Knackered old Porsche with loads of natural light - Boxster!

Discussion

trails said:

poppopbangbang said:

No money exchanged hands!

Blip already resolved, it's just calibration (the heads already got titanium gubbins) - essentially the transient calibration is always pretty slow to start with as you build data around keeping the cat happy in these scenarios. Blip can be pretty nasty for them if the cats already very hot as you essentially throw a low of fuel across it to get the engine to accel. This was running closed loop fueling through the blip with the DBW slowed accordingly to allow the closed loop fueling PIDs to keep up, a few revisions back it went to (mostly) open loop blip so way more aggressive.

If you didn't need to keep the cat happy then the drive by wire moves quicker than you can move your foot with all the amps behind it so at that point it's just rotating assembly mass that's the limit really.

I must have forgotten about the head build, I'm sure nobody on this thread doubted your ability to sort it quickly and easily

Blip already resolved, it's just calibration (the heads already got titanium gubbins) - essentially the transient calibration is always pretty slow to start with as you build data around keeping the cat happy in these scenarios. Blip can be pretty nasty for them if the cats already very hot as you essentially throw a low of fuel across it to get the engine to accel. This was running closed loop fueling through the blip with the DBW slowed accordingly to allow the closed loop fueling PIDs to keep up, a few revisions back it went to (mostly) open loop blip so way more aggressive.

If you didn't need to keep the cat happy then the drive by wire moves quicker than you can move your foot with all the amps behind it so at that point it's just rotating assembly mass that's the limit really.

Well it's a year today since I pulled the 2.5L out of the Boxster, so I thought a quick update was in order before heading out for Xmas eve beers.

It's done 3200 miles since I built it and has mostly behaved itself. There is still the odd random coolant leak but such is life when it's all silicone hoses and hose clips. Changing them all for constant tension clamps is not going to happen until the engine comes out in a couple of years time but aside from that not a lot to report.

We made the 400bhp "initial' target I had pretty easilly but a smaller / more modern turbo would move the boost threshold down and still give potential for 500bhp, which is the next development target.

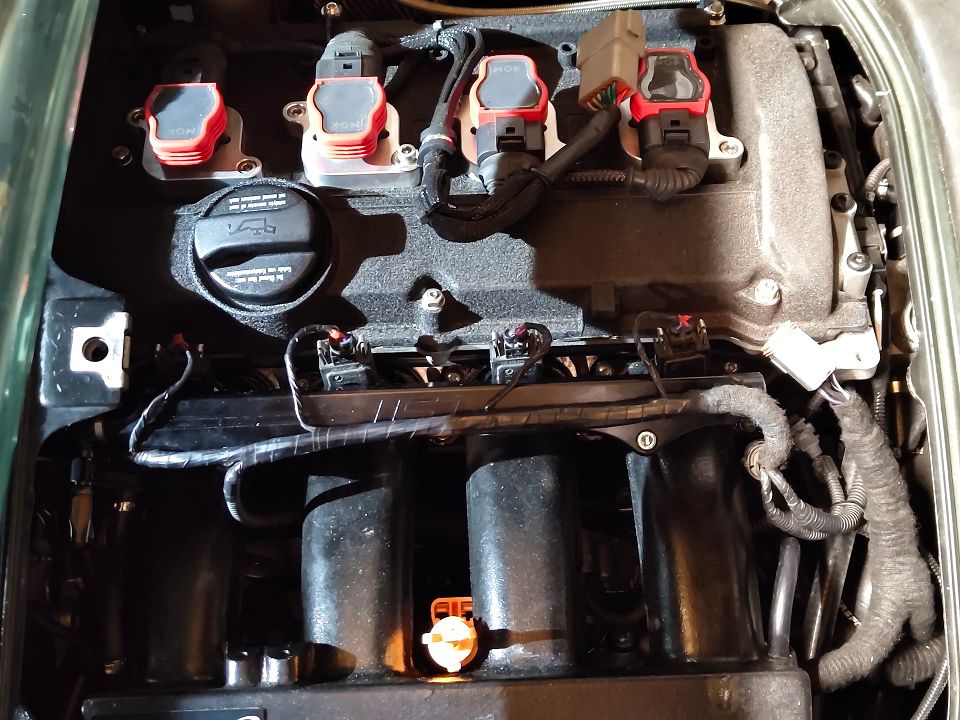

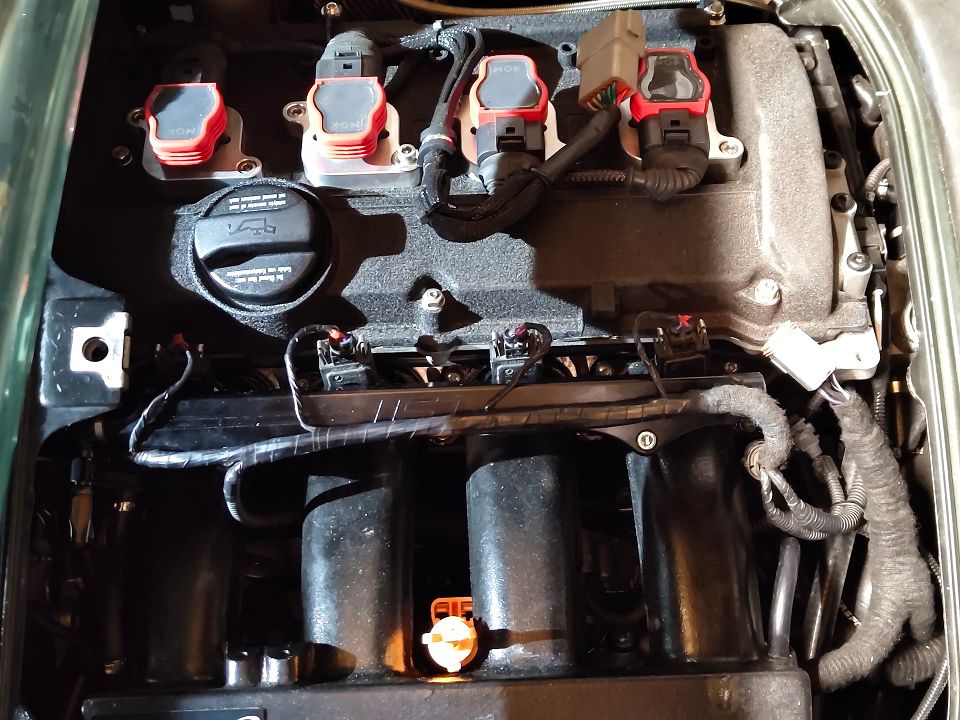

With the engine now a year old and a few thousand miles on it it's all weathered in quite nicely and looks fairly OEM in the bay now the shine has disapaeared from everything. There's a few witness marks on things from the various engine cover mods etc. and a few fasteners that I'd like to change to coated ones as they've gone a bit crusty but really I'm nit picking there.

It's now on Bilsteins as discussed earlier in this thread but thanks to getting distracted with the Cayenne and the Moroc Rally Raid I've done very little on the Booster since the start of last month.

I had a bit of time earlier so I finally fitted the billet aux water pump bracket and pulled off the old fuel lines and rail to replace it with the CTS one. The new rails is on -8 ORB fittings either end so I needed to get these round to 90 degree -6 to suit the required fuel line sizes.

First go clearly wasn't going to do the trick as we're way too close to the chassis at this, whilst it clears and won't touch in motion a mount failure or similar would result in it breaking the -6 90 off with all the bad stuff that would follow that so for the sake of FMEA alone I needed a nicer option.

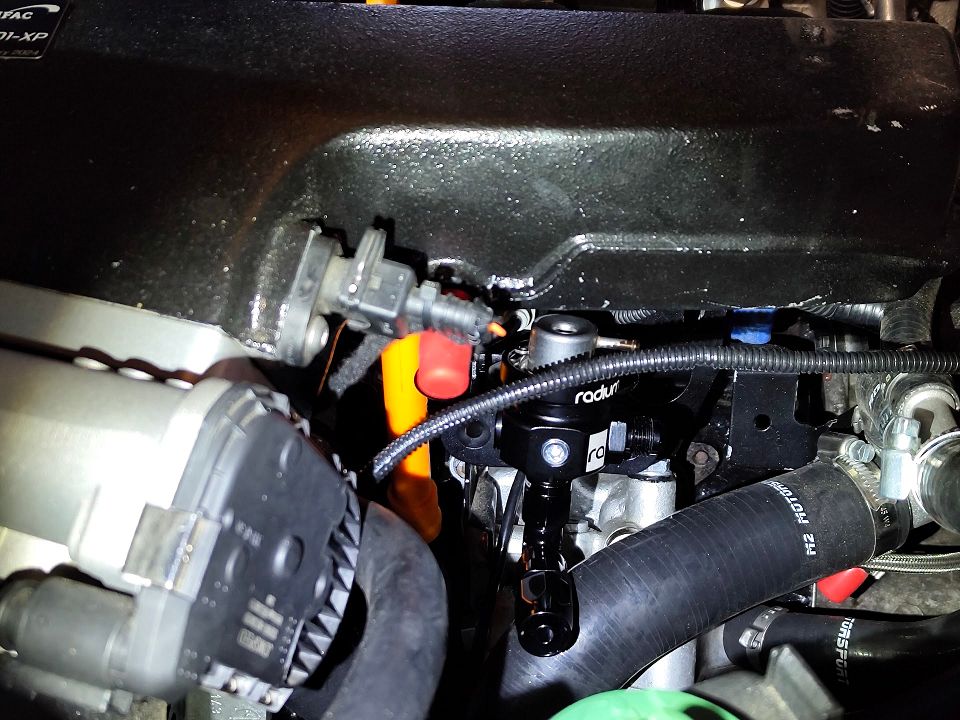

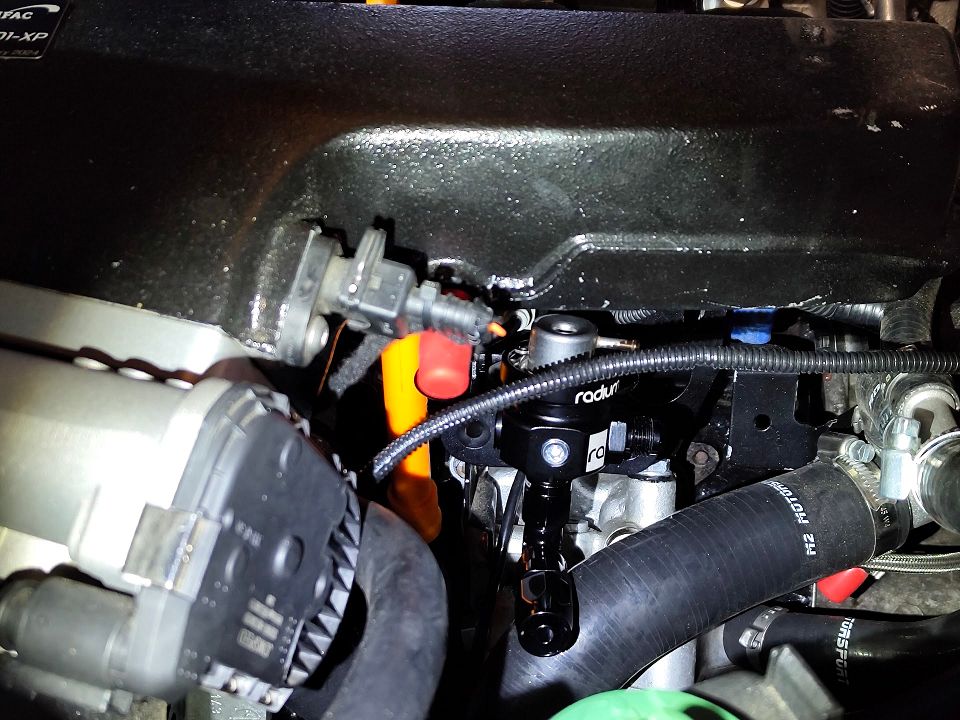

Luckily Radium make some lovely specialist fuel system bits including a low profile -8 ORB to 90 degree exit -6:

Much better:

Although Radium Shop have rather stitched me up by shipping a -6 ORB when two -8 were ordered:

