The 2012 Aluminium Racing Toboggan Build Thread (pic heavy)

Discussion

So, it's that time of year again chaps, dust off your spikey-heeled shoes and crash helmets, and get ready to throw yourself down a mountain at 40mph on a glorified home-made tea tray.

For those who missed it last year, I had a stab at making what I was too tight to buy, and ended up going a bit OTT....

So after a damned good thrashing last year, here's what I pulled out of the cupboard earlier tonight;

The 'original' Mk1 bad boy. Got very well used, and eventually almost flattened in Soll. Although it was clearing a good two feet off the ground before coming down with a 12 stone idiot sitting on top. The suspension worked a treat, perhaps too well. Up-side of this one, the suspension worked perfectly, boinged up and down like a good-un, and was surprisingly effective to 'tune' by winding up and down the tension of the spring. Down-side, the runners were too close together, and the seat too high. This meant sitting on it at speed was like being a pea on a drum, it was very twitchy at speed, and although it turned on a sixpence, it wasn't always in the direction you wanted.... Not great at 30mph though a forest track!

I might re-make this one, cut off the old, bent bottom part, widen the runners, use 1" tube instead of 3/4", and I've got a good idea to make the front 'hinge' work a lot more effectively. Or I might end up just scrapping it!

My favourite looking, the Mk2. Sleek, nice proportions, suspension worked OK (if a little stiff). However, it moved like a fish, and steered like a cow. The body-frame was FAR too stiff, hardly any flex at all (not helped with the front hinge arrangement), so although it was fast and super-stable, the corners let it down.

The last one, made of off-cuts and leftovers. Looks OK, and was certainly the best made of the lot (last one, so was getting OK-ish at the welding by then), but a very basic design, literally made with leftovers from the others.

Annoyingly, it was the best of the lot by a huge margin. Very, very fast (I managed nearly 60km/h, GPS logged), very stable, and superb on corners. The only down-point was that (as with all of them) you tend to slip forwards on the seat when you get bumped around, so there was an ongoing struggle to keep in the right position. This wasn't such a problem on the others as they weren't quite so fast!

So, the plan for this year.

I have this lot left over;

To make one or two more.

From experience, I've worked out the best ones are the ones with the lower centre of gravity (I know, this should have been obvious anyway), and also that have a bit of flex in the frame to allow the runners to tilt a little.

The other thing we learnt is that tobogganing isn't all about going fast on the straight bits! If your toboggan can't turn well on its own (without major foot and hand-work), then you lose a LOT of time on the corners.

The best toboggan will pretty much steer itself around a corner without any foot/hand slowing at all.

SO, the plan for this year is to build something like the 'offcuts' one, but with more flex, and somehow to allow leaning (or something) to flatten one runner whilst increasing the angle on the other. This should make it 'steer' without slowing.

At this moment in time, I have NO idea how to achieve this whatsoever.

Just off to draw a little diagram, I may need some help with this.

For those who missed it last year, I had a stab at making what I was too tight to buy, and ended up going a bit OTT....

So after a damned good thrashing last year, here's what I pulled out of the cupboard earlier tonight;

The 'original' Mk1 bad boy. Got very well used, and eventually almost flattened in Soll. Although it was clearing a good two feet off the ground before coming down with a 12 stone idiot sitting on top. The suspension worked a treat, perhaps too well. Up-side of this one, the suspension worked perfectly, boinged up and down like a good-un, and was surprisingly effective to 'tune' by winding up and down the tension of the spring. Down-side, the runners were too close together, and the seat too high. This meant sitting on it at speed was like being a pea on a drum, it was very twitchy at speed, and although it turned on a sixpence, it wasn't always in the direction you wanted.... Not great at 30mph though a forest track!

I might re-make this one, cut off the old, bent bottom part, widen the runners, use 1" tube instead of 3/4", and I've got a good idea to make the front 'hinge' work a lot more effectively. Or I might end up just scrapping it!

My favourite looking, the Mk2. Sleek, nice proportions, suspension worked OK (if a little stiff). However, it moved like a fish, and steered like a cow. The body-frame was FAR too stiff, hardly any flex at all (not helped with the front hinge arrangement), so although it was fast and super-stable, the corners let it down.

The last one, made of off-cuts and leftovers. Looks OK, and was certainly the best made of the lot (last one, so was getting OK-ish at the welding by then), but a very basic design, literally made with leftovers from the others.

Annoyingly, it was the best of the lot by a huge margin. Very, very fast (I managed nearly 60km/h, GPS logged), very stable, and superb on corners. The only down-point was that (as with all of them) you tend to slip forwards on the seat when you get bumped around, so there was an ongoing struggle to keep in the right position. This wasn't such a problem on the others as they weren't quite so fast!

So, the plan for this year.

I have this lot left over;

To make one or two more.

From experience, I've worked out the best ones are the ones with the lower centre of gravity (I know, this should have been obvious anyway), and also that have a bit of flex in the frame to allow the runners to tilt a little.

The other thing we learnt is that tobogganing isn't all about going fast on the straight bits! If your toboggan can't turn well on its own (without major foot and hand-work), then you lose a LOT of time on the corners.

The best toboggan will pretty much steer itself around a corner without any foot/hand slowing at all.

SO, the plan for this year is to build something like the 'offcuts' one, but with more flex, and somehow to allow leaning (or something) to flatten one runner whilst increasing the angle on the other. This should make it 'steer' without slowing.

At this moment in time, I have NO idea how to achieve this whatsoever.

Just off to draw a little diagram, I may need some help with this.

Right-ho, here's the principle.

To turn, you instinctively lean your body in the direction you want to turn in. You also stick your boot in the ground, and your hand out behind you, to make a tighter/faster turn.

To make this happen, you ideally want to change the angle of the runners so that they're doing a large part of the turn for you.

Here's a quick cobbled up diagram;

So, taking the basic aluminium model as a base, how the heck can you make this happen?

I've thought about using car suspension type bushes to allow flex, and bolt up from underneath, but it still doesn't solve the main issue of making the angles change depending on the weight transfer on top.

I've also thought about some sort of 'steering' joystick, that will move the runners around, but I've discounted this at the moment, as I don't think I'll be able to make it anywhere near strong enough. These things get a heck of a hammering!

Any ideas?

To turn, you instinctively lean your body in the direction you want to turn in. You also stick your boot in the ground, and your hand out behind you, to make a tighter/faster turn.

To make this happen, you ideally want to change the angle of the runners so that they're doing a large part of the turn for you.

Here's a quick cobbled up diagram;

So, taking the basic aluminium model as a base, how the heck can you make this happen?

I've thought about using car suspension type bushes to allow flex, and bolt up from underneath, but it still doesn't solve the main issue of making the angles change depending on the weight transfer on top.

I've also thought about some sort of 'steering' joystick, that will move the runners around, but I've discounted this at the moment, as I don't think I'll be able to make it anywhere near strong enough. These things get a heck of a hammering!

Any ideas?

snotrag said:

Come on - your a skier!

IMO your runners need to be convex, and far more flexible than that thick box section.

Think about a ski, unweighted, on a flat surface - the tips touch the ground, the centre is raised. Lean it to the left, press down (IE, your inside edge of your right boot in a left carving turn) - the ski is now tracking a curve on the ground.

Flexible, convex runners are the way to go IMO.

Yes, I did think this, even to the extent of making a Mk5, which isn't pictured above...IMO your runners need to be convex, and far more flexible than that thick box section.

Think about a ski, unweighted, on a flat surface - the tips touch the ground, the centre is raised. Lean it to the left, press down (IE, your inside edge of your right boot in a left carving turn) - the ski is now tracking a curve on the ground.

Flexible, convex runners are the way to go IMO.

Had exactly this, not actual skateboard trucks, but a similar arrangement with an angled king-pin, which tilted the carving-ski-type runners depending how weight was distributed.

Only thing was, it was a pisser to build, and never really worked that well.

But that COULD just be because I got the angles a bit fierce, and a big-ish lean on top meant a big-ish lean on the bottom too. If I could limit it a little, that may work.

Fellows, you may be on to something....

tvrolet said:

Except for these new fangled rocker skis where the tips and tails are off the snow

I'm sure it's loads of work, and you've maybe tried and dismissed it, but if you mount the runners wishbone style and so long as the distance between the mounts on the uprights is less than the distance between the mounts on the chassis, the from a neutral postion the runners will tilt out (positive camber) inder compression, and in under extension.

So if the chassis is tilted the outer runner will tilt more than the inner runner. It would be interesting to have a different ratio on the front of the runner to the rear as compression could cause the runner to twist. Might even be possible to use the flex in the runner between the 2 ratios as the 'spring' in the sustem.

