BMW 635CSi Restomod

Discussion

My plan of action after finishing the welding was to get the car on its wheels so I primed and raptor coated the wheel tubs, the underside of the car has already been done

Next up was to strengthen the diff mount, the diff bolts to a cross member from underneath with captive nuts so I decided to add strength by utilising the upper surface which happens to be part of the boot floor. I did this by drilling up through the original fixings and then making the upper holes large enough to drop some steel tubes in which were then welded in place. The whole lot was then capped with a 3mm steel plate. The idea is to bolt through from the top all the way through the original captive nuts and then use nuts over the protruding bolts which are now acting as studs.

The differential was sent away and the ratio was increased to 3.64 from 3.07 which should improve acceleration somewhat and at the same time the lock was increased to 40% instead of 25%. The rear axle was then built up using poly bushes and then fitted to the car

After this the engine bay and the boot were prepped and painted in Alpine White and gold foil applied to the bulkhead.

Once the boot was painted I fitted the bolts and secured the diff properly.

Next up was to strengthen the diff mount, the diff bolts to a cross member from underneath with captive nuts so I decided to add strength by utilising the upper surface which happens to be part of the boot floor. I did this by drilling up through the original fixings and then making the upper holes large enough to drop some steel tubes in which were then welded in place. The whole lot was then capped with a 3mm steel plate. The idea is to bolt through from the top all the way through the original captive nuts and then use nuts over the protruding bolts which are now acting as studs.

The differential was sent away and the ratio was increased to 3.64 from 3.07 which should improve acceleration somewhat and at the same time the lock was increased to 40% instead of 25%. The rear axle was then built up using poly bushes and then fitted to the car

After this the engine bay and the boot were prepped and painted in Alpine White and gold foil applied to the bulkhead.

Once the boot was painted I fitted the bolts and secured the diff properly.

Just caught up on the last month or so of uploads, what a cracking, cracking job OP-superb work.

I’m mid way through a mini restoration of my GT3 and I’m so glad I found one with no rust in it.

It’s easy to cut corners when you’re deep in the mire, a couple of times I’ve bolted things back up before undoing them the next day because I knew what I’d done wasn’t exactly perfect.

Once you’re in, you’re IN!

I’m mid way through a mini restoration of my GT3 and I’m so glad I found one with no rust in it.

It’s easy to cut corners when you’re deep in the mire, a couple of times I’ve bolted things back up before undoing them the next day because I knew what I’d done wasn’t exactly perfect.

Once you’re in, you’re IN!

Stick Legs said:

Speaking from experience, having had to weld a diff mount back into the boot floor of an E24, this is very wise.

My old e9 was the same, in fact the subframe used to crack on that till I got sick of welding it and took it out and strengthened it.The e24 subframe was also strengthened but I didn't get any photos of that.

Bought some bits for the car to cheer myself up a bit plus it's close enough to Christmas to call thema present to myself.

First up and H&R anti roll bar kit 30mm front and 25mm rear

Next up a tunnel mounted quick shift

I also ordered a staggered set of 2Forge 18"alloys 9J front and 10J rear, I also ordered a set of Nankang NS2R tyres. I really wanted a set of the new CRS tyres but couldn't run to those with all the other purchases

I also ordered a few other bits but I'm having to wait for them to be manufactured.

For no particular reason I decided to mount the brake and clutch fluid reservoirs and plumb them in. I decided to use bulkhead fittings rather than pass the pipe itself through the bulkhead as it is much easier to keep everything nice and neat

After this I moved onto the boot floor.