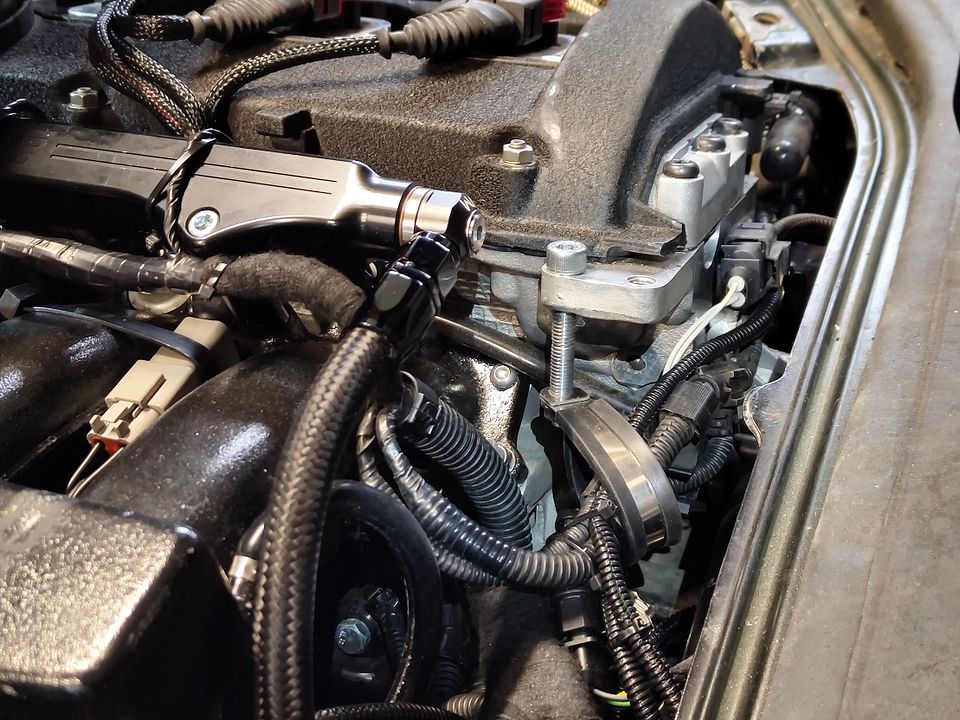

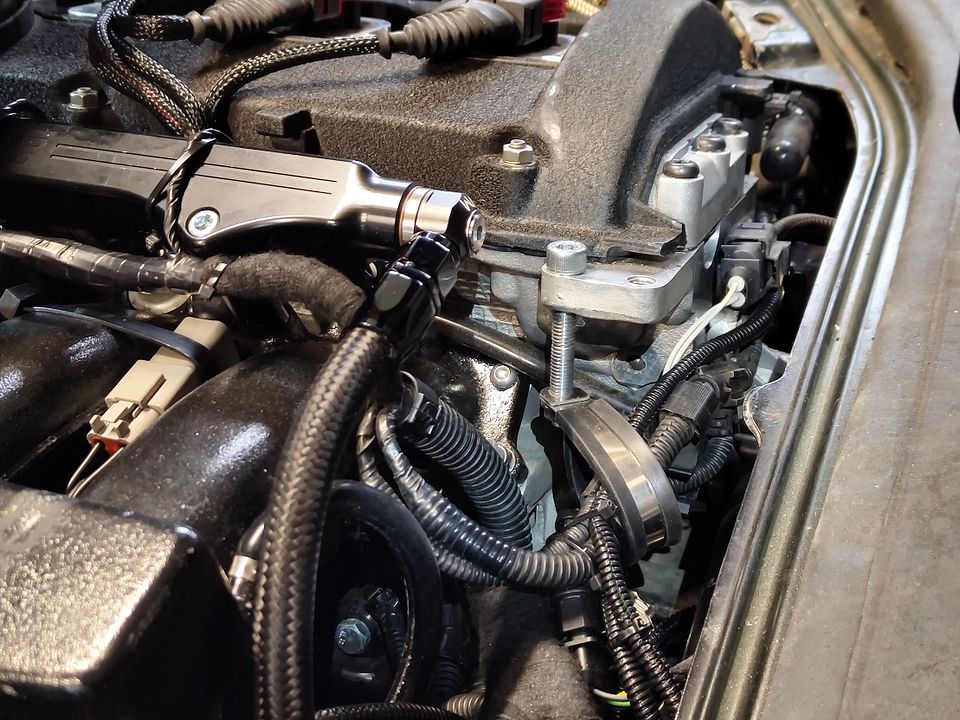

So not a lot more I can do with that until the new year. Still at least the rail looks good fitted:

Although I need to reroute the injector wiring loom to make it all package prettily.

The FPR packages nicely under the inlet manifold mounted off the sensor connector bracket that fits to the oil filter housing.

