Today i had a Maurissa Virgin Racing factory tour

Discussion

Last week I won a competition on GoMotorsport.net, the price was to get a behind the scenes tour of the Maurissa Virgin Racing Factory, and today was the day. I was a little excited.

Woke up at 5.30 on the road by 6.30 for the 220 mile trip. Needed to be there for 11. Left plenty of time incase of traffic. So i was pootling along the motorway making good time until 9 o'clock where i got stuck along with thousands of cars making their way into Coventry in a massive tailback because of a crash. No drama's i thought....... an hour later and im still 84 miles way, with an hour to get there. The queue finally ended and with some fairly 'spirited' driving got their for 11.01 AM.

First impressions:

Well it's smaller than i thought it would be, i knew it was going to be no Mclaren factory but i think i expected more than a couple of buildings on a industrial estate.

3 Massive lorries are in the car park, all ready loaded for Silverstone, and one in the process of being loaded in the loading bay.

When you walk into the main building you are greeted with this:

The lobby has a couple of trophy stands in it with helmets and a few trophies. These are from the days when this was the Manor Racing Formula 3 team, Kimi Raikkonen drove for them, as did Hamilton. They have a bunch of helmets but don't have Hamiltons. This is because his dad decided to keep it for themselves.

We then got taken through to the Hydraulics and Gears rooms. As you would expect of a F1 team, these places are immaculate, plain white with nothing lying around at all. We were asked not to take pictures of the bits in these rooms though, hence why the gearbox at the end is covered up here:

We handled a couple of the rear axles, incredibly light, made from aluminium and some other non disclosed material. The guide then showed us the gearbox and gear assembly, which alone was stated as costing £100,000. Incredibly intricate design, looked like a beautiful bit of engineering.

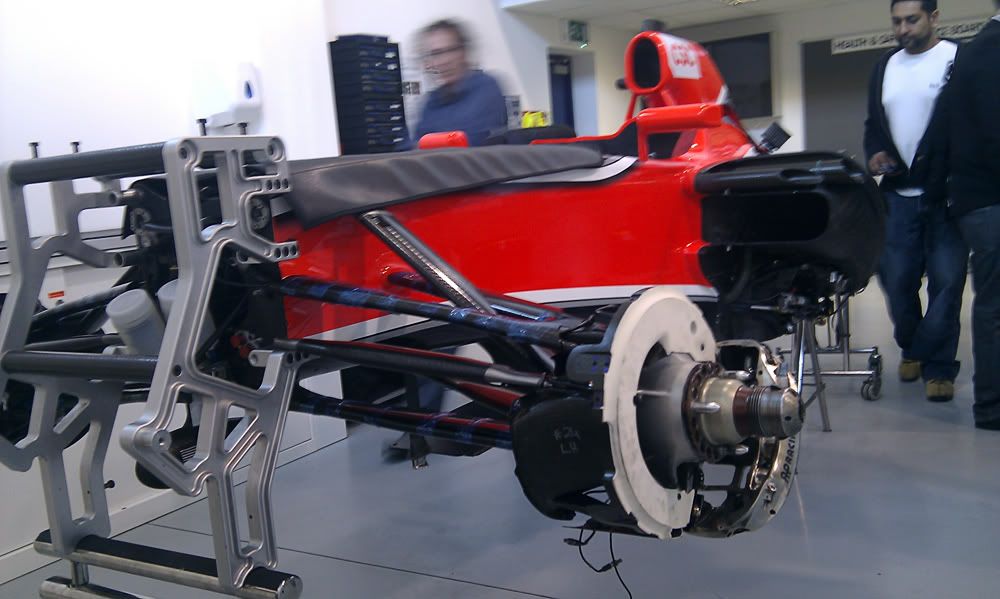

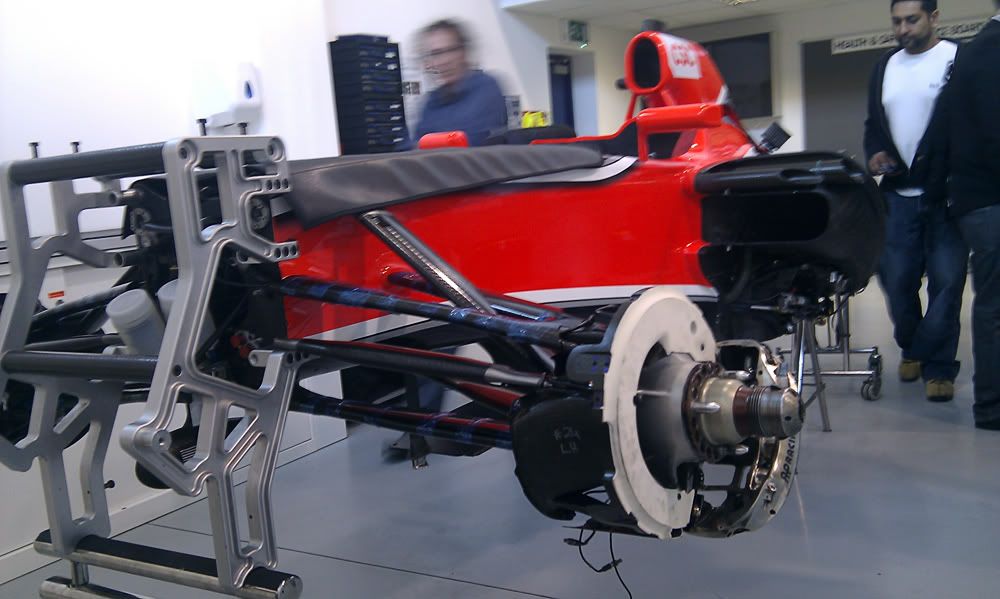

We then moved onto the main assembly room itself, Timo's and Jérôme's were semi stripped down:

We were shown Jérôme's car and had a brief chat about it.

The guide then got one of the engineers over to talk to us about the cars and teams themselves, spent about an hour discussing various parts of the design, the team, showing us how things work etc.

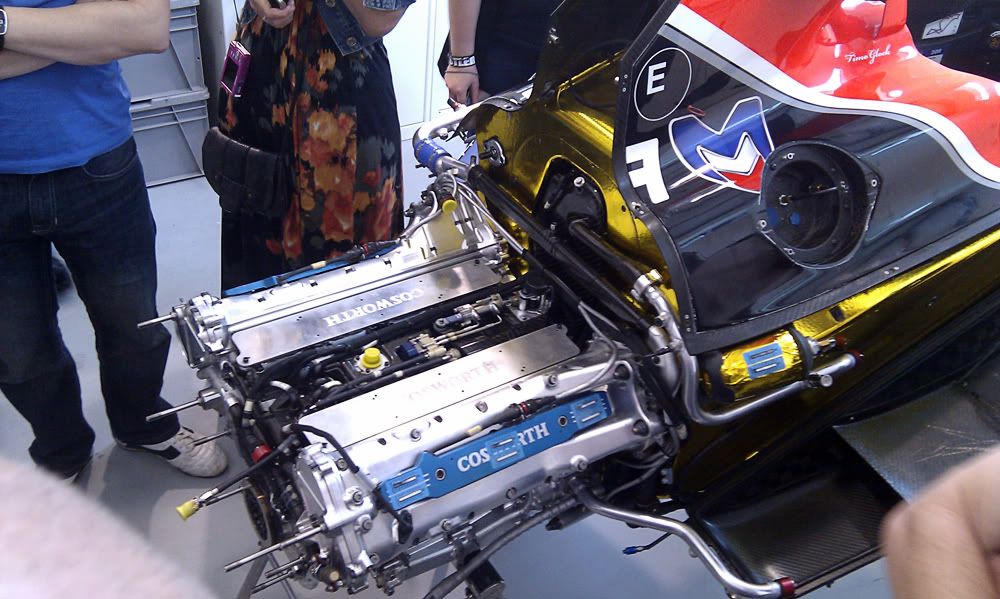

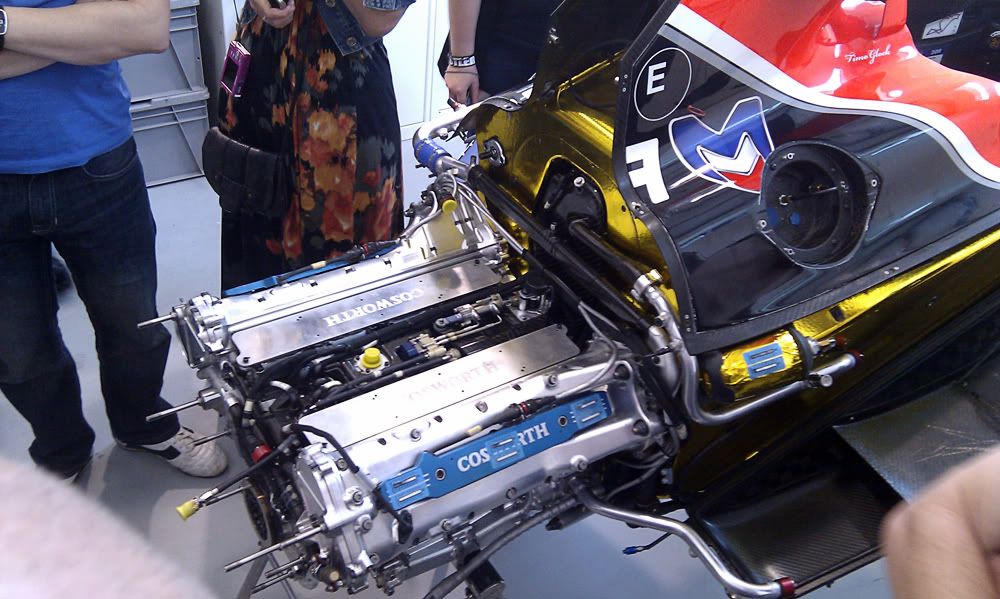

In the middle of the bay were two spare Cosworth engines, both producing about 700ish bhp.

A few more random pics:

Considering the near £1 million per car you wouldn't expect this kind of finish, but it's supposed to be very confortable for Jérôme

Had a quick handle of one of the suspension struts, crikey, they're pretty light, amazing the amount of forces they can handle. I watched as they were loading them into the back of the lorry. Each one is wrapped individually in it's own neoprene flight case and put into special racking.

We talked briefly a bit more about the team members roles and about the pitstops. Made me chuckle when he said that they are limited to 47 team members working for the chassis at the race and so their I.T guy is the rear jack man, and one of the truck drivers is the front wheel man.

Sadly we didn't get to meet Jérôme or Timo, but apparently they never come here, i guess there's no real reason for them to though. He said that the only reason they need to turn up is for seat fitting.

We then moved onto the second building, first room held the carbon fibre workshop, apparently these are the hardest working members of the team, on the track before everyone else, leave after everyone. So many repairs to do every track time.

We were shown what the floor plate is designed to do, how the air flow works etc.

Moving into the next room is where the storage is for the overseas containers. These are perfectly measured up to fit in Bernie's fleet of planes.

Loads of random bits and pieces dotted around here:

Stack of used wheel rims, notice the one with the massive bloomin hole in it, forgot to ask him how that was caused.

They then showed us the pit they have just dug, they are fitting in a 4 point simulation thing (can't remember the technical term) It simulates a race track by hydraulics moving pistons up and down in time with the bumps and kerbs etc.

We asked if they were planning on using a wind tunnel anytime or building one, no was the answer. They are allowed 40 terraflops of data on a computer program to simulate downforce etc. per month.

Finally we were shown the trophy room from their Formula 3 and Formula Renault days, sat there all nicely was Kimi Raikkonen's season winning Formula Renault

So then, all in all a cracking day was had. I learnt an incredible amount, and came out having much more support for the little guys. I'll find myself supporting them through races now aswell as Mclaren I think. One last thing, they are trying to get rid of the stigmata of being known as the Virgin team. Virgin support them now only as a sponsor rather than a part of the team, so they are trying to build themselves up as the MAURISSA virgin Racing Team.

Thanks for looking, any questions and i'll try and answer them

Woke up at 5.30 on the road by 6.30 for the 220 mile trip. Needed to be there for 11. Left plenty of time incase of traffic. So i was pootling along the motorway making good time until 9 o'clock where i got stuck along with thousands of cars making their way into Coventry in a massive tailback because of a crash. No drama's i thought....... an hour later and im still 84 miles way, with an hour to get there. The queue finally ended and with some fairly 'spirited' driving got their for 11.01 AM.

First impressions:

Well it's smaller than i thought it would be, i knew it was going to be no Mclaren factory but i think i expected more than a couple of buildings on a industrial estate.

3 Massive lorries are in the car park, all ready loaded for Silverstone, and one in the process of being loaded in the loading bay.

When you walk into the main building you are greeted with this:

The lobby has a couple of trophy stands in it with helmets and a few trophies. These are from the days when this was the Manor Racing Formula 3 team, Kimi Raikkonen drove for them, as did Hamilton. They have a bunch of helmets but don't have Hamiltons. This is because his dad decided to keep it for themselves.

We then got taken through to the Hydraulics and Gears rooms. As you would expect of a F1 team, these places are immaculate, plain white with nothing lying around at all. We were asked not to take pictures of the bits in these rooms though, hence why the gearbox at the end is covered up here:

We handled a couple of the rear axles, incredibly light, made from aluminium and some other non disclosed material. The guide then showed us the gearbox and gear assembly, which alone was stated as costing £100,000. Incredibly intricate design, looked like a beautiful bit of engineering.

We then moved onto the main assembly room itself, Timo's and Jérôme's were semi stripped down:

We were shown Jérôme's car and had a brief chat about it.

The guide then got one of the engineers over to talk to us about the cars and teams themselves, spent about an hour discussing various parts of the design, the team, showing us how things work etc.

In the middle of the bay were two spare Cosworth engines, both producing about 700ish bhp.

A few more random pics:

Considering the near £1 million per car you wouldn't expect this kind of finish, but it's supposed to be very confortable for Jérôme

Had a quick handle of one of the suspension struts, crikey, they're pretty light, amazing the amount of forces they can handle. I watched as they were loading them into the back of the lorry. Each one is wrapped individually in it's own neoprene flight case and put into special racking.

We talked briefly a bit more about the team members roles and about the pitstops. Made me chuckle when he said that they are limited to 47 team members working for the chassis at the race and so their I.T guy is the rear jack man, and one of the truck drivers is the front wheel man.

Sadly we didn't get to meet Jérôme or Timo, but apparently they never come here, i guess there's no real reason for them to though. He said that the only reason they need to turn up is for seat fitting.

We then moved onto the second building, first room held the carbon fibre workshop, apparently these are the hardest working members of the team, on the track before everyone else, leave after everyone. So many repairs to do every track time.

We were shown what the floor plate is designed to do, how the air flow works etc.

Moving into the next room is where the storage is for the overseas containers. These are perfectly measured up to fit in Bernie's fleet of planes.

Loads of random bits and pieces dotted around here:

Stack of used wheel rims, notice the one with the massive bloomin hole in it, forgot to ask him how that was caused.

They then showed us the pit they have just dug, they are fitting in a 4 point simulation thing (can't remember the technical term) It simulates a race track by hydraulics moving pistons up and down in time with the bumps and kerbs etc.

We asked if they were planning on using a wind tunnel anytime or building one, no was the answer. They are allowed 40 terraflops of data on a computer program to simulate downforce etc. per month.

Finally we were shown the trophy room from their Formula 3 and Formula Renault days, sat there all nicely was Kimi Raikkonen's season winning Formula Renault

So then, all in all a cracking day was had. I learnt an incredible amount, and came out having much more support for the little guys. I'll find myself supporting them through races now aswell as Mclaren I think. One last thing, they are trying to get rid of the stigmata of being known as the Virgin team. Virgin support them now only as a sponsor rather than a part of the team, so they are trying to build themselves up as the MAURISSA virgin Racing Team.

Thanks for looking, any questions and i'll try and answer them

Very nice write up, thanks for posting it.

I can't help thinking that this may contribute to the fact that they're racing for a team right at the back of the grid...

OP said:

Sadly we didn't get to meet Jérôme or Timo, but apparently they never come here, i guess there's no real reason for them to though. He said that the only reason they need to turn up is for seat fitting.

I can't help thinking that this may contribute to the fact that they're racing for a team right at the back of the grid...

Great write-up; thank you for sharing it. Re the compute power issue, the RRA limits this to an average of 40 teraflops in any 8-week period; the teams must report CFD and wind-tunnel use to the FIA at the end of each period. In order to get to that number, you need a system (or systems) capable of running much faster than that, so that the average is optimised to the allowance.

Teraflops = 1000000000000 floating point operations per second (FLOPS). A handheld calculator is capable of just a few FLOPs or so. An Intel Core i7 980 XE (6 cores) has a theoretical peak performance of around 400 times less, so this is not an enormous number. A single computer (or cluster of computers running together in concert) running at 40 teraflops would be one of the fastest 700 or so computers in the world. According to Nick Wirth, his cluster has around 10,000 cores.

Teraflops = 1000000000000 floating point operations per second (FLOPS). A handheld calculator is capable of just a few FLOPs or so. An Intel Core i7 980 XE (6 cores) has a theoretical peak performance of around 400 times less, so this is not an enormous number. A single computer (or cluster of computers running together in concert) running at 40 teraflops would be one of the fastest 700 or so computers in the world. According to Nick Wirth, his cluster has around 10,000 cores.

Thanks for the write up. It's strange to see a couple of very highly technical, very expensive motor cars effectively being built and run out a warehouse with a couple of trucks parked out back. In comparison with the McLaren Technical Centre is really puts the teams budgets into perspective.

Rouleur said:

Very nice write up, thanks for posting it.

I can't help thinking that this may contribute to the fact that they're racing for a team right at the back of the grid...

How odd. Surely by the drivers being at the team it would help them?OP said:

Sadly we didn't get to meet Jérôme or Timo, but apparently they never come here, i guess there's no real reason for them to though. He said that the only reason they need to turn up is for seat fitting.

I can't help thinking that this may contribute to the fact that they're racing for a team right at the back of the grid...

When I worked as a spotter in Indy lights, lots of the drivers could be found working with their teams out of race weekends at the team bases.

IndyAndy777 said:

Rouleur said:

Very nice write up, thanks for posting it.

I can't help thinking that this may contribute to the fact that they're racing for a team right at the back of the grid...

How odd. Surely by the drivers being at the team it would help them?OP said:

Sadly we didn't get to meet Jérôme or Timo, but apparently they never come here, i guess there's no real reason for them to though. He said that the only reason they need to turn up is for seat fitting.

I can't help thinking that this may contribute to the fact that they're racing for a team right at the back of the grid...

When I worked as a spotter in Indy lights, lots of the drivers could be found working with their teams out of race weekends at the team bases.

IndyAndy777 said:

Rouleur said:

Very nice write up, thanks for posting it.

I can't help thinking that this may contribute to the fact that they're racing for a team right at the back of the grid...

How odd. Surely by the drivers being at the team it would help them?OP said:

Sadly we didn't get to meet Jérôme or Timo, but apparently they never come here, i guess there's no real reason for them to though. He said that the only reason they need to turn up is for seat fitting.

I can't help thinking that this may contribute to the fact that they're racing for a team right at the back of the grid...

When I worked as a spotter in Indy lights, lots of the drivers could be found working with their teams out of race weekends at the team bases.

skwdenyer said:

Great write-up; thank you for sharing it. Re the compute power issue, the RRA limits this to an average of 40 teraflops in any 8-week period; the teams must report CFD and wind-tunnel use to the FIA at the end of each period. In order to get to that number, you need a system (or systems) capable of running much faster than that, so that the average is optimised to the allowance.

Teraflops = 1000000000000 floating point operations per second (FLOPS). A handheld calculator is capable of just a few FLOPs or so. An Intel Core i7 980 XE (6 cores) has a theoretical peak performance of around 400 times less, so this is not an enormous number. A single computer (or cluster of computers running together in concert) running at 40 teraflops would be one of the fastest 700 or so computers in the world. According to Nick Wirth, his cluster has around 10,000 cores.

Spot-on. I can't say too much as I do work with MVR on the CFD front, but have a hint: when you say fastest 700, try using a factor of, let's say for example, 7, to reduce that number. Ten years ago, the computer as it stands now could have maybe been top 10 - but it's very hard to know because a lot of supercomputers around the world are classified or not declared in terms of their performance.Teraflops = 1000000000000 floating point operations per second (FLOPS). A handheld calculator is capable of just a few FLOPs or so. An Intel Core i7 980 XE (6 cores) has a theoretical peak performance of around 400 times less, so this is not an enormous number. A single computer (or cluster of computers running together in concert) running at 40 teraflops would be one of the fastest 700 or so computers in the world. According to Nick Wirth, his cluster has around 10,000 cores.

The big question is whether or not 40tflops is equivalent to the wind tunnel testing hours.

RenesisEvo said:

Spot-on. I can't say too much as I do work with MVR on the CFD front, but have a hint: when you say fastest 700, try using a factor of, let's say for example, 7, to reduce that number. Ten years ago, the computer as it stands now could have maybe been top 10 - but it's very hard to know because a lot of supercomputers around the world are classified or not declared in terms of their performance.

The big question is whether or not 40tflops is equivalent to the wind tunnel testing hours.

Re the 'top 500', I was observing that a single machine rated at 40tflops would rank there. In order to get an average of 40tflops over 8 weeks, I'd imagine you needed a lot more than that available; job scheduling isn't that good, some sim work will be IO bound rather than CPU bound, and so on. Based upon when I did a lot FE work, I'd have estimated we needed 3tflops theoretical peak performance for each tflop of sustained performance; I'd guess that scheduling (and optimising the system build around the likely workload mix) would mean that that number would be closer to 2-2.5. The fastest thing I was involved in building was a single system image 40gflop machine which, at the time, was eye-wateringly quick and expensive. That was a long time ago; it is quite salutary how that room-sized behemoth could today be matched by a single Sandy Bridge i7 The big question is whether or not 40tflops is equivalent to the wind tunnel testing hours.

FWIW Moore's law - if applied to cost - would imply that that room-sized SSI machine would cost only £4k in 1998 money, and - if applied to system physical size - would be the size of a desktop machine. Not actually a bad approximation, as it happens, allowing for the cost and size of decent IO to go with the processing

skwdenyer said:

In order to get an average of 40tflops over 8 weeks, I'd imagine you needed a lot more than that available; job scheduling isn't that good, some sim work will be IO bound rather than CPU bound, and so on.

Yup, you are right, 40tflops is the average. Peak is... something else  and when comparing peak (well, our peak is a sustainable peak, that's another story) it's well up there.

and when comparing peak (well, our peak is a sustainable peak, that's another story) it's well up there.skwdenyer said:

That was a long time ago; it is quite salutary how that room-sized behemoth could today be matched by a single Sandy Bridge i7

Certainly, given the kit we had, the kit we have now, and what I've seen/heard about what could be available from Intel et al., in the future (if not already at the moment), the capacity to do CFD will increasingly be only limited by the speed of design work and pre-processing. And the regulations. It will be interesting to see what we can do with CFD in 5 or 10 years time.

Anyway, back to topic - hope you enjoyed your tour of MVR, OP - seeing Jaguar's facility in MK way back in 2001 when I was at secondary school was one of the reasons why I wanted to work in F1; it only took 7 more years of study, hard graft and a bit of luck!

I had a similar tour of the force India (ex Jordan) factory last year and couldn't believe the size or lack of it. We were given access to everything but strictly no photos. There was little space and practiced their pit stops on the factory floor next to the cars they were building. A real eye opener. Then I was at mclaren for the fans forum on thurs and the front show area was bigger than the entire force India factory.

That put things into perspective.

That put things into perspective.

Gassing Station | General Motorsport | Top of Page | What's New | My Stuff

just gives me a picture of a prompt to upgrade photobucket?

just gives me a picture of a prompt to upgrade photobucket?