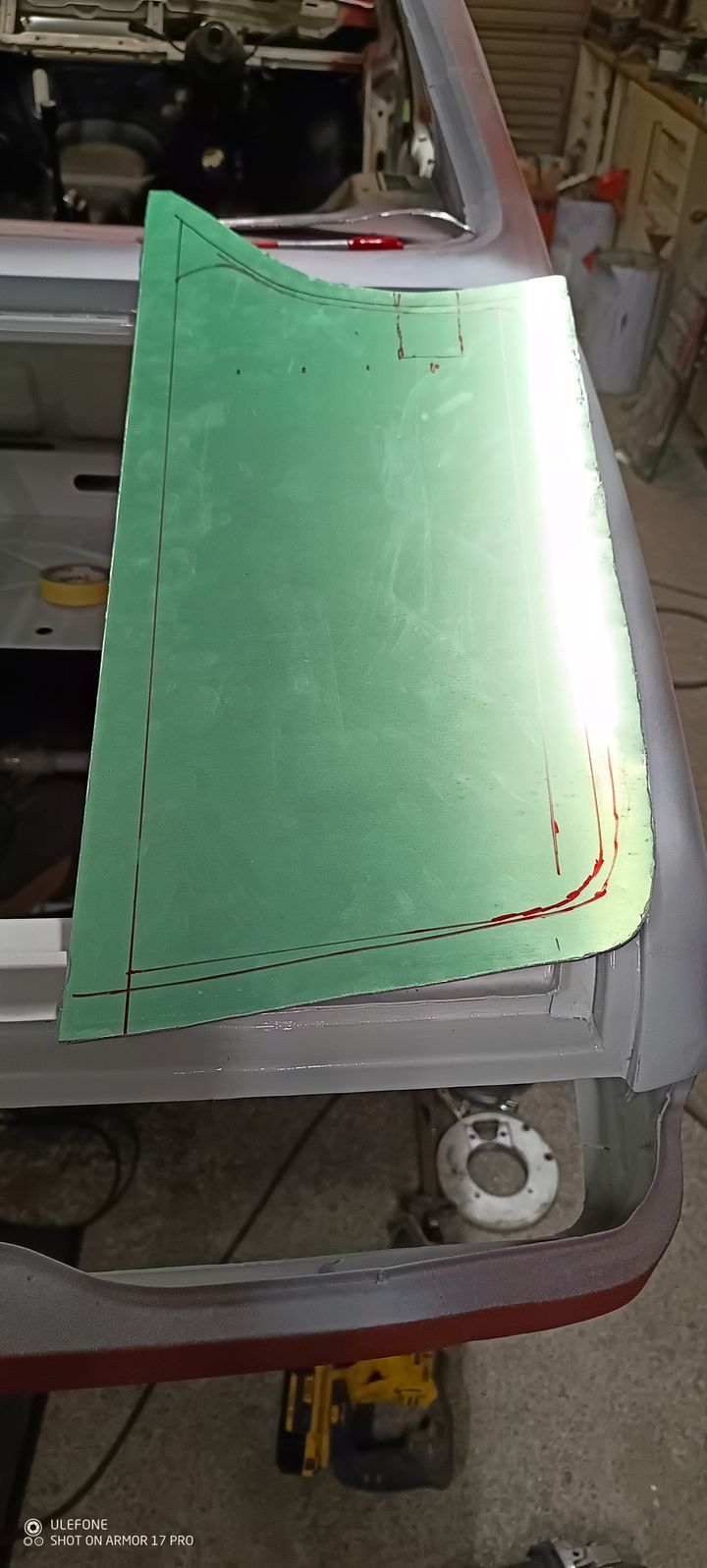

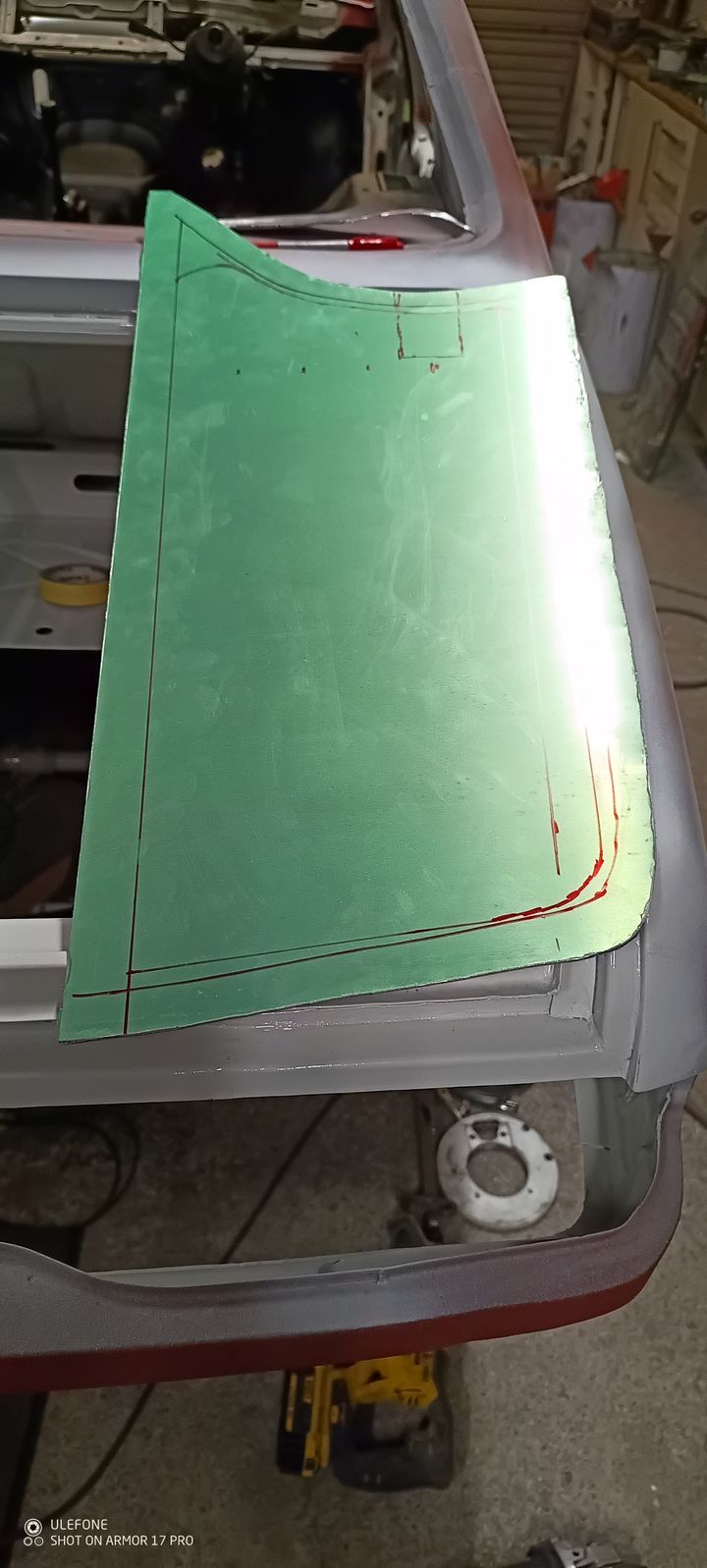

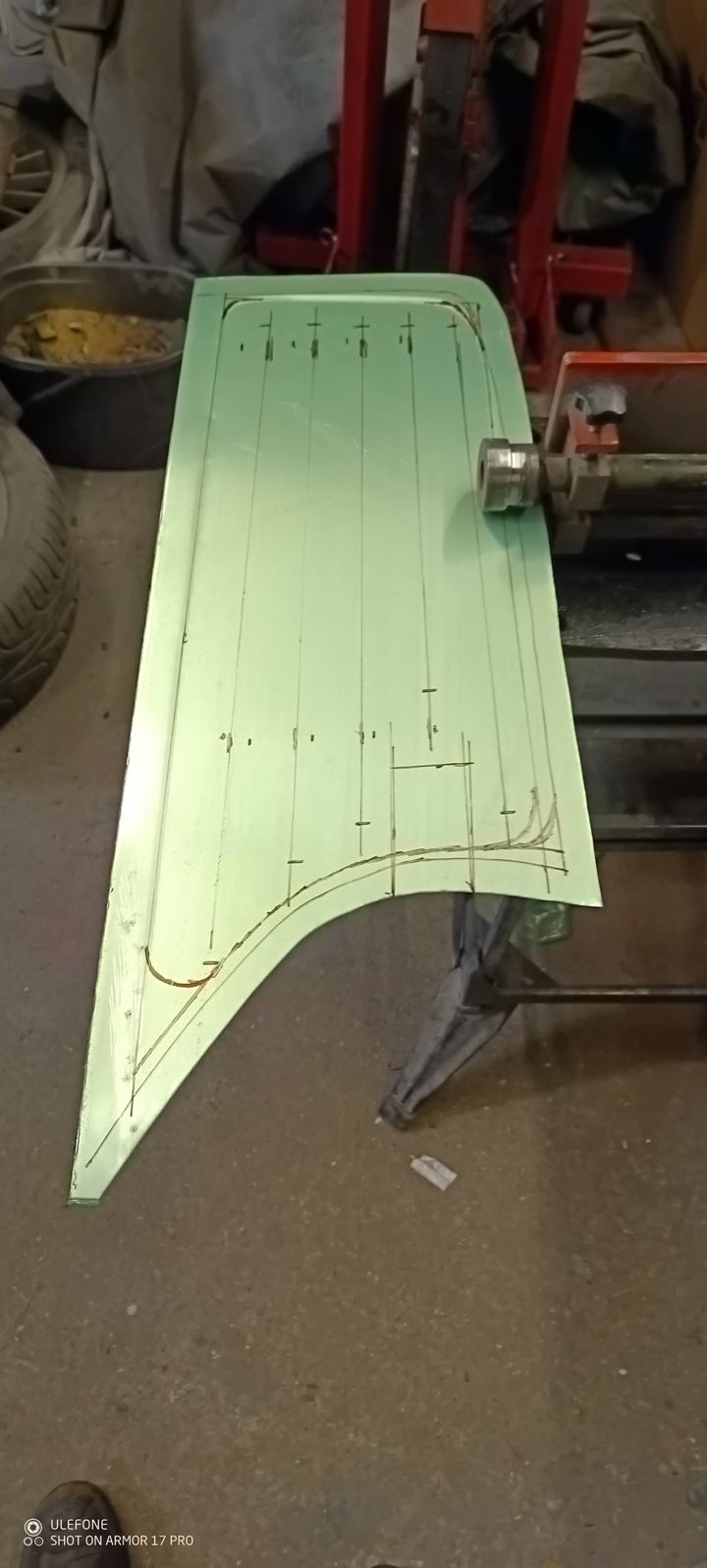

As I am trying to make the car as light a possible with the exception of some interior trim I decided to make the boot floor from aluminium. I had always planned to make a deeper than original boot floor so that I could put the fuel tank inside the boot with the ultimate aim being to make the underside as smooth as possible to reduce drag and also increase down force more on that later in the build. After the individual pieces were made they were fixed using a combination of glue and rivets.

[url]

[url]

|https://forums-images.pistonheads.com/85136/202412227949848[/url]

|https://forums-images.pistonheads.com/85136/202412227949848[/url]

Next up is to make some top hat sections to make the floor more rigid and to give me something to sit the fuel tank on and then mount the fuel tank.

First up and H&R anti roll bar kit 30mm front and 25mm rear

Next up a tunnel mounted quick shift