I'll make a nicer bracket for this rather than the one that came with the reg but for now this will do for making lines off. The lines will all be -6 from the original points on the chassis to the rail so a much more reliable and long term solution than what was on there originally. I've converted a standard fuel filter to -6 with a bolt on adaptor and the return side with a push fit to -6. Amazing what is off the shelf these days

The job list is pretty small once this is done, just a bolt check, service and once over and a quick pipe reroute to change how the oil cooler is fed coolant. It'll be back on the road in the new year ready to go to Centre Gravity for setup and then I'm looking forward to a summer of blatting about with the roof down making WRC noises.... not long until the sun is back out right?

Have a great Xmas all and here's to 2025.

It's done 3200 miles since I built it and has mostly behaved itself. There is still the odd random coolant leak but such is life when it's all silicone hoses and hose clips. Changing them all for constant tension clamps is not going to happen until the engine comes out in a couple of years time but aside from that not a lot to report.

We made the 400bhp "initial' target I had pretty easilly but a smaller / more modern turbo would move the boost threshold down and still give potential for 500bhp, which is the next development target.

With the engine now a year old and a few thousand miles on it it's all weathered in quite nicely and looks fairly OEM in the bay now the shine has disapaeared from everything. There's a few witness marks on things from the various engine cover mods etc. and a few fasteners that I'd like to change to coated ones as they've gone a bit crusty but really I'm nit picking there.

It's now on Bilsteins as discussed earlier in this thread but thanks to getting distracted with the Cayenne and the Moroc Rally Raid I've done very little on the Booster since the start of last month.

I had a bit of time earlier so I finally fitted the billet aux water pump bracket and pulled off the old fuel lines and rail to replace it with the CTS one. The new rails is on -8 ORB fittings either end so I needed to get these round to 90 degree -6 to suit the required fuel line sizes.

First go clearly wasn't going to do the trick as we're way too close to the chassis at this, whilst it clears and won't touch in motion a mount failure or similar would result in it breaking the -6 90 off with all the bad stuff that would follow that so for the sake of FMEA alone I needed a nicer option.

Luckily Radium make some lovely specialist fuel system bits including a low profile -8 ORB to 90 degree exit -6:

Much better:

Although Radium Shop have rather stitched me up by shipping a -6 ORB when two -8 were ordered:

So not a lot more I can do with that until the new year. Still at least the rail looks good fitted:

Although I need to reroute the injector wiring loom to make it all package prettily.

The FPR packages nicely under the inlet manifold mounted off the sensor connector bracket that fits to the oil filter housing.

I'll make a nicer bracket for this rather than the one that came with the reg but for now this will do for making lines off. The lines will all be -6 from the original points on the chassis to the rail so a much more reliable and long term solution than what was on there originally. I've converted a standard fuel filter to -6 with a bolt on adaptor and the return side with a push fit to -6. Amazing what is off the shelf these days

The job list is pretty small once this is done, just a bolt check, service and once over and a quick pipe reroute to change how the oil cooler is fed coolant. It'll be back on the road in the new year ready to go to Centre Gravity for setup and then I'm looking forward to a summer of blatting about with the roof down making WRC noises.... not long until the sun is back out right?

Have a great Xmas all and here's to 2025.

Well if the rain ever stops we're ready to go chase some GT3s again:

I finished the new fuel rail and lines setup off last week, this upgrade was partly for reliability, partly to improve clearance around the rear of the engine by allowing for relocation of the fuel pressure regulator and partly because AN fittings looks cool.

I've converted the fuel system to AN fittings from bulkhead rearwards so essentially everything chassis is original Porsche but everything in the engine bay is motorsporty AN fittings. I didn't want anything too bling so they're all black accordingly. The fuel filter posted a slight challenge but a special fitting got us there:

\

\

With that done and the missing Radium fitting finally showing up I bolted the rest of it up accordingly. The fuel line runs are as per standard when it gets to the sides of the bay and follow the same runs as the standard lines did.

I'm not 100% happy with the loom packaging on the rail. The rail is a very impressive bit of CNC machining but is needlessly detailed and over engineered / big which means the harness packaging is less than optimum... This is on the list to resolve but it may get done as part of a new engine harness as I quite fancy building a Type 44/ DR25 harness for it as some point. For now it's in the keep an eye on it bucket.

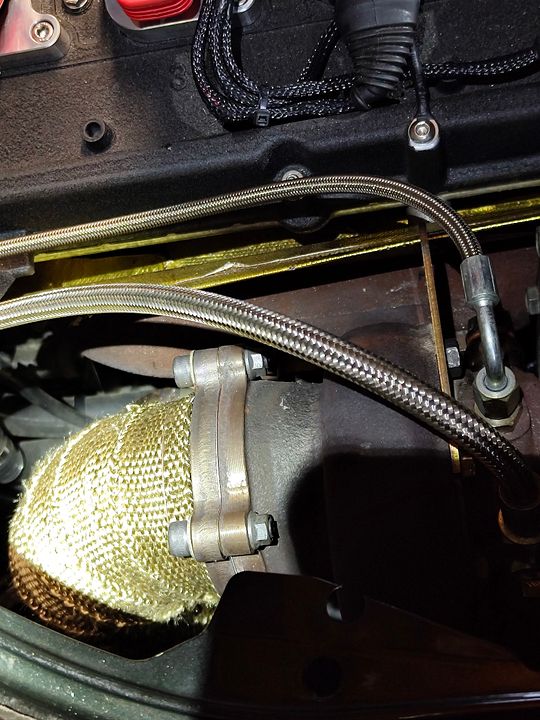

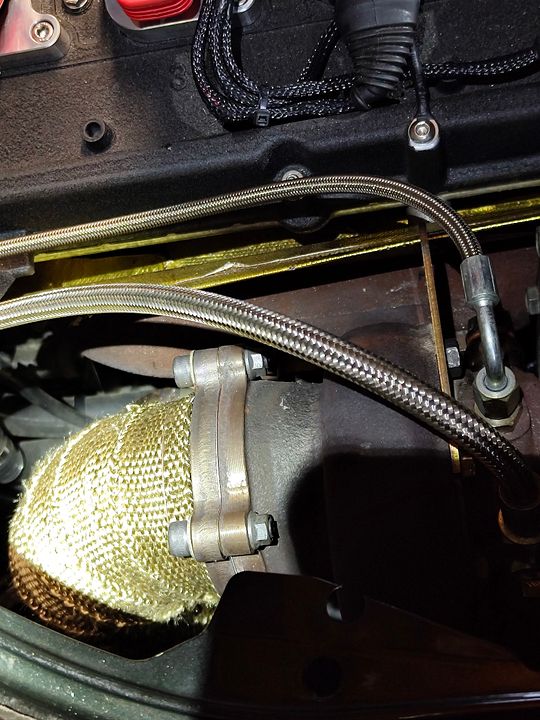

Speaking of things I'm not 100% happy with, I did a bit of a tidy up and reroute on the engine harness as having replumbed the coolant system around the oil cooler this had removed a few uneeded lines making more room round the back of the engine. The harness tidied up nicely but I needed a way to carry the harness round the back of the rocker cover. As such behold the M8 bolt turned down and threaded to M6 on the end to carry a P-clip:

This is a bit kit car even for me so I'll draw up a nice bracket that can be laser cut and folded to replace it, but for now it's good enough - at least the Radium fittings and posh braided line look good.... In the above pic you can also see a new DT12 connector between the manifold runners. This was another part of the loom tidy where I have made an extension to allow the coil wiring harness to run under the manifold. It's all a bit tidier but that's another 24 wiring terminations so another 24 failure points.... hence the desire to build a proper harness now.

- at least the Radium fittings and posh braided line look good.... In the above pic you can also see a new DT12 connector between the manifold runners. This was another part of the loom tidy where I have made an extension to allow the coil wiring harness to run under the manifold. It's all a bit tidier but that's another 24 wiring terminations so another 24 failure points.... hence the desire to build a proper harness now.

Aside from all that it's had a big service, all the usual bits and bobs as well as a decent spanner check. I have to say doing the plugs on this is so civilised now compared to the M96 that was in there

Nothing significant to report, the oil was in great condition with no debris, plugs looked good with no signs of bad stuff happening and (with the exception of one thing) aside from a few hose clips that wanted a nip up nothing has moved or creeped in the bay and no more witnessing visible than what had been created whilst we were testing.

I also gave the gearbox a birthday:

Several people have recommended I try this Liqui-Moly GL5 in the box as it's apparently very good. We'll see how it holds up! The oil that came out was debris free so the box doesn't seem to be complaining too much about having 300 odd ftlbs through it.

The one thing that was not behaving was the turbo and related which appeared keen to make it's own way off the engine. This isn't too surprising as the GT series bolted flange turbos were always a bit keen on this. We had a loose turbo to manifold bolt and a missing downpipe bolt. These things happen and there's a lot of thermal expansion going on there so to try and mitigate it I've gone to a set of OEM production BMW turbo bolts to pin the turbine housing to the manifold and extended the downpipe bolts to allow for fitting some k-nuts:

This ought to keep things in place until I get to the point of swapping the turbo machinery side of things out for a more modern option. On that point the plan is to get to 500bhp this year via a change in cam profile and the fitment of a G25-550 turbo of some description. The idea being that the more efficient turbo gets the power band / boost threshold down to offset that lost by the more aggresive cams.

Minimum accpetable power will be 480bhp, as at that it's the same power to weight ratio as Ferrari F40 so that'll do

I finished the new fuel rail and lines setup off last week, this upgrade was partly for reliability, partly to improve clearance around the rear of the engine by allowing for relocation of the fuel pressure regulator and partly because AN fittings looks cool.

I've converted the fuel system to AN fittings from bulkhead rearwards so essentially everything chassis is original Porsche but everything in the engine bay is motorsporty AN fittings. I didn't want anything too bling so they're all black accordingly. The fuel filter posted a slight challenge but a special fitting got us there:

\

\With that done and the missing Radium fitting finally showing up I bolted the rest of it up accordingly. The fuel line runs are as per standard when it gets to the sides of the bay and follow the same runs as the standard lines did.

I'm not 100% happy with the loom packaging on the rail. The rail is a very impressive bit of CNC machining but is needlessly detailed and over engineered / big which means the harness packaging is less than optimum... This is on the list to resolve but it may get done as part of a new engine harness as I quite fancy building a Type 44/ DR25 harness for it as some point. For now it's in the keep an eye on it bucket.

Speaking of things I'm not 100% happy with, I did a bit of a tidy up and reroute on the engine harness as having replumbed the coolant system around the oil cooler this had removed a few uneeded lines making more room round the back of the engine. The harness tidied up nicely but I needed a way to carry the harness round the back of the rocker cover. As such behold the M8 bolt turned down and threaded to M6 on the end to carry a P-clip:

This is a bit kit car even for me so I'll draw up a nice bracket that can be laser cut and folded to replace it, but for now it's good enough

- at least the Radium fittings and posh braided line look good.... In the above pic you can also see a new DT12 connector between the manifold runners. This was another part of the loom tidy where I have made an extension to allow the coil wiring harness to run under the manifold. It's all a bit tidier but that's another 24 wiring terminations so another 24 failure points.... hence the desire to build a proper harness now.

- at least the Radium fittings and posh braided line look good.... In the above pic you can also see a new DT12 connector between the manifold runners. This was another part of the loom tidy where I have made an extension to allow the coil wiring harness to run under the manifold. It's all a bit tidier but that's another 24 wiring terminations so another 24 failure points.... hence the desire to build a proper harness now. Aside from all that it's had a big service, all the usual bits and bobs as well as a decent spanner check. I have to say doing the plugs on this is so civilised now compared to the M96 that was in there

Nothing significant to report, the oil was in great condition with no debris, plugs looked good with no signs of bad stuff happening and (with the exception of one thing) aside from a few hose clips that wanted a nip up nothing has moved or creeped in the bay and no more witnessing visible than what had been created whilst we were testing.

I also gave the gearbox a birthday:

Several people have recommended I try this Liqui-Moly GL5 in the box as it's apparently very good. We'll see how it holds up! The oil that came out was debris free so the box doesn't seem to be complaining too much about having 300 odd ftlbs through it.

The one thing that was not behaving was the turbo and related which appeared keen to make it's own way off the engine. This isn't too surprising as the GT series bolted flange turbos were always a bit keen on this. We had a loose turbo to manifold bolt and a missing downpipe bolt. These things happen and there's a lot of thermal expansion going on there so to try and mitigate it I've gone to a set of OEM production BMW turbo bolts to pin the turbine housing to the manifold and extended the downpipe bolts to allow for fitting some k-nuts:

This ought to keep things in place until I get to the point of swapping the turbo machinery side of things out for a more modern option. On that point the plan is to get to 500bhp this year via a change in cam profile and the fitment of a G25-550 turbo of some description. The idea being that the more efficient turbo gets the power band / boost threshold down to offset that lost by the more aggresive cams.

Minimum accpetable power will be 480bhp, as at that it's the same power to weight ratio as Ferrari F40 so that'll do

Oooh it’s my favourite game. Find the perfect conversion candidate.

https://www.ebay.co.uk/itm/186945548015?mkcid=16&a...

https://www.ebay.co.uk/itm/186945548015?mkcid=16&a...

Edited by eltax91 on Thursday 20th February 07:46

eltax91 said:

Oooh it’s my favourite game. Find the perfect conversion candidate.

https://www.ebay.co.uk/itm/186945548015

I thought you really need one of the early 2.5 for Booster'ing?

https://www.ebay.co.uk/itm/186945548015

ATM said:

I thought you really need one of the early 2.5 for Booster'ing?

2.5L or 2000MY 2.7. Both of these are suitable as they have the K01 dash pack. The 2.7 is e-gas as standard but there is now a nice adaptor box to make converting the chassis side connectors easy.

Edited by poppopbangbang on Thursday 20th February 11:23

ATM said:

So would this control the old school throttle cable?

No all Booster spec cars are drive by wire. The e-gas cars use a later ECU which has more chassis integration at the ECU connectors. To retain a standard and unmodified chassis loom this box splits out the required IO onto DTMs so it's just a case of crimping the mating DTM halves onto the ME 7.5 VW/Audi engine loom and plugging it in. ATM said:

eltax91 said:

Oooh it’s my favourite game. Find the perfect conversion candidate.

https://www.ebay.co.uk/itm/186945548015

I thought you really need one of the early 2.5 for Booster'ing?

https://www.ebay.co.uk/itm/186945548015

poppopbangbang said:

ATM said:

I thought you really need one of the early 2.5 for Booster'ing?

2.5L or 2000MY 2.7. Both of these are suitable as they have the K01 dash pack. The 2.7 is e-gas as standard but there is now a nice adaptor box to make converting the chassis side connectors easy.

Edited by poppopbangbang on Thursday 20th February 11:23

Megaflow said:

I think this has been asked already, but I have forgotten and can't find it, what makes 2001MY onwards not suitable?

Two main things, the first is that the electronics package changed significantly from 2001 onwards making more use of CANBus and complex dash pack elements. I have already reverse engineered the CANBus for 996 and 997 but the integration element becomes more complex and the ability to break the functional safety of the ABS etc. starts to rear its head. The second is that the rules around type approved catalytics systems apply from March 2001 onwards. Anything before this just has to meet or exceed the performance of the original system. Anything afterwards must be type approved / homologated for the vehicle. There isn't a homologated cat for a 20V in a Boxster.

poppopbangbang said:

Megaflow said:

I think this has been asked already, but I have forgotten and can't find it, what makes 2001MY onwards not suitable?

Two main things, the first is that the electronics package changed significantly from 2001 onwards making more use of CANBus and complex dash pack elements. I have already reverse engineered the CANBus for 996 and 997 but the integration element becomes more complex and the ability to break the functional safety of the ABS etc. starts to rear its head. The second is that the rules around type approved catalytics systems apply from March 2001 onwards. Anything before this just has to meet or exceed the performance of the original system. Anything afterwards must be type approved / homologated for the vehicle. There isn't a homologated cat for a 20V in a Boxster.

Thank you!

Megaflow said:

poppopbangbang said:

Megaflow said:

I think this has been asked already, but I have forgotten and can't find it, what makes 2001MY onwards not suitable?

Two main things, the first is that the electronics package changed significantly from 2001 onwards making more use of CANBus and complex dash pack elements. I have already reverse engineered the CANBus for 996 and 997 but the integration element becomes more complex and the ability to break the functional safety of the ABS etc. starts to rear its head. The second is that the rules around type approved catalytics systems apply from March 2001 onwards. Anything before this just has to meet or exceed the performance of the original system. Anything afterwards must be type approved / homologated for the vehicle. There isn't a homologated cat for a 20V in a Boxster.

Thank you!

Bright Halo said:

Does anyone actually check that post March 2001 cars have a type approved cat? MOT stations certainly do not and I would have thought it past old bill level of knowledge/expertise to know what to check. Is the risk there but incredibly low?

Yes, but we’re talking about someone selling a niche kit here to fit said engine to said car. So he can’t very well advertise it for use in these circumstances….If someone were to buy it without reading that detail and go ahead and fit it, well then that’s on them isn’t it?

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff