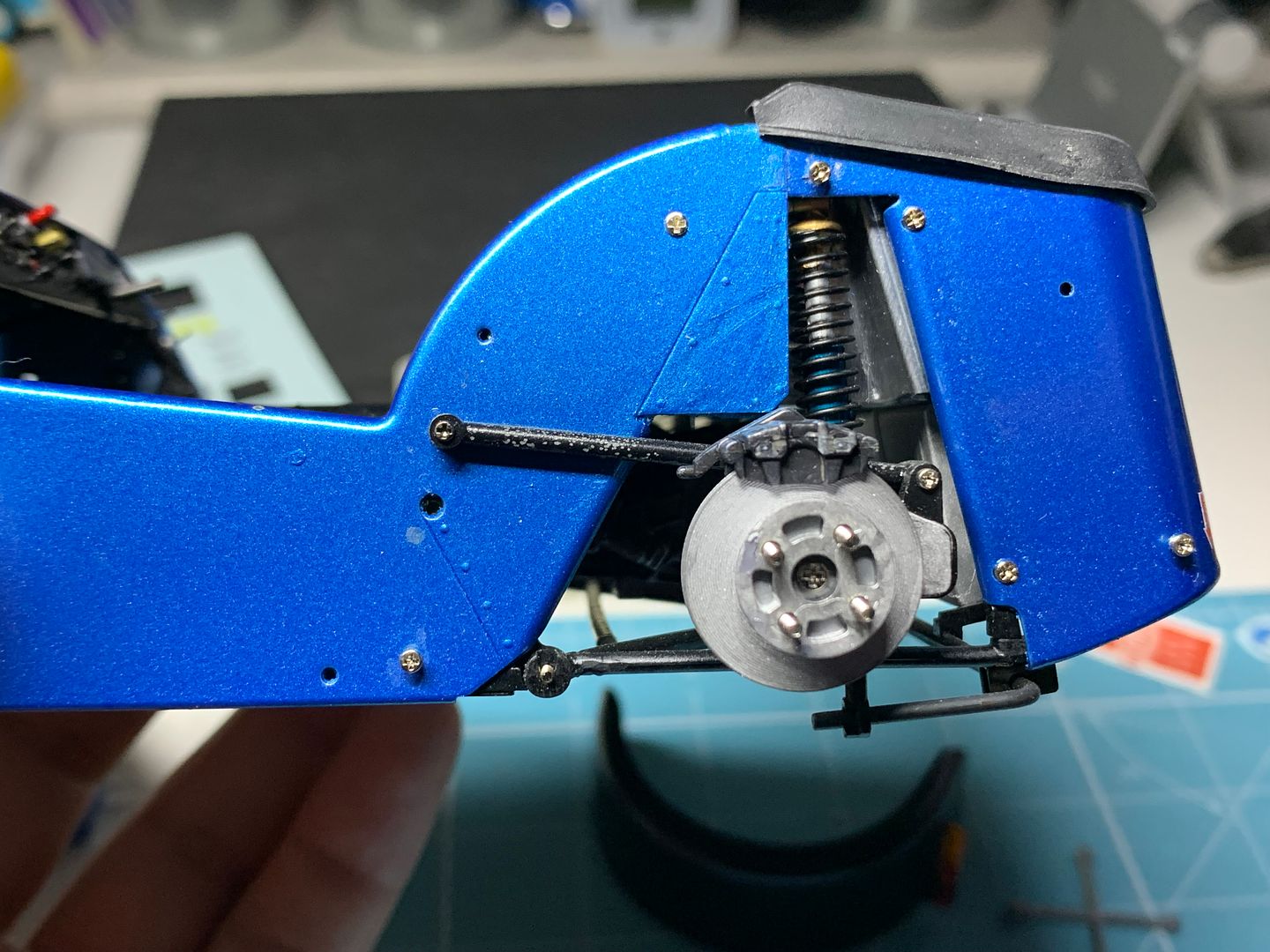

Incidentally, the Tamiya kit is so well made that it even has the alternative suspension mounts that the 'real' car has - in this model the trailing arm (link arm?) is fitted in 'comfort' mode - the lower boss is for better handling. It is all to do with 'rear steer' on the de-dion tube, and this kit actually can be used to demonstrate the difference and why the 2 positions work - I'll make a video next time I make one...

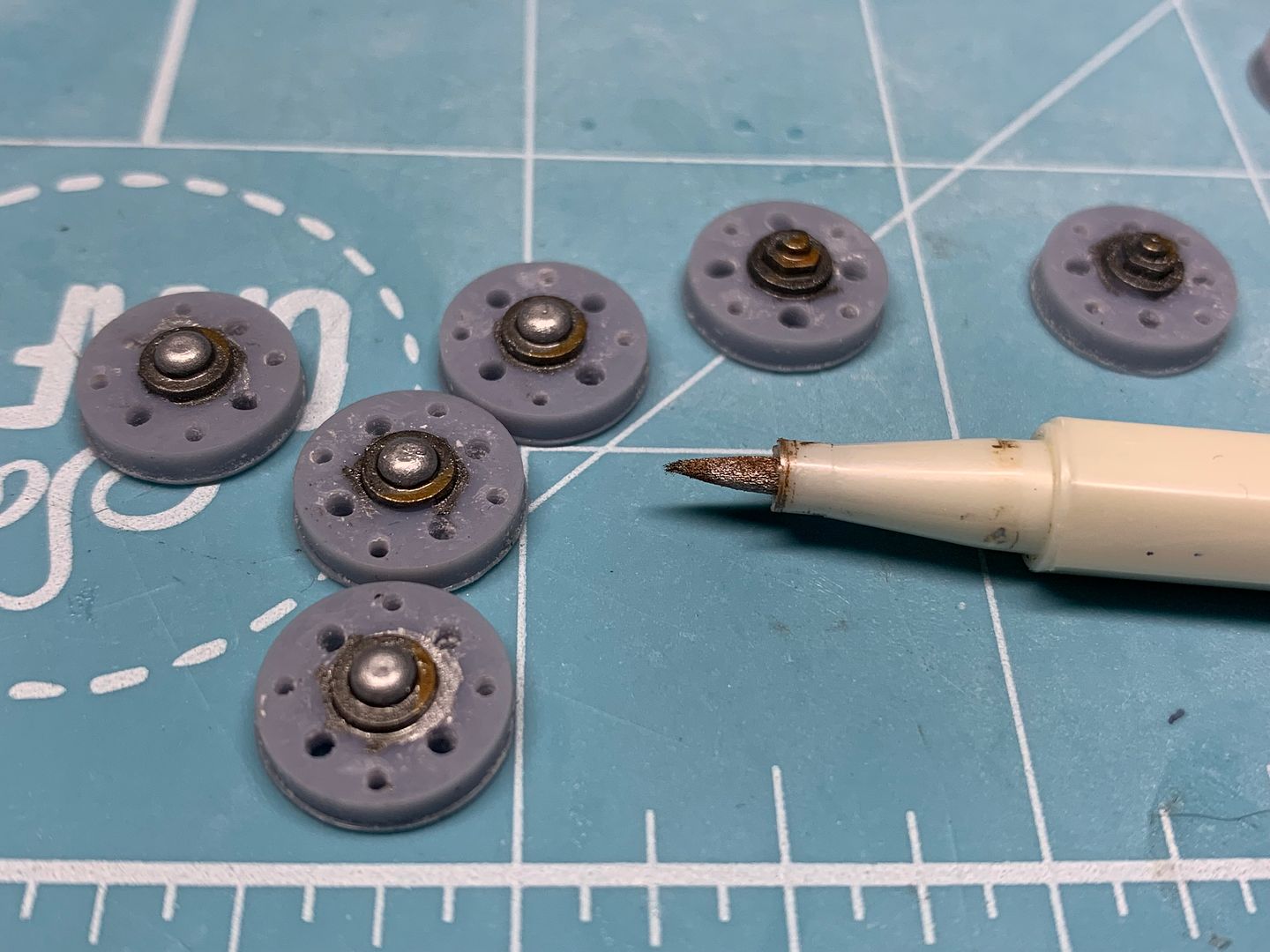

So I drew up some 'spacers' (I wanted a slightly wider track) which included the rear bub bolt and the front bearing grease cap. These would mount on the existing wheel bolts, and fit snuggly into my new alloys.

I used my trusty metallic pens to colour these - quick and effective!

Needed to finish one of the cages...

...and some more decals.

I tried a bit of clear resin to make the rear fog and reverse lights - I'd made the casing already, so made the 'lens' to fit inside. I thought I'd try a few details inside in the lens to see if it showed when painted (with clear red) - it actually worked quite well! I used a bit of silver paint inside the lens to help, especially with the reverse light. I'll add some screw details later...

I had a back-up plan using some clear red reflectors cut up, but the printed clear worked well...

...although I did have some weird artifacting with some of the prints - I think what happened was that the first few layers stuck to the FEP film, not the plate - then it stuck, and then i was getting some refraction of the UVA light through the clear resin - no idea, but I managed to get a few pieces that worked for what I needed.

I needed to find a way to fit my wheels - the bolt holes did not quite line up - I think the file was scaled slightly over the years, but I wanted something stronger anyway...

Incidentally, the Tamiya kit is so well made that it even has the alternative suspension mounts that the 'real' car has - in this model the trailing arm (link arm?) is fitted in 'comfort' mode - the lower boss is for better handling. It is all to do with 'rear steer' on the de-dion tube, and this kit actually can be used to demonstrate the difference and why the 2 positions work - I'll make a video next time I make one...

So I drew up some 'spacers' (I wanted a slightly wider track) which included the rear bub bolt and the front bearing grease cap. These would mount on the existing wheel bolts, and fit snuggly into my new alloys.

I used my trusty metallic pens to colour these - quick and effective!

Needed to finish one of the cages...

...and some more decals.

Gassing Station | Scale Models | Top of Page | What's New | My Stuff