Plan B is to mount the runners in the centre only leaving the ends to flex.

Plan C could be to mount the runners on a ball-joint front at back right down on the runner, plus a lever-type arrangement to tilt the runners independently of the chassis and the ball joints would also let the runners flex.

Plan D is to buy a tea tray.

Plan A - Very interesting, superb idea. That will get some serious though. The only problem is, the runners aren't really possible to have too flexible. I tried 16 gauge ally and it wasn't strong enough, couldn't bend it. Slightly curved runners is a possibility though. But, if they tilt, and in different ratios, that could work very well indeed, and might be enough.

I'm sure it's loads of work, and you've maybe tried and dismissed it, but if you mount the runners wishbone style and so long as the distance between the mounts on the uprights is less than the distance between the mounts on the chassis, the from a neutral postion the runners will tilt out (positive camber) inder compression, and in under extension.

So if the chassis is tilted the outer runner will tilt more than the inner runner. It would be interesting to have a different ratio on the front of the runner to the rear as compression could cause the runner to twist. Might even be possible to use the flex in the runner between the 2 ratios as the 'spring' in the sustem.

Plan B is to mount the runners in the centre only leaving the ends to flex.

Plan C could be to mount the runners on a ball-joint front at back right down on the runner, plus a lever-type arrangement to tilt the runners independently of the chassis and the ball joints would also let the runners flex.

Plan D is to buy a tea tray.

Plan B - Hadn't thought of that, but I don't think I could make it strong enough anyway.

Plan C - This is the sort of lines I was thinking along earlier tonight. Loads of free movement, with a steering type mechanism. The only down-side of this is you often need, at speed, at least one arm and one leg spare to steer, and stop yourself coming off altogether, so I'm not sure the steering would be too hard to keep control of. Weight shifting would be much easier.

Plan D - Yeah, but I'd buy a tea tray, then try and adapt it with better steering, put some angle on the edges, and add some high density polyethylene to the base to lower the friction, add suspension, carbon fibre seat.....

Thank you so much for that, lots of food for thought!

joe58 said:

My proposal.

Low seat, wide ski stance. More stability.

Skis (green) are connected to the seat by single wishbones (red).

The suspension struts (pink) are connected to near the outer edges of the seat and the outer edges of the skis. This in theory when you lean will push down the struts which due to being connected to the outer edges of the skis and in theory allow you to carve.

Also a similar action will happen on the outer ski. The strut will pull the outer edge of the ski up allowing the inner edge to push into the snow and carve.

Tried to take what I know about skiing and stuff and put it into a simple proposal.

May work. May not.

If this does work or not and you crash I accept no liability.

This looks good in principle, but the problem would be actually making the damned thing!Low seat, wide ski stance. More stability.

Skis (green) are connected to the seat by single wishbones (red).

The suspension struts (pink) are connected to near the outer edges of the seat and the outer edges of the skis. This in theory when you lean will push down the struts which due to being connected to the outer edges of the skis and in theory allow you to carve.

Also a similar action will happen on the outer ski. The strut will pull the outer edge of the ski up allowing the inner edge to push into the snow and carve.

Tried to take what I know about skiing and stuff and put it into a simple proposal.

May work. May not.

If this does work or not and you crash I accept no liability.

Suspension is quite hard to find, and what's mostly out there is heavy, 700 lb/ft mountain bike kit, which is very stiff, and would allow much movement.

That said, I have a plan forming of a mix of this, and plan A above.

It's all got quite technical. Fantastic.

Mx5guy said:

I guess a simple fix for the seat is changing the angle slightly, as I guess most of the time you will be going down, so it could help reduce the problem of sliding forward (or is it just bouncing around all over the place)?

Yes, I think will form part of the plan. If I can fabricate it, it'll be shaped more like a sun-lounger, with a dip in the middle.Depending on the route, it can get quite bumpy! Soll is the worst (read: best) for this. Some of the ruts are getting near waist deep, so if you hit it at 30-40km/h, you get some serious air! The smaller ones just throw you out of the saddle.

It's much fun.

joe58 said:

Just a quick sketch. I understand what you mean about the suspension struts. In this 3/4 sketch it shows the simple concave seat. This will probably need a small skeleton of tubes under it to keep it's shape then the skin obviously.

Shown are the simple singular wishbones(One at each corner) attaching to more the inner edges. Hopefully these could be attached as shown in the red at either end?

The same attachment can be applied to the struts. Hopefully due to the low profile of the sled cycle struts could be used due to length restrictions.

The seat, could you get away will a more dense cushion cut to shape placed nearer the front and in theory leaning forward in you boots if you were skiing. Tried to design the thing as a sit down skier basically. Then you can put your bum up towards the cushion and legs over it, therefore eliminating you sliding forward. Also handles on the top edges of the main seat section will help steer/ carve.

'Quick sketch'? I built the last five of these on less detail than that. Shown are the simple singular wishbones(One at each corner) attaching to more the inner edges. Hopefully these could be attached as shown in the red at either end?

The same attachment can be applied to the struts. Hopefully due to the low profile of the sled cycle struts could be used due to length restrictions.

The seat, could you get away will a more dense cushion cut to shape placed nearer the front and in theory leaning forward in you boots if you were skiing. Tried to design the thing as a sit down skier basically. Then you can put your bum up towards the cushion and legs over it, therefore eliminating you sliding forward. Also handles on the top edges of the main seat section will help steer/ carve.

I like the wishbone idea. It reminded me of the old RC car wishbones, with all the adjustable bits, and I don't see any reason I could sort of replicate a similar fashion, to make the angles adjustable for fine tuning.

A bit like these;

but the other way up.

And having thought about it, there's no reason the runners couldn't have handles themselves.

Adding a handle on each runner would give a bit of stability to the rider, something to grab hold of, and would ultimately allow better weight shifting and moving the angle of the runner directly at the same time.

Of course, I have NO idea how I'm going to actually make any of this.

J B L said:

maser_spyder said:

So, it's that time of year again chaps, dust off your spikey-heeled shoes and crash helmets, and get ready to throw yourself down a mountain at 40mph on a glorified home-made tea tray.

For those who missed it last year, I had a stab at making what I was too tight to buy, and ended up going a bit OTT....

Yes. Me. Any chance of a link about last year's antics?

For those who missed it last year, I had a stab at making what I was too tight to buy, and ended up going a bit OTT....

(sorry I'm not much of an engineer and can't design stuff.... I'd buy them though

)

)http://www.pistonheads.com/gassing/topic.asp?h=0&a...

Life Saab Itch said:

I think everyone is getting a bit complicated here.

If it was me I'd be looking to use the frame as it's own spring.

Mount the front and back of the runners to the frame solidly at the bottom (to keep the runner at the right angle, but pivoting at the top, then halfway along the runner, mount a strut with joints on to the opposite side of the base

The effect of this should be that if you lean to the left, the right runner gets pushed outwards in to a curve to turn you left.

This way is very "Colin Chapman" and should result in a light sled.

How much turn you get will depend on how much flex the runners have in them. I'd build them too thin, then if they are too flexible pour molten wax down them to stiffen them up, or something.

This will be a trial and error effort involving lots of lying around on the garage floor on it leaning and seeing if it changes the shape of the runner.

The idea is sound though.

Now this was actually my original plan.If it was me I'd be looking to use the frame as it's own spring.

Mount the front and back of the runners to the frame solidly at the bottom (to keep the runner at the right angle, but pivoting at the top, then halfway along the runner, mount a strut with joints on to the opposite side of the base

The effect of this should be that if you lean to the left, the right runner gets pushed outwards in to a curve to turn you left.

This way is very "Colin Chapman" and should result in a light sled.

How much turn you get will depend on how much flex the runners have in them. I'd build them too thin, then if they are too flexible pour molten wax down them to stiffen them up, or something.

This will be a trial and error effort involving lots of lying around on the garage floor on it leaning and seeing if it changes the shape of the runner.

The idea is sound though.

Basically take the 'simple' sled, but make the connection from the uprights to the runners slightly flexible (using car suspension bushes or similar), rather than solid (welded) arrangement. So there's flex, but not 'movement' on the runners.

Then use a fairly simple cross-brace, so that leaning on the left would push out the right hand runner, and basically 'weight' it. If possible, put another simple counter-brace in to un-weight the inside runner at the same time.

As you say, all very 'Chapman-esque', keeping it lightweight and simple.

Actually, I have a feeling the same bloody thing is going to happen as last year. I've already got five home-made toboggans, and that way it's going, I'm going to end up with at least another two or three.

1) Technical, adjustable wishbone type with quad suspension mounts and carving style runners.

+ Likely to be highly effective at turning corners, satisfying build (if it works).

- Difficult to fabricate with my basic skills. Likely to go badly wrong!

2) Basic, Lotus-style suspension design, with simple cross-bracing to weight the opposite runner.

+ Easy build, can probably do this in a day or two. Should be as good as the 'best' one from last year, but with improvements. Not likely to go wrong at all as it's so simple.

- Will still need to use hand/foot brakes to make cornering, to some extent, and hence lose speed.

Oh sod it. I'd better go and order some more aluminium.

King David said:

I should state from the offset that I don't have even the slightest level of engineering knowledge or ability. But have you looked at Mountain Board trucks? They are fairly wide and extremely tough and you can buy different stiffness shocks to moderate levels of lean.

http://www.extremekiteshop.com/kites/mbs-matrix-pr...

Looks great, I was thinking along the lines of cutting the end off, welding a plate on here, hacking a bit off there, then saw the price. http://www.extremekiteshop.com/kites/mbs-matrix-pr...

Shame, they'd be near perfect otherwise for a slightly different (number 3) design.

doogz said:

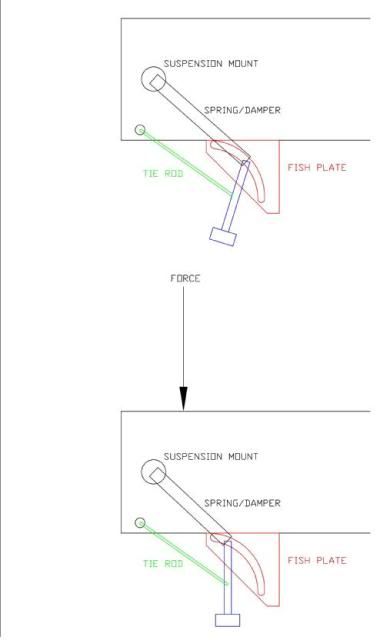

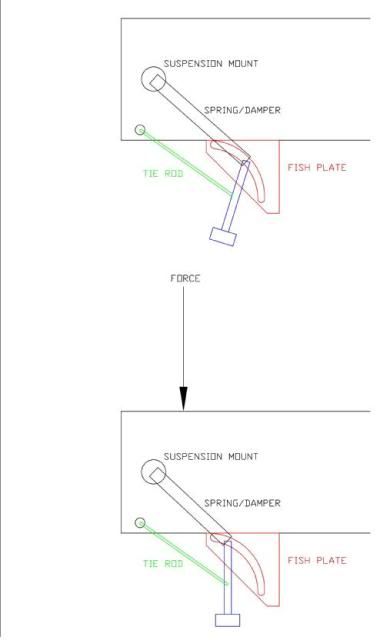

Bit fiddly, and i've not exactly worked it through, but this is the first thing that popped into my head:

Fish plate with cut out to control rotation of upper end of 'leg' with a damper/spring to control compression, and a tie bar to hold it together.

10/10 for ingenuity, looks like a good little system.

Fish plate with cut out to control rotation of upper end of 'leg' with a damper/spring to control compression, and a tie bar to hold it together.

But minus several million for seriously over-estimating what I'm capable of fabricating!

Just buying some ally now, tube, flat bar, rectangular tube. That's it.

Assume I'll be making this from Corn Flakes packets, and that would be nearer my level.

So, how easy is it to CNC aluminium?

And who can do it? Is it hard to set up?

Looking at these wishbone suspension mounts, and I can't help thinking the whole thing would be ten times better if this was done with precision kit, rather than my ham-fisted angle grinder technique.

The rest of it, runners, brackets (actually, CNC brackets would be loads easier too), seat, can all be done with a standard pipe bender, it's the moving parts that need some care and attention.

Any ideas?

And who can do it? Is it hard to set up?

Looking at these wishbone suspension mounts, and I can't help thinking the whole thing would be ten times better if this was done with precision kit, rather than my ham-fisted angle grinder technique.

The rest of it, runners, brackets (actually, CNC brackets would be loads easier too), seat, can all be done with a standard pipe bender, it's the moving parts that need some care and attention.

Any ideas?

Gassing Station | Homes, Gardens and DIY | Top of Page | What's New | My Stuff