I also ordered a staggered set of 2Forge 18"alloys 9J front and 10J rear, I also ordered a set of Nankang NS2R tyres. I really wanted a set of the new CRS tyres but couldn't run to those with all the other purchases

I also ordered a few other bits but I'm having to wait for them to be manufactured.

For no particular reason I decided to mount the brake and clutch fluid reservoirs and plumb them in. I decided to use bulkhead fittings rather than pass the pipe itself through the bulkhead as it is much easier to keep everything nice and neat

After this I moved onto the boot floor.

As I am trying to make the car as light a possible with the exception of some interior trim I decided to make the boot floor from aluminium. I had always planned to make a deeper than original boot floor so that I could put the fuel tank inside the boot with the ultimate aim being to make the underside as smooth as possible to reduce drag and also increase down force more on that later in the build. After the individual pieces were made they were fixed using a combination of glue and rivets.

Next up is to make some top hat sections to make the floor more rigid and to give me something to sit the fuel tank on and then mount the fuel tank.

Edited by gazzol on Sunday 22 December 22:22

Edited by gazzol on Sunday 22 December 22:25

Gorilla Bloke said:

Thats some stunning tin-bashing work!

Takes me back to my poor attempts during sheet metal units in my apprenticeship to really appreciate the skill involved

Thanks I'm pleased with how it's turned out but it's all pretty basic stuff really and my skill level isn't that great. I watch a lot of YouTube videos of really skilled sheep metal workers making whole panels and in some cases whole car bodies and I am completely in awe of their abilities.Takes me back to my poor attempts during sheet metal units in my apprenticeship to really appreciate the skill involved

Fabulous and some top notch fabrication.

I’ve been repairing some fibreglass damage on my Elise over Christmas and adding some aluminium bracing to stop it happening again. It’s stuff that’s hidden when the car is together so while I’ve taken care it’s far from perfect cosmetically. This metal work makes my efforts look like a monkey hurling s t at a wall.

t at a wall.

I’ve been repairing some fibreglass damage on my Elise over Christmas and adding some aluminium bracing to stop it happening again. It’s stuff that’s hidden when the car is together so while I’ve taken care it’s far from perfect cosmetically. This metal work makes my efforts look like a monkey hurling s

t at a wall.

t at a wall.gazzol said:

Thanks I'm pleased with how it's turned out but it's all pretty basic stuff really and my skill level isn't that great. I watch a lot of YouTube videos of really skilled sheep metal workers making whole panels and in some cases whole car bodies and I am completely in awe of their abilities.

Basic to you perhaps, but that boot looks amazing, give yourself some credit man

gazzol said:

Gorilla Bloke said:

Thats some stunning tin-bashing work!

Takes me back to my poor attempts during sheet metal units in my apprenticeship to really appreciate the skill involved

Thanks I'm pleased with how it's turned out but it's all pretty basic stuff really and my skill level isn't that great. I watch a lot of YouTube videos of really skilled sheep metal workers making whole panels and in some cases whole car bodies and I am completely in awe of their abilities.Takes me back to my poor attempts during sheet metal units in my apprenticeship to really appreciate the skill involved

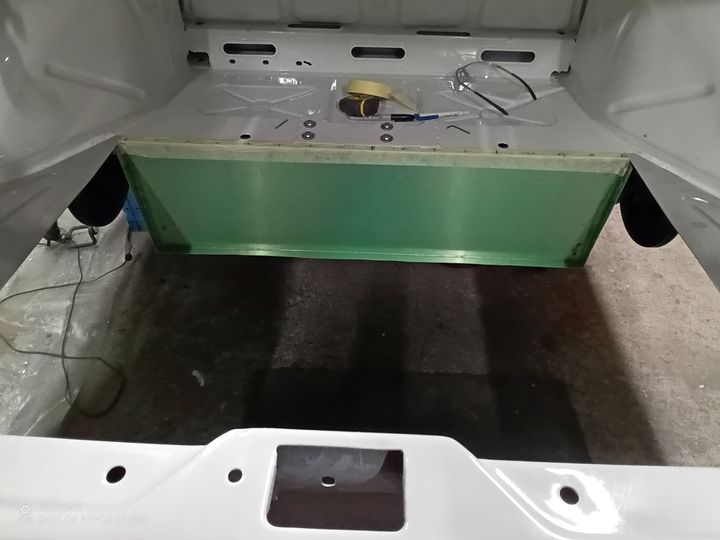

Small update, I folded up some top hat sections in aluminium and bonded them to the boot floor. This will make the floor more rigid and gives me something to mount the fuel tank on. Once the glue had set I measured up, fitted some rivnuts and mounted the fuel tank using rubber between the tank and any contact points.

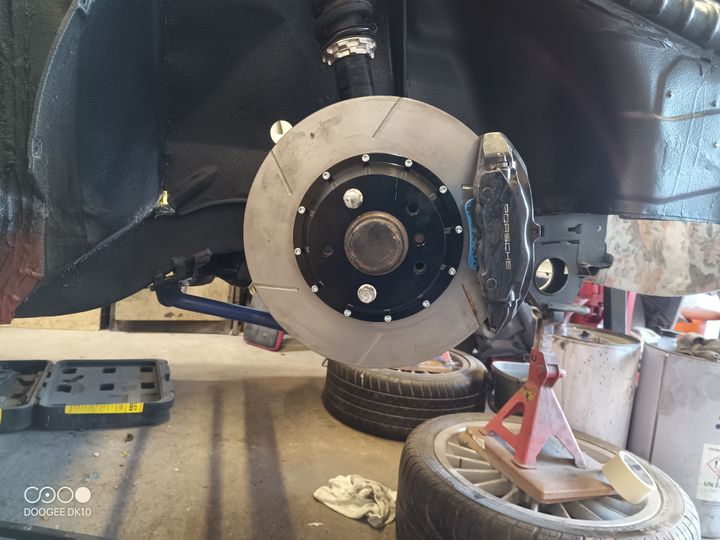

Next up was to mount the Brembo 4 pot brake calipers that i already had. Unfortunately I couldn't use the discs that I already had (300mm rear and 320mm front) because when I trial fitted the calipers with the discs fitted to the car the calipers were touching the original mounting lugs. To clarify, the original brakes used lug mount and the Porsche calipers I have are radial mount so in order to use the calipers there needs to be a gap between the two mounting points to leave room for an adapter bracket and I didn't have a gap so I had to go even bigger on the discs if I wanted to use the Brembo calipers. I ended up with 320mm in the rear and a huge 350mm in the front which is far bigger than a car of this weight really needs but this is where I am. I made some adaptor brackets from steel and painted them.

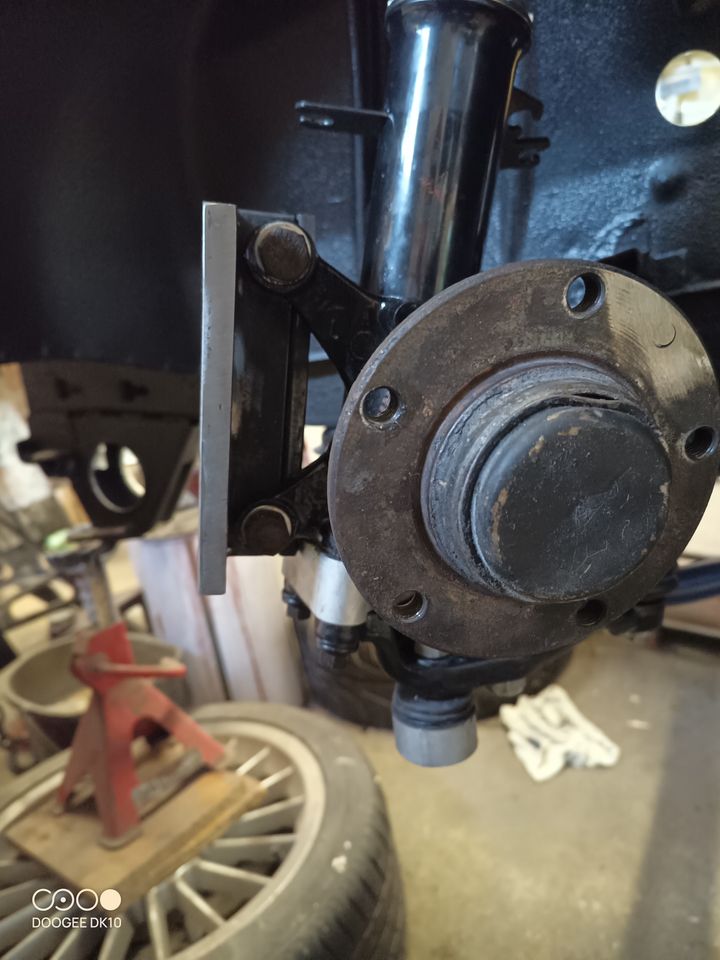

I bought some bump steer/roll centre correctors which came with extended bolts by ARP the only problem was the hub was threaded M10 and the bolts were M12, no problem I thought I'll just re-drill any tap the hubs, easier said than done. I don't know what grade of steel these hubs are made from but man they were hard, they were the most difficult thing I've ever had to tap each hole took 10-15 minutes to tap and there was only 10-12mm to cut through. In the last photo you can see how much I had to tap through as a guide the spacer is 30mm thick.

Next up was to mount the Brembo 4 pot brake calipers that i already had. Unfortunately I couldn't use the discs that I already had (300mm rear and 320mm front) because when I trial fitted the calipers with the discs fitted to the car the calipers were touching the original mounting lugs. To clarify, the original brakes used lug mount and the Porsche calipers I have are radial mount so in order to use the calipers there needs to be a gap between the two mounting points to leave room for an adapter bracket and I didn't have a gap so I had to go even bigger on the discs if I wanted to use the Brembo calipers. I ended up with 320mm in the rear and a huge 350mm in the front which is far bigger than a car of this weight really needs but this is where I am. I made some adaptor brackets from steel and painted them.

I bought some bump steer/roll centre correctors which came with extended bolts by ARP the only problem was the hub was threaded M10 and the bolts were M12, no problem I thought I'll just re-drill any tap the hubs, easier said than done. I don't know what grade of steel these hubs are made from but man they were hard, they were the most difficult thing I've ever had to tap each hole took 10-15 minutes to tap and there was only 10-12mm to cut through. In the last photo you can see how much I had to tap through as a guide the spacer is 30mm thick.

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff