Knackered old Porsche with loads of natural light - Boxster!

Discussion

eltax91 said:

Greedydog said:

If I was going to do this I'd definitely want to use a 987 as a base. Are the differences versus a 986 too great?

Why does it have to me a 987, out of interest?Greedydog said:

If I was going to do this I'd definitely want to use a 987 as a base. Are the differences versus a 986 too great?

Mechanically they're pretty much the same car, but the big thing stopping doing anything post 2.5L 986 is the emissions homologation aspect of things. Post 1st March 2001 the emissions device i.e. catalytic converter needs to be type approved, this type approval determines that the cat will meet the original operating specifications on the vehicle it is type approved for (https://www.gov.uk/government/publications/catalytic-convertors/catalytic-converters-and-diesel-particulate-filters)The problem comes when you've swapped engines on a post type approval requirement vehicle and now want a Cat for it, there isn't anything type approved for that application and parts suppliers can't sell you a none type approved one without leaving themselves open to prosecution and/or fines. You can of course fit a "motorsport" one or import something from another country but the regulation is the vehicle must have a type approved cat.... Visual or performance measurement of the emissions system are coming and part of this will obviously reference type approval.

When I first considered the whole Booster thing I wanted to build a car which was absolutely legal, no matter what regs came in over the next few years. The first consideration was how to do the project as a straight repower that required no modifications to the chassis or drivetrain and therefore aligned well with the DVLA IVA requirements and associated radically altered vehicle rules. This was the driver in doing it all on the engine mounts where no modification to the chassis is required. The second was emissions, 2.5L Boxsters are pre type approval requiremenet so we can fit a cat which hits the required performance elements for flow and emissions performance without a type approval issue.

Basically what this breaks down to is that you can build a 2.5L 986 based "Booster' and have good confidence it will remain road legal even with future regulation changes and/or enforcement. You can't do that with the same confidence on a later car.

Huff said:

Stick Legs said:

I don’t own a Porsche but quite fancy a Booster manual.

This!I'd happily buy such a thing.

It was just too expensive and too long winded to go through commercial licencing and related for a project of this size I'm afraid, hence there not being an ISBN on the back etc. It just seemed a far nicer way of providing the instructions than a load of A4 printed pages

poppopbangbang said:

Sorry chaps but they're for bundling in with the kit. I can't sell them as some of the imagery in there is under educational/informative licence not commercial.

It was just too expensive and too long winded to go through commercial licencing and related for a project of this size I'm afraid, hence there not being an ISBN on the back etc. It just seemed a far nicer way of providing the instructions than a load of A4 printed pages

As a graphic designer for ... comparable things ... as a side-gig in a former life: I totally respect that POV.It was just too expensive and too long winded to go through commercial licencing and related for a project of this size I'm afraid, hence there not being an ISBN on the back etc. It just seemed a far nicer way of providing the instructions than a load of A4 printed pages

ATB!

poppopbangbang said:

IMI A said:

having covered 300,000 miles in 986 Boxster. Having said that not driven one on Cup 2 this is the main reason with muscular mid range from G 3076 I think you've made a pocket rocket. Would love to see this back to back against the new RS Spyder. Love it!

Great work! Always a pleasure to meet someone else with several 100K of Porsche driving under their belt  and thank you for the kind words.

and thank you for the kind words.It's surprisingly quick even without an LSD as the mechanical from the Cup 2s is pretty significant, as such it doesn't really spin a wheel up until there is quite a bit of cornering load and steering angle going on. We'll see what it's like on the new dampers as it will squat a lot less then and in turn transfer less weight to the driven wheels.

I really want to try it with a twin scroll G25-550 on there as I am pretty sure I can make the same torque 1200RPM or so lower which with the shorter ratios in the new box would be quite something!

poppopbangbang said:

Greedydog said:

If I was going to do this I'd definitely want to use a 987 as a base. Are the differences versus a 986 too great?

Mechanically they're pretty much the same car, but the big thing stopping doing anything post 2.5L 986 is the emissions homologation aspect of things. Post 1st March 2001 the emissions device i.e. catalytic converter needs to be type approved, this type approval determines that the cat will meet the original operating specifications on the vehicle it is type approved for (https://www.gov.uk/government/publications/catalytic-convertors/catalytic-converters-and-diesel-particulate-filters)The problem comes when you've swapped engines on a post type approval requirement vehicle and now want a Cat for it, there isn't anything type approved for that application and parts suppliers can't sell you a none type approved one without leaving themselves open to prosecution and/or fines. You can of course fit a "motorsport" one or import something from another country but the regulation is the vehicle must have a type approved cat.... Visual or performance measurement of the emissions system are coming and part of this will obviously reference type approval.

When I first considered the whole Booster thing I wanted to build a car which was absolutely legal, no matter what regs came in over the next few years. The first consideration was how to do the project as a straight repower that required no modifications to the chassis or drivetrain and therefore aligned well with the DVLA IVA requirements and associated radically altered vehicle rules. This was the driver in doing it all on the engine mounts where no modification to the chassis is required. The second was emissions, 2.5L Boxsters are pre type approval requiremenet so we can fit a cat which hits the required performance elements for flow and emissions performance without a type approval issue.

Basically what this breaks down to is that you can build a 2.5L 986 based "Booster' and have good confidence it will remain road legal even with future regulation changes and/or enforcement. You can't do that with the same confidence on a later car.

poppopbangbang said:

Center Gravity and Bilstein have also done some great work and got Booster spec PSS10 turned around PDQ!

Spring rates are very close to M030 but obviously with a more capable damper inside them so this, along with the adjustability of the damper, should allow for decent suspension compliance and grip on the vast majority of surfaces whilst also being track day capable (within the limits of a sensible road car) when turned up. The ride height adjustment also means we can account for the reduced weight of the vehicle and the slight change in balance.

Can I ask about these please, thanks. I understand the adjustability is a bonus. So ride height and I assume corner weighting. Also you mentioned 'turned up' so I'm assuming you will twiddle your knobs to stiffer when about to go attacking tracks. But I'm curious about the more capable statement. Are these much more capable than the Bilstein fixed spring platform offerings like b4, b6, b8 etc. I guess their rebuild service is yet another entry in the plus column too. Would the likes of Ohlins or KW be much better or only marginal or is it difficult to really feel the difference on a car between a good damper and a really good damper. And are you going this route partly because CG are backing them as their preferred kit or setup?

Spring rates are very close to M030 but obviously with a more capable damper inside them so this, along with the adjustability of the damper, should allow for decent suspension compliance and grip on the vast majority of surfaces whilst also being track day capable (within the limits of a sensible road car) when turned up. The ride height adjustment also means we can account for the reduced weight of the vehicle and the slight change in balance.

People forget that dampers are for the transient changes, springs are for the dynamics. Once you've turned in the dynamics are pretty static.

I see cars these days lowered so no suspension movement & with springs as hard as nails & dampers wound up to 11. And they bounce like a ping pong ball. Colin Chapman had it right

I see cars these days lowered so no suspension movement & with springs as hard as nails & dampers wound up to 11. And they bounce like a ping pong ball. Colin Chapman had it right

ATM said:

Can I ask about these please, thanks. I understand the adjustability is a bonus. So ride height and I assume corner weighting. Also you mentioned 'turned up' so I'm assuming you will twiddle your knobs to stiffer when about to go attacking tracks. But I'm curious about the more capable statement. Are these much more capable than the Bilstein fixed spring platform offerings like b4, b6, b8 etc. I guess their rebuild service is yet another entry in the plus column too. Would the likes of Ohlins or KW be much better or only marginal or is it difficult to really feel the difference on a car between a good damper and a really good damper. And are you going this route partly because CG are backing them as their preferred kit or setup?

As I mentioned earlier I was really looking at what the best "bang per buck" was for the Booster setup, the Bilstein option is pretty much that. As you know I'm a big fan of Ohlins products but based on my experience on the 996 there are some additional costs to factor in to make the most of them. KW I've never gotten on well with from a performance perspective. In terms of more capable I was refering to the OEM spec dampers that comprised the M030 kit, however it should be noted than the PSS10 is a more optimised damper for performance use than the standard ones as the choice of oil and valving design is more compatible with the damper doing lots of medium to high frequency work than a standard road car damper. The adjustability is also very useful, it's single way (so combined bump and rebound) but still provides a decent range of adjustment without the complexity of multiple adjusters that create opportunity for confusion.

I did look at a few fixed platform options but the neccesity to then get some springs made to get the ride height correct made it a bit of a none starter when Bilstein could supply a kit with sensible spring rates and ride height adjustment fairly off the shelf.

So nothings says comitted like running two projects at once  so with the Cayenne parts piling up I've been tinkering with the cruise stalk this evening. I'm really keen to get this on the car as a quick and tactile way of selecting boost modes etc.

so with the Cayenne parts piling up I've been tinkering with the cruise stalk this evening. I'm really keen to get this on the car as a quick and tactile way of selecting boost modes etc.

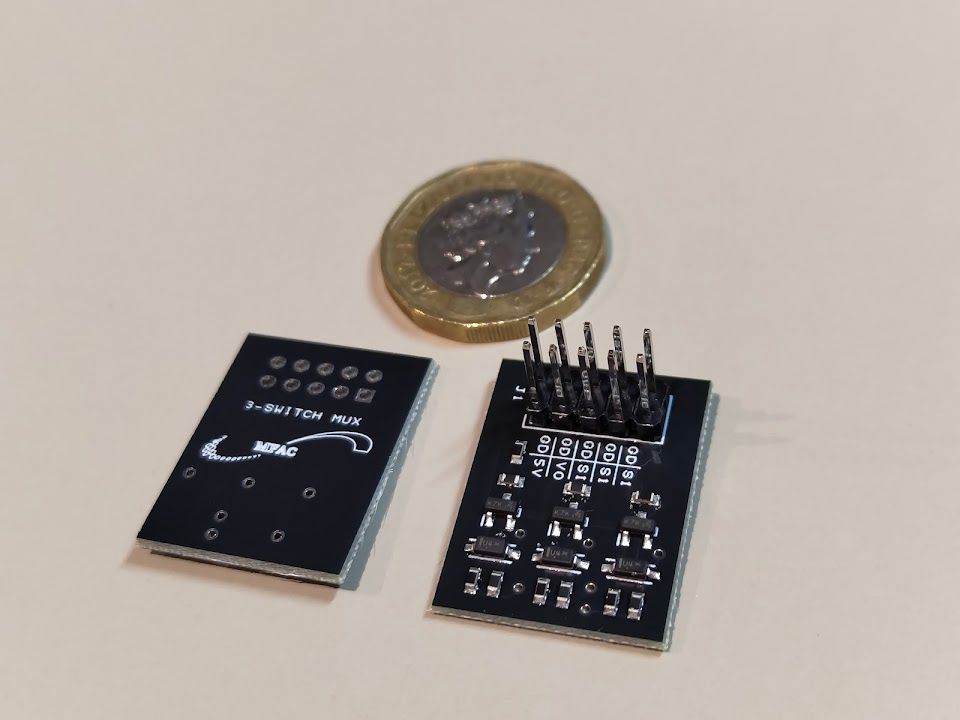

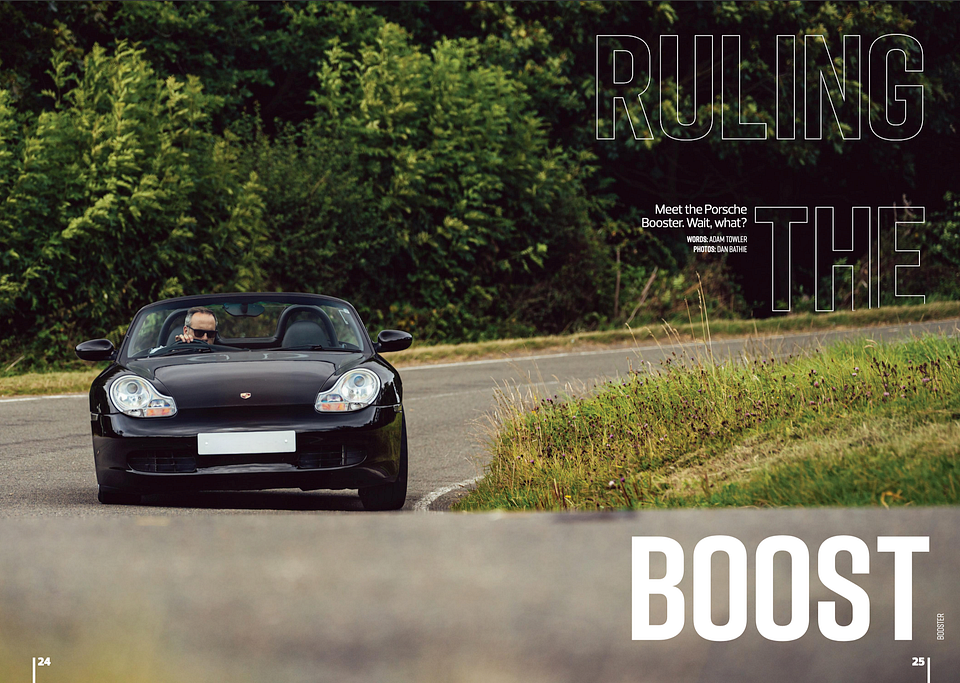

The switch multiplexers are done and have come out really well:

Pound for scale:

I have the option with these as wire too or pin header to connect the switches. They've been designed to be a little bit universal as I have a hundred of them and only need one Either way pin header is really useful for testing on the bench. I've already tabled this out in the CANChecked display and it works well, can't fault the capability of the CANChecked stuff, even if it is a touch fiddly to setup.

Either way pin header is really useful for testing on the bench. I've already tabled this out in the CANChecked display and it works well, can't fault the capability of the CANChecked stuff, even if it is a touch fiddly to setup.

I've not made any progress with the Bilsteins yet as I had an argument with a molehill last weekend and am still limping.... so electronics only this week until I can bend both legs again!

Oh and if anyone wants a switch multiplexer let me know.... I'm well stocked

so with the Cayenne parts piling up I've been tinkering with the cruise stalk this evening. I'm really keen to get this on the car as a quick and tactile way of selecting boost modes etc.

so with the Cayenne parts piling up I've been tinkering with the cruise stalk this evening. I'm really keen to get this on the car as a quick and tactile way of selecting boost modes etc. The switch multiplexers are done and have come out really well:

Pound for scale:

I have the option with these as wire too or pin header to connect the switches. They've been designed to be a little bit universal as I have a hundred of them and only need one

Either way pin header is really useful for testing on the bench. I've already tabled this out in the CANChecked display and it works well, can't fault the capability of the CANChecked stuff, even if it is a touch fiddly to setup.

Either way pin header is really useful for testing on the bench. I've already tabled this out in the CANChecked display and it works well, can't fault the capability of the CANChecked stuff, even if it is a touch fiddly to setup.I've not made any progress with the Bilsteins yet as I had an argument with a molehill last weekend and am still limping.... so electronics only this week until I can bend both legs again!

Oh and if anyone wants a switch multiplexer let me know.... I'm well stocked

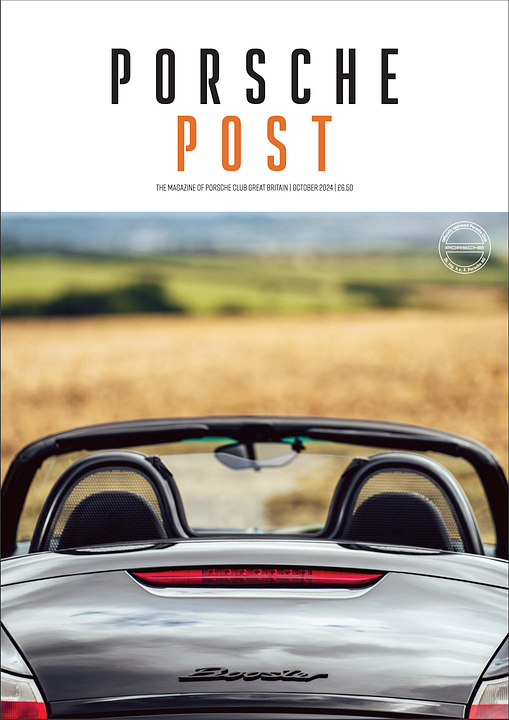

On the cover of this months Porsche Post

Hugely proud moment to see it in print and a great article by Adam Towler on the car, the thought process and its performance.

If you're not a Porsche Club GB member you can join online to read it (https://www.porscheclubgb.com/news-and-events/news/2024/september/read-the-october-issue-of-porsche-post) and for those that are the mag should have arrived today. I'll ask permission to reproduce the article in due course so I can share it here but this likely won't be for a month or so I'm afraid.

Also in a lovely circular way it's pretty much a year exactly since I started building the engine, 12 months from an engine on the stand to a mag feature isn't bad going really!

conanius said:

Congratulations on the magazine feature - I'm just sitting down to read it with a coffee after the postie just delivered it. Nick had hinted in our region chat that it was on the way !

Hope you found it a good read

I was very pleased with the write up, both the guys at Badgers and myself had put a lot of work into getting it to drive well and generally behave like a production car should do, so it was great to see this picked up so clearly in the feature.

As part of the next round of upgrades / finishing I'm collecting various parts. One of these is a fancy billet fuel rail kit that's come in from the States (mainly so I can relocate the FPR). Now full admission, I didn't really look that closely at what I was buying as the price was about right and there's only so many places you can buy stuff from..... great example of the absolute state of some parts of modern tuner market coming up!

Looks tidy enough right? I mean the machining is pretty rough and the annodising a bit patchy but it's a reasonable on a cost for the spindle time that's in it basis....

Oh.... every drill through from the injector bosses to the main rail is absolutely full of burrs.... at least they're nicely annodised

But wait it gets better!

Nice billet FPR carrier... designed to have the cross drillings sealed with a grub screw, only they're both straight threads and there's no sealing surface inside the cross drilling or shoulder for the screw to bottom on, so guess we'll just let that leak then or 577 it and hope?

Still at least they can't have cocked up sealing the main feed and end cap right.... oh those sealing washers are the wrong size then, and it's supplied with a double male AN fitting to go between the rail and FPR housing.... but they're both open threads i.e. no conical seat for the AN to seal to, so I guess we're sealing on the hex at both ends then with an incorrectly sized cheap aluminium crush washer.

Still it's not like this can get any worse right? Well... as the bore in the feed has to be offset to clear the exit gallery then if you use an AN fitting you get this:

Which is about a 40% reduction in CSA.

So the best case with this is if it doesn't leak and set the car on fire the engine melts because the injectors are full of swarf.... maybe the restrictive entry to the reg is to compensate for the injector FOD?

This wasn't cheap, cheap either, it was going rate for this sort of thing but it's a good example of why you should always, always do basic quality and engineering checks on anything that's not designed by an OEM and out of their supply chain. Of course there are many, many tuner market companies doing great work and producing proper, motorsport level components with all the quality systems one would expect in that environment.... but there's also a lot that aren't.

In this case it's a copy of another, very similar setup but it's been copied with no understanding of how the assembly should work. In the "real" version the sealing is via o-rings, the interface between the FPR housing and the rail is a threaded tube which uses lock rings to clamp up on the o-rings and the gallery sealing plugs are taper fit.

The rail is probably salvageable with a reaming and a session in the ultrasonic cleaner but the rest is very much going in the bin!

Looks tidy enough right? I mean the machining is pretty rough and the annodising a bit patchy but it's a reasonable on a cost for the spindle time that's in it basis....

Oh.... every drill through from the injector bosses to the main rail is absolutely full of burrs.... at least they're nicely annodised

But wait it gets better!

Nice billet FPR carrier... designed to have the cross drillings sealed with a grub screw, only they're both straight threads and there's no sealing surface inside the cross drilling or shoulder for the screw to bottom on, so guess we'll just let that leak then or 577 it and hope?

Still at least they can't have cocked up sealing the main feed and end cap right.... oh those sealing washers are the wrong size then, and it's supplied with a double male AN fitting to go between the rail and FPR housing.... but they're both open threads i.e. no conical seat for the AN to seal to, so I guess we're sealing on the hex at both ends then with an incorrectly sized cheap aluminium crush washer.

Still it's not like this can get any worse right? Well... as the bore in the feed has to be offset to clear the exit gallery then if you use an AN fitting you get this:

Which is about a 40% reduction in CSA.

So the best case with this is if it doesn't leak and set the car on fire the engine melts because the injectors are full of swarf.... maybe the restrictive entry to the reg is to compensate for the injector FOD?

This wasn't cheap, cheap either, it was going rate for this sort of thing but it's a good example of why you should always, always do basic quality and engineering checks on anything that's not designed by an OEM and out of their supply chain. Of course there are many, many tuner market companies doing great work and producing proper, motorsport level components with all the quality systems one would expect in that environment.... but there's also a lot that aren't.

In this case it's a copy of another, very similar setup but it's been copied with no understanding of how the assembly should work. In the "real" version the sealing is via o-rings, the interface between the FPR housing and the rail is a threaded tube which uses lock rings to clamp up on the o-rings and the gallery sealing plugs are taper fit.

The rail is probably salvageable with a reaming and a session in the ultrasonic cleaner but the rest is very much going in the bin!

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff