Full circle into a Marina again. My 73 Morris Marina Coupe

Discussion

anonymous said:

[redacted]

Thats a solid theory, but I do wish it was a bit brighter so I could see when I accidentally leave the high beam on when it isn't dark.Its also interesting to note that all my wiring diagrams, and owners manual, say the high beam indicator light should be at the bottom of the speedo, not the top of the aux dials. The light a the bottom of the speedo does nothing, and is red. There is mention it might be a brake warning lamp of some sort, probably in the higher spec models.

Typically, being sat for 25 odd years, none of the hydraulics work. The clutch pedal is solid, and the brake pedal goes to the floor, and both do nothing to their respective components.

I removed and stripped the clutch master and slave a while back, just to see what was going on. The slave was definitely seized, as using a long prybar on the clutch fork to compress the slave resulted in a sudden BANG and it started to move freely. I still needed to remove it to inspect though, as it was obviously getting hung up on something.

The Aussies are a bit smarter than the Brits with the slave cylinder. The UK cars you need to remove the clutch line, remove the clutch pin, and then try to slide the cylinder towards the rear of the car, and get it out from between its housing and the clutch fork. Sometimes this is easy, other times it requires a special tool to push the clutch fork back to create space. The Aus cars have a circlip to secure the slave, so once that and the clutch line is removed, the slave slides towards the front of the car, where there is ample space to remove it. In fact, one of the UK manuals I have claims the slave can ONLY be removed if the gearbox is removed from the car!

UK cars

And Aus cars

With the slave removed and on the bench, I removed the pushrod pin and boot. You can see the rusty sludge that the piston has moved.

After I cleaned the sludge out of the holes in the circlip and removed it, the guts of the cylinder came out with some prodding.

Everything actually looked reasonably good, with minimal signs of rust in the bore. There was some at the very front, which a quick touch up with fine sandpaper fixed no issue. I'll be reusing this slave, but have a new seal kit for it. I could have gotten away with reusing the existing seal, it looked fine, but don't want to do the job twice for the sake of a few quid. That kit arrived the other day, so will rebuild that soon.

The master on the other hand is a write off.

I removed it from the car, removed the pushrod, and thats as far as I can go

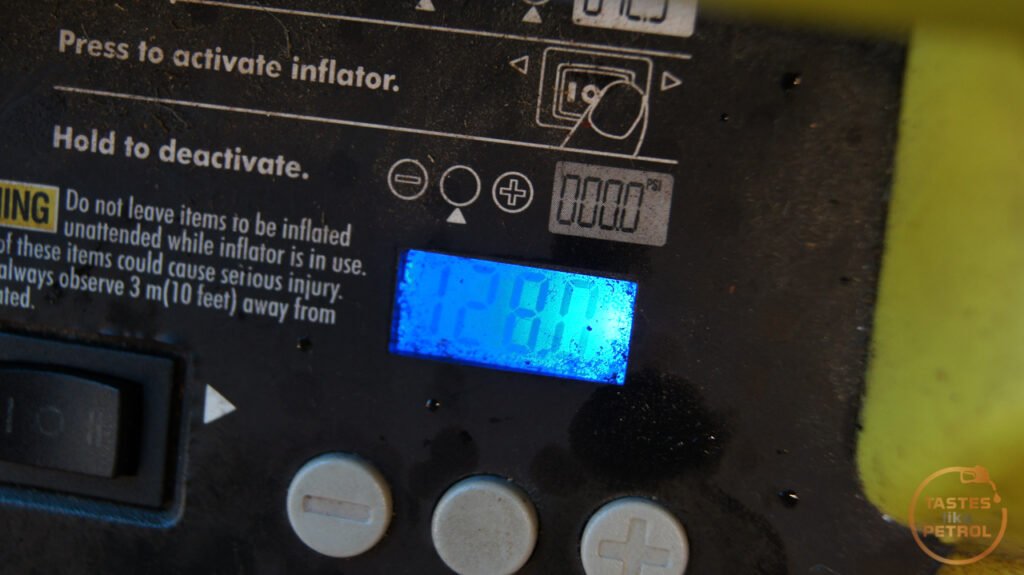

No amount of "gently tapping" will force that piston out. I ended up putting about 70PSI behind it, and only got this far

I can only presume the piston and/or the bore is rusty and just binding. It turns out this is a Spitfire master cylinder, so have ordered a complete replacement and will fit that when it arrives.

Moving along, I started work on the brakes. This work was proceeded by buying some basic parts and finding some in the boot. I purchased all new hoses for the front and rear. The fronts are from a Series 3 Land Rover (2x BR0764) and the rear is from a Triumph Spitfire (1x GBH166). I found a new old stock master cylinder rebuild kit in the boot, purchased new in Tokoroa in 2001.

I had previously tried to bleed the system but got zero fluid from any of the bleed nipples, even when trying to draw the fluid through under vacuum. There was fluid in the reservoir when I got the car, but it was a bit low, so I thought I would top it off before trying to draw it through. Pouring in dot4 resulted in the weirdest "mixing" I've seen. The fluid kinda floated around and when it slowly mixed it kinda sparkled and didn't look right. I sucked the fluid out, and sure enough, I'm 90% sure the master cylinder was filled with engine oil. It smelt like clean engine oil. Even sucking it all out left some sludge in the bottom of the reservoir.

This was a bit easier to strip down. A few hard bashes on the vice and the piston popped out, covering my hand in whatever sludge was in the bore, chunks and all.

I was trying to think of why you would fill the reservoir with oil and the only reason I could come up with was to stop the bore rusting. Well, it didn't. With the piston removed, there was some minor rust on the sides of the bore, but bad rust and pitting at the very end, where the seal on the end needs to block the reservoir. I cleaned it up as much as I could. The rust on the sides of the bore wiped off with some fine sandpaper.

The piston had some light corrosion on it, but looked OK otherwise.

This is the end seal, you can see all the crud built up around it

The seals weren't too bad, but having the new kit already I swapped them all over and reassembled. A quick test on the bench showed that it seemed to be working as it should, so I reinstalled it into the car.

Now it was time to work on the hoses and calipers. I started on the front. The hoses came off reasonably easily. With the hose disconnected from the hard line I attached my vacuum bleeder to suck through fluid and flush the line. I like using the green fluid as it's really obvious when the new fluid is coming through.

Out of curiosity, once I removed the hose I connected the vac pump up to one end, left the other end open and tried to pull air through it. Nothing. Blocked solid, and even with the most suction that pump can draw, not a single drop of air could get through.

I was warned about these style hoses, the old style with that textured outer layer, when I redid the hoses on the TVR. The rear hose on the TVR was of this style, and apparently they are known for internally degrading and blocking up over time. The other side was the same, completely blocked.

The new Land Rover pattern hoses look nice enough

I temporarily reconnected the old hose to the hard line, just to block the end of it in the mean time so I can draw a vacuum from the reservoir.

The other side had some questionable looking fluid in the lines, but flushed OK.

With the hoses off I began removing the calipers. I'm glad I previously vacuumed most of the cobwebs off. Ugh.

These were well stuck on, but some hammering and levering saw them jump off the rotor. I'm hoping the rotors will clean up OK, will need to check their thickness.

Everything looked and felt like it had been on there far too long. Even removing the pad retaining pins was a pain, but lots of hammering and lots of CRC got them out.

The previous owner got their monies worth from the pads.

One of the piston boots was missing its retaining clip, and was just floating around.

I had to get creative to try and force the pistons out. One is moving freely, but one is jammed solid. Even 128psi couldnt shift it. I'll need to try and shock it with my actual air compressor, not slowly build pressure with the tyre inflator.

The other caliper isn't much better, neither piston felt like moving on that one.

The one piston I did get out was a disappointment though, the chrome coating is flaking off in places and there is scoring and corrosion on it, so all the pistons will need to be replaced. I already have a seal kit, but will wait on new pistons now. Might even paint the calipers in the meantime to make them flashy (even if you can see them with the wheels on).

The last job for the day was to remove the rear hose. There is only one, as the fluid goes to the RH side wheel cylinder and then crosses over to the LH side one. Another old textured hose.

New hose partly connected. I'm pleased at hose easily these old hoses came off. A ratcheting spanner certainly helps for the lock nut though.

And new hose installed.

Another quick test with the vac pump, and sure enough, another completely blocked hose

Pays to check your hoses and replace them if they are the old style.

With the new hose in place, the only other thing to do was flush the lines with new fluid. There was quite a bit of fluid in the cylinders and lines. Didn't look too bad, and no rust, so hopefully that means the rear wheel cylinders are still OK. I can get the kits to rebuild them locally, so will see if they work first and go from there.

And keep pulling it through until it goes green

Unfortunately I tried pumping the pedal with the system all buttoned up, and the master cylinder is blowing fluid back into the reservoir, indicating the end seal isn't sealing. I have reached out to a couple of companies that should be able to sleeve the cylinder and will see what they say.

In the mean time, off to make a list of more parts I need to buy.

I removed and stripped the clutch master and slave a while back, just to see what was going on. The slave was definitely seized, as using a long prybar on the clutch fork to compress the slave resulted in a sudden BANG and it started to move freely. I still needed to remove it to inspect though, as it was obviously getting hung up on something.

The Aussies are a bit smarter than the Brits with the slave cylinder. The UK cars you need to remove the clutch line, remove the clutch pin, and then try to slide the cylinder towards the rear of the car, and get it out from between its housing and the clutch fork. Sometimes this is easy, other times it requires a special tool to push the clutch fork back to create space. The Aus cars have a circlip to secure the slave, so once that and the clutch line is removed, the slave slides towards the front of the car, where there is ample space to remove it. In fact, one of the UK manuals I have claims the slave can ONLY be removed if the gearbox is removed from the car!

UK cars

And Aus cars

With the slave removed and on the bench, I removed the pushrod pin and boot. You can see the rusty sludge that the piston has moved.

After I cleaned the sludge out of the holes in the circlip and removed it, the guts of the cylinder came out with some prodding.

Everything actually looked reasonably good, with minimal signs of rust in the bore. There was some at the very front, which a quick touch up with fine sandpaper fixed no issue. I'll be reusing this slave, but have a new seal kit for it. I could have gotten away with reusing the existing seal, it looked fine, but don't want to do the job twice for the sake of a few quid. That kit arrived the other day, so will rebuild that soon.

The master on the other hand is a write off.

I removed it from the car, removed the pushrod, and thats as far as I can go

No amount of "gently tapping" will force that piston out. I ended up putting about 70PSI behind it, and only got this far

I can only presume the piston and/or the bore is rusty and just binding. It turns out this is a Spitfire master cylinder, so have ordered a complete replacement and will fit that when it arrives.

Moving along, I started work on the brakes. This work was proceeded by buying some basic parts and finding some in the boot. I purchased all new hoses for the front and rear. The fronts are from a Series 3 Land Rover (2x BR0764) and the rear is from a Triumph Spitfire (1x GBH166). I found a new old stock master cylinder rebuild kit in the boot, purchased new in Tokoroa in 2001.

I had previously tried to bleed the system but got zero fluid from any of the bleed nipples, even when trying to draw the fluid through under vacuum. There was fluid in the reservoir when I got the car, but it was a bit low, so I thought I would top it off before trying to draw it through. Pouring in dot4 resulted in the weirdest "mixing" I've seen. The fluid kinda floated around and when it slowly mixed it kinda sparkled and didn't look right. I sucked the fluid out, and sure enough, I'm 90% sure the master cylinder was filled with engine oil. It smelt like clean engine oil. Even sucking it all out left some sludge in the bottom of the reservoir.

This was a bit easier to strip down. A few hard bashes on the vice and the piston popped out, covering my hand in whatever sludge was in the bore, chunks and all.

I was trying to think of why you would fill the reservoir with oil and the only reason I could come up with was to stop the bore rusting. Well, it didn't. With the piston removed, there was some minor rust on the sides of the bore, but bad rust and pitting at the very end, where the seal on the end needs to block the reservoir. I cleaned it up as much as I could. The rust on the sides of the bore wiped off with some fine sandpaper.

The piston had some light corrosion on it, but looked OK otherwise.

This is the end seal, you can see all the crud built up around it

The seals weren't too bad, but having the new kit already I swapped them all over and reassembled. A quick test on the bench showed that it seemed to be working as it should, so I reinstalled it into the car.

Now it was time to work on the hoses and calipers. I started on the front. The hoses came off reasonably easily. With the hose disconnected from the hard line I attached my vacuum bleeder to suck through fluid and flush the line. I like using the green fluid as it's really obvious when the new fluid is coming through.

Out of curiosity, once I removed the hose I connected the vac pump up to one end, left the other end open and tried to pull air through it. Nothing. Blocked solid, and even with the most suction that pump can draw, not a single drop of air could get through.

I was warned about these style hoses, the old style with that textured outer layer, when I redid the hoses on the TVR. The rear hose on the TVR was of this style, and apparently they are known for internally degrading and blocking up over time. The other side was the same, completely blocked.

The new Land Rover pattern hoses look nice enough

I temporarily reconnected the old hose to the hard line, just to block the end of it in the mean time so I can draw a vacuum from the reservoir.

The other side had some questionable looking fluid in the lines, but flushed OK.

With the hoses off I began removing the calipers. I'm glad I previously vacuumed most of the cobwebs off. Ugh.

These were well stuck on, but some hammering and levering saw them jump off the rotor. I'm hoping the rotors will clean up OK, will need to check their thickness.

Everything looked and felt like it had been on there far too long. Even removing the pad retaining pins was a pain, but lots of hammering and lots of CRC got them out.

The previous owner got their monies worth from the pads.

One of the piston boots was missing its retaining clip, and was just floating around.

I had to get creative to try and force the pistons out. One is moving freely, but one is jammed solid. Even 128psi couldnt shift it. I'll need to try and shock it with my actual air compressor, not slowly build pressure with the tyre inflator.

The other caliper isn't much better, neither piston felt like moving on that one.

The one piston I did get out was a disappointment though, the chrome coating is flaking off in places and there is scoring and corrosion on it, so all the pistons will need to be replaced. I already have a seal kit, but will wait on new pistons now. Might even paint the calipers in the meantime to make them flashy (even if you can see them with the wheels on).

The last job for the day was to remove the rear hose. There is only one, as the fluid goes to the RH side wheel cylinder and then crosses over to the LH side one. Another old textured hose.

New hose partly connected. I'm pleased at hose easily these old hoses came off. A ratcheting spanner certainly helps for the lock nut though.

And new hose installed.

Another quick test with the vac pump, and sure enough, another completely blocked hose

Pays to check your hoses and replace them if they are the old style.

With the new hose in place, the only other thing to do was flush the lines with new fluid. There was quite a bit of fluid in the cylinders and lines. Didn't look too bad, and no rust, so hopefully that means the rear wheel cylinders are still OK. I can get the kits to rebuild them locally, so will see if they work first and go from there.

And keep pulling it through until it goes green

Unfortunately I tried pumping the pedal with the system all buttoned up, and the master cylinder is blowing fluid back into the reservoir, indicating the end seal isn't sealing. I have reached out to a couple of companies that should be able to sleeve the cylinder and will see what they say.

In the mean time, off to make a list of more parts I need to buy.

jamesson said:

This is great work. I wish I had a fraction of your talent. Looking forward to further updates in due course.

I believe most people with an interest in working on cars should be able to do most of what I do, it's just a matter of being methodical, and it always helps to read the workshop manual cover to cover a few times. I'm not a mechanic, have no training, and didn't grow up around cars.bolidemichael said:

Wait, what?!

I'm sorry, but the breadth of your knowledge and know how - cracking the issue of the TVR's K-Jet (iirc) system and diagnosing the cack-handedness of previous bodges. That was all brilliant stuff and so detailed. You're bluffing us just because we're in Blighty and can't throw tomatoes at you. Right?

Nope, not kidding. The only qualification I have is to fix Apple computers (which I haven't done for years) I'm sorry, but the breadth of your knowledge and know how - cracking the issue of the TVR's K-Jet (iirc) system and diagnosing the cack-handedness of previous bodges. That was all brilliant stuff and so detailed. You're bluffing us just because we're in Blighty and can't throw tomatoes at you. Right?

Otherwise, I tanked at school and dropped out early.

Otherwise, I tanked at school and dropped out early.Paul S4 said:

A few years ago I had a 1970 lotus Elan S4SE drophead that had been in the family, and was completely restored by my late Uncle.

I had that car for over 12 years, and in the time I did quite a lot of work on it...so i got to know the underside quite well...!

Anyway, the clutch slave cylinder was very similar to your Marina set up, so it was easy to replace as it had the same circlip arrangement. On my car it was very close to the stainless exhaust system, which got very hot ( that car was driven as Colin Chapman intended !!) and over time the heat got to the slave so I had to change it a few times. I also replaced the hard steel line with an aftermarket braided stainless steel one, which helped with the clutch action...somehow !

I also recall the the first time I had clutch issues after I took over custodianship of the Elan, I changed the clutch fluid and it was just a black goo.... I reckon that the rubber seals had gone.

Anyway, just thought I would add this out of interest as Lotus used a lot of parts from other car companies.....in that sense the Elan was a 'kit car'...in fact 80% of them were sold as self assembly kits to save the "Purchase Tax" of the time, so that explains why there is a lot of difference in the way some of those cars have been put together !!

Apologies for going off topic....

Gosh that sounds an awful lot like the TVR; bits of other cars thrown together and not always in the best design. Sounds like a heatshield might have helped with that issue.I had that car for over 12 years, and in the time I did quite a lot of work on it...so i got to know the underside quite well...!

Anyway, the clutch slave cylinder was very similar to your Marina set up, so it was easy to replace as it had the same circlip arrangement. On my car it was very close to the stainless exhaust system, which got very hot ( that car was driven as Colin Chapman intended !!) and over time the heat got to the slave so I had to change it a few times. I also replaced the hard steel line with an aftermarket braided stainless steel one, which helped with the clutch action...somehow !

I also recall the the first time I had clutch issues after I took over custodianship of the Elan, I changed the clutch fluid and it was just a black goo.... I reckon that the rubber seals had gone.

Anyway, just thought I would add this out of interest as Lotus used a lot of parts from other car companies.....in that sense the Elan was a 'kit car'...in fact 80% of them were sold as self assembly kits to save the "Purchase Tax" of the time, so that explains why there is a lot of difference in the way some of those cars have been put together !!

Apologies for going off topic....

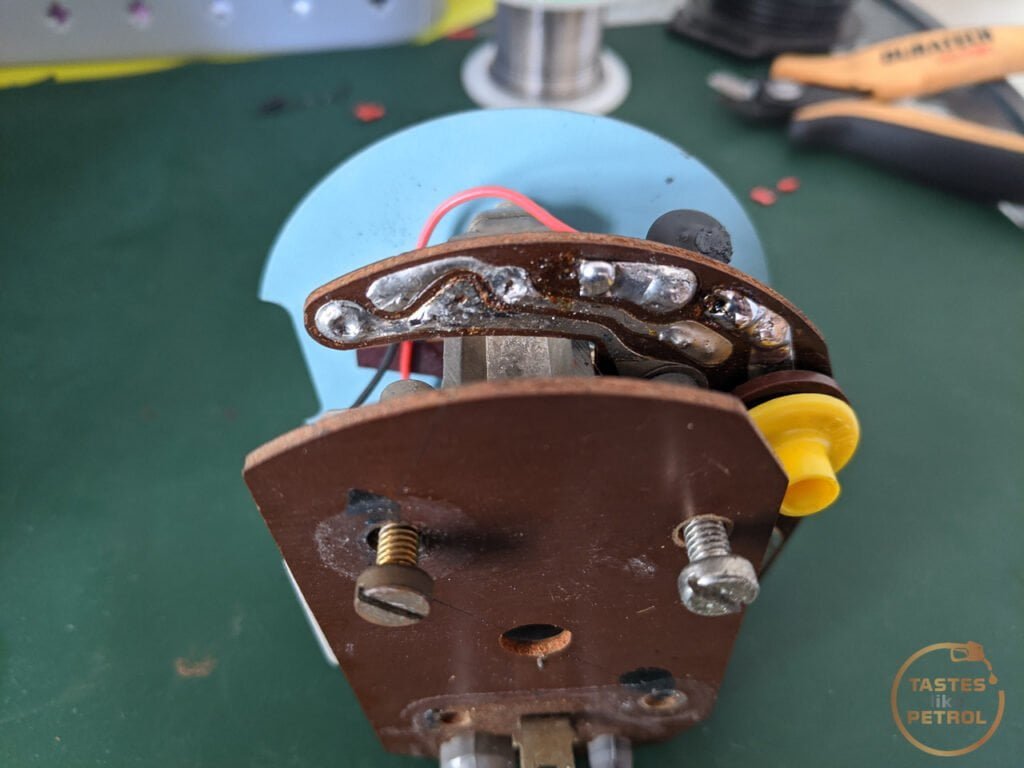

Pistons are out. The fluid that was behind them was disgusting. There was also a buildup in the lowest point of the caliper which I had to chip out during cleaning.

This pitting is what I was up against. It was grabbing the seal for dear life. Used a combo of air from my compressor, whilst beating the heck out of the piston with a punch in the direction of removal to get them out.

The calipers cleaned up alright after a dip in the parts washer. Now sitting in a bath of Evaporust to clean any rust out.

Waiting on the new pistons to arrive and then I'll rebuild the calipers.

This pitting is what I was up against. It was grabbing the seal for dear life. Used a combo of air from my compressor, whilst beating the heck out of the piston with a punch in the direction of removal to get them out.

The calipers cleaned up alright after a dip in the parts washer. Now sitting in a bath of Evaporust to clean any rust out.

Waiting on the new pistons to arrive and then I'll rebuild the calipers.

I refurbished the rear drum brake setup today. I almost left it as is, but I'm glad I didn't as it definitely needed stripping down.

I removed the drums a while back and had a quick visual inspection, and whilst one side looked like it had been under the ocean, there was no brake fluid or axle grease where it shouldn't be.

I started on the LH side, which didn't look like it had been under the sea, but instead had been full of bugs and spiders. The whole drum was packed with cobwebs and took a lot of cleaning and vacuuming to not be grossed out.

The shoes look really good, almost new I'd say, and everything was very dry. Someone had been in here before though as this big, annoying to install, spring should be behind the shoes, not in front of them.

Removing the shoes is a case of removing the little retaining spring pins, removing the big spring and then the pair of shoes can be withdrawn from the backing plate.

With the shoes out the cylinder can be removed by undoing the pipe(s), removing the boot, sliding the U shaped clip downwards and the spring clip upwards. The cylinder should be free to remove.

This one looked OK. The boot was torn, and the piston had some crud built up on it, but the bore was clean. The piston seal looked so good I probably could have reused it, but since I ordered a replacement seal kit anyway, I replaced it. The seal kit for this car is from a Spitfire and has 3/4" (19.05mm) bore.

With the build up carefully scraped off and polished with some fine sandpaper, the new piston seal goes on.

Now, before installing the piston in the cylinder again, install the boot first. This is a real prick of a job as it needs to stretch over the top, and it's a very tight fit.

And carefully install back into the cylinder. I chose to lube the cylinder walls and piston/seal with brake fluid for assembly.

Reinstall the clip and you're done.

There isn't a heck of a lot to a wheel cylinder on these.

I cleaned up and greased the self-adjuster. This just rests in the bottom of the cylinder but must turn freely.

Now clean the backing plate up, especially at the points where the cylinder and shoes contact it (the six raised bumps on the top and bottom, as well as the anchor where the end of the shoes rest and behind the wheel cylinder). I used a wire brush and brake clean. Once clean, use thin smears of copper or brake grease on those contact points.

Once the cylinder and hand brake lever is installed, reinstall the shoes. I found this easiest with the double spring in one end (shoe end), rest the top shoe on the hub, whilst inserting the lower shoe into the self-adjuster and then the shoe anchor. Now the top shoe can be installed. Take care not to lose the little metal H piece that sits above the handbrake lever where it goes through the shoe.

Don't forget to install the retaining pins and the big spring. As mentioned, this should be behind the shoes, and I found levering it in place with a long flat blade screwdriver easiest. It takes a few tries.

Done.

Rebuilt cylinder

So cocky, on went the drum

Now to move onto the other side.

This one was very crusty. Obviously water had gotten into the drum somehow, and couldn't get out until it dried over time. This drum had plugs in the adjuster holes, whilst the other side didn't. Explains why the bugs liked that side, and the water got stuck in this side.

The cylinder on this side was looking particularly average.

Removing the shoes shows how crusty it was

The adjuster was completely seized. No chance of self-adjustment here. Just as an aside, the self-adjustment works by means of pulling on the hand brake. Pulling the hand brake pulls up on the top shoe, creating the friction to stop the car, but the movement of that lever also moves the metal tang in the photo below from left to right. As it heads on over to the right it catches the teeth of the adjuster, which winds the threaded inner section that the lower shoe rests on up and down. The whole cylinder is free to move up and down in its mount, which evens out the braking between the two shoes. Simple.

Removing the cylinder on this side was a little more of a pain as it has the inlet and the link pipe, instead of just the inlet and a bleeder like the other side. Both freed off with some careful force, and out came the cylinder.

The adjuster came off the end after a couple of careful taps with a hammer. It was packed with furry corrosion behind it.

As was the space under the boot on the top. This concerned me a bit as it didn't bode well for the condition of the bore.

The piston is completely compressed and didn't move by hand

It did move with some gentle persuasion with a long screwdriver though

I had to get a bit more angry to get it out further. A long spanner was used as the lever for this

And out it popped

The bore looks worse than it is. The cylinder is aluminium, so it's not really rust, just a build up of gunk stuck to the bore. I suspect the piston is stainless as other than more gunk on it, it was immaculate. The seal on the other hand was rubbish as there is a big tear/cut in it.

Mmm, more crusty fur

I tidied the bore up with some careful scraping, and then some very fine sandpaper. There is some staining on the walls, but there are no marks you can feel. The walls are very smooth.

The rest of the cylinder got scraped and wire brushed before a good clean out and the new seal kit fitted.

Before refitting, the back plate was de-crusted with a wire brush and then brake clean.

The cylinder was refitted. The locking method for these is a bit of a pain, but simple enough. The spring clip goes down from the top first, with the dimples pointing outwards (away from the cylinder). The locking U shaped clip then slides up over top of the spring clip, and locks into the dimples. I used a flat blade screwdriver to press down on the top of the spring clip, and pliers to tap up on the U clip.

And the wheel cylinder is in.

The shoes got a quick scuff with some rough sandpaper to clean the surface up a bit, and then they were fitted. They look fine but had some rust marks where they had been in contact with the drum.

And the completed assembly

The friction surface on the drum was quite rusty too, so that got a wire brush before fitting. It's good enough that any other rust should be scraped off once the car is on the road and the brakes operate.

Drum fitted

Unfortunately I can't test them as the master cylinder is off being re-sleeved, and the front brakes also need to go back on, but hopefully it won't be long.

I removed the drums a while back and had a quick visual inspection, and whilst one side looked like it had been under the ocean, there was no brake fluid or axle grease where it shouldn't be.

I started on the LH side, which didn't look like it had been under the sea, but instead had been full of bugs and spiders. The whole drum was packed with cobwebs and took a lot of cleaning and vacuuming to not be grossed out.

The shoes look really good, almost new I'd say, and everything was very dry. Someone had been in here before though as this big, annoying to install, spring should be behind the shoes, not in front of them.

Removing the shoes is a case of removing the little retaining spring pins, removing the big spring and then the pair of shoes can be withdrawn from the backing plate.

With the shoes out the cylinder can be removed by undoing the pipe(s), removing the boot, sliding the U shaped clip downwards and the spring clip upwards. The cylinder should be free to remove.

This one looked OK. The boot was torn, and the piston had some crud built up on it, but the bore was clean. The piston seal looked so good I probably could have reused it, but since I ordered a replacement seal kit anyway, I replaced it. The seal kit for this car is from a Spitfire and has 3/4" (19.05mm) bore.

With the build up carefully scraped off and polished with some fine sandpaper, the new piston seal goes on.

Now, before installing the piston in the cylinder again, install the boot first. This is a real prick of a job as it needs to stretch over the top, and it's a very tight fit.

And carefully install back into the cylinder. I chose to lube the cylinder walls and piston/seal with brake fluid for assembly.

Reinstall the clip and you're done.

There isn't a heck of a lot to a wheel cylinder on these.

I cleaned up and greased the self-adjuster. This just rests in the bottom of the cylinder but must turn freely.

Now clean the backing plate up, especially at the points where the cylinder and shoes contact it (the six raised bumps on the top and bottom, as well as the anchor where the end of the shoes rest and behind the wheel cylinder). I used a wire brush and brake clean. Once clean, use thin smears of copper or brake grease on those contact points.

Once the cylinder and hand brake lever is installed, reinstall the shoes. I found this easiest with the double spring in one end (shoe end), rest the top shoe on the hub, whilst inserting the lower shoe into the self-adjuster and then the shoe anchor. Now the top shoe can be installed. Take care not to lose the little metal H piece that sits above the handbrake lever where it goes through the shoe.

Don't forget to install the retaining pins and the big spring. As mentioned, this should be behind the shoes, and I found levering it in place with a long flat blade screwdriver easiest. It takes a few tries.

Done.

Rebuilt cylinder

So cocky, on went the drum

Now to move onto the other side.

This one was very crusty. Obviously water had gotten into the drum somehow, and couldn't get out until it dried over time. This drum had plugs in the adjuster holes, whilst the other side didn't. Explains why the bugs liked that side, and the water got stuck in this side.

The cylinder on this side was looking particularly average.

Removing the shoes shows how crusty it was

The adjuster was completely seized. No chance of self-adjustment here. Just as an aside, the self-adjustment works by means of pulling on the hand brake. Pulling the hand brake pulls up on the top shoe, creating the friction to stop the car, but the movement of that lever also moves the metal tang in the photo below from left to right. As it heads on over to the right it catches the teeth of the adjuster, which winds the threaded inner section that the lower shoe rests on up and down. The whole cylinder is free to move up and down in its mount, which evens out the braking between the two shoes. Simple.

Removing the cylinder on this side was a little more of a pain as it has the inlet and the link pipe, instead of just the inlet and a bleeder like the other side. Both freed off with some careful force, and out came the cylinder.

The adjuster came off the end after a couple of careful taps with a hammer. It was packed with furry corrosion behind it.

As was the space under the boot on the top. This concerned me a bit as it didn't bode well for the condition of the bore.

The piston is completely compressed and didn't move by hand

It did move with some gentle persuasion with a long screwdriver though

I had to get a bit more angry to get it out further. A long spanner was used as the lever for this

And out it popped

The bore looks worse than it is. The cylinder is aluminium, so it's not really rust, just a build up of gunk stuck to the bore. I suspect the piston is stainless as other than more gunk on it, it was immaculate. The seal on the other hand was rubbish as there is a big tear/cut in it.

Mmm, more crusty fur

I tidied the bore up with some careful scraping, and then some very fine sandpaper. There is some staining on the walls, but there are no marks you can feel. The walls are very smooth.

The rest of the cylinder got scraped and wire brushed before a good clean out and the new seal kit fitted.

Before refitting, the back plate was de-crusted with a wire brush and then brake clean.

The cylinder was refitted. The locking method for these is a bit of a pain, but simple enough. The spring clip goes down from the top first, with the dimples pointing outwards (away from the cylinder). The locking U shaped clip then slides up over top of the spring clip, and locks into the dimples. I used a flat blade screwdriver to press down on the top of the spring clip, and pliers to tap up on the U clip.

And the wheel cylinder is in.

The shoes got a quick scuff with some rough sandpaper to clean the surface up a bit, and then they were fitted. They look fine but had some rust marks where they had been in contact with the drum.

And the completed assembly

The friction surface on the drum was quite rusty too, so that got a wire brush before fitting. It's good enough that any other rust should be scraped off once the car is on the road and the brakes operate.

Drum fitted

Unfortunately I can't test them as the master cylinder is off being re-sleeved, and the front brakes also need to go back on, but hopefully it won't be long.

catfood12 said:

First car Marina survivor here too.

What engine is that ?! What handbrake linkage on the rear axle !?

We had the 1275 A series and 1800 B Series engines in the UK, oh, and holed rusty fuel tanks from the factory.

The 1.8TC here was a B series OHV with twin SUs. What's your OHC engine ?! The 1750 from the Allegro ?

The 1.7 and 2.0 Itals (Marina facelift) had the later O series engine in the UK...

Oh, and the handbrake linkage wasn't like yours on the rear diff.....

I worked for TVNZ for a time and lived up in Albany in the 2000s. Lots of 1960s and 1970s imports from the first gen Brits over there... Some stunning Mexicos and Lotus Ford stuff....

The engine is the 1750cc OHC E-Series BMC engine, as you mention, also used in the Maxi and Allegro. The first Marinas sold in NZ/Aus were locally made (either in NZ from kits shipped from Aus, or built in Aus) and used a lot of local content to meet requirements back then. We got the "UK spec" cars from MK2 onwards, up to the late MK3 with the O-Series, but we never got the Ital. Apparently, the Marina was always meant to get the E-Series, but cost cutting meant it got the A and B instead, so technically the NZ/Aus cars are more original to the design.

What engine is that ?! What handbrake linkage on the rear axle !?

We had the 1275 A series and 1800 B Series engines in the UK, oh, and holed rusty fuel tanks from the factory.

The 1.8TC here was a B series OHV with twin SUs. What's your OHC engine ?! The 1750 from the Allegro ?

The 1.7 and 2.0 Itals (Marina facelift) had the later O series engine in the UK...

Oh, and the handbrake linkage wasn't like yours on the rear diff.....

I worked for TVNZ for a time and lived up in Albany in the 2000s. Lots of 1960s and 1970s imports from the first gen Brits over there... Some stunning Mexicos and Lotus Ford stuff....

The rear axle is a local content item (along with all the braking system which is a "Girlock" copy of the Uk Girling gear), a Bog Warner type 68 as also fitted to Fords, Toyotas and Mitsubishis built in Aus at the time. The hand brake system is bespoke to this setup.

So, I've been digging with the stripping wheel on the grinder. I poked this scab a while back...

And yesterday I went full bore at it.

The previous owner was definitely a sculptor. There are places where the bog is 1-2CM thick.

Its messy AF, so will leave the rest of the stripping until I can get the car outside and make the rest of the dust natures problem

The strange thing is, the bog doesn't need to be this thick. I got a profile gauge today and using the good LH side as a sample, I compared it to the stripped RH side. Its not perfect, but its a lot closer to useable than I expected. There is no way it needed that much bog.

Once I have the rest of the bog off I'm going to etch prime the panel (takes the shine away, which is making it hard to see the shape) and then try my hand at shaping it with a hammer and dolly. Not sure how much better I can make the swage line, as its almost gone in places, but we'll see. Worst case, I keep an eye out for a replacement panel cut.

And yesterday I went full bore at it.

The previous owner was definitely a sculptor. There are places where the bog is 1-2CM thick.

Its messy AF, so will leave the rest of the stripping until I can get the car outside and make the rest of the dust natures problem

The strange thing is, the bog doesn't need to be this thick. I got a profile gauge today and using the good LH side as a sample, I compared it to the stripped RH side. Its not perfect, but its a lot closer to useable than I expected. There is no way it needed that much bog.

Once I have the rest of the bog off I'm going to etch prime the panel (takes the shine away, which is making it hard to see the shape) and then try my hand at shaping it with a hammer and dolly. Not sure how much better I can make the swage line, as its almost gone in places, but we'll see. Worst case, I keep an eye out for a replacement panel cut.

Finally, it's been a long time in the making, but for the first time in many years the Marina has brakes.

In the previous post, I refurbed and reassembled the rear brakes, but in the meantime I had also been working on the rest of the system. Unfortunately, things like this take time and money, both of which are a sticking point for me at the moment (mainly time, I'm waiting over a month for parts from the UK).

Even further back I started to strip the front calipers, which after some creative work with my compressor, I managed to do. First, I reinstalled the old pads, with a pry bar between them and used that to restrict the movement of the pistons, whilst pressurising the caliper and tapping the caliper body with a hammer. Eventually the pistons moved a little, but what made the biggest movement was using a punch and hammer to drive the piston out of the bore. Obviously, this is super destructive, so don't do this to pistons you want to keep (but pistons you want to keep shouldn't be stuck like these)

Out came one piston, along with a lot of sludge

This allowed me to slip the old piston back in after greasing it up, and using it to block the bore, and drive just the other piston out. I tried clamps, but there wasn't enough space with what I had, so ended up using a hose clamp to keep the piston from moving.

It worked a treat, and I ended up getting all four pistons out of the calipers in this way.

Now, before I go further, heed my warnings. Playing with hydraulics, compressed air, and brake fluid, is a dangerous game. Make sure you wear all your PPE. If it's not the crushing force of a piston flying out, it could be pressured brake fluid spraying into your face.

I should know, at one point when forcing 100+psi into the caliper I ended up with a fine mist of brake fluid spraying into my face. Thankfully I had safety glasses on, which stopped me from taking an eyeful of brake fluid and being blind, but it still wasn't pleasant. I have now upgraded to a full face shield for work like this.

As well as spraying my face, I didn't realise the fluid had travelled a meter or so behind me and ended up on the front of the Honda. Unfortunately, this sat on the paint and headlight overnight. The paint seems to have survived with only some minor marking, but the headlight has stained badly and will need replacing.

So yes, take care of yourself and your surroundings. ALWAYS wear the correct PPE. Also remember that plain old water neutralises brake fluid, so that should be the go-to for cleaning it off. Hydraulics are dangerous, if you aren't confident in what you are doing, seek professional support for the job.

Anyway, moving on, this is why the pistons were stuck. Deep corrosion.

After scrubbing the calipers in the parts washer, they spent a couple of days in the Evaporust bath to remove the rust.

They aren't perfect, and I probably should have painted them, but at the end of the day they are clean, internally rust-free and won't be seen behind the wheels.

I purchased a seal kit to suit the Girling Type 14 calipers as used on the Spitfire, PN GRK5005, which worked a treat. These Girlock calipers are almost an exact copy of the Girlings.

In went the piston seals, with lots of rubber grease. Make sure these sit flat, and arent twisted or pinched.

Next it's piston time. The pistons I used are once again from a Girling Type 14, PN 516212. These are slightly different where the dust boot sits. The Girlock pistons don't have a retaining groove, just a lip. The Girlings have a recessed groove. I figure since the seals I'm using are for the Girling, the Girlings pistons will be just fine (and to note, the old Girlock seals are visually the same). The overall dimensions of the piston are the same. Girling on the left, Girlock on the right.

The Girling piston had a much bigger lead in chamfer, which helps during assembly.

Pressing the pistons in was easy enough by hand. Lots of rubber grease, place it square and press it in with fingertips. Once it seats a bit, I used a long spanner over the face of the piston to push down evenly with both hands (one hand on each side of the caliper). It should go in with minimal force.

The dust boot is a prick. The inner lip sits in the piston recess, the outer lip just rests on the lip around the piston bore. A retaining ring holds it in place by friction. Getting this ring in place, without it pulling the boot off, took a few tries.

I found the easiest way to do it was to line the ends of the ring up so they are touching (spreading the ring open), and working from the back (opposite the open end of the ring) work it around the boot, holding it in place whilst you stretch the open ends of the ring into place. It's hard to describe, and do, but will make sense after a few tries.

Two calipers with new seals, pistons and boots.

I cleaned up the bleed nipples, making sure they were clear (they weren't), and refit the hard pipes. That's the calipers done.

Next in the firing line was the front rotors. I measured them a while ago and they came out as more or less new thickness, and have no lips. I feel like they were replaced not long before the car was laid up. Because of this, I don't want to replace them, that would be a damn waste. I was going to just send it, and use the pads to scrape the rust off them when it drives, but thought better of that when I had a good look. Crusty.

The best thing in this case was to remove the hub and rotor, and send the rotors off to be skimmed.

Before removing the hubs, I measured the runout in them. There should be 0.0245 - 0.1270mm play. This is to allow the bearings to expand when they warm up in use. Too tight and they will bind and fail. Too loose and they will wobble about and fail.

Well, the Lh side had this much play

0.185mm play. Quite a bit above the maximum allowable. I'm getting an awful lot of use out of my dial indicator with these old cars!

The RH side had zero play, not a thing. So both sides were set wrong. Glad I looked.

The LH side split pin was.... split. It's missing a whole leg, and was only sitting in place. It also pays to loosen the rotor bolts whilst the hub is on the car, just in case you need to stop it spinning. The rattle gun did this with no effort.

With the hub nut removed, the whole lot comes off pretty easily. The stub axle looks in good shape if a bit dirty.

One hub with rotor.

As a matter of course I bought a wheel bearing kit, as the old grease looked horrible, and there were signs of wear on the outer bearing races. The outer bearing was an LM11949 and the inner was L44649.

The back of the rotor looks worse than the front

Unlike the TVR, the rotors on the Marina came off easily with only minimal tapping with a hammer. I drove the old outer races out with a hammer and punch and gave the hub a good clean in the parts washer.

The rotors were sent away to be machined and came back looking good. They could've skimmed a little more off, but I'm sure the pads will scrub them clean in no time.

Before the rotor goes back on, the new bearings were pressed into the hub. The new bearings.

The new race was pressed in with the old race, and a deep socket

The rotor was loosely attached. Note the markings on the hub reminding me the rotor bolts aren't torqued. This can only be done on the car, using a long pry bar to lock the hub from spinning.

The bearings were packed and fitted, along with a new seal.

Before fitting the hub, I quickly swapped the old blocked front hoses for the new ones. These are Land Rover hoses, PN BR0764

And on goes the hub.

Set to the correct runout

With the caps and calipers fitted

Both hubs had the rotor bolts torqued down, so the markings were removed

The last few pieces of the puzzle were the master cylinder (which I sent off to be resleeved and rekitted), a new brake pipe from the master cylinder (since I damaged the old one removing it. A friend helped make a new one), and new pad fitting kit (in transit from the UK).

The brake master and clutch slave I sent away to be resleeved came back looking lovely. Nice new stainless bores, as well as a good cleanup. Won't have to worry about these rusting up again.

Of course, I couldn't just fit the nice clean cylinder to the rubbish looking firewall plate, so that got a wire brush and a coat of paint.

It's hard to believe it's the same master cylinder, and the same cap. I cleaned and used Araldite to fix the crack in the cap.

The pedals got new clevis pins, since the old ones had seen their share of work!

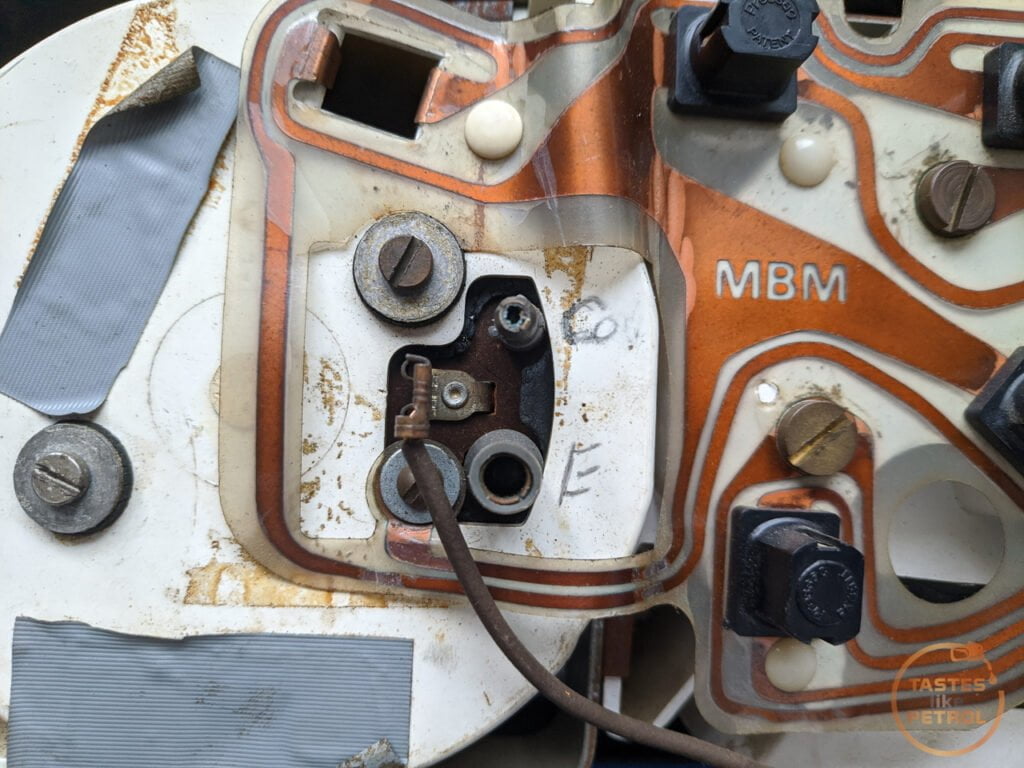

And finally, the brake light switch was tested

Which revealed that it didn't work. The switch is easy enough to strip, these tabs on the side need to be pressed to remove the bottom of the unit and pull the guts out

How this switch works confused me for a bit. When you remove the top from the bottom, it actually moves where the internal contact is, and if you don't spot it during disassembly it can be confusing. It got to the point I purchased a cheap replacement so I could work out how it's assembled.

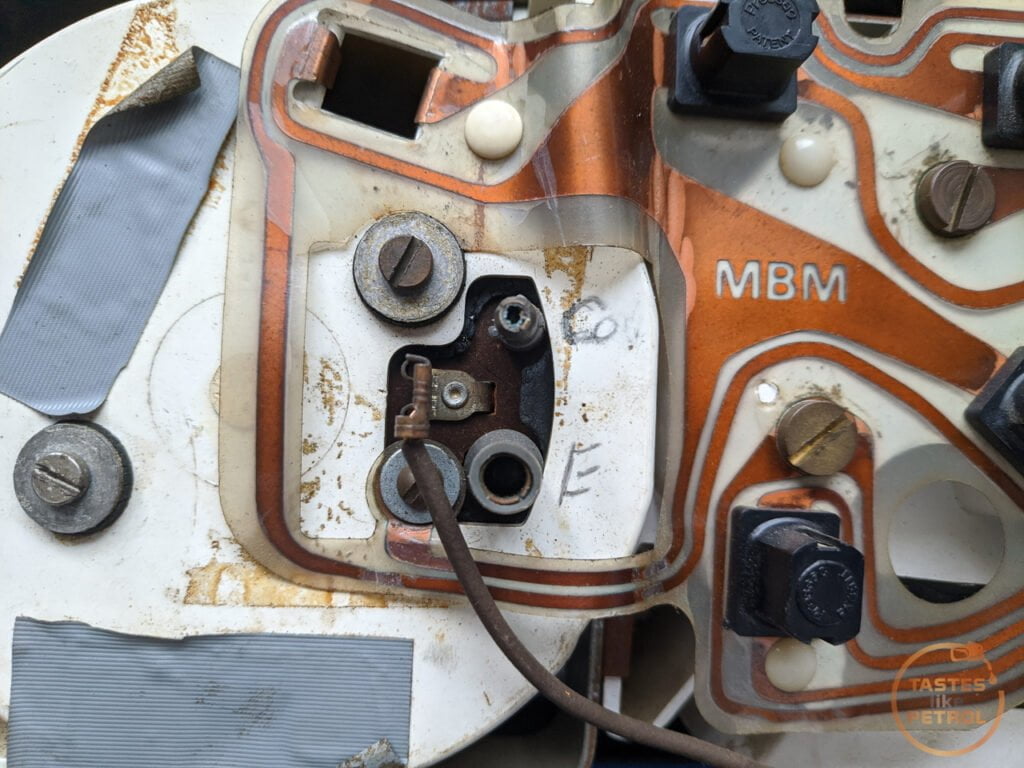

This is whats inside the switch, and how it came apart

As it turns out, as seen on this replacement switch, the U shaped contact goes under the two legs.

It's a Normally Closed switch, so it makes a circuit when the switch is released. When the brake pedal is pressed it's releasing the switch, which makes the circuit, otherwise normally it's pressed in, which moves the U shaped contact away from the two legs. The spring sits under the U shaped contact which pushes it up.

The replacement switch was a bit cheap, so instead I cleaned up the contacts of the old one and reassembled it. It takes some fiddling to keep the contact under the two legs whilst you slip the base in to the top housing, but it can be done.

A test shows that when pressed, the circuit is broken

And released, it makes the circuit

The original Lucas Australia switch lives to fight another day.

The pad fitting kit finally arrived today, so I fitted the NOS pads, new shims and new pins. It's a bit of a pain with new pads and new thickness rotors, its all very tight, but it's there.

I then drew fluid through with a vacuum bleeder, until all three bleed nipples had clean fluid coming through. Then it was back to the old one-man bleeder to finish the job. The brake pedal is now firm, with good travel. The rear adjusters have adjusted up (can hear the shoes slightly dragging the drum), and the hand brake is working. Everything needs a good bedding in, but for now, everything is doing what it should, and there seems to be no leaks. I don't know when it last had brakes, but it may not have been in this millennium.

Now all I'm waiting on is a clutch master cylinder, which is en route from the UK, and a drive shaft that will be on its way to me tomorrow from down south. Once they arrive, we should be good for a trip up the driveway. Excite.

In the previous post, I refurbed and reassembled the rear brakes, but in the meantime I had also been working on the rest of the system. Unfortunately, things like this take time and money, both of which are a sticking point for me at the moment (mainly time, I'm waiting over a month for parts from the UK).

Even further back I started to strip the front calipers, which after some creative work with my compressor, I managed to do. First, I reinstalled the old pads, with a pry bar between them and used that to restrict the movement of the pistons, whilst pressurising the caliper and tapping the caliper body with a hammer. Eventually the pistons moved a little, but what made the biggest movement was using a punch and hammer to drive the piston out of the bore. Obviously, this is super destructive, so don't do this to pistons you want to keep (but pistons you want to keep shouldn't be stuck like these)

Out came one piston, along with a lot of sludge

This allowed me to slip the old piston back in after greasing it up, and using it to block the bore, and drive just the other piston out. I tried clamps, but there wasn't enough space with what I had, so ended up using a hose clamp to keep the piston from moving.

It worked a treat, and I ended up getting all four pistons out of the calipers in this way.

Now, before I go further, heed my warnings. Playing with hydraulics, compressed air, and brake fluid, is a dangerous game. Make sure you wear all your PPE. If it's not the crushing force of a piston flying out, it could be pressured brake fluid spraying into your face.

I should know, at one point when forcing 100+psi into the caliper I ended up with a fine mist of brake fluid spraying into my face. Thankfully I had safety glasses on, which stopped me from taking an eyeful of brake fluid and being blind, but it still wasn't pleasant. I have now upgraded to a full face shield for work like this.

As well as spraying my face, I didn't realise the fluid had travelled a meter or so behind me and ended up on the front of the Honda. Unfortunately, this sat on the paint and headlight overnight. The paint seems to have survived with only some minor marking, but the headlight has stained badly and will need replacing.

So yes, take care of yourself and your surroundings. ALWAYS wear the correct PPE. Also remember that plain old water neutralises brake fluid, so that should be the go-to for cleaning it off. Hydraulics are dangerous, if you aren't confident in what you are doing, seek professional support for the job.

Anyway, moving on, this is why the pistons were stuck. Deep corrosion.

After scrubbing the calipers in the parts washer, they spent a couple of days in the Evaporust bath to remove the rust.

They aren't perfect, and I probably should have painted them, but at the end of the day they are clean, internally rust-free and won't be seen behind the wheels.

I purchased a seal kit to suit the Girling Type 14 calipers as used on the Spitfire, PN GRK5005, which worked a treat. These Girlock calipers are almost an exact copy of the Girlings.

In went the piston seals, with lots of rubber grease. Make sure these sit flat, and arent twisted or pinched.

Next it's piston time. The pistons I used are once again from a Girling Type 14, PN 516212. These are slightly different where the dust boot sits. The Girlock pistons don't have a retaining groove, just a lip. The Girlings have a recessed groove. I figure since the seals I'm using are for the Girling, the Girlings pistons will be just fine (and to note, the old Girlock seals are visually the same). The overall dimensions of the piston are the same. Girling on the left, Girlock on the right.

The Girling piston had a much bigger lead in chamfer, which helps during assembly.

Pressing the pistons in was easy enough by hand. Lots of rubber grease, place it square and press it in with fingertips. Once it seats a bit, I used a long spanner over the face of the piston to push down evenly with both hands (one hand on each side of the caliper). It should go in with minimal force.

The dust boot is a prick. The inner lip sits in the piston recess, the outer lip just rests on the lip around the piston bore. A retaining ring holds it in place by friction. Getting this ring in place, without it pulling the boot off, took a few tries.

I found the easiest way to do it was to line the ends of the ring up so they are touching (spreading the ring open), and working from the back (opposite the open end of the ring) work it around the boot, holding it in place whilst you stretch the open ends of the ring into place. It's hard to describe, and do, but will make sense after a few tries.

Two calipers with new seals, pistons and boots.

I cleaned up the bleed nipples, making sure they were clear (they weren't), and refit the hard pipes. That's the calipers done.

Next in the firing line was the front rotors. I measured them a while ago and they came out as more or less new thickness, and have no lips. I feel like they were replaced not long before the car was laid up. Because of this, I don't want to replace them, that would be a damn waste. I was going to just send it, and use the pads to scrape the rust off them when it drives, but thought better of that when I had a good look. Crusty.

The best thing in this case was to remove the hub and rotor, and send the rotors off to be skimmed.

Before removing the hubs, I measured the runout in them. There should be 0.0245 - 0.1270mm play. This is to allow the bearings to expand when they warm up in use. Too tight and they will bind and fail. Too loose and they will wobble about and fail.

Well, the Lh side had this much play

0.185mm play. Quite a bit above the maximum allowable. I'm getting an awful lot of use out of my dial indicator with these old cars!

The RH side had zero play, not a thing. So both sides were set wrong. Glad I looked.

The LH side split pin was.... split. It's missing a whole leg, and was only sitting in place. It also pays to loosen the rotor bolts whilst the hub is on the car, just in case you need to stop it spinning. The rattle gun did this with no effort.

With the hub nut removed, the whole lot comes off pretty easily. The stub axle looks in good shape if a bit dirty.

One hub with rotor.

As a matter of course I bought a wheel bearing kit, as the old grease looked horrible, and there were signs of wear on the outer bearing races. The outer bearing was an LM11949 and the inner was L44649.

The back of the rotor looks worse than the front

Unlike the TVR, the rotors on the Marina came off easily with only minimal tapping with a hammer. I drove the old outer races out with a hammer and punch and gave the hub a good clean in the parts washer.

The rotors were sent away to be machined and came back looking good. They could've skimmed a little more off, but I'm sure the pads will scrub them clean in no time.

Before the rotor goes back on, the new bearings were pressed into the hub. The new bearings.

The new race was pressed in with the old race, and a deep socket

The rotor was loosely attached. Note the markings on the hub reminding me the rotor bolts aren't torqued. This can only be done on the car, using a long pry bar to lock the hub from spinning.

The bearings were packed and fitted, along with a new seal.

Before fitting the hub, I quickly swapped the old blocked front hoses for the new ones. These are Land Rover hoses, PN BR0764

And on goes the hub.

Set to the correct runout

With the caps and calipers fitted

Both hubs had the rotor bolts torqued down, so the markings were removed

The last few pieces of the puzzle were the master cylinder (which I sent off to be resleeved and rekitted), a new brake pipe from the master cylinder (since I damaged the old one removing it. A friend helped make a new one), and new pad fitting kit (in transit from the UK).

The brake master and clutch slave I sent away to be resleeved came back looking lovely. Nice new stainless bores, as well as a good cleanup. Won't have to worry about these rusting up again.

Of course, I couldn't just fit the nice clean cylinder to the rubbish looking firewall plate, so that got a wire brush and a coat of paint.

It's hard to believe it's the same master cylinder, and the same cap. I cleaned and used Araldite to fix the crack in the cap.

The pedals got new clevis pins, since the old ones had seen their share of work!

And finally, the brake light switch was tested

Which revealed that it didn't work. The switch is easy enough to strip, these tabs on the side need to be pressed to remove the bottom of the unit and pull the guts out

How this switch works confused me for a bit. When you remove the top from the bottom, it actually moves where the internal contact is, and if you don't spot it during disassembly it can be confusing. It got to the point I purchased a cheap replacement so I could work out how it's assembled.

This is whats inside the switch, and how it came apart

As it turns out, as seen on this replacement switch, the U shaped contact goes under the two legs.

It's a Normally Closed switch, so it makes a circuit when the switch is released. When the brake pedal is pressed it's releasing the switch, which makes the circuit, otherwise normally it's pressed in, which moves the U shaped contact away from the two legs. The spring sits under the U shaped contact which pushes it up.

The replacement switch was a bit cheap, so instead I cleaned up the contacts of the old one and reassembled it. It takes some fiddling to keep the contact under the two legs whilst you slip the base in to the top housing, but it can be done.

A test shows that when pressed, the circuit is broken

And released, it makes the circuit

The original Lucas Australia switch lives to fight another day.

The pad fitting kit finally arrived today, so I fitted the NOS pads, new shims and new pins. It's a bit of a pain with new pads and new thickness rotors, its all very tight, but it's there.

I then drew fluid through with a vacuum bleeder, until all three bleed nipples had clean fluid coming through. Then it was back to the old one-man bleeder to finish the job. The brake pedal is now firm, with good travel. The rear adjusters have adjusted up (can hear the shoes slightly dragging the drum), and the hand brake is working. Everything needs a good bedding in, but for now, everything is doing what it should, and there seems to be no leaks. I don't know when it last had brakes, but it may not have been in this millennium.

Now all I'm waiting on is a clutch master cylinder, which is en route from the UK, and a drive shaft that will be on its way to me tomorrow from down south. Once they arrive, we should be good for a trip up the driveway. Excite.

Bingo. Girling Lockheed. AUS made to meet the "local content" requirements. So far all Girlock stuff has been direct ripoffs of Girling (except the clutch slave, which Girlock altered the design for the better, but still used a Girling seal kit).

I would've painted the calipers if they were going to be seen, but I'm currently doing this work on almost no budget (no job, no income for hobbies) and it was either use an old can of red paint, or don't paint. I chose not to paint them, and you won't see them behind the steelies.

I would've painted the calipers if they were going to be seen, but I'm currently doing this work on almost no budget (no job, no income for hobbies) and it was either use an old can of red paint, or don't paint. I chose not to paint them, and you won't see them behind the steelies.

It feels like it's been a huge uphill battle getting a working tacho in this car, but I think I have finally mastered it.

Over the past few months, I have somehow ended up with a few different clusters, including two with the elusive tachometer module, and the one with the non-functioning clock I previously made a post about.

The first three dial with tacho I bought from Trademe.

It was the correct Aus cluster, with the lower 5500RPM redline, and a couple of other small differences as I would later find out.

Eager to get the tacho in and working I started to dig around the wiring diagrams to work out what I needed to do. I had heard rumours that the wiring was already in the dash, behind the cluster, and sure enough, after some poking around, I noticed a white wire tucked away with a joiner in the middle of it. This tracked with what I was expecting to find based on the wiring diagrams.

It was a big loop in the harness. I fished it out from behind the duct and unplugged it. A couple of quick checks and I was sure it was the coil trigger for the tacho. On the cars without tachos, this is just looped in the dash but needs to be connected or it cuts power to the coil. I guess it made it cheaper and easier, to just use the one harness.

The back of the tacho unit has corresponding bullet terminals

So I plugged it into the dash, and bam, nothing happened. Well, the alt/oil lights worked as they should, but the tacho was dead. I was a bit miffed

Nothing more to do then but to get to disassembly and find out what's wrong. The tacho unit is held into its housing by a couple of screws through the back, and the fascia/glass in the front.

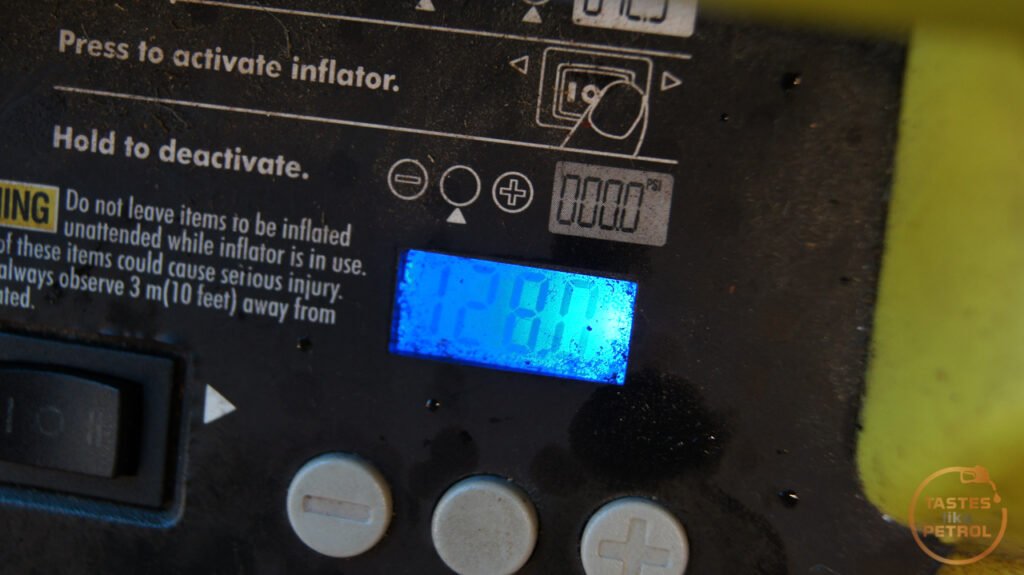

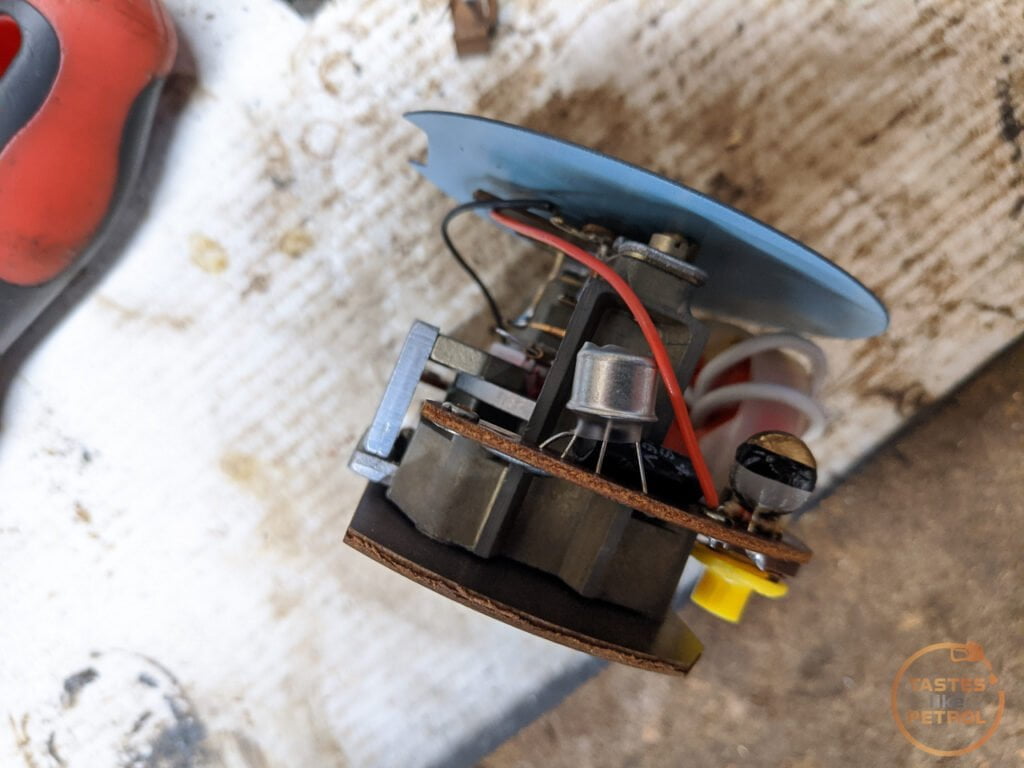

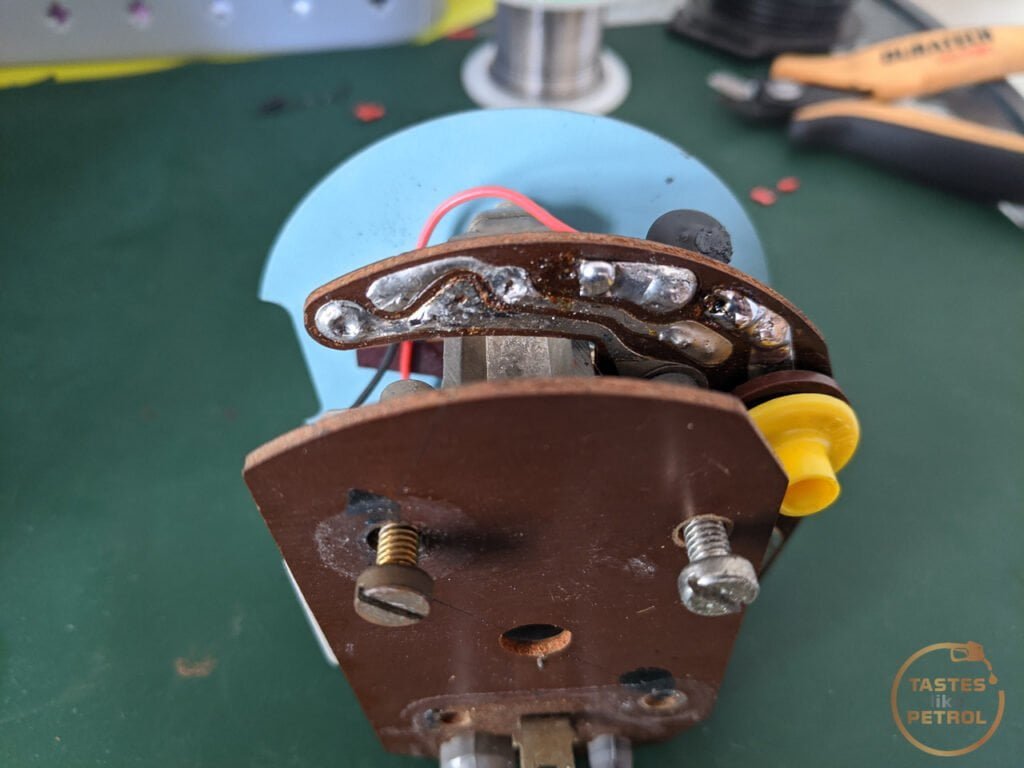

This is what the module looks like removed.

Having already googled "why does my Smiths RVI tacho not work" I could already see something was wrong.

Those four holes in the foreground, under that red wire? Yeah, according to google there should be a transistor there, and it's crucial to the operation of the unit.

The solder pads had clearly been messed with too. It looked like someone had desoldered the component with a blowtorch.

I hit the seller up and asked if he knew why it's been molested, and he just pleaded ignorance and fobbed me off with a "oh well, it's an old part".

I suspect the capacitor or transistor had failed at some point (which is common) and someone tried to fix it. Failing to have the right parts on hand or something, they just chucked it back together and set it aside.

As fate would have it, a fellow classic car sufferer on a forum I'm on knew I'm suffering the Marina affliction and mentioned that he had come across some Marina bits as part of a garage clearout, and would I be interested in a cluster he found? Heck yeah I would! The legend donated this to the cause, so a huge Thank You.

So, this was the second tacho cluster I have. It came in a tidy surround, but it was brown, not black. No issue, They are easy to swap, and I only really needed the guts.

Differences to observe. The silver rings around the dials, instead of the black the Aus cars have, the 6000RPM redline on the tacho face (ignore the askew tacho, I had already started to disassemble it), and the different markings on the fuel and temp scales (0 instead of E, and adding the N to temp). One final difference I didn't notice initially, is the warning lights are different, with some either doing different functions, or in the case of the indicator telltale lamps, not there at all. The UK cars seem to use one single green light to show the indicator is on, whilst the Aus cars use the two spaces above the center dial as left and right signals.

But it barely exceeded 1000rpm when revving the engine. I think this one may have been suffering from the known issues Smiths RVI tachos suffer from (bad capacitors), but instead of messing around with the old inductive RVI style guts, I spent a hefty whack of cash on the Spiyda RVI-RVC conversion board.

The original RVI tacho is current sensing, so it intercepts the power feed to the ignition coil, and by some wizardry senses the pulses and creates a signal for the tacho to output. The issue with this is apparently the tacho only works with points, and in the future I want the option of upgrading to electronic ignition without having to replace the tacho again, so it had to go.

The Spiyda board removes all the existing guts from the tacho, and replaces it with a new board that reads the signal from the negative terminal on the coil (like 90% of tachometers). Heck, it can even be fed a signal from an ECU. It's pretty swish stuff.

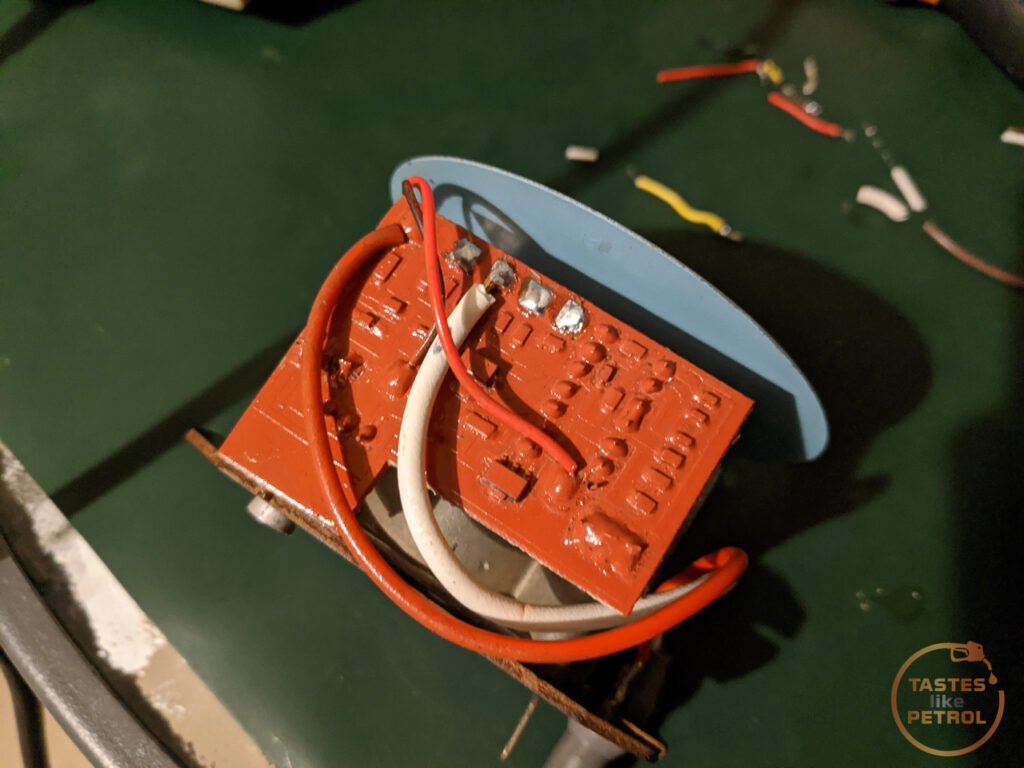

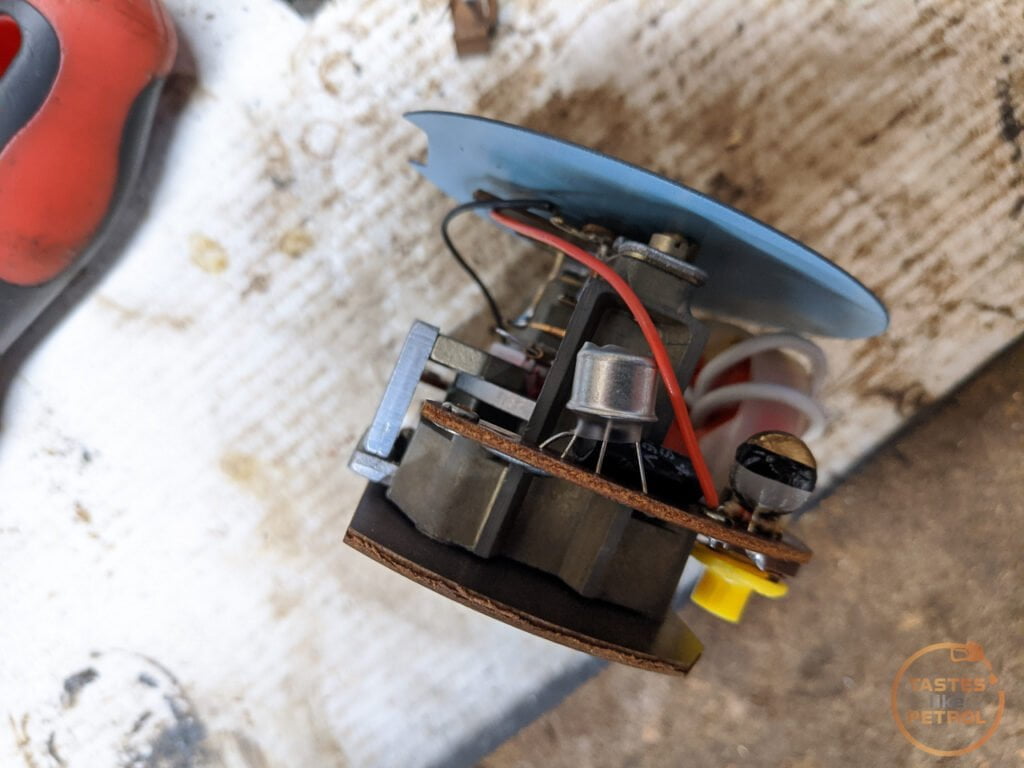

I stripped the second tacho out of the housing, and you can see the missing component of tacho one here; the silver can is a special transistor.

I started with the guts of the first tacho since that one was dead in the water anyway. Spiyda has extensive instructions on its site, here, so follow those, but this is how I went about it.

The first step is to remove the needle. You don't need to mark where the needle sits, just make sure the mechanism is against its stop when you refit the needle. To remove it I used an old business card with a notch cut in it, and a sturdy fork. The business card is to reduce the risk of damage to the face.

A swift lever upwards popped the needle off.

Two little screws secure the face. The kit comes with a tiny screwdriver to remove these.

Now cut the power feed wire, and the two thin wires to the mechanism and remove the two screws holding the circuit to the frame. It should pull off the front.

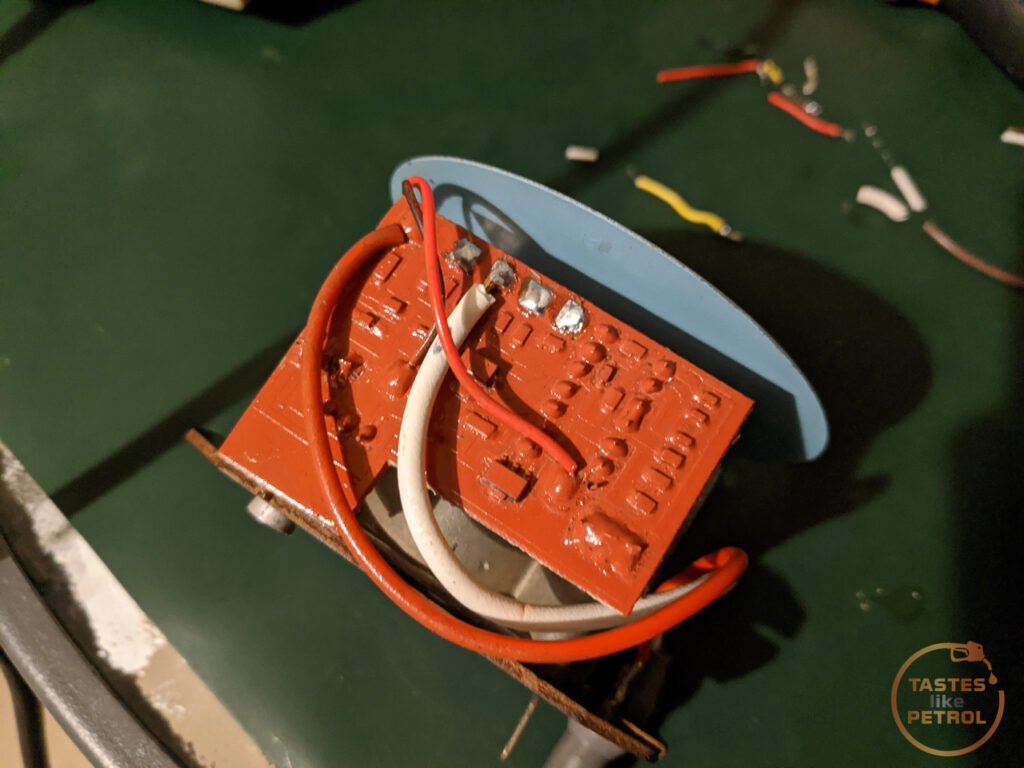

The new board then gets screwed in place

Now solder the wires in their respective places (in my case the black and red wires had to be swapped). and you're ready for testing and calibrating.

Now, I did make a mistake in the above photo. It turns out that the video I was following, made by Spiyda, was out of date, so you no longer calibrate the unit by putting the red clip onto the tacho feed (which I made from the old RVI tacho feed, by cutting a section off and soldering it to the board). Instead, you need to clip the red clip to the solder pad on the far right, closest to the big chip (on the other side of the board), or solder pad number 4.

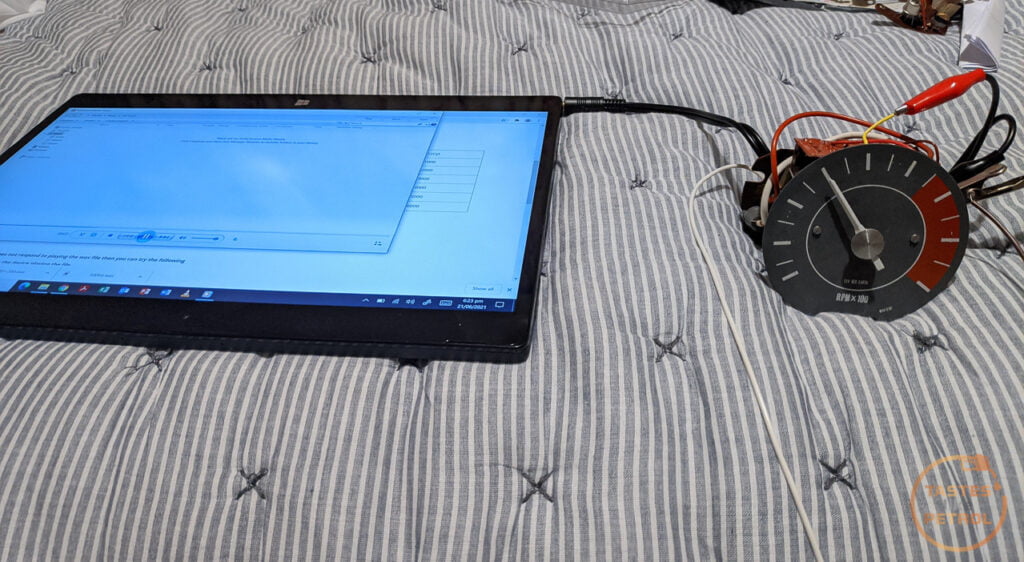

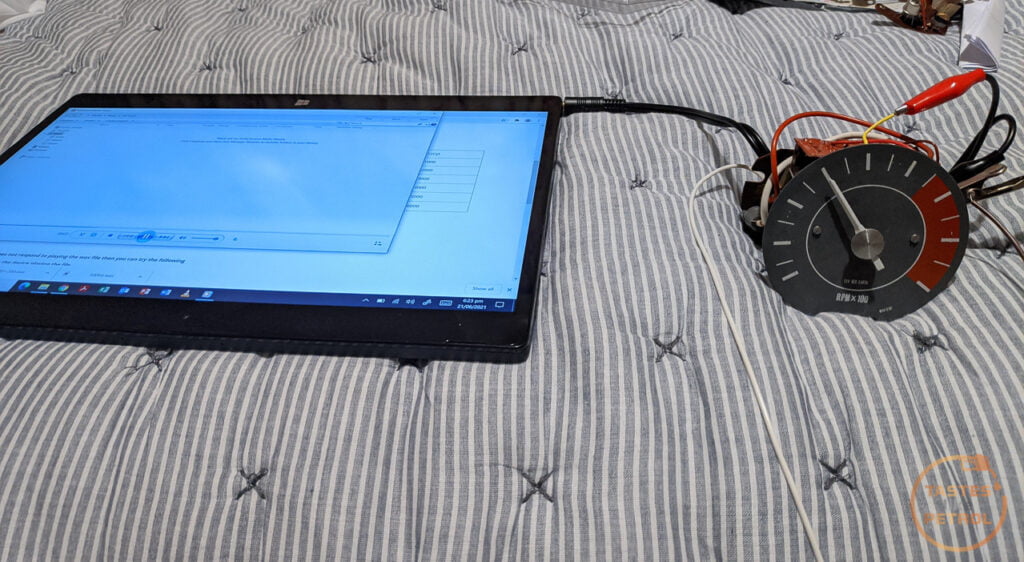

With 12v connected to the spade terminal on the back, the red clip on the solder pad and the black clip on the metal frame, it's time to calibrate.

Now, this was a real ballache for me. In the end, I don't know why it suddenly started to work properly, or what I did differently, but it was chaos.

The instruction and files to download for calibration are on the Spiyda site, here.

Basically, you play a square wave audio file at a certain frequency through the cable at full volume. That frequency should correspond with a certain RPM reading on the tacho. Since I was using a low revving 4 cylinder engine, I used the 100 and 200hz files as this should read 3000rpm and 6000rpm on the tacho.

I had various levels of success depending on what device I was using. My Macbook, no good. My phone, initially average. My windows based Dell tablet, good but with some issues.

I could get it to read 3000rpm, but doubling the frequency would either make the needle drop or only increase by a small amount. There was also a big jump in the needle at the start and it kinda crept down. This Gif shows the issue I was having. This is the 100-200 sweep, where it starts at 100hz and then shifts to 200hz. You can see the 100hz once the needle settles down, but then when it changes to 200hz the needle drops to just under 2500RPM.

I had been in contact with Spiyda support for a while, since even before calibration issues I had issues getting the unit to respond in the first place, and they had been very helpful in getting to where I was, with prompt replies, but then the support suddenly went cold and I heard nothing further from them.

It even got to the point of stripping down the second tacho and seeing if the issues were limited to the first one; they weren't.

I persisted with various things, and eventually I had great success using my phone. I don't know what changed, or why it worked now but didn't earlier, but suddenly I had 3000RPM at 100hz and 6000RPM at 200hz. It needed a small tweak of the calibration pot on the back, but it was rock solid.

With much excitement, I rushed to the garage and reassembled it into its housing.

And with a temporary wire run outside the car from the coil negative to the cluster, I fired the engine up. Nothing. *Sigh*

And then I remembered there were options for the input. There was a high voltage and low voltage signal option. In hindsight, if I had paid attention initially I wouldn't have wired the input to the high voltage "sports coil" option, and should've used the "normal coil" option. Oops.

It was easy to fix once I removed the guts from the cluster and moved the white wire one pad to the right.

I reassembled the cluster and plugged it in.

https://youtu.be/YC74v52vYlk

Success! I've run the car a couple of times since, and the tacho seems to be fairly accurate. It doesn't need to be 100% accurate, just within the ballpark is good enough, and better than Leyland would've done. It responds quickly and is very stable.

I still need to run the tacho wire inside the car, but that's easy enough to do. I should probably fit the surround back on the gauges too since they are more or less done now.

Over the past few months, I have somehow ended up with a few different clusters, including two with the elusive tachometer module, and the one with the non-functioning clock I previously made a post about.

The first three dial with tacho I bought from Trademe.

It was the correct Aus cluster, with the lower 5500RPM redline, and a couple of other small differences as I would later find out.

Eager to get the tacho in and working I started to dig around the wiring diagrams to work out what I needed to do. I had heard rumours that the wiring was already in the dash, behind the cluster, and sure enough, after some poking around, I noticed a white wire tucked away with a joiner in the middle of it. This tracked with what I was expecting to find based on the wiring diagrams.

It was a big loop in the harness. I fished it out from behind the duct and unplugged it. A couple of quick checks and I was sure it was the coil trigger for the tacho. On the cars without tachos, this is just looped in the dash but needs to be connected or it cuts power to the coil. I guess it made it cheaper and easier, to just use the one harness.

The back of the tacho unit has corresponding bullet terminals

So I plugged it into the dash, and bam, nothing happened. Well, the alt/oil lights worked as they should, but the tacho was dead. I was a bit miffed

Nothing more to do then but to get to disassembly and find out what's wrong. The tacho unit is held into its housing by a couple of screws through the back, and the fascia/glass in the front.

This is what the module looks like removed.

Having already googled "why does my Smiths RVI tacho not work" I could already see something was wrong.

Those four holes in the foreground, under that red wire? Yeah, according to google there should be a transistor there, and it's crucial to the operation of the unit.

The solder pads had clearly been messed with too. It looked like someone had desoldered the component with a blowtorch.

I hit the seller up and asked if he knew why it's been molested, and he just pleaded ignorance and fobbed me off with a "oh well, it's an old part".

I suspect the capacitor or transistor had failed at some point (which is common) and someone tried to fix it. Failing to have the right parts on hand or something, they just chucked it back together and set it aside.

As fate would have it, a fellow classic car sufferer on a forum I'm on knew I'm suffering the Marina affliction and mentioned that he had come across some Marina bits as part of a garage clearout, and would I be interested in a cluster he found? Heck yeah I would! The legend donated this to the cause, so a huge Thank You.

So, this was the second tacho cluster I have. It came in a tidy surround, but it was brown, not black. No issue, They are easy to swap, and I only really needed the guts.

Differences to observe. The silver rings around the dials, instead of the black the Aus cars have, the 6000RPM redline on the tacho face (ignore the askew tacho, I had already started to disassemble it), and the different markings on the fuel and temp scales (0 instead of E, and adding the N to temp). One final difference I didn't notice initially, is the warning lights are different, with some either doing different functions, or in the case of the indicator telltale lamps, not there at all. The UK cars seem to use one single green light to show the indicator is on, whilst the Aus cars use the two spaces above the center dial as left and right signals.

- removes anorak* Right, so this cluster. Excitedly I plugged it into the car, and we had some success. The tacho moved!

But it barely exceeded 1000rpm when revving the engine. I think this one may have been suffering from the known issues Smiths RVI tachos suffer from (bad capacitors), but instead of messing around with the old inductive RVI style guts, I spent a hefty whack of cash on the Spiyda RVI-RVC conversion board.

The original RVI tacho is current sensing, so it intercepts the power feed to the ignition coil, and by some wizardry senses the pulses and creates a signal for the tacho to output. The issue with this is apparently the tacho only works with points, and in the future I want the option of upgrading to electronic ignition without having to replace the tacho again, so it had to go.

The Spiyda board removes all the existing guts from the tacho, and replaces it with a new board that reads the signal from the negative terminal on the coil (like 90% of tachometers). Heck, it can even be fed a signal from an ECU. It's pretty swish stuff.

I stripped the second tacho out of the housing, and you can see the missing component of tacho one here; the silver can is a special transistor.

I started with the guts of the first tacho since that one was dead in the water anyway. Spiyda has extensive instructions on its site, here, so follow those, but this is how I went about it.

The first step is to remove the needle. You don't need to mark where the needle sits, just make sure the mechanism is against its stop when you refit the needle. To remove it I used an old business card with a notch cut in it, and a sturdy fork. The business card is to reduce the risk of damage to the face.

A swift lever upwards popped the needle off.

Two little screws secure the face. The kit comes with a tiny screwdriver to remove these.

Now cut the power feed wire, and the two thin wires to the mechanism and remove the two screws holding the circuit to the frame. It should pull off the front.

The new board then gets screwed in place

Now solder the wires in their respective places (in my case the black and red wires had to be swapped). and you're ready for testing and calibrating.

Now, I did make a mistake in the above photo. It turns out that the video I was following, made by Spiyda, was out of date, so you no longer calibrate the unit by putting the red clip onto the tacho feed (which I made from the old RVI tacho feed, by cutting a section off and soldering it to the board). Instead, you need to clip the red clip to the solder pad on the far right, closest to the big chip (on the other side of the board), or solder pad number 4.

With 12v connected to the spade terminal on the back, the red clip on the solder pad and the black clip on the metal frame, it's time to calibrate.

Now, this was a real ballache for me. In the end, I don't know why it suddenly started to work properly, or what I did differently, but it was chaos.

The instruction and files to download for calibration are on the Spiyda site, here.

Basically, you play a square wave audio file at a certain frequency through the cable at full volume. That frequency should correspond with a certain RPM reading on the tacho. Since I was using a low revving 4 cylinder engine, I used the 100 and 200hz files as this should read 3000rpm and 6000rpm on the tacho.

I had various levels of success depending on what device I was using. My Macbook, no good. My phone, initially average. My windows based Dell tablet, good but with some issues.

I could get it to read 3000rpm, but doubling the frequency would either make the needle drop or only increase by a small amount. There was also a big jump in the needle at the start and it kinda crept down. This Gif shows the issue I was having. This is the 100-200 sweep, where it starts at 100hz and then shifts to 200hz. You can see the 100hz once the needle settles down, but then when it changes to 200hz the needle drops to just under 2500RPM.