500+bhp Mk3 Fiesta Project

Discussion

This project started out as a £400 track car with a 2.0 conversion but has ended up as a full restoration and big power build.

The first post will be a copy & paste from another forum but I will continue to update this thread:

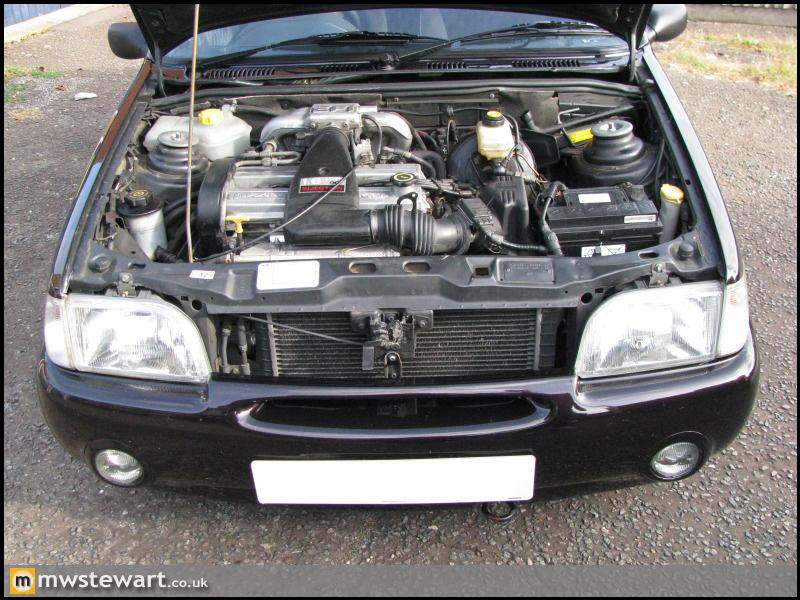

A few snippets from the Mk3 project I'm working on. Another distraction from the Quattro! I should have this one 'out the door' over Easter.

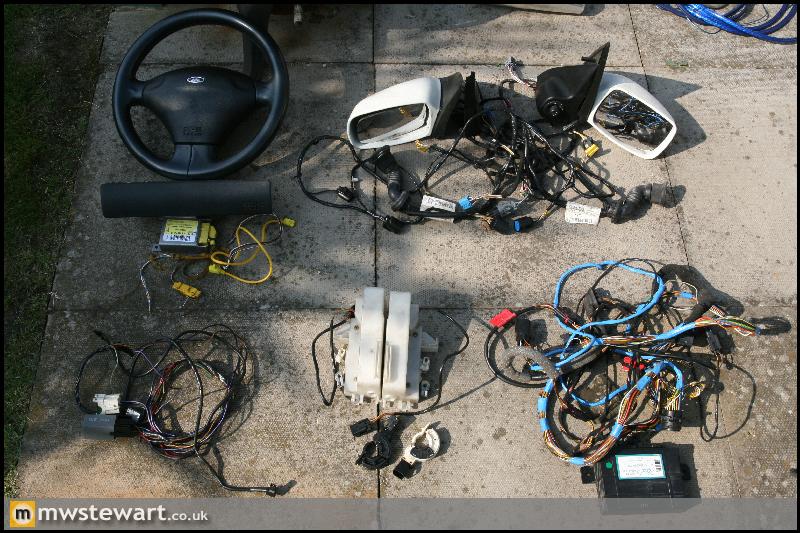

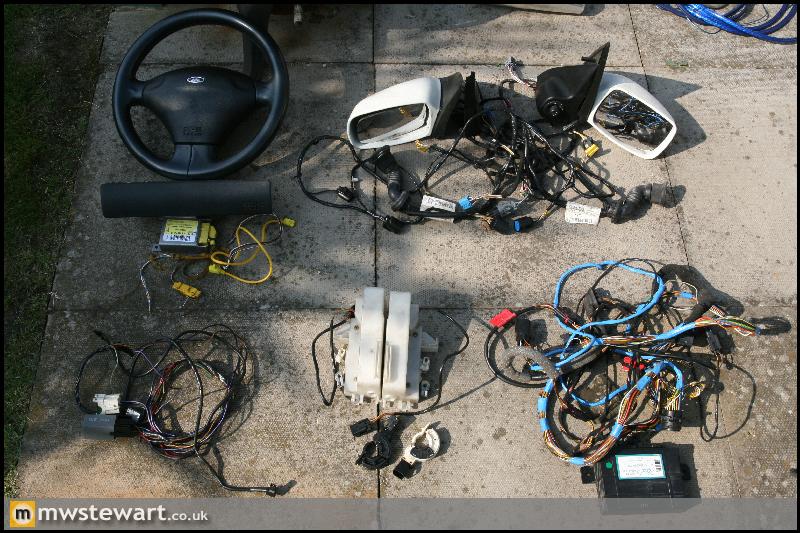

£1k worth of new Ford bits so far to get it to my standard. I want to improve all the driver interfaces and make sure the car feels & drives as optimally as possible for the spec. A few of the parts that have gone on:

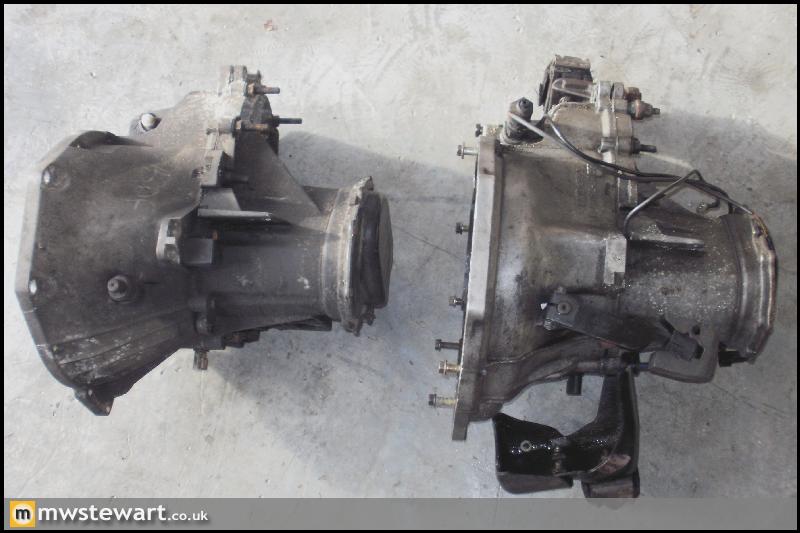

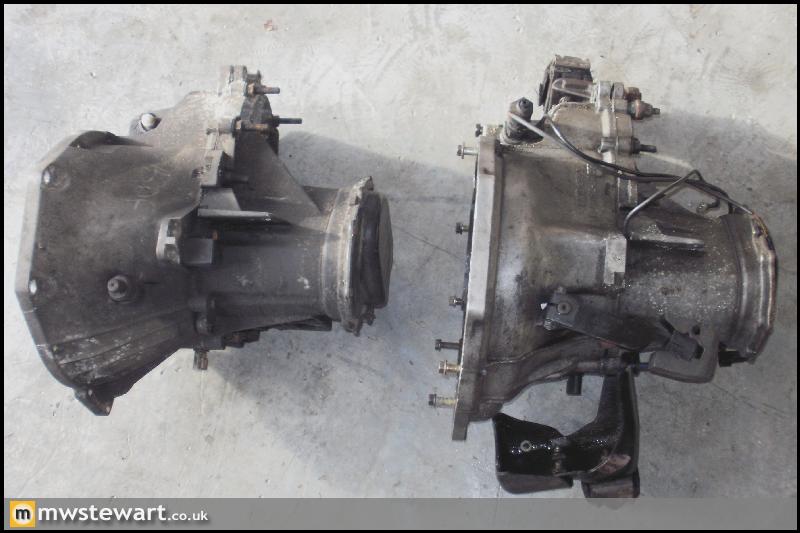

Low mileage Escort 1.8 Zetec iB5 (left). Non-Si/Gti for higher ratios.

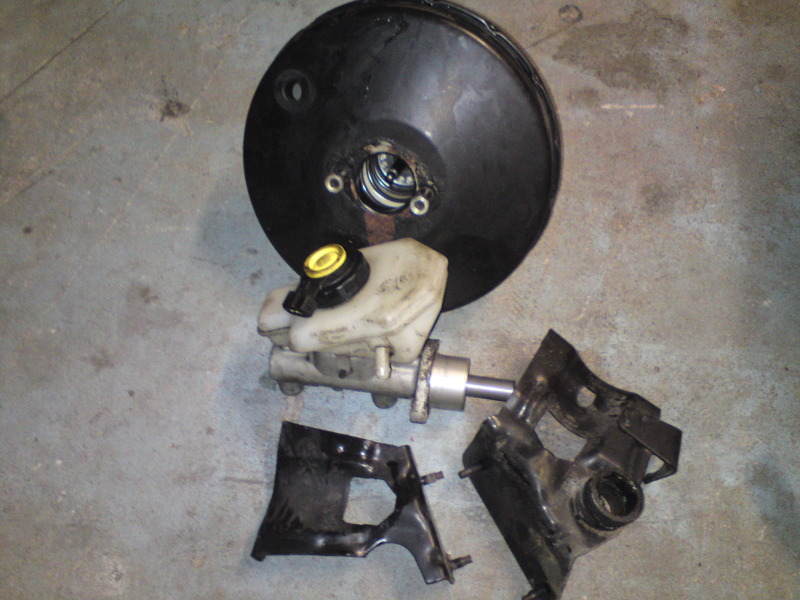

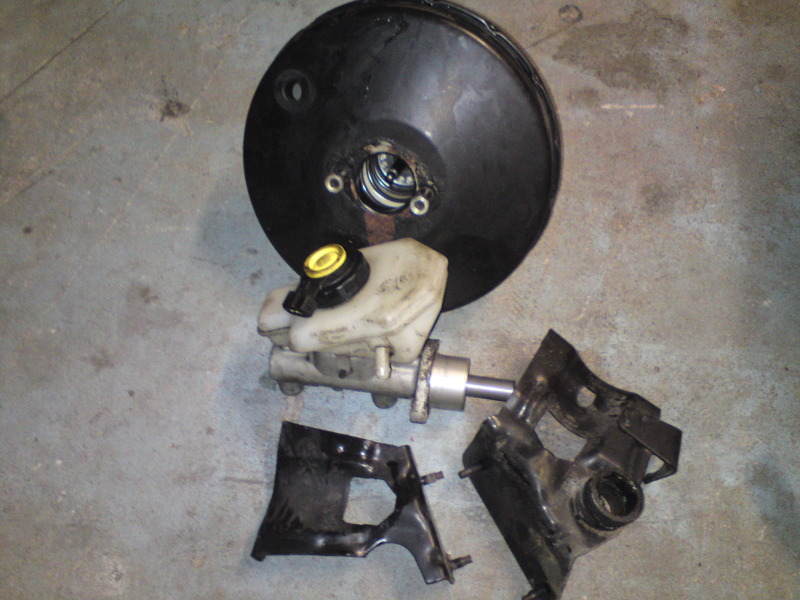

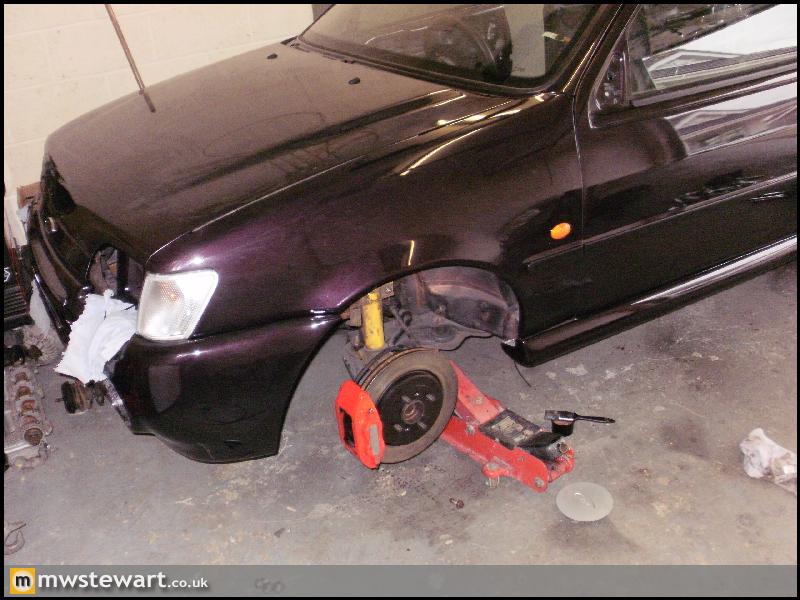

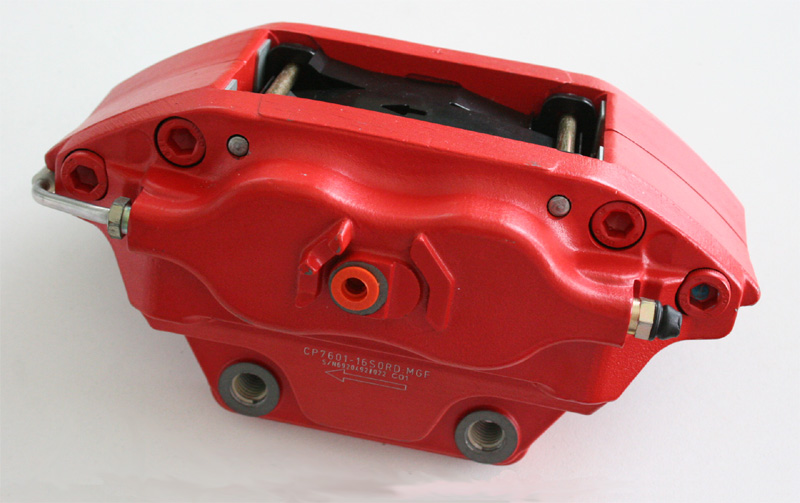

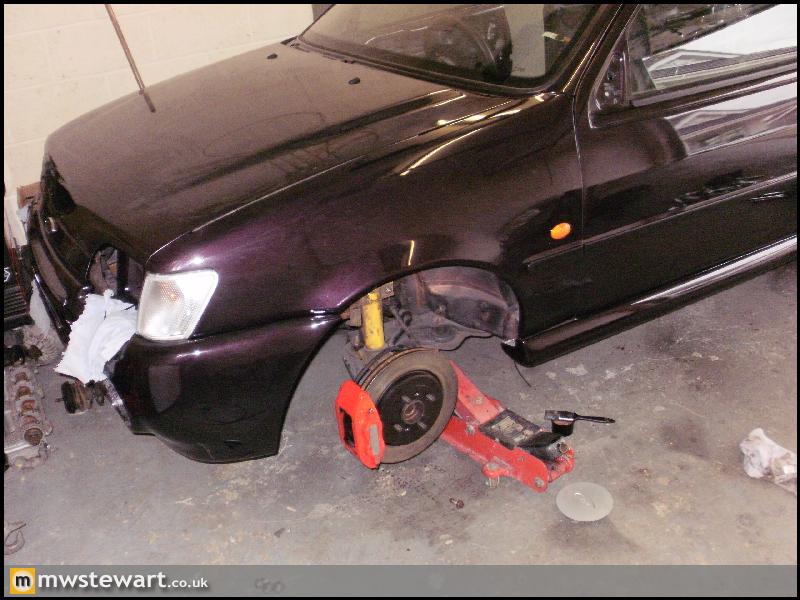

Mk7 Fiesta Brakes and Mk2 Mondeo Servo/MC. My brief is 14" wheels and good brakes, Mk7 brakes are 260mm but have the largest pistons yet used by Ford on this size.

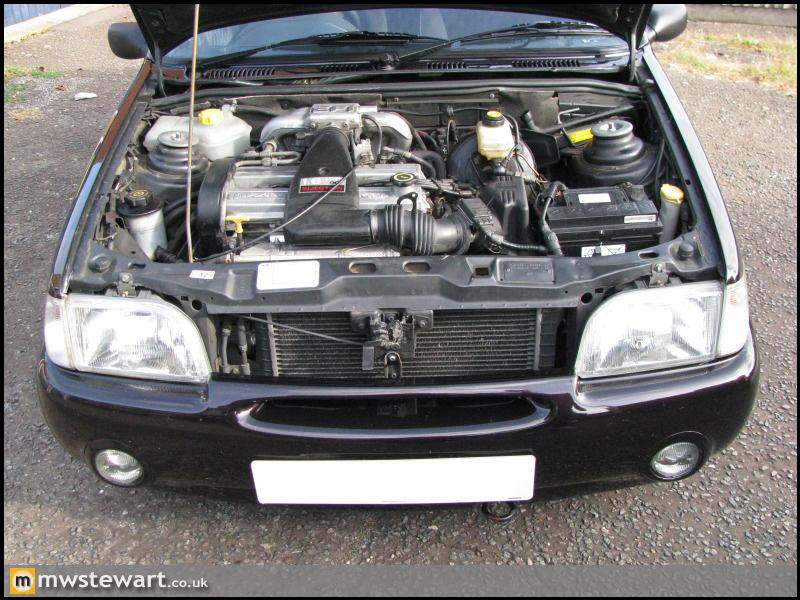

HO

Changing Petrol 5th for Diesel 5th. I gave up trying to find a 5th gear puller, so fabricated my own.

Diesel 5th vs 1800 Zetec 5th

Done

Shafts rebuilt, all gen. Ford - although I'm about to do away with standard O/S and fit something different.

Puma linkage. Did this 10 years ago and is still one of my favourite mods on the Mk3.

ST170 manifold and Saab downpipe.

Lambda relocated to just before cat, and cat entrance area shortened by 2".

Bosses added for standard shield etc. Looks standard:

Rebuilding Recaros. I bought several interiors to get a pair of superb seats. I reset side bolster supports to original position etc.

More to come when I have time to write it up properly.

Here it is. 61K and Full Service History, all old Bills, MOTs etc. There was a mark on the tailgate and bonnet but I've replaced both since these photos.

Ford gearboxes

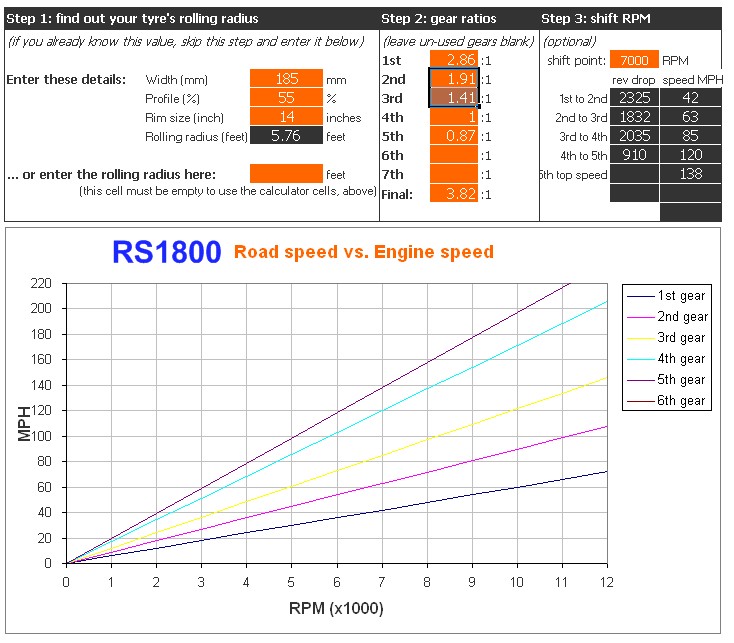

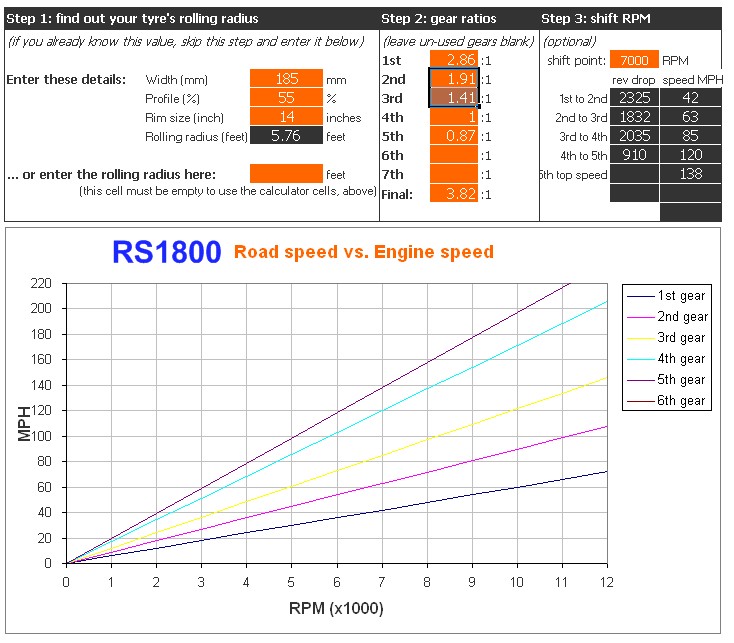

The Petrol 1800 5th is mismatched for the 2.0 so I plotted the gear/speed graphs:

RS1800 gearbox:

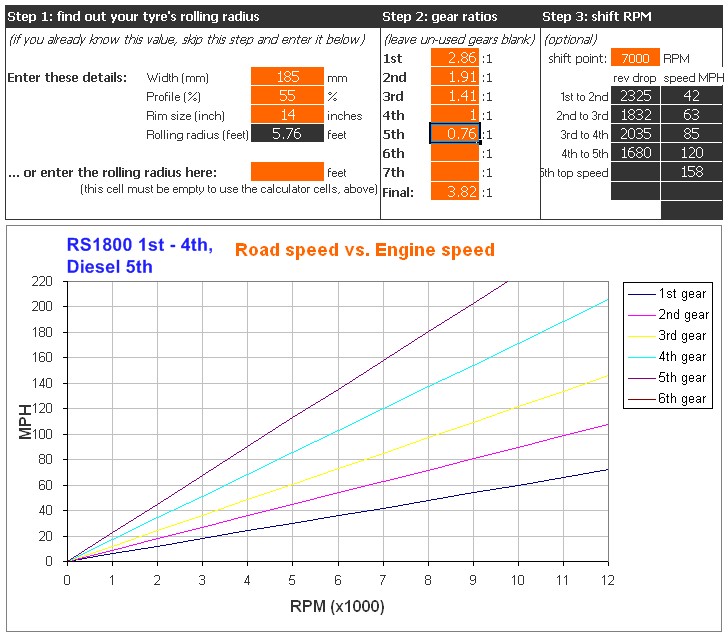

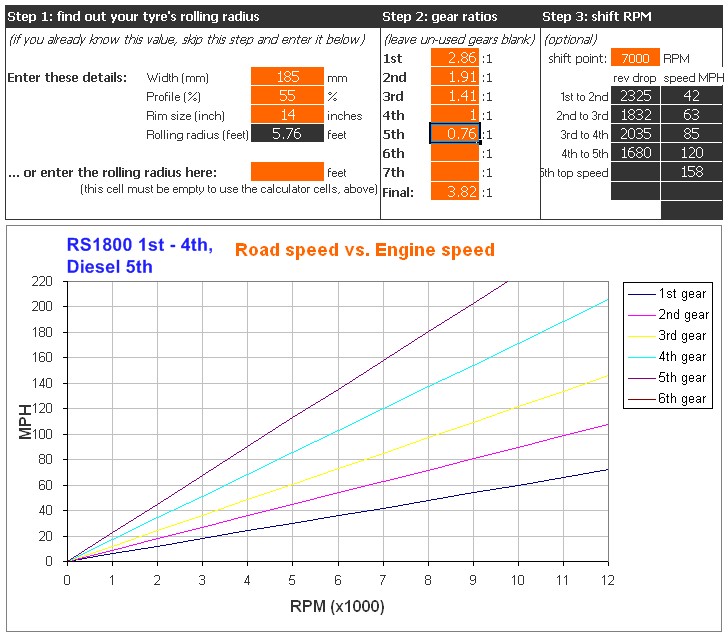

Rebuilt with Diesel 5th:

You can see on the RS1800 graph just how short the 5th is, this is to negate the lack of torque from the 1800 engine. The 2.0 can cope with much more than the 0.87:1 5th.

Adding the 0.76:1 5th gives a nice spread of ratios without too much rev drop between 4th-5th.

I believe some Escort 1.8 Zetec's had the 0.76:1 5th

Ford gearboxes: early b5 vs later iB5:

iB5 bellhousing is easy to spot, look at the top profile in my image. One of the major weak points of the BC 'box is case flex. the iB5 bellhousing was redesigned to negate this as much as possible. The later revisions took webbing to an extreme! iB5's are easy enough to find.

There is no such thing as an 'uprated' BC gearbox in terms of bearings and synchros. The later BC 'boxes had 8 diff bolts as opposed to the earlier 6, but this doesn't really help reliability - just torque handling (to a point!).

The first post will be a copy & paste from another forum but I will continue to update this thread:

A few snippets from the Mk3 project I'm working on. Another distraction from the Quattro! I should have this one 'out the door' over Easter.

£1k worth of new Ford bits so far to get it to my standard. I want to improve all the driver interfaces and make sure the car feels & drives as optimally as possible for the spec. A few of the parts that have gone on:

Low mileage Escort 1.8 Zetec iB5 (left). Non-Si/Gti for higher ratios.

Mk7 Fiesta Brakes and Mk2 Mondeo Servo/MC. My brief is 14" wheels and good brakes, Mk7 brakes are 260mm but have the largest pistons yet used by Ford on this size.

HO

Changing Petrol 5th for Diesel 5th. I gave up trying to find a 5th gear puller, so fabricated my own.

Diesel 5th vs 1800 Zetec 5th

Done

Shafts rebuilt, all gen. Ford - although I'm about to do away with standard O/S and fit something different.

Puma linkage. Did this 10 years ago and is still one of my favourite mods on the Mk3.

ST170 manifold and Saab downpipe.

Lambda relocated to just before cat, and cat entrance area shortened by 2".

Bosses added for standard shield etc. Looks standard:

Rebuilding Recaros. I bought several interiors to get a pair of superb seats. I reset side bolster supports to original position etc.

More to come when I have time to write it up properly.

Here it is. 61K and Full Service History, all old Bills, MOTs etc. There was a mark on the tailgate and bonnet but I've replaced both since these photos.

Ford gearboxes

The Petrol 1800 5th is mismatched for the 2.0 so I plotted the gear/speed graphs:

RS1800 gearbox:

Rebuilt with Diesel 5th:

You can see on the RS1800 graph just how short the 5th is, this is to negate the lack of torque from the 1800 engine. The 2.0 can cope with much more than the 0.87:1 5th.

Adding the 0.76:1 5th gives a nice spread of ratios without too much rev drop between 4th-5th.

I believe some Escort 1.8 Zetec's had the 0.76:1 5th

Ford gearboxes: early b5 vs later iB5:

iB5 bellhousing is easy to spot, look at the top profile in my image. One of the major weak points of the BC 'box is case flex. the iB5 bellhousing was redesigned to negate this as much as possible. The later revisions took webbing to an extreme! iB5's are easy enough to find.

There is no such thing as an 'uprated' BC gearbox in terms of bearings and synchros. The later BC 'boxes had 8 diff bolts as opposed to the earlier 6, but this doesn't really help reliability - just torque handling (to a point!).

Edited by mwstewart on Wednesday 13th February 14:47

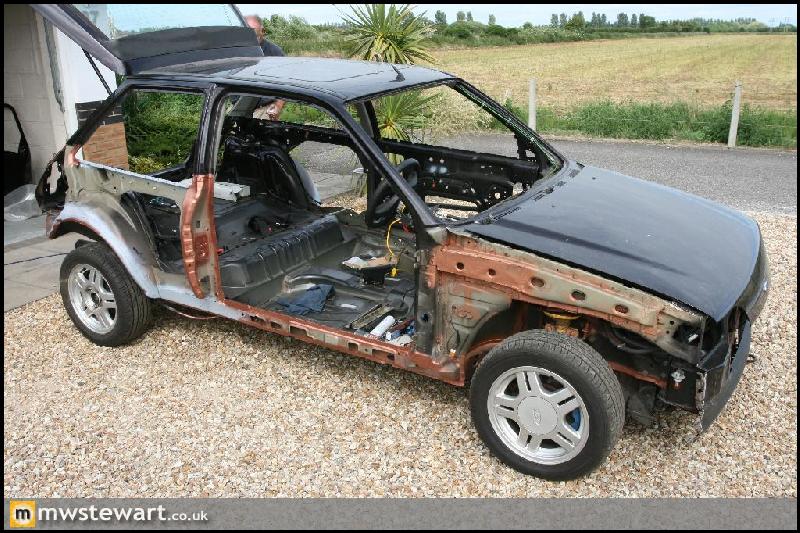

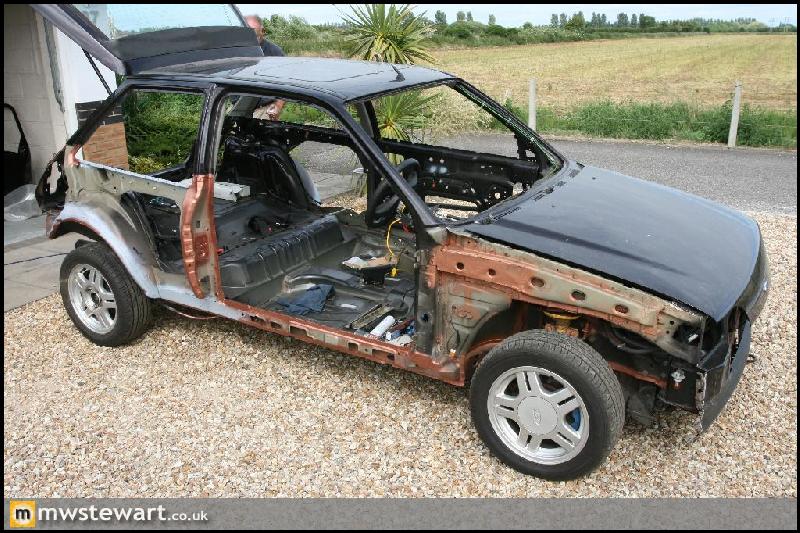

I regret buying this. I can't just buy a car and leave it 'as is': It's taken up too much time! Current works are:

[*]New Ford doors

[*]New Ford tailgate

[*]New Ford rear quarters

[*]New Ford Bonnet

[*]Front Wings

[*]Front Valance

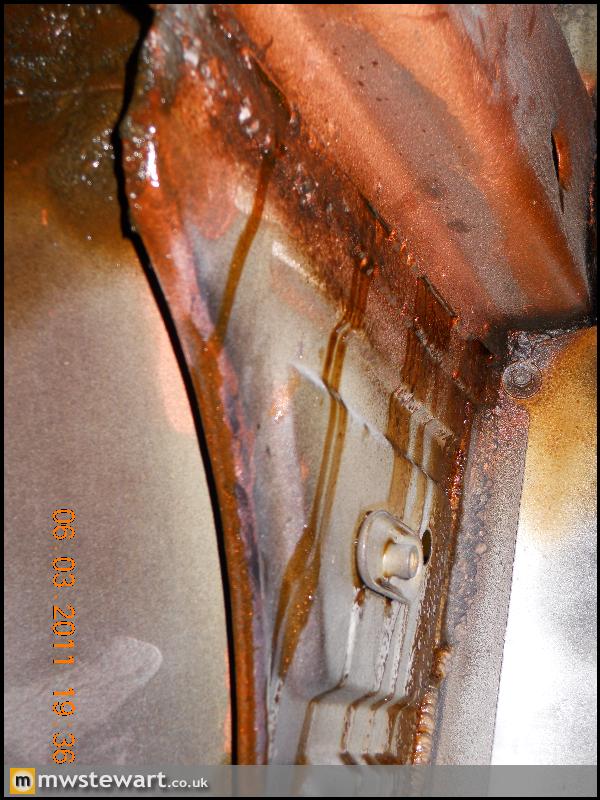

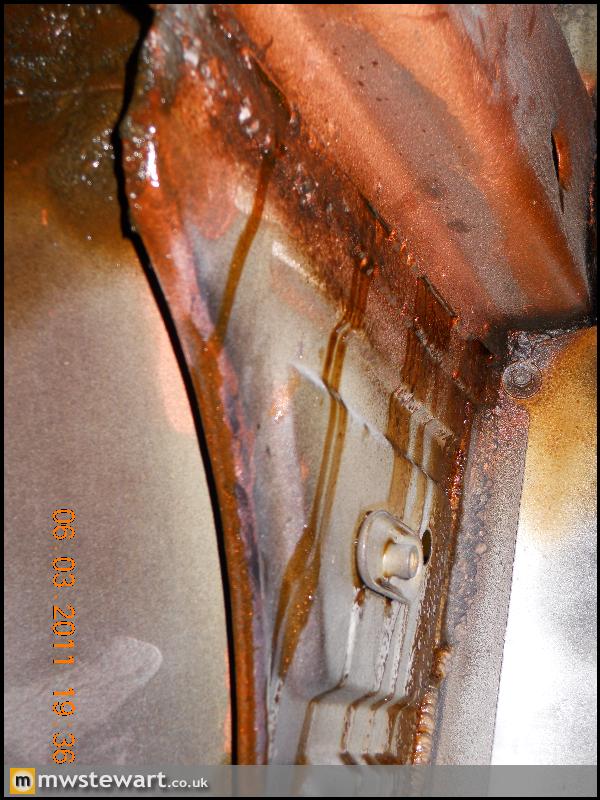

The shell is good, one of the better ones I've seen but it's 15 years old so isn't without rust - I've noticed the front inner wings tend to go on these. The only giveaway is a few tiny blemishes on the outside face that look completely innocent, but corrosion inside is advanced to the point that it is detrimental to occupant safety. I rebuilt both inner wing outer sections with 2mm sheet (Standard is 1mm)

I've started using spray copper grease in place of waxoyl. It's perfect and you can pick up 12 cans for £35. It gets into the seams much better than waxoyl and is easier to use.

I've wired up electric mirrors, heated front screen, deadlocks and Ford alarm (had an ultra rare 2 door deadlock loom) and also a passenger airbag (being a Mk3.5 the electric pack loom plugs in without further modification).

ZS rear beam, RS2K front brakes (keeping 14's), RS1800 wheels with new Falkens all round. New GMAX all round. Pretty much everything on the car with a service life or wear limit is brand new and genuine Ford, from wiring to bushes, engine pumps, track rods, lower arms, top mounts, all hoses, engine gaskets, screws, bolts, new genuine steering rack (I find the PAS racks loose their sharpness after 40k) etc. etc. Too much to list.

I have a perfect set of FRST Recaro's and my G/F's mum is re trimming the centres in Si fabric. I've got several rolls of sound deadening.

Engine wise it's HO inlet, ST170 manifold I made to fit, and I have a set of Dunnel cams to go in. New genuine clutch, skimmed flywheel - everything is refurbished. Exhaust is Scorpion but it annoys me so a standard one will go on (standard are straight through anyway and I prefer the deeper note a mild steel exhaust gives)

I've done an iB5 conversion with custom ratios and a new Puma linkage.

All fluids are genuine Ford.

I'm hoping to paint it within 2 months.

Panels were replaced due to car park dents - not rust.

Small update, managed to get a weekend on the Si:

The car was manual locks/manual windows. I'm adding:

Passenger Airbag, Mk5 Drivers Airbag, Ultra-rare leather steering wheel for 'thumb notch' type Airbag,

Electric Mirrors,

Heated Front Screen,

Deadlocks,

Ford Alarm

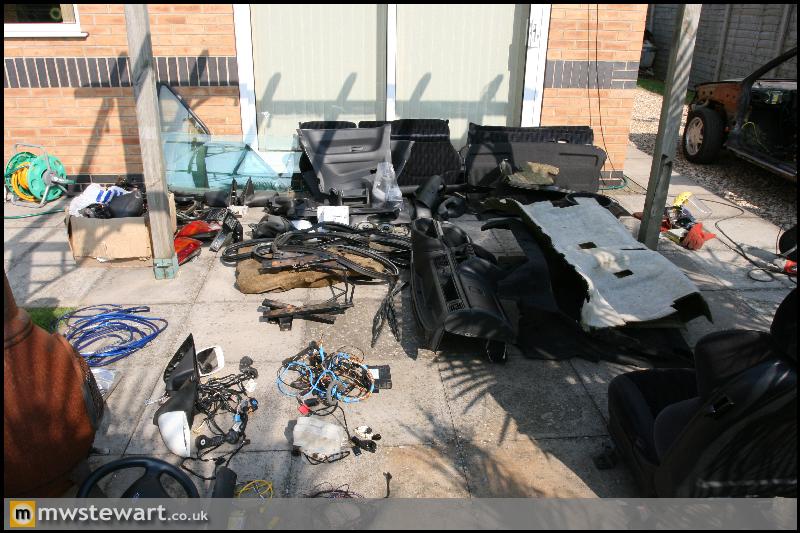

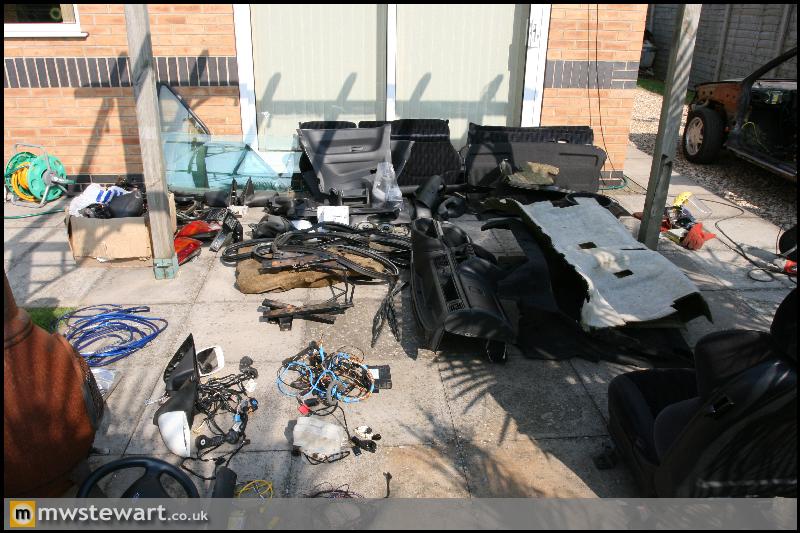

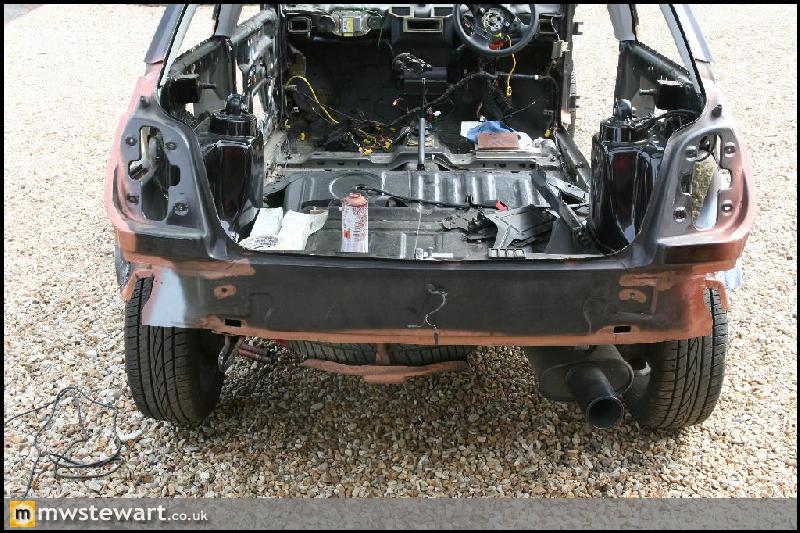

I stripped the rest of the interior out:

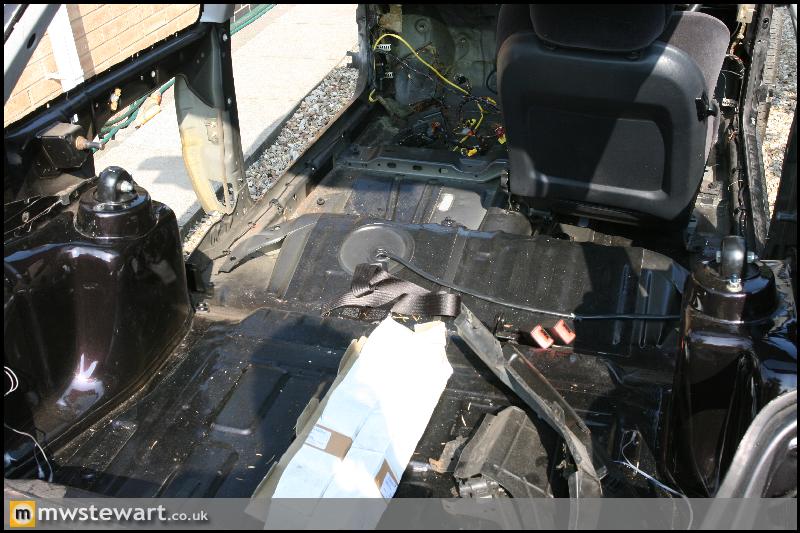

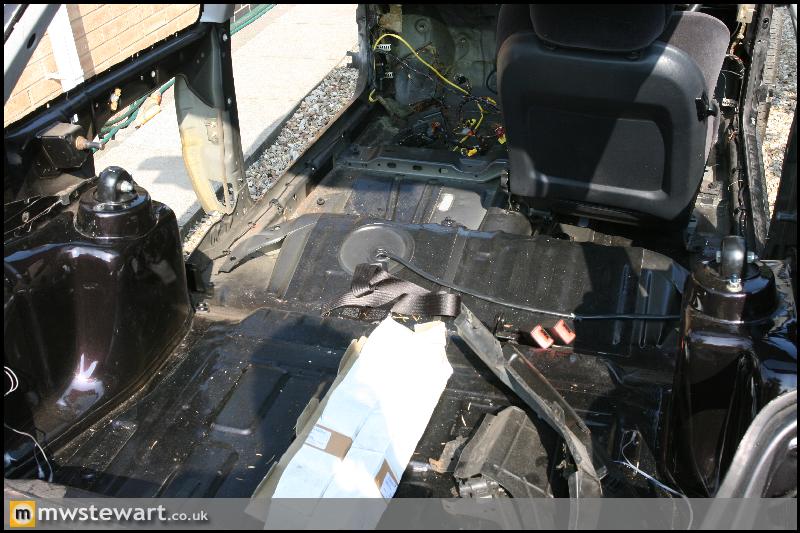

Perfect floors and rear turrets:

Interstingly - the O/S turret is Mk3.5 but the N/S is Mk3 - Ford must have been using up old stock!

Dunnel cams:

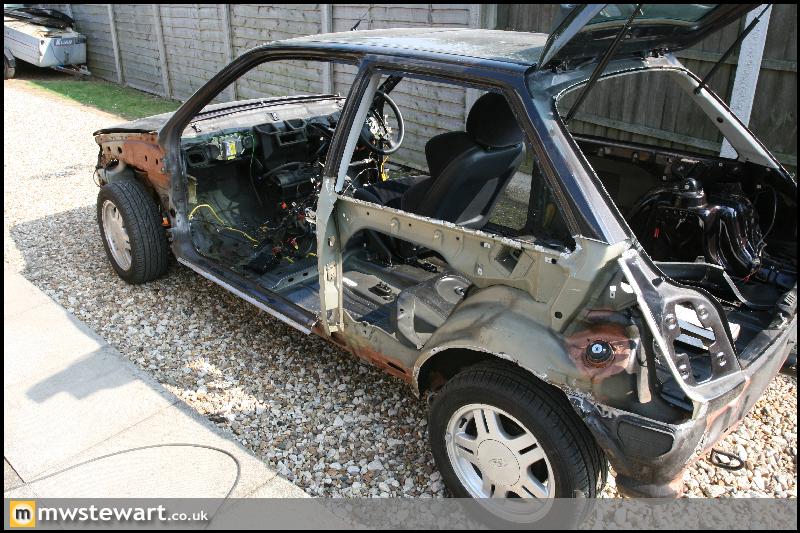

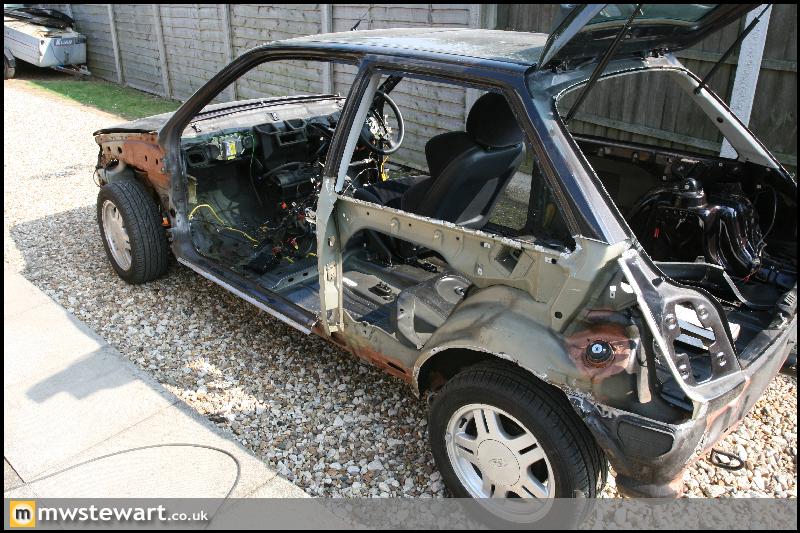

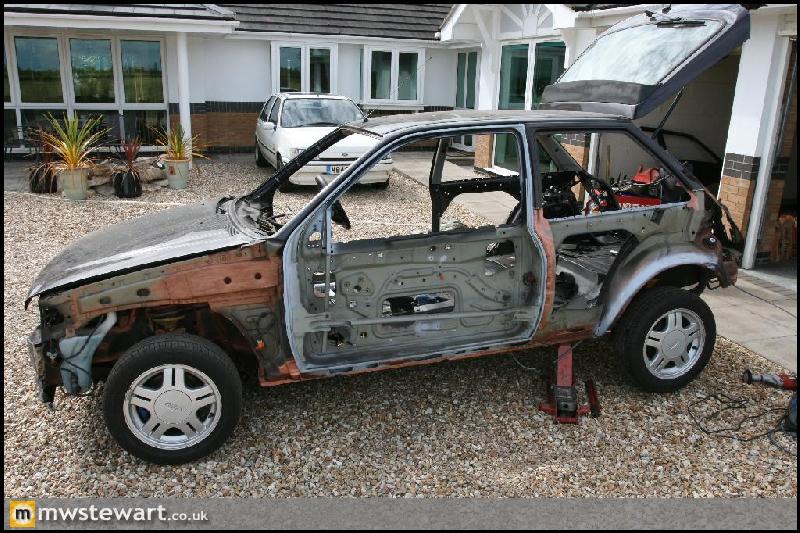

As it stands:

I have Thursday and Friday off to carry on. I've tracked down some more new genuine panels - this time doors, door skins and quarters, which I will collect on Wednesday evening. I now have enough to 're-skin' this one and keep a complete set spare, so I'll choose the best are and use them. The Genuine Ford replacement panels (front wings excluded) are literally half the thickness of the original parts - it's pretty shocking TBH given that sills and rear quarters are structural! (In fact some of the pattern part panels I have are probably thicker). A re-skinned car is never going to be as good as an original one! Still, the Quattro shell is 100% original so that's all the matters really.

I have bought a lot of sound deadening (non-bitumen type) and every piece of trim is going to be backed with a deadening sheet, and trim mounting surfaces will be finished with a 1mm layer of RTV to prevent noise.

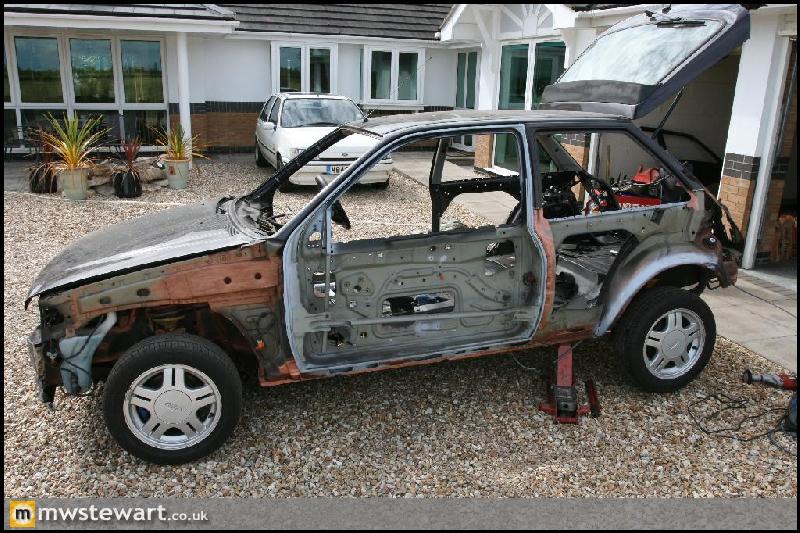

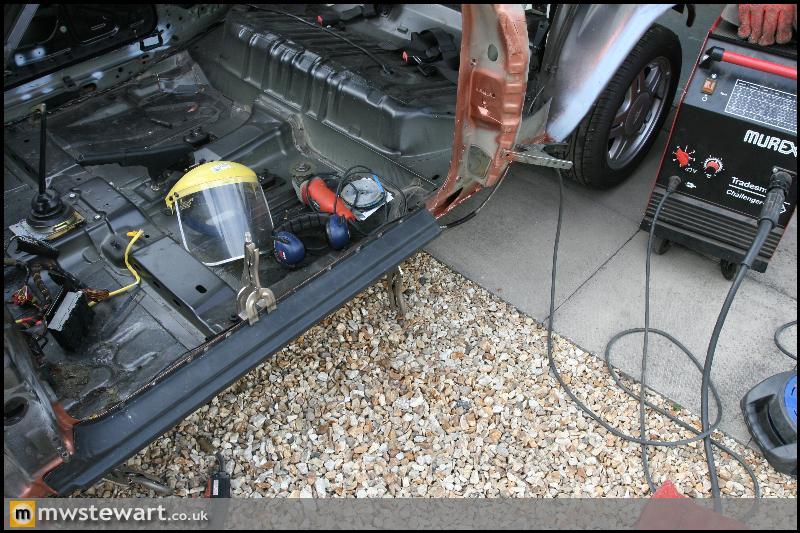

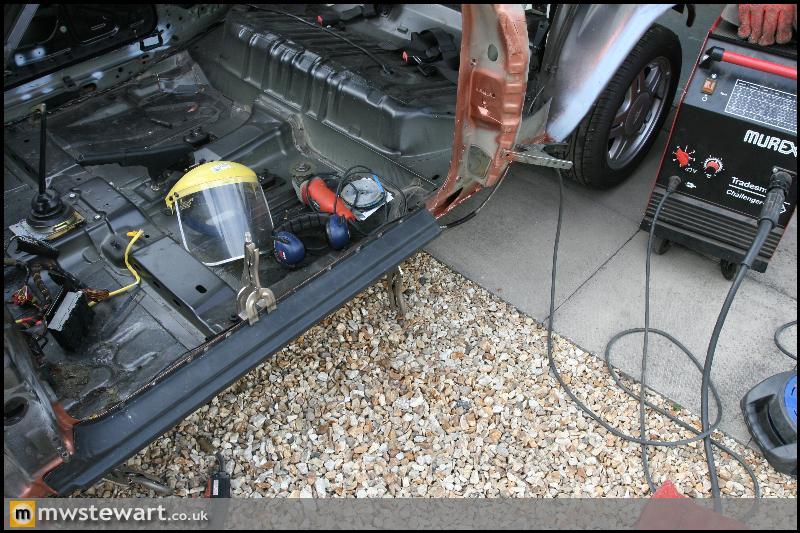

Few things going on today:

Gen Panels to go on, including a pair of new door skins:

My Dad has taken a day off and he's helping me by re-skinning the doors:

While I make progress on the shell - and make a few minor repairs:

Got some brand new genuine headlamp protectors also

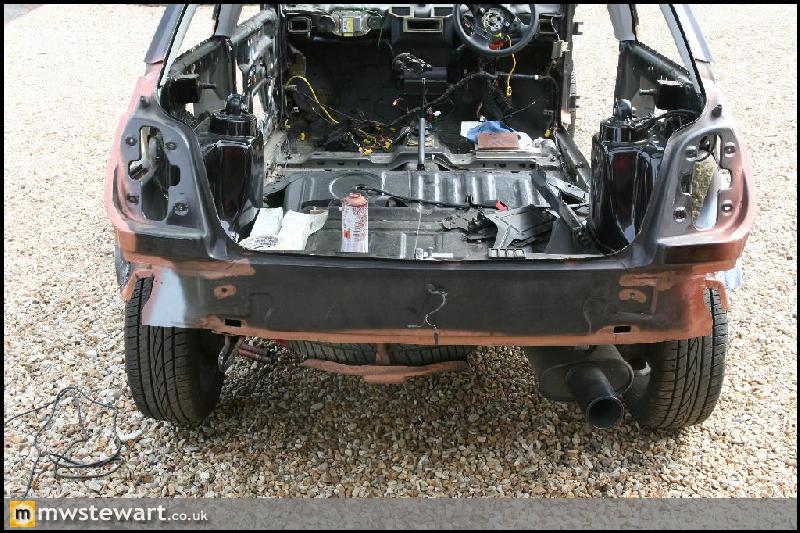

Some more reconstructive surgery, this time on the rear panel (the gap is supposed to be that wierd shape):

Rear edge of door reveal (the bit that usually rusts)

The complete door skin process:

Rear inner arches

The rubber mallet/block of wood method for fitting the door skins is not good, I wouldn't recommend anyone does it that way. My Dad sourced the correct tool from someone her knew - we did the whole skin in 10 minutes flat!

The Mk3.5 has an extra sill section - an intermediate sill that is spot welded to the bottom of the outer sill. This is the sole reason Mk3.5's tend to rot out so badly in that area. I chop off the bottom section, and bend up 'L' shape pieces so I can weld it directly to the inner sill.

This retains the additional rigidity of the Mk3.5 but minimises the amount of lap joints in the sill area.

New inner arch on the N/S

And the car is ready for panels:

It doesn't look like much has changed, but any corrosion is now gone. It's taken hours to get this far and do it well.

O/S Full Sill and rear quarter on

Part of the Mk3's deisgn which I find absurd is the sunroof drain locations - why drain water into the most vulnerable area of the car, where 3 sheets of metal are spot welded? I have run each drain out and clear of the sills:

Panel alignment:

O/S now complete:

I got this far on the N/S:

I had repaired my back panel but decided to order a Mk5 back panel and reinforcement, just in case there's anything hidden in the seams. This weekend should see the outer panel work finished once and for all, and maybe see the application of some primer!

I now have a Puma dash and A/C Airbox, and I'm keeping my eye out for a low mileage Escort Zetec engine from which I will take A/C pump & brackets/Alt/Pas pump arrangement (front cross member will be modified slightly for this). XRSi is cutting out a Mk5 Bulkhead for me so I can fit the Puma dashboard correctly.

I have these sitting on my desk today:

Mk4/Mk5/Puma (Fiesta DX) front strut top inserts. I'm going to drill out the Mk3 turret inserts and weld these in, front and rear (xrsi is cutting out the rear turret inserts from the same ZS as these aren't available separately from Ford). The strut tops are a massive weak point on the Mk3 - even Poly bushes can only limit the amount of deflection so much; I had considered comissioning a pair of machined cups to fit around the base of the front mounts when fitted, to prevent deflection, but even then the car would be compromised. The Mk4/5 tops are superb so will give be a quieter ride and much less geometry change. I'll be running Sport Ka front hubs (I'm fitting ABS), and Zetec-S struts.

I'm also waiting for an equal length drive shaft from a ZS, to further improve handling.

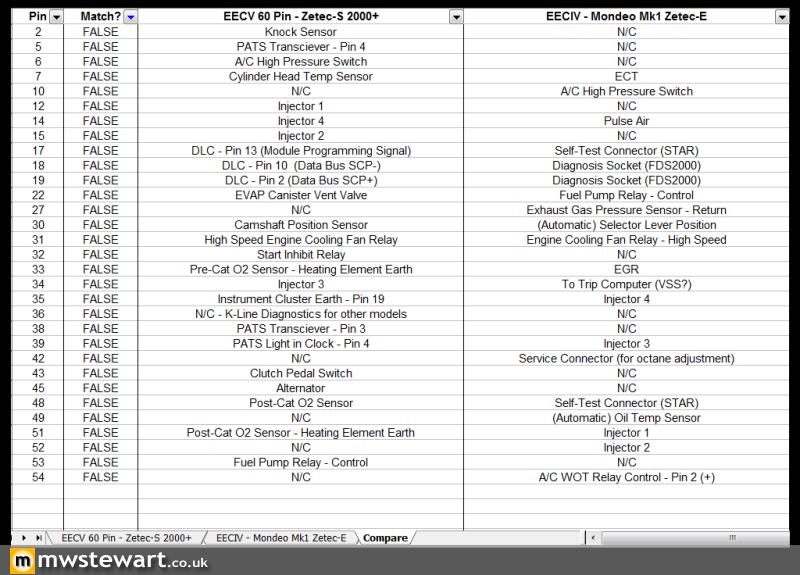

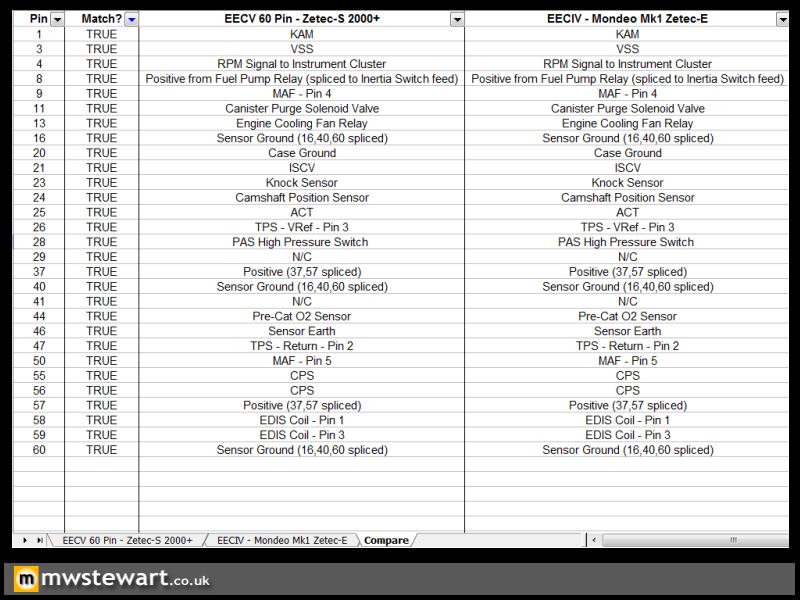

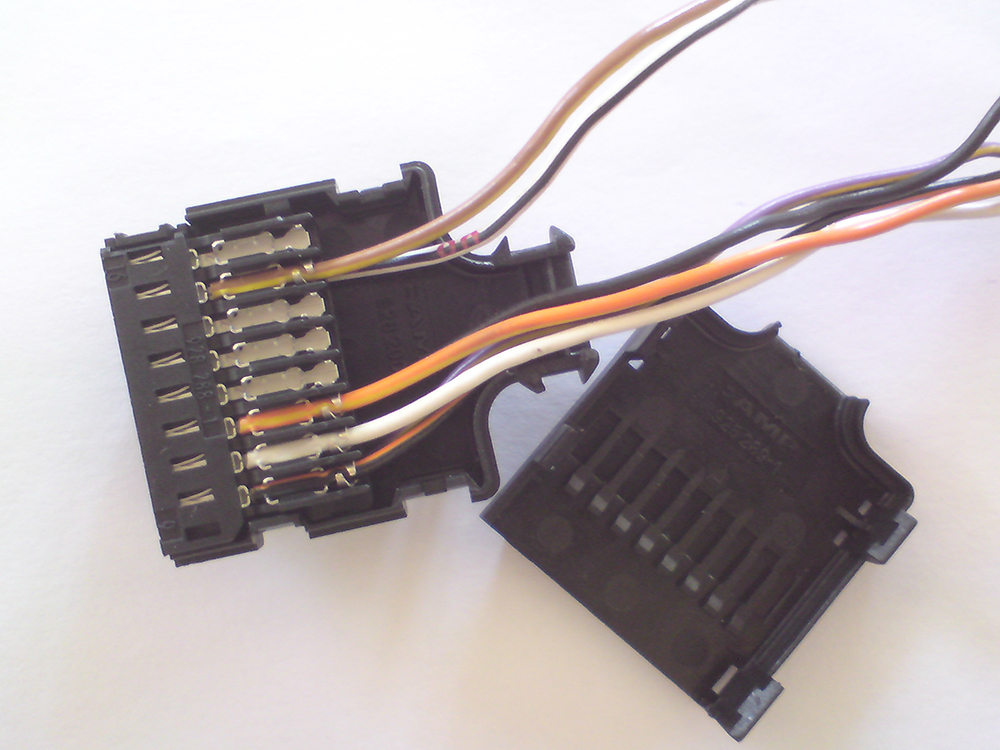

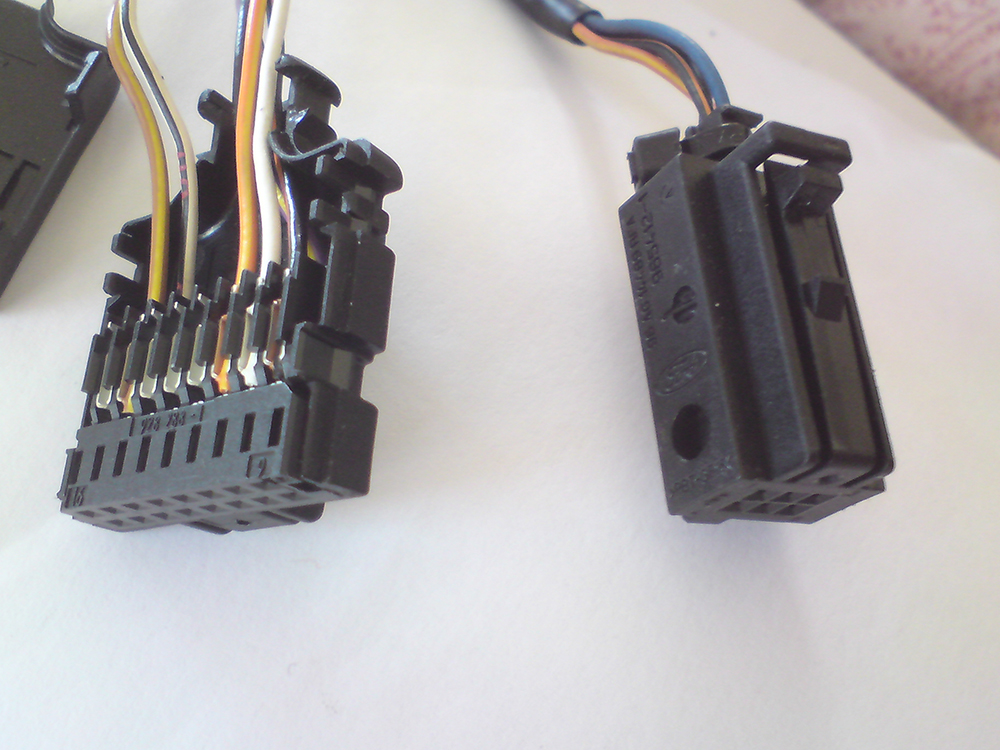

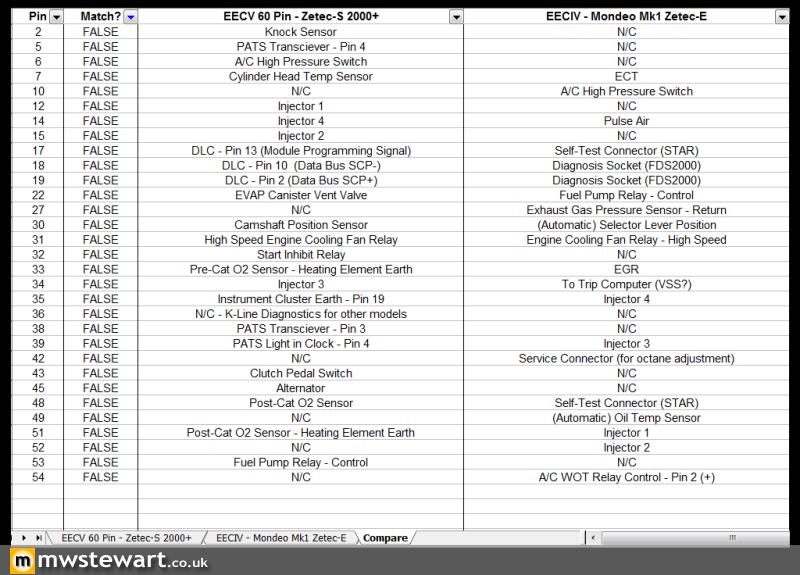

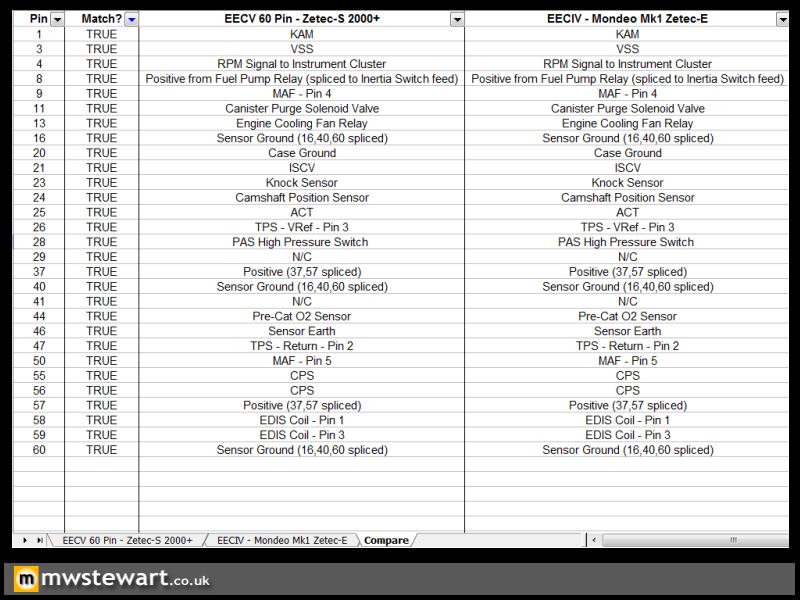

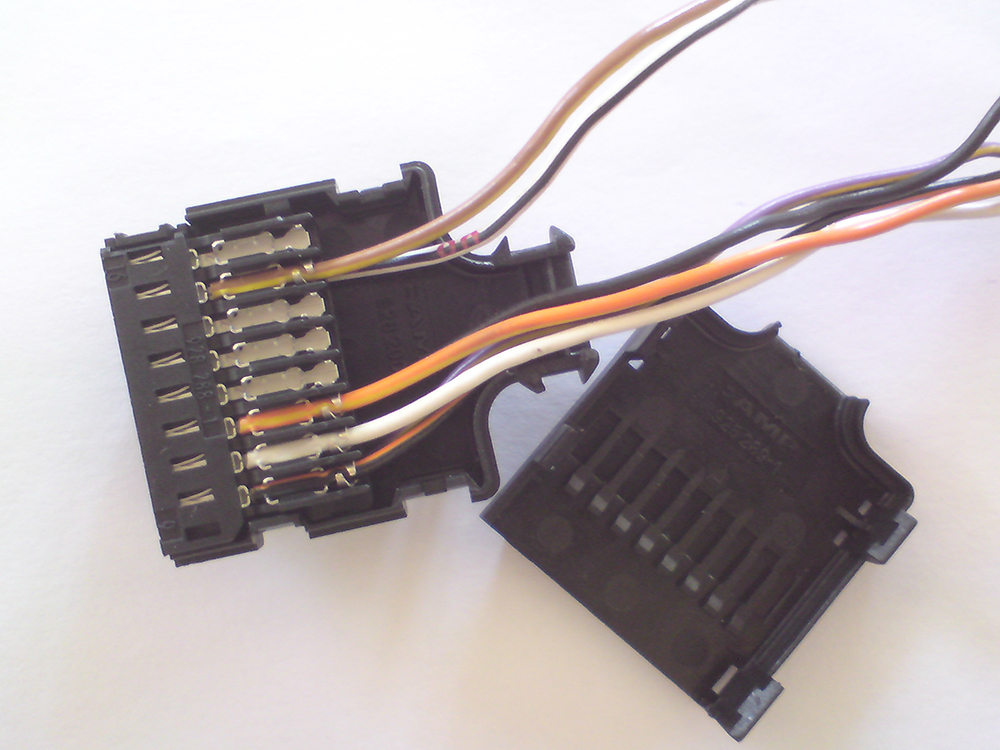

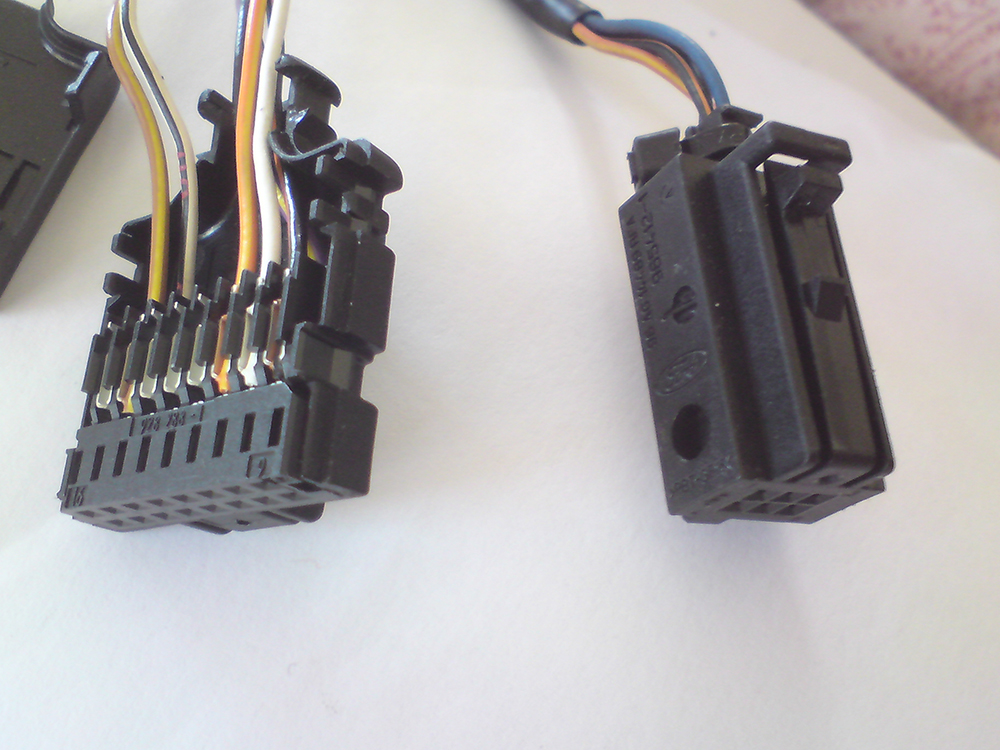

I have a full Zetec-S loom that I got from a year old car back in '02 - this was destined for the 'quattro' car but obviously no longer required! I will fit this to get remote locking and the A/C wiring (which is easy enough to wire up anyway) and switchable ABS/TC. I have a spare EECV ECU from which I'm going to chop off the connector and make a plug and play EECV-EECIV connector lead so I can leave the ZS loom largely standard.

As my 2.0 EECIV ECU is from a Mondeo it already runs code for ECU-based control of two primary cooling fans and 1 A/C fan. The ZS loom has this wiring present which will save me time! In the engine bay, I'll modify the (all black) plug-in engine loom to suit the Zetec-E. This way I maintain the main EECV wiring so I can plug in a standard ZS engine loom whenever I want in order to fit a Mk1 Focus RS Engine and run it from EECV with relative ease.

EECV PATS is internal, so PATS wiring will be removed from my Si loom and integrated into the ZS loom. I already have the matching key for the ZS GEM so the remote locking works, and I had a key blank cut to match the Si. I've yet to see if the Mk3 PATS Key transceiver fits inside a Mk5 remote locking key, but I don't anticipate any big headaches.

I have taken 2x Mk3.5 looms and 1x Mk5 Fiesta Zetec-S loom with me back to London so I can work on them in the evening.

I'm gathering some information to make adapter plugs for the ZS loom. As a recap, I'm going to run the ZS loom and make an adapter block to join the ZS EECV connector on the car loom directly to a 2.0 EEC-IV ECU from a Mk1 Mondeo (to run a 2.0 Silver Top Zetec-E). I think this will be a nice and neat way of running the ZS loom in a Mk3.

Non-ECU Connections on the ZS car loom that I need to change to suit the Mk3 chassis are:

[*] Headlamp connectors,

[*] Add separate front indicator connector connectors,

[*] Tailgate release button connector,

[*] Engine Cooling fan connector,

[*] Change position of screen wash pump connector,

[*] Add low-screenwash sensor

[*] Modify the ABS/Traction Control relay feed wire to be switched from the cockpit.

[*] I will use a Mk5 interior light, steering wheel and column stalks as they are all different to the Mk3.[/list]

ECU Connections on the ZS engine loom:

[*] Looking at wiring diagrams today I've found that pin 17 on the EEC-IV ECU (which goes to the STAR DCL Connector on the Mk3) can be used as a MIL/Check Engine Light, which is great - I will join EECIV Pin 17 to pin 36 on the EECV connector, which runs to a MIL in the ZS instrument cluster.

[*] The only additional sensors used by the ZS are knock, cylinder head temp, and a second (post-cat) 02 sensor. None of these are used by EECIV in the UK Mondeo application, so I won't need to bridge these to the EECIV ECU.

[*] The Mk3 uses a simple thermostatic switch in the radiator (we all know the cylindrical 2 pin fan switch), whereas newer models use the ECU to intelligently control the fan for a number of reasons (faster warm up, better fuel economy etc.). As my 2.0 EECIV ECU is from a Mondeo it already runs code for ECU-based control of a cooling fan. EECIV pinouts are:

EECIV pin 13 - Cooling Fan relay - EECV pin 13

EECIV pin 31 - High Speed Colling Fan relay - EECV pin 31

EECIV pin 54 - A/C WOT Relay (cuts out the compressor during WOT conditions) - EECV pin 54

You can see that the Ford engineers kept some pins the same between EECIV and EECV for historical & ease-of-service reasons!

I had a quick look at the ZS loom last night.

Loom overview: 2002 Mk5 Fiesta 1.6 Zetec-S

Spec:

[*]ABS

[*]Air Conditioning

[*]Air Recirculation

[*]Deadlock Central Locking

[*]Door ajar warning

[*]Electric Mirrors

[*]Ford Alarm

[*]Front Fog Lights

[*] Headlamp Range Adjustment

[*]Heated Front Screen

[*]Low Screenwash warning

[*]Passenger Airbag

[*]Remote Locking and Tailgate release (RF)

[*]Seatbelt pre-tensioners

[*]Tailgate Release

[*]Traction Control

Front Indicators - These are in fact on a separate connector to the headlamps and use the same AMP Junior Timer Housing type connector as the Mk3, so are a straight swap.

Headlamps - The ZS headlamp connector is completely different to the Mk3 and incorporates 3 wires for the headlamp range adjustment motor. I dismantled a scrap Mk5 headlamp and found that the headlamps internal loom forms a perfect adapter loom to go from the ZS headlamp multiplug to a H4 main bulb, a W5W sidelight bulb and separate 3 pin plug for the adjustment motor. I will purchase some Mk3 motorised LHD headlamps from German eBay, and swap the front glass for a RHD version to leave me with fully-operative MK3 range adjustment headlamps.

Heated Screen - This is the same setup as Mk3/3.5 - the screen loom plugs in underneath the dash.

MAF - This is part of the 'main' loom and uses the 'next generation' all plastic style multiplug rather than the old Junior Timer Housing. I don't want to cut any of the main loom so I'm going to swap my MAF for either a 1.7 Puma or Focus/Mondeo 2.0 Series 3 Zetec MAF.

IAT - Part of the main ZS loom. EECIV uses only ACT, so IAT isn't required for the Series 1 Zetec. I will fit the sensor to my Air box for neatness.

Front and Rear 02 Sensors - These are part of the main ZS Loom and use a newer Cylindrical female multiplugs, so I will solder a ZS male multiplug to the Mondeo 02 sensor. The rear 02 sensor isn't used in the UK Mk1 Mondeo so will remain disconnected.

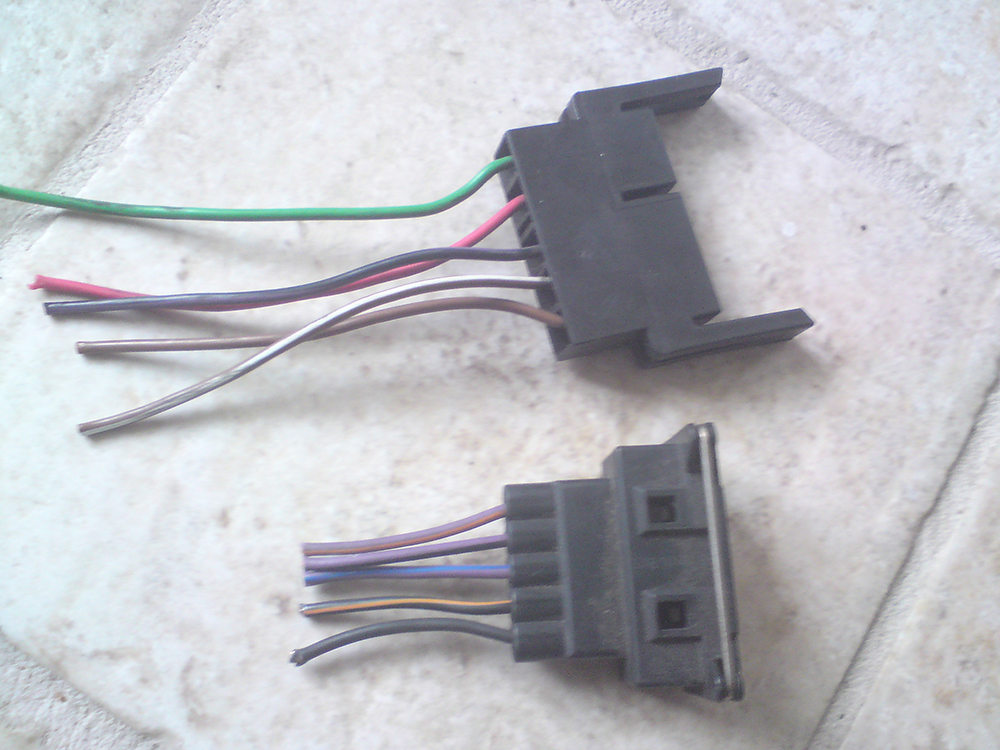

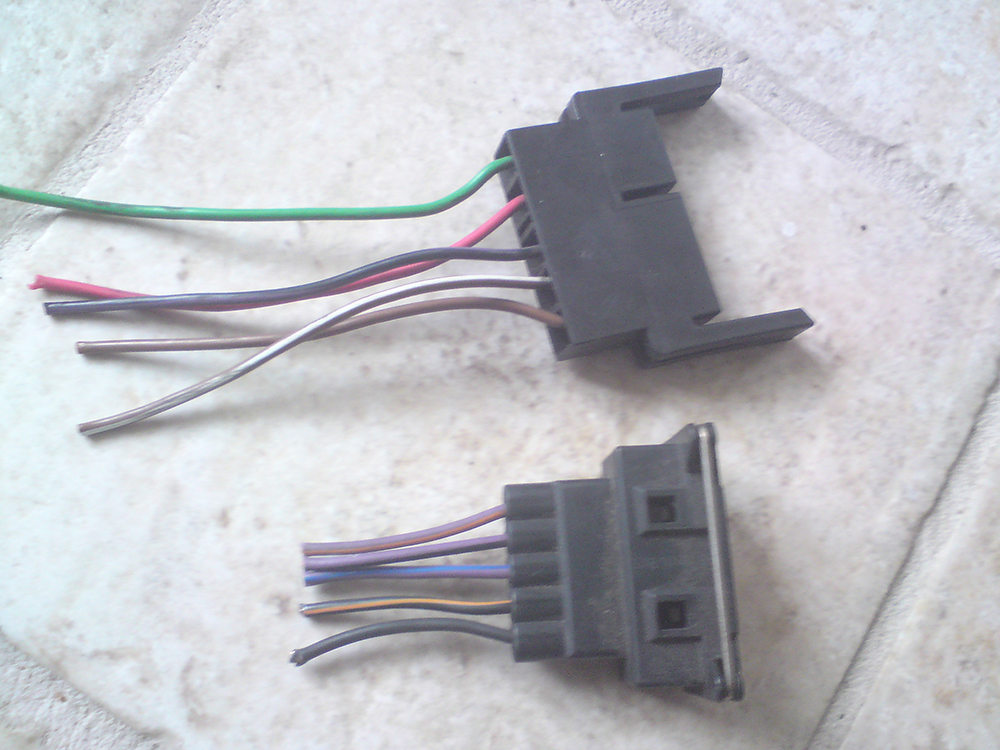

ABS/Traction Control - The Mk1 Mondeo had this as an option, and used the same style switch as the Mk5 tailgate release (like the Mk3 Electric Window switch). The Mondeo switch is now discontinued but I have bought one from a breakers:

I got the multiplug and some wiring with it. I will wire this to a latching relay to control power to the ABS/TC module.

The remainder of the engine sensor plugs are split between two separate sub looms which can be disconnected from the main ZS loom. Most connections are by the next-generation all-plastic style connectors which weren't used on the Mk3 Fiesta. The Mk1 Mondeo did however use them, so I have the option of replacing all of my current sensors with either Mk1/2 Mondeo or Mk1 Focus sensors, which would enable me to keep the ZS engine loom standard.

PATS, and fitment of an Ice warning/outside temperature display clock will be my next areas of attention.

I now have a Genuine Ford Mk4/5 upper Bulkhead panel, so I can correctly fit the Puma dash, wiring and heater box/pollen filter.

I changed my mind regarding the centre console layout - I was planning to use a Midnight Black (phase 2) Mk5 console and mounting the Mondeo TC button above the Mk5 tailgate release button. I'm no longer going down this route and instead I just bought a complete ST170 centre console with TC and heated seat buttons, along with an additional Focus gear gaitor for the ib5 type gearboxes (non lift-up reverse).

[*]New Ford doors

[*]New Ford tailgate

[*]New Ford rear quarters

[*]New Ford Bonnet

[*]Front Wings

[*]Front Valance

The shell is good, one of the better ones I've seen but it's 15 years old so isn't without rust - I've noticed the front inner wings tend to go on these. The only giveaway is a few tiny blemishes on the outside face that look completely innocent, but corrosion inside is advanced to the point that it is detrimental to occupant safety. I rebuilt both inner wing outer sections with 2mm sheet (Standard is 1mm)

I've started using spray copper grease in place of waxoyl. It's perfect and you can pick up 12 cans for £35. It gets into the seams much better than waxoyl and is easier to use.

I've wired up electric mirrors, heated front screen, deadlocks and Ford alarm (had an ultra rare 2 door deadlock loom) and also a passenger airbag (being a Mk3.5 the electric pack loom plugs in without further modification).

ZS rear beam, RS2K front brakes (keeping 14's), RS1800 wheels with new Falkens all round. New GMAX all round. Pretty much everything on the car with a service life or wear limit is brand new and genuine Ford, from wiring to bushes, engine pumps, track rods, lower arms, top mounts, all hoses, engine gaskets, screws, bolts, new genuine steering rack (I find the PAS racks loose their sharpness after 40k) etc. etc. Too much to list.

I have a perfect set of FRST Recaro's and my G/F's mum is re trimming the centres in Si fabric. I've got several rolls of sound deadening.

Engine wise it's HO inlet, ST170 manifold I made to fit, and I have a set of Dunnel cams to go in. New genuine clutch, skimmed flywheel - everything is refurbished. Exhaust is Scorpion but it annoys me so a standard one will go on (standard are straight through anyway and I prefer the deeper note a mild steel exhaust gives)

I've done an iB5 conversion with custom ratios and a new Puma linkage.

All fluids are genuine Ford.

I'm hoping to paint it within 2 months.

Panels were replaced due to car park dents - not rust.

Small update, managed to get a weekend on the Si:

The car was manual locks/manual windows. I'm adding:

Passenger Airbag, Mk5 Drivers Airbag, Ultra-rare leather steering wheel for 'thumb notch' type Airbag,

Electric Mirrors,

Heated Front Screen,

Deadlocks,

Ford Alarm

I stripped the rest of the interior out:

Perfect floors and rear turrets:

Interstingly - the O/S turret is Mk3.5 but the N/S is Mk3 - Ford must have been using up old stock!

Dunnel cams:

As it stands:

I have Thursday and Friday off to carry on. I've tracked down some more new genuine panels - this time doors, door skins and quarters, which I will collect on Wednesday evening. I now have enough to 're-skin' this one and keep a complete set spare, so I'll choose the best are and use them. The Genuine Ford replacement panels (front wings excluded) are literally half the thickness of the original parts - it's pretty shocking TBH given that sills and rear quarters are structural! (In fact some of the pattern part panels I have are probably thicker). A re-skinned car is never going to be as good as an original one! Still, the Quattro shell is 100% original so that's all the matters really.

I have bought a lot of sound deadening (non-bitumen type) and every piece of trim is going to be backed with a deadening sheet, and trim mounting surfaces will be finished with a 1mm layer of RTV to prevent noise.

Few things going on today:

Gen Panels to go on, including a pair of new door skins:

My Dad has taken a day off and he's helping me by re-skinning the doors:

While I make progress on the shell - and make a few minor repairs:

Got some brand new genuine headlamp protectors also

Some more reconstructive surgery, this time on the rear panel (the gap is supposed to be that wierd shape):

Rear edge of door reveal (the bit that usually rusts)

The complete door skin process:

Rear inner arches

The rubber mallet/block of wood method for fitting the door skins is not good, I wouldn't recommend anyone does it that way. My Dad sourced the correct tool from someone her knew - we did the whole skin in 10 minutes flat!

The Mk3.5 has an extra sill section - an intermediate sill that is spot welded to the bottom of the outer sill. This is the sole reason Mk3.5's tend to rot out so badly in that area. I chop off the bottom section, and bend up 'L' shape pieces so I can weld it directly to the inner sill.

This retains the additional rigidity of the Mk3.5 but minimises the amount of lap joints in the sill area.

New inner arch on the N/S

And the car is ready for panels:

It doesn't look like much has changed, but any corrosion is now gone. It's taken hours to get this far and do it well.

O/S Full Sill and rear quarter on

Part of the Mk3's deisgn which I find absurd is the sunroof drain locations - why drain water into the most vulnerable area of the car, where 3 sheets of metal are spot welded? I have run each drain out and clear of the sills:

Panel alignment:

O/S now complete:

I got this far on the N/S:

I had repaired my back panel but decided to order a Mk5 back panel and reinforcement, just in case there's anything hidden in the seams. This weekend should see the outer panel work finished once and for all, and maybe see the application of some primer!

I now have a Puma dash and A/C Airbox, and I'm keeping my eye out for a low mileage Escort Zetec engine from which I will take A/C pump & brackets/Alt/Pas pump arrangement (front cross member will be modified slightly for this). XRSi is cutting out a Mk5 Bulkhead for me so I can fit the Puma dashboard correctly.

I have these sitting on my desk today:

Mk4/Mk5/Puma (Fiesta DX) front strut top inserts. I'm going to drill out the Mk3 turret inserts and weld these in, front and rear (xrsi is cutting out the rear turret inserts from the same ZS as these aren't available separately from Ford). The strut tops are a massive weak point on the Mk3 - even Poly bushes can only limit the amount of deflection so much; I had considered comissioning a pair of machined cups to fit around the base of the front mounts when fitted, to prevent deflection, but even then the car would be compromised. The Mk4/5 tops are superb so will give be a quieter ride and much less geometry change. I'll be running Sport Ka front hubs (I'm fitting ABS), and Zetec-S struts.

I'm also waiting for an equal length drive shaft from a ZS, to further improve handling.

I have a full Zetec-S loom that I got from a year old car back in '02 - this was destined for the 'quattro' car but obviously no longer required! I will fit this to get remote locking and the A/C wiring (which is easy enough to wire up anyway) and switchable ABS/TC. I have a spare EECV ECU from which I'm going to chop off the connector and make a plug and play EECV-EECIV connector lead so I can leave the ZS loom largely standard.

As my 2.0 EECIV ECU is from a Mondeo it already runs code for ECU-based control of two primary cooling fans and 1 A/C fan. The ZS loom has this wiring present which will save me time! In the engine bay, I'll modify the (all black) plug-in engine loom to suit the Zetec-E. This way I maintain the main EECV wiring so I can plug in a standard ZS engine loom whenever I want in order to fit a Mk1 Focus RS Engine and run it from EECV with relative ease.

EECV PATS is internal, so PATS wiring will be removed from my Si loom and integrated into the ZS loom. I already have the matching key for the ZS GEM so the remote locking works, and I had a key blank cut to match the Si. I've yet to see if the Mk3 PATS Key transceiver fits inside a Mk5 remote locking key, but I don't anticipate any big headaches.

I have taken 2x Mk3.5 looms and 1x Mk5 Fiesta Zetec-S loom with me back to London so I can work on them in the evening.

I'm gathering some information to make adapter plugs for the ZS loom. As a recap, I'm going to run the ZS loom and make an adapter block to join the ZS EECV connector on the car loom directly to a 2.0 EEC-IV ECU from a Mk1 Mondeo (to run a 2.0 Silver Top Zetec-E). I think this will be a nice and neat way of running the ZS loom in a Mk3.

Non-ECU Connections on the ZS car loom that I need to change to suit the Mk3 chassis are:

[*] Headlamp connectors,

[*] Add separate front indicator connector connectors,

[*] Tailgate release button connector,

[*] Engine Cooling fan connector,

[*] Change position of screen wash pump connector,

[*] Add low-screenwash sensor

[*] Modify the ABS/Traction Control relay feed wire to be switched from the cockpit.

[*] I will use a Mk5 interior light, steering wheel and column stalks as they are all different to the Mk3.[/list]

ECU Connections on the ZS engine loom:

[*] Looking at wiring diagrams today I've found that pin 17 on the EEC-IV ECU (which goes to the STAR DCL Connector on the Mk3) can be used as a MIL/Check Engine Light, which is great - I will join EECIV Pin 17 to pin 36 on the EECV connector, which runs to a MIL in the ZS instrument cluster.

[*] The only additional sensors used by the ZS are knock, cylinder head temp, and a second (post-cat) 02 sensor. None of these are used by EECIV in the UK Mondeo application, so I won't need to bridge these to the EECIV ECU.

[*] The Mk3 uses a simple thermostatic switch in the radiator (we all know the cylindrical 2 pin fan switch), whereas newer models use the ECU to intelligently control the fan for a number of reasons (faster warm up, better fuel economy etc.). As my 2.0 EECIV ECU is from a Mondeo it already runs code for ECU-based control of a cooling fan. EECIV pinouts are:

EECIV pin 13 - Cooling Fan relay - EECV pin 13

EECIV pin 31 - High Speed Colling Fan relay - EECV pin 31

EECIV pin 54 - A/C WOT Relay (cuts out the compressor during WOT conditions) - EECV pin 54

You can see that the Ford engineers kept some pins the same between EECIV and EECV for historical & ease-of-service reasons!

I had a quick look at the ZS loom last night.

Loom overview: 2002 Mk5 Fiesta 1.6 Zetec-S

Spec:

[*]ABS

[*]Air Conditioning

[*]Air Recirculation

[*]Deadlock Central Locking

[*]Door ajar warning

[*]Electric Mirrors

[*]Ford Alarm

[*]Front Fog Lights

[*] Headlamp Range Adjustment

[*]Heated Front Screen

[*]Low Screenwash warning

[*]Passenger Airbag

[*]Remote Locking and Tailgate release (RF)

[*]Seatbelt pre-tensioners

[*]Tailgate Release

[*]Traction Control

Front Indicators - These are in fact on a separate connector to the headlamps and use the same AMP Junior Timer Housing type connector as the Mk3, so are a straight swap.

Headlamps - The ZS headlamp connector is completely different to the Mk3 and incorporates 3 wires for the headlamp range adjustment motor. I dismantled a scrap Mk5 headlamp and found that the headlamps internal loom forms a perfect adapter loom to go from the ZS headlamp multiplug to a H4 main bulb, a W5W sidelight bulb and separate 3 pin plug for the adjustment motor. I will purchase some Mk3 motorised LHD headlamps from German eBay, and swap the front glass for a RHD version to leave me with fully-operative MK3 range adjustment headlamps.

Heated Screen - This is the same setup as Mk3/3.5 - the screen loom plugs in underneath the dash.

MAF - This is part of the 'main' loom and uses the 'next generation' all plastic style multiplug rather than the old Junior Timer Housing. I don't want to cut any of the main loom so I'm going to swap my MAF for either a 1.7 Puma or Focus/Mondeo 2.0 Series 3 Zetec MAF.

IAT - Part of the main ZS loom. EECIV uses only ACT, so IAT isn't required for the Series 1 Zetec. I will fit the sensor to my Air box for neatness.

Front and Rear 02 Sensors - These are part of the main ZS Loom and use a newer Cylindrical female multiplugs, so I will solder a ZS male multiplug to the Mondeo 02 sensor. The rear 02 sensor isn't used in the UK Mk1 Mondeo so will remain disconnected.

ABS/Traction Control - The Mk1 Mondeo had this as an option, and used the same style switch as the Mk5 tailgate release (like the Mk3 Electric Window switch). The Mondeo switch is now discontinued but I have bought one from a breakers:

I got the multiplug and some wiring with it. I will wire this to a latching relay to control power to the ABS/TC module.

The remainder of the engine sensor plugs are split between two separate sub looms which can be disconnected from the main ZS loom. Most connections are by the next-generation all-plastic style connectors which weren't used on the Mk3 Fiesta. The Mk1 Mondeo did however use them, so I have the option of replacing all of my current sensors with either Mk1/2 Mondeo or Mk1 Focus sensors, which would enable me to keep the ZS engine loom standard.

PATS, and fitment of an Ice warning/outside temperature display clock will be my next areas of attention.

I now have a Genuine Ford Mk4/5 upper Bulkhead panel, so I can correctly fit the Puma dash, wiring and heater box/pollen filter.

I changed my mind regarding the centre console layout - I was planning to use a Midnight Black (phase 2) Mk5 console and mounting the Mondeo TC button above the Mk5 tailgate release button. I'm no longer going down this route and instead I just bought a complete ST170 centre console with TC and heated seat buttons, along with an additional Focus gear gaitor for the ib5 type gearboxes (non lift-up reverse).

Edited by mwstewart on Wednesday 13th February 15:32

Thanks to tompetRS for some Focus Mk1/1.5 wiring diagrams.

xrsi has taken some pics of the parts that I'm buying from him.

Mk5 rear turrets:

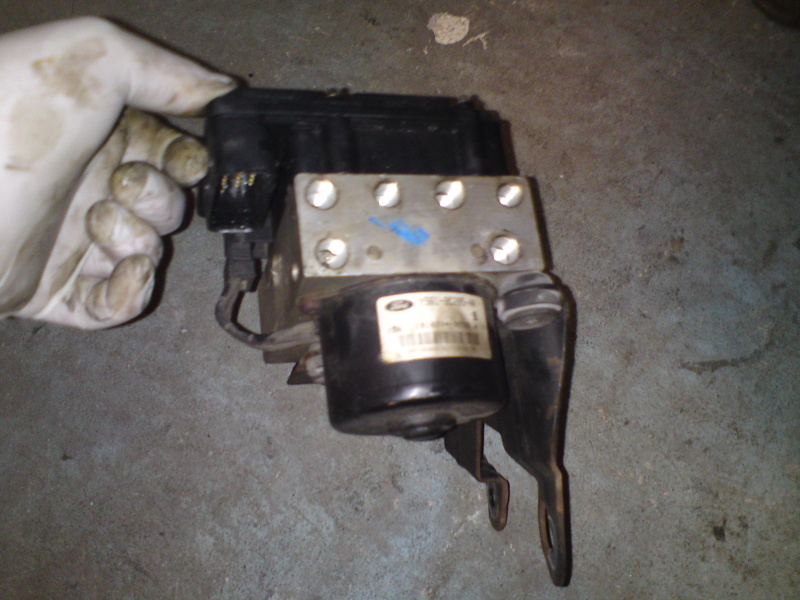

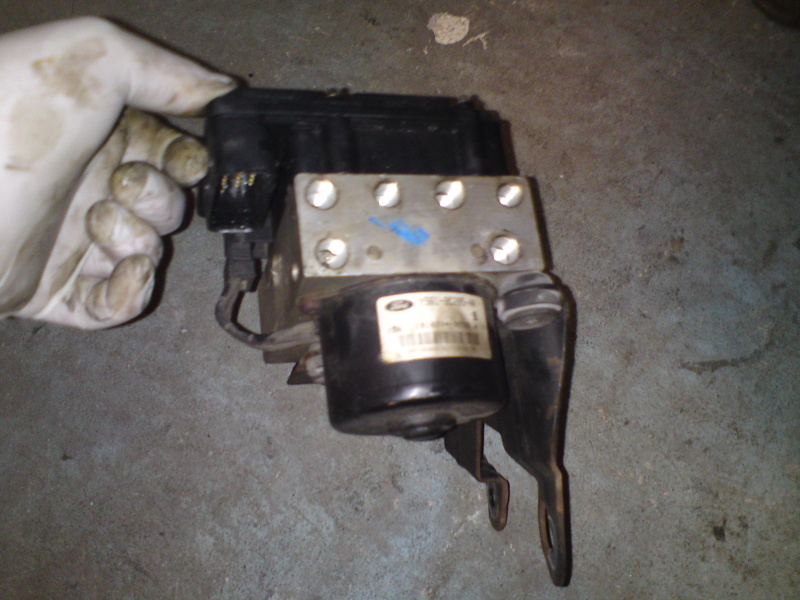

ABS/TC module

Equal length drive shaft:

ZS brake servo, brake pedal and link bar - I have a suspicion that the Pedal ratio is higher in the Mk5:

I also bought some cruise control buttons last week, from a Mk1 Focus. I'm going to fit Cruise Control. I'm pretty sure I can get the cruise control buttons mounted to the Mk3.5 steering wheel and end up with it all looking OEM. The only challenge will be the lack of contacts on the Fiesta slip ring/clock spring. I will either double up the standard clock spring ribbon, or modify a Focus one somehow.

My temp clock:

I'll be back this weekend to carry on with it.

I have done some analysis of the the Mk1 Mondeo and Phase 2 Zetec-S Wiring Diagrams:

I'm a bit gutted that the Zetec-S only runs the 60- Pin EECV ECU because I wanted to perform the majority of wiring prep work now to support a Focus RS Engine on EECV (aftermarket management just doesn't compare IMO). At least the ZS does run the SCP bus, which will enable me to fit some more interesting instruments at some point, and get some data logging on the go.

Looks like I need to find a 104 Pin FRS Engine bay loom for when I do get the FRS Engine. I missed a brand new one a few days ago for £44 not realising at the time that the ZS only had 60 pins. Doh!

For now, the main priority is to use the ZS loom to run the Series 1 2.0 from EECIV, which can be done quite easily. The ZS engine bay loom just unplugs from the engine bay fuse box anyway, so it's not a major project to take it out and modify it later on.

Recaro retirm progress - thanks to my girlfriend's Mum!

I helped by stripping the old covers into their component parts:

Then cut new pieces using the FRST fabric as templates:

Here's a thigh bolster, now in Si fabric:

More tomorrow.

I had some time off last week and spent four days on the body, with the kind help of my Dad. I'm really happy with how its turned out, it's now finally ready for etch primer, but it took four days to get how I want it.

I reached a point where I decided to respray every panel, including the interior area. The shell will be sprayed as Ford did - no masking (aside from the wheel wells and chassis number). I welded in a Mk5 bulkhead, rear turrets and front turrets (modified slightly to correct the roll-centre).

I think I already mentioned that I have a set of low-mileage ST170 brakes on their way, and I've got a set of Mk5 Zetec-S GMAX to go on initially, and once I'm happy these will be replaced by Bilstein B8 struts.

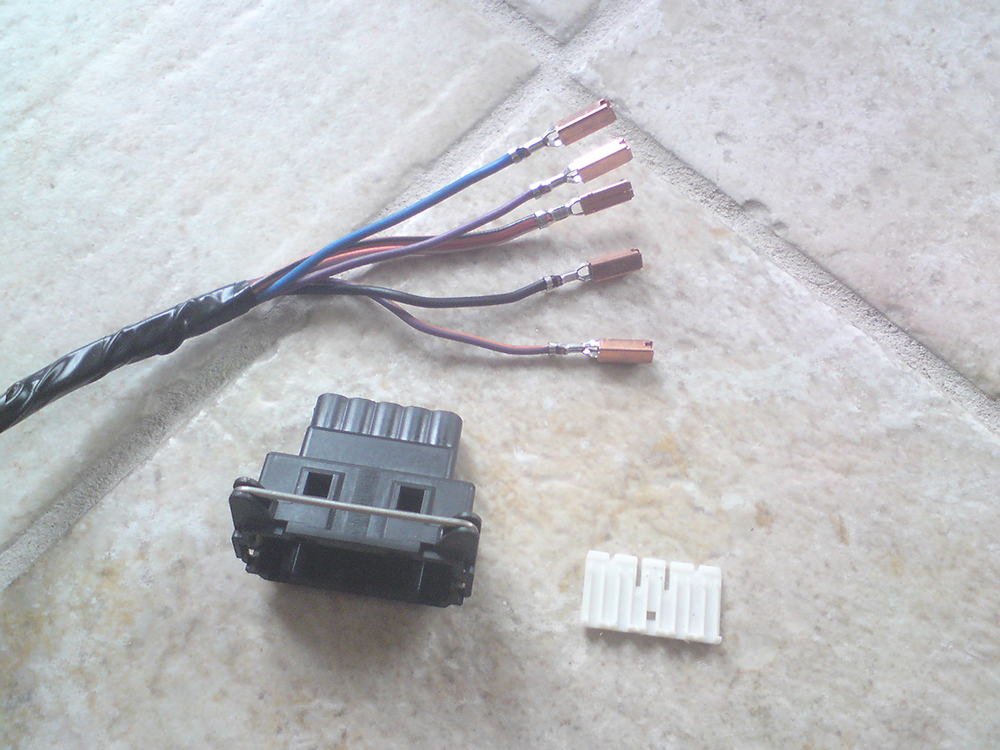

On the Electronics side, I have the loom with me here in London and I've wired in an Ice warning/outside temp clock and Focus heated washer jets. I have a Waco Heated Seat kit on order along to go on with the freshly trimmed Recaro covers. I ordered a Focus gear surround trim with the OEM heated seat switches. I have re-wired the rear lamp connectors to suit the Mk3:

I replaced the wiper motor with the Mk3 connector. I made the decision to keep the Mk3 motor - I could have easily swapped it for a Mk5 mechanism, but I didn't for 2 reaons: 1) I have a low mileage Mk3 motor which still operates at the correct speed, and 2) I didn't swap for the Mk5 scuttle, on which the fins are blocked off above the wiper. The Mk5 does use a waterproof AMP Timer Housing connector, but I'd rather keep the shielded Mk3 motor for guaranteed reliability in wet weather.

I discovered on eTIS that the Mk5 was available in some markets with Keyless Entry, which is really impressive for the age. I need to track down part numbers for the correct GEM.

The crap photos/text update here do not represent the amount of work that's gone into the car, but it will all come together soon and then I'll post something more interesting.

My mind is still on the engine, as a N/A 2.0 Zetec-E doesn't match the quality of the rest of the car!

My Dad wet flatted the car for me after I went back last time (the car is at my parents house in the midlands - I live in London). He did an awesome job, really good of him!

I delayed the painting today to get the Mk5 rear turrets fitted. Excuse the state of the shell, it's filthy due to ongoing works:

No lap joints here! They have gone on in the way Ford would have built the shell, it took a couple of hours to unpick the seams but it's worth it.

Mk5 bulkhead in place. I have also seam welded the A pillar and bulkhead area to stiffen the scuttle.

Mk5 Back panel. It took a lot of modification to fit well, including a little panel beating. I wouldn't recommend it as it's simply not worth the effort for the small gain. It would have taken less time to modify the Mk3 version with a hammer and dolly.

Small jobs left for the morning: seam seal all new joins, and modify the bonnet to accept the Focus heated washer jets.

It will be in etch primer tomorrow afternoon, and then standard primer for tomorrow evening. I should have the base coat on during Saturday 8)

Some photos of the modifications required to correctly fit a Mk4/5/Puma dash. After seeing a few of these done and the work that was undertaken, I had the impression that it sat relatively well in the Mk3 chassis - it doesn't at all.

The work I've done:

Remove Mk3 upper centre mount and weld on Mk5 version approximately 15mm closer to windscreen

Substantially modify the steering column

Cut off the face of the A pillar mounts, and weld on a new face 7mm further forward.

Weld strengthening plate in centre console area for dash to floor bracket.

Weld in Mk5 bulkhead area.

Here are a few photos from the steering column work. I made a hybrid Mk3/Mk5 column support, so I can retain the Mk3 steering shaft and ignition key bracket.

Mk3 column:

Brand new Mk5 column:

Mk3 upper brace removed:

Rear box removed from Mk5 column (steering tube is different):

Modified Mk5 column support sleeved over the Mk3 lower section:

Primer photos later

1 coat of 2k etch primer (on panels), and 1 coat of HS filler primer.

Everything was painted seperately, I've just put the various parts back on the car to move it around:

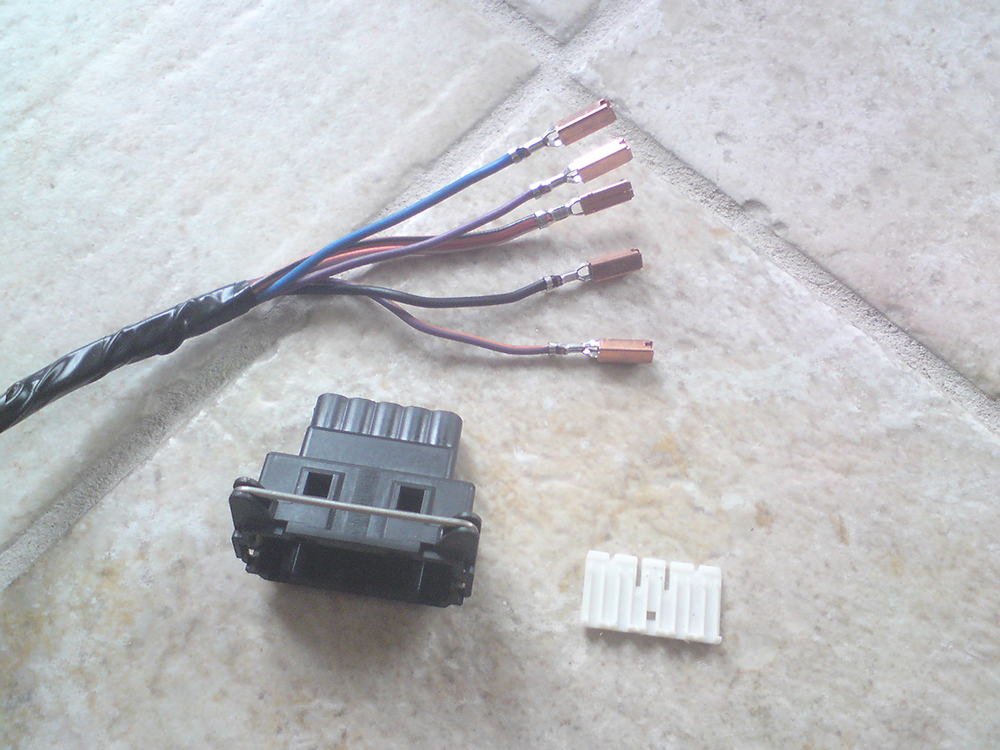

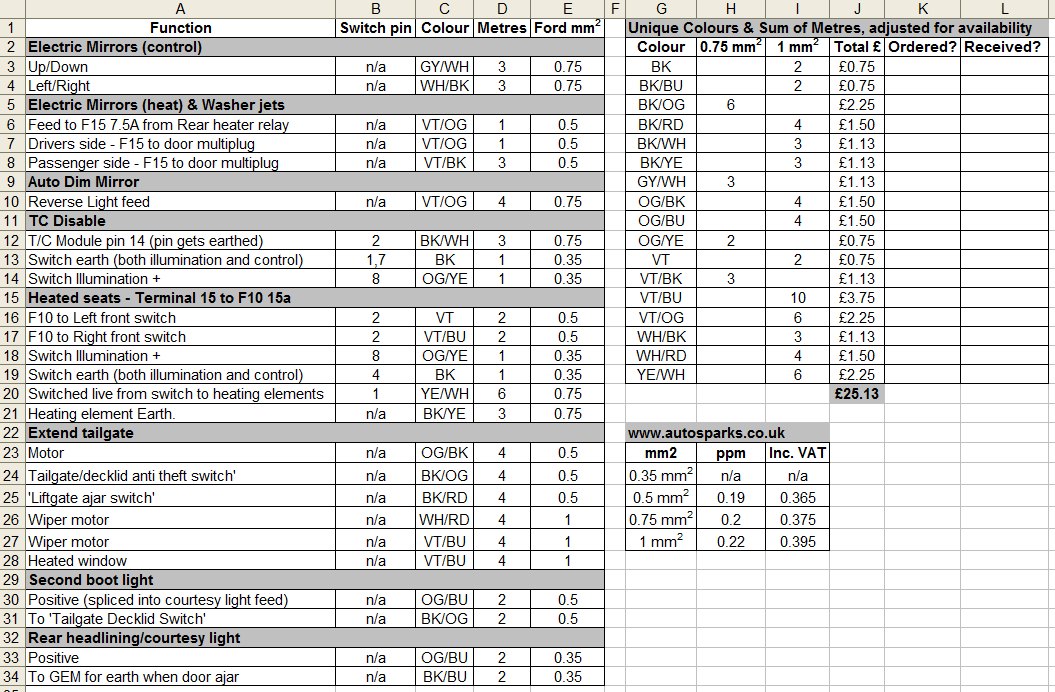

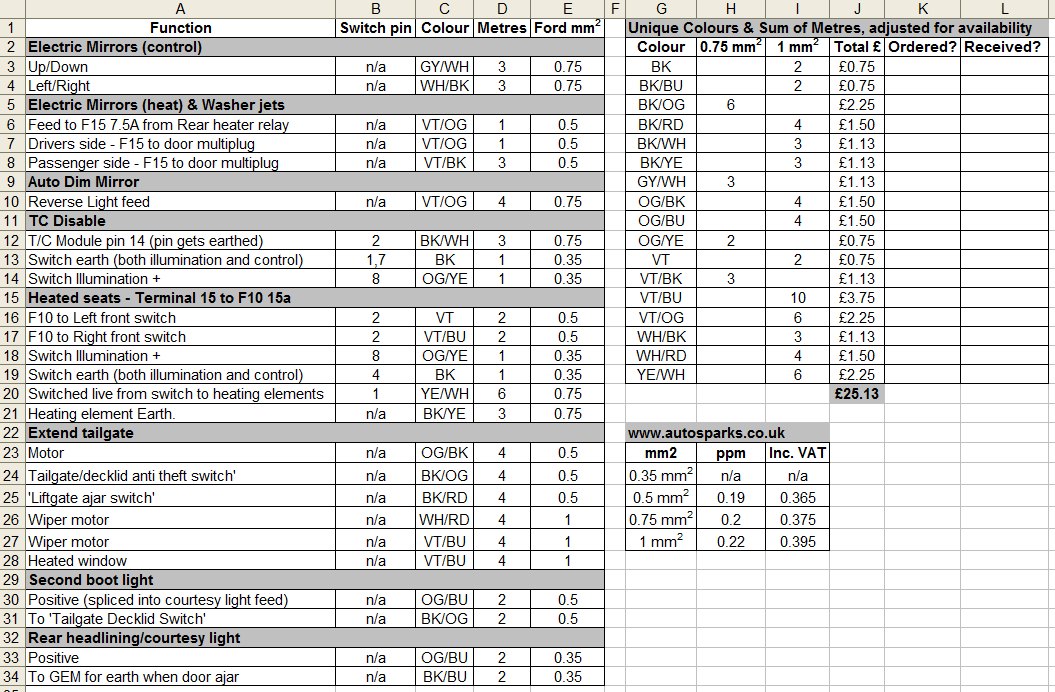

Small update, I've put together an order for the additional Thin Wall cable that I need to add extra features to the loom. I found a supplier who can match all of the MY2000+ Ford colours, which is great. It took a while!

I will be spraying the base coat this weekend.

The wiring turned up, so I've started on that.

1200 wet and dry for the primer:

Dark Aubergine:

The joys of painting in a garage :lol:

First coat of base coat (needs another):

Some engine purchases.

Brand new Ford Crate Engine - Series 3/Black Top 2.0

Brand new Focus RS Mk1 Pistons and Rods

I was going to fit a Focus RS engine, but the cost/benefit ratio didn't stack up for me. I appreciate the FRS lump has a 30% increased flow water pump, and unique cams, and valve springs, but the design goal for this project is a road car. It'll be given to my girlfriend for her runabout (I'll pinch it for the odd track day!), so power will be capped to 280ish bhp. For this I don't need anything exotic in terms of hardware, and it will be managed by EECV management for great driveability.

Lacquer - Part 1 of many

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

If Satan did electrical work...

.JPG)

One pair of the motor coil feed wires has burnt out on my compressor.

.JPG)

I've replaced them...

.JPG)

...but the motor still hums when I turn it on. I've ordered a new start and run capacitor: they look pretty old and are cheap enough compared to the cost of a new motor.

.JPG)

.JPG)

I suspect a new 3hp motor may be in order, but I'll try swapping out the caps first. I'll tidy up the motor wiring whatever happens!

I'm a bit disappointed as I could have got the first coat of lacquer on the car today, and I'm anxious to get it done ahead of the really cold weather. I'm back in 3 weeks' time so I hope it's still fairly mild.

Ahh well. At least this happened before I started rather than half way through a panel

The Exhaust Manifold has arrived (that is not my chair!):

I'll soon have some photos of the shell complete with lacquer and after being and 'mopped'.

Old manifold sold. That didn't take long, One hr in fact!

Meet the new one

Focus WRC Inconel manifold

I have tracked down a V Band exhaust housing, TiAL make one in both .64 and .86 A/R

This is perfect, but only worth doing if the WRC external wastegate tubes fit under the bonnet. I'll have to test fit in order to find out.

xrsi has taken some pics of the parts that I'm buying from him.

Mk5 rear turrets:

ABS/TC module

Equal length drive shaft:

ZS brake servo, brake pedal and link bar - I have a suspicion that the Pedal ratio is higher in the Mk5:

I also bought some cruise control buttons last week, from a Mk1 Focus. I'm going to fit Cruise Control. I'm pretty sure I can get the cruise control buttons mounted to the Mk3.5 steering wheel and end up with it all looking OEM. The only challenge will be the lack of contacts on the Fiesta slip ring/clock spring. I will either double up the standard clock spring ribbon, or modify a Focus one somehow.

My temp clock:

I'll be back this weekend to carry on with it.

I have done some analysis of the the Mk1 Mondeo and Phase 2 Zetec-S Wiring Diagrams:

I'm a bit gutted that the Zetec-S only runs the 60- Pin EECV ECU because I wanted to perform the majority of wiring prep work now to support a Focus RS Engine on EECV (aftermarket management just doesn't compare IMO). At least the ZS does run the SCP bus, which will enable me to fit some more interesting instruments at some point, and get some data logging on the go.

Looks like I need to find a 104 Pin FRS Engine bay loom for when I do get the FRS Engine. I missed a brand new one a few days ago for £44 not realising at the time that the ZS only had 60 pins. Doh!

For now, the main priority is to use the ZS loom to run the Series 1 2.0 from EECIV, which can be done quite easily. The ZS engine bay loom just unplugs from the engine bay fuse box anyway, so it's not a major project to take it out and modify it later on.

Recaro retirm progress - thanks to my girlfriend's Mum!

I helped by stripping the old covers into their component parts:

Then cut new pieces using the FRST fabric as templates:

Here's a thigh bolster, now in Si fabric:

More tomorrow.

I had some time off last week and spent four days on the body, with the kind help of my Dad. I'm really happy with how its turned out, it's now finally ready for etch primer, but it took four days to get how I want it.

I reached a point where I decided to respray every panel, including the interior area. The shell will be sprayed as Ford did - no masking (aside from the wheel wells and chassis number). I welded in a Mk5 bulkhead, rear turrets and front turrets (modified slightly to correct the roll-centre).

I think I already mentioned that I have a set of low-mileage ST170 brakes on their way, and I've got a set of Mk5 Zetec-S GMAX to go on initially, and once I'm happy these will be replaced by Bilstein B8 struts.

On the Electronics side, I have the loom with me here in London and I've wired in an Ice warning/outside temp clock and Focus heated washer jets. I have a Waco Heated Seat kit on order along to go on with the freshly trimmed Recaro covers. I ordered a Focus gear surround trim with the OEM heated seat switches. I have re-wired the rear lamp connectors to suit the Mk3:

I replaced the wiper motor with the Mk3 connector. I made the decision to keep the Mk3 motor - I could have easily swapped it for a Mk5 mechanism, but I didn't for 2 reaons: 1) I have a low mileage Mk3 motor which still operates at the correct speed, and 2) I didn't swap for the Mk5 scuttle, on which the fins are blocked off above the wiper. The Mk5 does use a waterproof AMP Timer Housing connector, but I'd rather keep the shielded Mk3 motor for guaranteed reliability in wet weather.

I discovered on eTIS that the Mk5 was available in some markets with Keyless Entry, which is really impressive for the age. I need to track down part numbers for the correct GEM.

The crap photos/text update here do not represent the amount of work that's gone into the car, but it will all come together soon and then I'll post something more interesting.

My mind is still on the engine, as a N/A 2.0 Zetec-E doesn't match the quality of the rest of the car!

My Dad wet flatted the car for me after I went back last time (the car is at my parents house in the midlands - I live in London). He did an awesome job, really good of him!

I delayed the painting today to get the Mk5 rear turrets fitted. Excuse the state of the shell, it's filthy due to ongoing works:

No lap joints here! They have gone on in the way Ford would have built the shell, it took a couple of hours to unpick the seams but it's worth it.

Mk5 bulkhead in place. I have also seam welded the A pillar and bulkhead area to stiffen the scuttle.

Mk5 Back panel. It took a lot of modification to fit well, including a little panel beating. I wouldn't recommend it as it's simply not worth the effort for the small gain. It would have taken less time to modify the Mk3 version with a hammer and dolly.

Small jobs left for the morning: seam seal all new joins, and modify the bonnet to accept the Focus heated washer jets.

It will be in etch primer tomorrow afternoon, and then standard primer for tomorrow evening. I should have the base coat on during Saturday 8)

Some photos of the modifications required to correctly fit a Mk4/5/Puma dash. After seeing a few of these done and the work that was undertaken, I had the impression that it sat relatively well in the Mk3 chassis - it doesn't at all.

The work I've done:

Remove Mk3 upper centre mount and weld on Mk5 version approximately 15mm closer to windscreen

Substantially modify the steering column

Cut off the face of the A pillar mounts, and weld on a new face 7mm further forward.

Weld strengthening plate in centre console area for dash to floor bracket.

Weld in Mk5 bulkhead area.

Here are a few photos from the steering column work. I made a hybrid Mk3/Mk5 column support, so I can retain the Mk3 steering shaft and ignition key bracket.

Mk3 column:

Brand new Mk5 column:

Mk3 upper brace removed:

Rear box removed from Mk5 column (steering tube is different):

Modified Mk5 column support sleeved over the Mk3 lower section:

Primer photos later

1 coat of 2k etch primer (on panels), and 1 coat of HS filler primer.

Everything was painted seperately, I've just put the various parts back on the car to move it around:

Small update, I've put together an order for the additional Thin Wall cable that I need to add extra features to the loom. I found a supplier who can match all of the MY2000+ Ford colours, which is great. It took a while!

I will be spraying the base coat this weekend.

The wiring turned up, so I've started on that.

1200 wet and dry for the primer:

Dark Aubergine:

The joys of painting in a garage :lol:

First coat of base coat (needs another):

Some engine purchases.

Brand new Ford Crate Engine - Series 3/Black Top 2.0

Brand new Focus RS Mk1 Pistons and Rods

I was going to fit a Focus RS engine, but the cost/benefit ratio didn't stack up for me. I appreciate the FRS lump has a 30% increased flow water pump, and unique cams, and valve springs, but the design goal for this project is a road car. It'll be given to my girlfriend for her runabout (I'll pinch it for the odd track day!), so power will be capped to 280ish bhp. For this I don't need anything exotic in terms of hardware, and it will be managed by EECV management for great driveability.

Lacquer - Part 1 of many

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

If Satan did electrical work...

.JPG)

One pair of the motor coil feed wires has burnt out on my compressor.

.JPG)

I've replaced them...

.JPG)

...but the motor still hums when I turn it on. I've ordered a new start and run capacitor: they look pretty old and are cheap enough compared to the cost of a new motor.

.JPG)

.JPG)

I suspect a new 3hp motor may be in order, but I'll try swapping out the caps first. I'll tidy up the motor wiring whatever happens!

I'm a bit disappointed as I could have got the first coat of lacquer on the car today, and I'm anxious to get it done ahead of the really cold weather. I'm back in 3 weeks' time so I hope it's still fairly mild.

Ahh well. At least this happened before I started rather than half way through a panel

The Exhaust Manifold has arrived (that is not my chair!):

I'll soon have some photos of the shell complete with lacquer and after being and 'mopped'.

Old manifold sold. That didn't take long, One hr in fact!

Meet the new one

Focus WRC Inconel manifold

I have tracked down a V Band exhaust housing, TiAL make one in both .64 and .86 A/R

This is perfect, but only worth doing if the WRC external wastegate tubes fit under the bonnet. I'll have to test fit in order to find out.

Edited by mwstewart on Wednesday 13th February 15:35

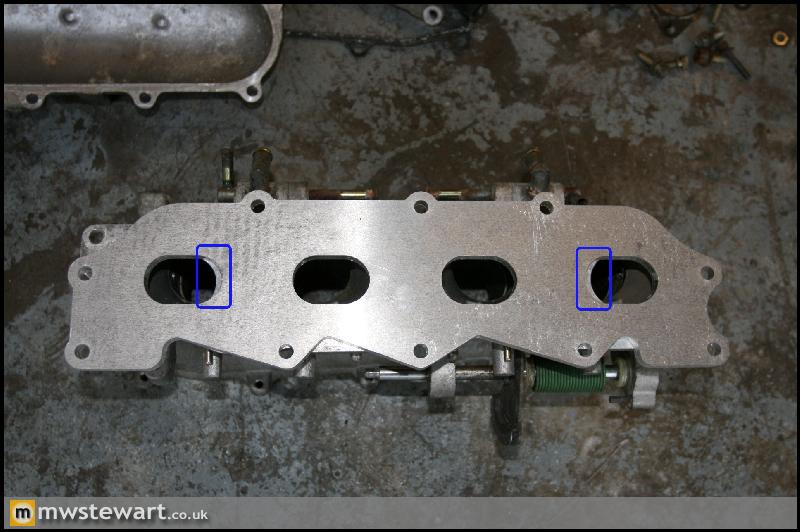

New inlet manifold. I've wanted to use this manifold for about nine years now, but never had a project that would suit it.

It has 46mm ITB's and a great plenum design that I can easily space to suit my capacity requirements.

It's going to be a lot of work, and I'm not sure about fitment around a black top alternator, and also in my application the engine will be tilted to aid weight distribution, but if I can make it work it'll be amongst the best of the Zetec inlet manifolds to date.

Here are the port centres compared with a Rover inlet gasket, pretty close! A small amount of welding and porting required on Cyl. 1 and 4.

Other examples:

For a Turbo app the ITBs don't make any difference at WOT, although going from part throttle to WOT is much crisper. It's worth it for the small outlay of the second hand manifold.

Loom work ongoing.

[list]

[*]Electric mirrors

[*]Heated mirror glass, heated washer jets - both switch on with the heated rear window

[*]Switchable TC

[*]Heated Seats

[*]Additional boot light

[*]Rear passenger courtesy light[/list]

I have bought and used OEM wiring colours, and the correct fabric tape for interior sections.

I managed to get a complete set of Black Top ancillaries that have done only 4k miles.

All my weekends are booked up 'till Christmas, so this will be the last update for a while.

More parts have arrived:

New HFS loom

Courtesy lights for under the sun visors

Heated Front Seat Kit

I'll probably add some footwell lights and a second boot light.

More nick-nacks: Glove box light and additional boot light.

Looks good considering it's covered in dust from the mop.

I had a boy fit the new heated screen.

I now have bags of new bits to wade through as I start rebuilding her

I have bought a Focus RS Mk1 inlet manifold and some brand new injectors. This obviously is a bolt on solution for the Zetec, so I'm going to use this initially whilst I take some time to sort out the Pulsar inlet.

If I stay this route, then the Ford Racing manifold becomes an option.

I could do with a spare 1.8/2.0 head to help mock up the Pulsar inlet.

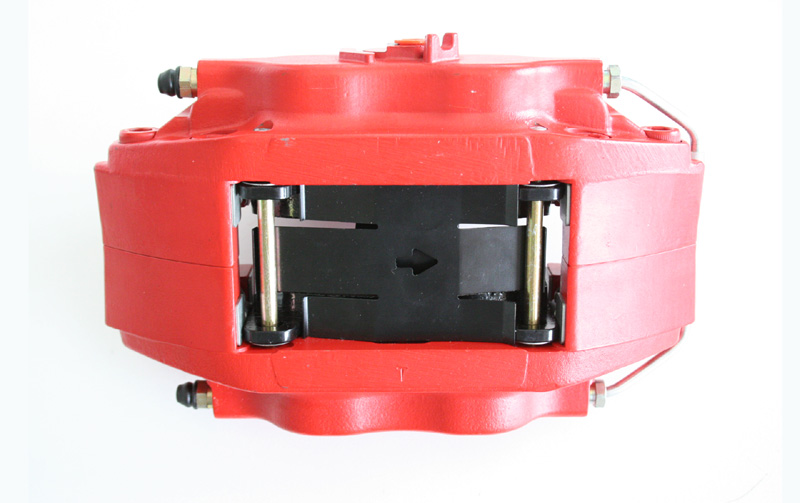

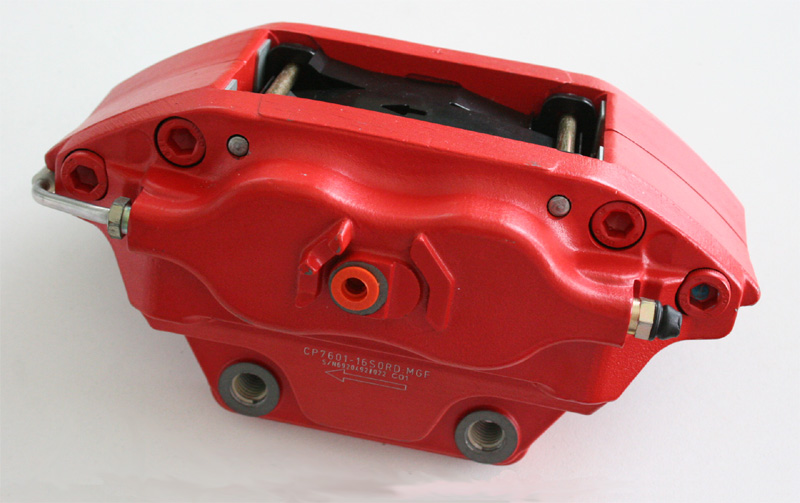

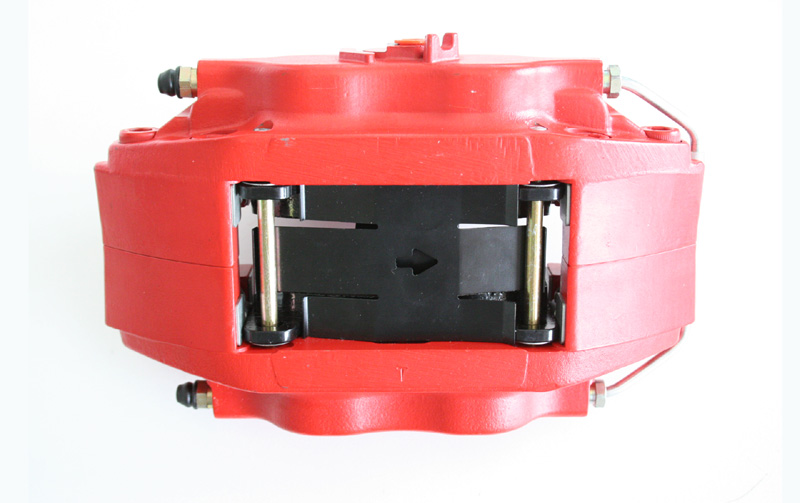

I did some research into dimensions/specifications of various OEM fitment four pot calipers from different brands, knowing that the obvious choices are just blatantly over priced. I setteld on the MGTF Trophy/T160 AP Racing calipers:

The MG area will be milled flat, the calipers resprayed in gloss black with the standard yellow AP Racing decals i.e.:

My choice was based on the data which I collected:

MGTF

PCD: 4x98.5 mm

Wheel Centre bore: 56.6 mm

Caliper lug spacing: 82.55 mm

Disc size: 304 mm

Fiesta

PCD: 4×108 mm

Wheel Centre bore: 63.4 mm

Caliper lug spacing: 82.55 mm

I plan to use the calipers with ST170 discs. The loss of 2mm on each side of the disc is offset by a ridge on the MG pads. If the ST170 discs don't suit the caliper offset then I will have the centre bores on the MG discs enlarged and the holes milled to suit the Ford PCD.

The Calipers should be a bolt on solution, if not they will be modified to suit. Two piece discs will be added later. All in, I've saved at least £1200 off an AP kit.

New wiper arms, full set of badges, sunroof bracket seals, door catches and some Mk8 Fiesta front panel clips to hold on the side skirts.

Butyl based Sound Deadening in tailgate, doors and rear quarters (thanks Dad), then the locks, motors etc. were added.

Dinitrol 3125 added to door and tailgate reveals prior to reassembly.

This adapter tube gives a 1m reach into box sections and its special head gives a 360 degree spray of wax, it's been very useful. I've pumped two cans into each sill.

New Mk5 Deadlocks and strikers.

I bought Mk3.5 strikers not knowing the Mk5 part was different: they look nearly identical, but there are a few small & important dimensional differences. I'll have to wait until after the holidays to order some Mk5 versions (Mk5 left, Mk3.5 right):

I also dropped off the brakes to my local engineers to have a few changes made.

Got some new bits:

Focus RS head - Ported and fully rebuilt with oversize valves, new stems etc.

Newman sports cams

Vernier pulleys

Focus RS ECU, Wiring Loom and Key

Focus RS Fuel Rail and Injectors

Focus RS Inlet manifold

Another set of brand new FRS pistons (I'll keep these as spares)

I've already got some of the above, so this gives me chance to pick and choose.

Well the interior retrim is being handled by someone else, which leaves the following main chunks of work:

- Engine build

- Wiring

- Engine bay modifications (ABS, engine mounts, gearbox mounts)

- Engine bay paint

- General reassembly

I've decided to outsource the engine build to someone else because the reality is that this project would likely end up going into next year. I've just got too much going on now to really get this Si finished in a decent amount of time - which is a bit pointless in this case as it isn't a show car; I'm building it as something that can be used every day! I'm a bit dissapointed about this in one way, as it's something I'm more than capable of doing and I feel like I'm giving away part of my project to someone else - but I had to make a sensible decision here based on what I can realisitcally get done in a sensible timeframe.

I've been friends with Ian Howell for years now so he's going to take on my engine build to get away from the Wife and Kids for a bit What I'll get back is 400bhp ready to bolt in, which leaves me to sort out fabrication and rebuilding the car, so I may actually get it on the road for this summer.

What I'll get back is 400bhp ready to bolt in, which leaves me to sort out fabrication and rebuilding the car, so I may actually get it on the road for this summer.

""[u]Desired Spec[/u]

* I'd like to keep the rev ceiling at 7.5k for long term reliability.

* I'd like to do whatever possible to keep NVH to a minimum (if that's at all possible)

* 400bhp max

Long term reliability is also a consideration for me, I'd like it to be 'turn key' for years to come. The car won't be used for any kind of launches or sprinting, but I do like flat out high speed driving, so I'd like it to be able to withstand that. I hadn't added anything regads engine response, rev band etc as I doubt this is much of a consideration in something so light as a Fiesta!

Most important to me would be low speed tractability and good manners (I suspect this is down to the map) - I'd like to be able to take the car away for a weekend and use it for 'normal' activities and around town if I wanted.""

Dropped off the engine today, spec is:

[list]

[*]Ported exhaust side (being a Black Top the inlet flows 20% more than a Sliver Top as standard)

[*]Ians exhaust cam and vernier pulleys on both cams

[*]Focus RS Pistons

[*]Ians rods to suit the 22mm pin pistons

[*]GT2871R and I'm going for a bigger exhaust housing to reduce back pressure - this will raise boost threshold by 250rpm but keep under bonnet temps lower

[*]TiAL stainless steel exhaust housing

[*]Pulsar inlet manifold

[*]Couple of thou honed from the standard bores to allow more expansion room for the pistons, because I want the engine to withstand my high speed driving (props to Ian for this as I wouldn't have known this tip!)

[*]WRC Inconel exhaust manifold[/list]

That's about it - there's really not much work involved to get 400, especially when starting with a brand new Black Top! I'm having it mapped on the Dyno with Pectel T2; I thought T2 was prehistoric but Ian assured me that the processor in it is still better than Autronic. I asked for 400 and Ian said I'll get a good 400 - so we'll have to wait and see what that means :lol:

I'm working on the car today and tomorrow. I hope to get the side skirts on, and the mk5 pedal box in.

I fabricated some brackets to hold the edge of the RS skirts firmly against the sill - I rolled a step into some 1mm sheet which will trap the return lip on the inside edge of the skirts. No they're not perfectly straight, I rough cut them with an angle grinder :lol:

Mk8 Fiesta front panel clips for the bottom of the skirts (up into the sill) - these weren't long enough in the end, I think they were over £1 each and I over ordered in a big way :lol:

I will try something like this:

Drilling holes for the brackets and trim clips - I pumped a load more wax into each hole until it was dripping out of the sill join. I then painted each sill with semi-set Waxoyl.

Brackets fitted and a skirt fitted to show the good fit

Windows are in, new side mouldings, new weather seals etc (had to wait an age for the Mk5 aperture seals as they were on back order!) and new genuine lights all round - although I have changed my mind about the lights and will fit some smoked side repeaters and my UK RS accessory rear lamps. Here's the car with the skirts and new brakes fitted. I'm going for silver calipers with blue AP Racing decals.

I'm still waiting for a Mk5 aerial which is on back order, when it arrives the car will be water tight and I can give it a good clean. I will take some pics with a decent camera when that's done!

£370 gets you this - i.e. not a lot, mainly fixtures and fittings!

Arch spats back on:

Genuine Ford Stainless scuff plates and the correct Mk5 strikers:

New deadlocks and full spec door looms fitted, new door lock & handle rods, new check straps, and new bungs for the a pillars :

New screws for sunroof brackets, and new foam gaskets behind:

The orange indicators really didn't suit Aubergine, smoked looks much better

Just ordered a set of Team Dynamics Pro Race 1.2 in Gloss Anthracite, 7x16 ET38 and with 195/45/16 F1 GSD3.

I'm now focusing on the engine bay so I can get it painted.

Pulsar inlet stripped down ready for modification.

Throttle plates removed.

Here's a 10mm alloy Zetec inlet flange laid over the top to show the port work involved:

Next up is my Mk2 Focus TC/ABS module (right) compared with the Mk5 Fiesta ABS module (left). Physically they very similar which means the Mk5 mounting bracket can be swapped to the Focus module for relatively easy mounting to the Mk3 bay. The only major difference is the wiring plug, and the fact the Focus module uses a different type of ABS sensor.

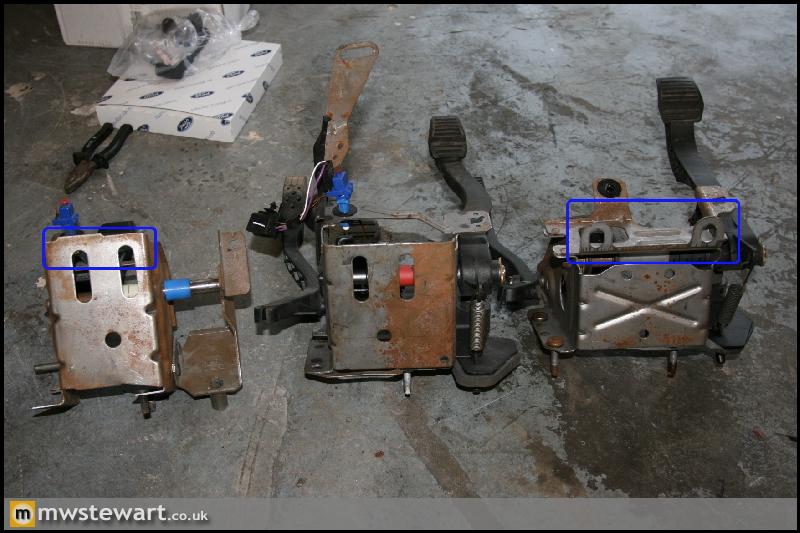

Hydraluic clutch conversion. I was going to use the Mk5 pedal box as I wanted the improved brake link bar setup from that model, but I remembered I had a nearly new Sport Ka pedal box which had the same upgrade, and after some examination it's a near enough bolt on part (the Ka is much more closely aligned with the Mk3 than the Mk4/5 are).

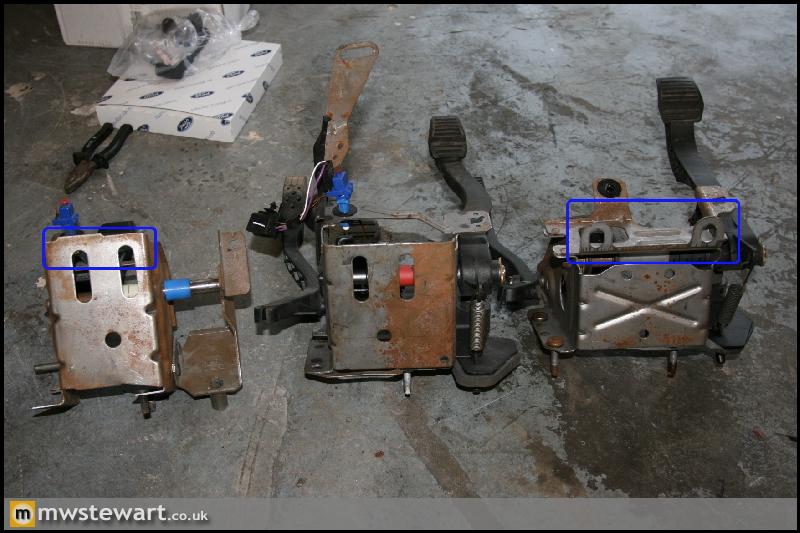

Mk5 (left) Ka (centre), Mk3 (right)

Mk3 (left) Ka (centre), Mk5 (right). You can see the entirely different dimensions of the mk5 box:

I've just given Ian H the go-ahead for a big valve head, double valve springs and 500+ capability. Ian hasn't used a GTX yet so I've been looking in to them to see what they offer. The unit in my kind of power range would be the GTX3071R, which would see 550.

It's been mainly the Subaru guys testing these so far and there is some good data out there if you can find it.The GTX3071R has a similar 60mm Turbine to the GT3076R and dyno tests have shown that the GT3071R (60mm) and GT3076R spooled up pretty much the same on the Dyno, so I'd expect the GTX3071R to be very similar.

""We always tell customers, buy the turbo that fits your needs and nothing bigger as it will be slower responding for no reason. In the case of the GTX3071r, I see no reason to sell these as it should spool the same and will make less power than the GTX3076. What I would say is this customer should consider buying the GT3076r as it flows about the same and costs much less. Keep in mind I am guessing that the GTX3071 spools just like a GT3071 because of my results I found with the GT3076/GTX3076 comparison, and my GT3071/GT3076 comparison all using the same turbine wheel.

If you want more response than the GT3076r then you need to look at the GT3071r with the smaller 56.5mm turbine wheel. Garrett doesn't offer this with a GTx wheel which is too bad.""

The 56.5mm wheel is missing for me at the moment! The one thing that does attract me to the GTX is the noise, or lack of it from the new 11 vane turbine.

The best of the links I found:

http://forums.nasioc.com/forums/showthread.php?t=2...

http://bbs.scoobynet.com/799025-scoobyclinics-turb...

I also just found a local powder coating firm who actually undercoat, none of the firms I've used in the past have done this and I learnt from experience that the less durable finishes like satin always chip and leave rust after a while. I will be going for undercoat this time as it saves me from getting suspension components hot dip galvanised first by a different firm! I'll be going for gloss black as I find it more durable.

I've spent the last two Saturday's at different breakers and I've now managed to amass the parts I need for the entire project. It's been a while since I've been to a scrap yard, and it seems as time has moved on and now the majority of Mk5's in are now of a poor standard! It took me a while to find some decent parts from the Mk5's they had in.

Some more inspiration from the Mk5: bracing the bulkhead by joining the rear face of the front chassis legs to the scuttle panel. The brackets were fashioned from CDS and the mounts were pressed into 1.5mm sheet, then the high tensile bolts welded into the recess so they stuck through. Big thanks to my Dad who was helping me today!:

Location of chassis legs marked on the bulkhead. Note spot welds:

Mounts welded in and braces on. You may think 'that won't do anything!', but I've placed them so that the brackets are under compression when tightened, and it has actually done a great job of further reinforcing the scuttle area (which I already seam welded):

I discovered that non-deadlock lock barrels don't have the nessecary tab to actuate the barrel sensors, so I got a set of deadlock barrels from the breakers and rebuilt my existing ones to suit (note the extra tab):

In the car with new lock rods and sensor

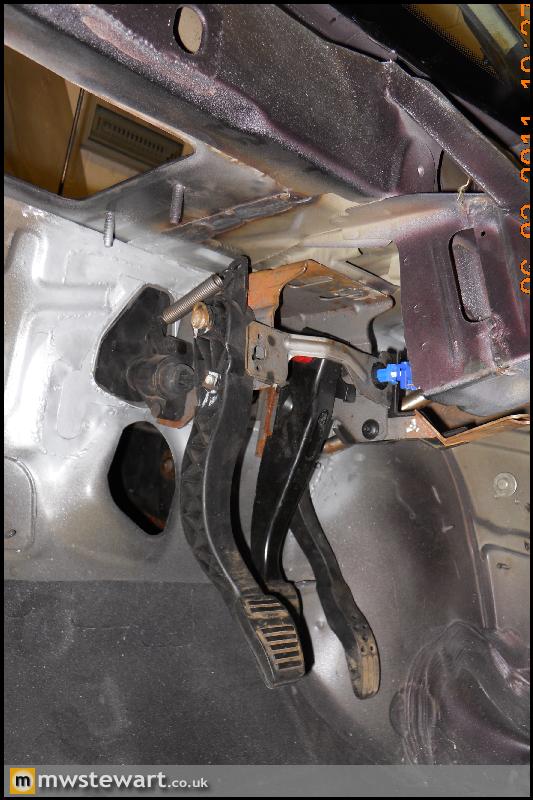

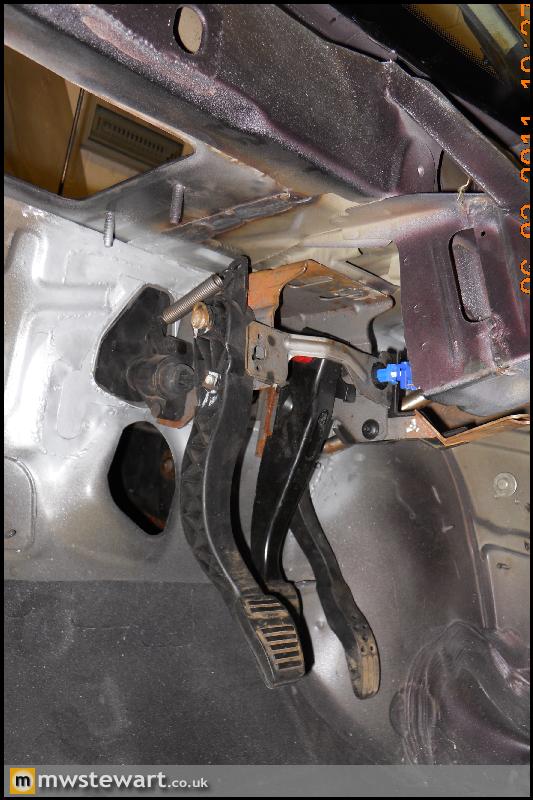

Next up was the hydraulic clutch conversion, which involved some time consuming fabrication. Standard pedal box area:

New plate in to reinforce the pedal box area, cover up the original heater matrix outlet, and house the hydraulic clutch housing of the Ka pedal box:

And the same again on the servo bracket. I want to improve pedal feel as much as possible, so I reinforced the bulkhead knowing that it flexes under heavy breaking:

Primed:

Ka Pedal box in:

I've now got all the small clips and fastenings for the shell - I'm pretty fussy and don't like over spray on anything, even if it's not seen, so all of these will be fitted:

Finally I gave all front end chassis sections a good application of Dinitrol and I cannot recommend this product highly enough. I used to thin Wayoyl with paraffin, but if you go too far with that then you've lost all the protection. The Dinitrol comes out of the can like water but sets with a decent thickness - it's brilliant:

It has 46mm ITB's and a great plenum design that I can easily space to suit my capacity requirements.

It's going to be a lot of work, and I'm not sure about fitment around a black top alternator, and also in my application the engine will be tilted to aid weight distribution, but if I can make it work it'll be amongst the best of the Zetec inlet manifolds to date.

Here are the port centres compared with a Rover inlet gasket, pretty close! A small amount of welding and porting required on Cyl. 1 and 4.

Other examples:

For a Turbo app the ITBs don't make any difference at WOT, although going from part throttle to WOT is much crisper. It's worth it for the small outlay of the second hand manifold.

Loom work ongoing.

[list]

[*]Electric mirrors

[*]Heated mirror glass, heated washer jets - both switch on with the heated rear window

[*]Switchable TC

[*]Heated Seats

[*]Additional boot light

[*]Rear passenger courtesy light[/list]

I have bought and used OEM wiring colours, and the correct fabric tape for interior sections.

I managed to get a complete set of Black Top ancillaries that have done only 4k miles.

All my weekends are booked up 'till Christmas, so this will be the last update for a while.

More parts have arrived:

New HFS loom

Courtesy lights for under the sun visors

Heated Front Seat Kit

I'll probably add some footwell lights and a second boot light.

More nick-nacks: Glove box light and additional boot light.

Looks good considering it's covered in dust from the mop.

I had a boy fit the new heated screen.

I now have bags of new bits to wade through as I start rebuilding her

I have bought a Focus RS Mk1 inlet manifold and some brand new injectors. This obviously is a bolt on solution for the Zetec, so I'm going to use this initially whilst I take some time to sort out the Pulsar inlet.

If I stay this route, then the Ford Racing manifold becomes an option.

I could do with a spare 1.8/2.0 head to help mock up the Pulsar inlet.

I did some research into dimensions/specifications of various OEM fitment four pot calipers from different brands, knowing that the obvious choices are just blatantly over priced. I setteld on the MGTF Trophy/T160 AP Racing calipers:

The MG area will be milled flat, the calipers resprayed in gloss black with the standard yellow AP Racing decals i.e.:

My choice was based on the data which I collected:

MGTF

PCD: 4x98.5 mm

Wheel Centre bore: 56.6 mm

Caliper lug spacing: 82.55 mm

Disc size: 304 mm

Fiesta

PCD: 4×108 mm

Wheel Centre bore: 63.4 mm

Caliper lug spacing: 82.55 mm

I plan to use the calipers with ST170 discs. The loss of 2mm on each side of the disc is offset by a ridge on the MG pads. If the ST170 discs don't suit the caliper offset then I will have the centre bores on the MG discs enlarged and the holes milled to suit the Ford PCD.

The Calipers should be a bolt on solution, if not they will be modified to suit. Two piece discs will be added later. All in, I've saved at least £1200 off an AP kit.

New wiper arms, full set of badges, sunroof bracket seals, door catches and some Mk8 Fiesta front panel clips to hold on the side skirts.

Butyl based Sound Deadening in tailgate, doors and rear quarters (thanks Dad), then the locks, motors etc. were added.

Dinitrol 3125 added to door and tailgate reveals prior to reassembly.

This adapter tube gives a 1m reach into box sections and its special head gives a 360 degree spray of wax, it's been very useful. I've pumped two cans into each sill.

New Mk5 Deadlocks and strikers.

I bought Mk3.5 strikers not knowing the Mk5 part was different: they look nearly identical, but there are a few small & important dimensional differences. I'll have to wait until after the holidays to order some Mk5 versions (Mk5 left, Mk3.5 right):

I also dropped off the brakes to my local engineers to have a few changes made.

Got some new bits:

Focus RS head - Ported and fully rebuilt with oversize valves, new stems etc.

Newman sports cams

Vernier pulleys

Focus RS ECU, Wiring Loom and Key

Focus RS Fuel Rail and Injectors

Focus RS Inlet manifold

Another set of brand new FRS pistons (I'll keep these as spares)

I've already got some of the above, so this gives me chance to pick and choose.

Well the interior retrim is being handled by someone else, which leaves the following main chunks of work:

- Engine build

- Wiring

- Engine bay modifications (ABS, engine mounts, gearbox mounts)

- Engine bay paint

- General reassembly

I've decided to outsource the engine build to someone else because the reality is that this project would likely end up going into next year. I've just got too much going on now to really get this Si finished in a decent amount of time - which is a bit pointless in this case as it isn't a show car; I'm building it as something that can be used every day! I'm a bit dissapointed about this in one way, as it's something I'm more than capable of doing and I feel like I'm giving away part of my project to someone else - but I had to make a sensible decision here based on what I can realisitcally get done in a sensible timeframe.

I've been friends with Ian Howell for years now so he's going to take on my engine build to get away from the Wife and Kids for a bit

What I'll get back is 400bhp ready to bolt in, which leaves me to sort out fabrication and rebuilding the car, so I may actually get it on the road for this summer.

What I'll get back is 400bhp ready to bolt in, which leaves me to sort out fabrication and rebuilding the car, so I may actually get it on the road for this summer.""[u]Desired Spec[/u]

* I'd like to keep the rev ceiling at 7.5k for long term reliability.

* I'd like to do whatever possible to keep NVH to a minimum (if that's at all possible)

* 400bhp max

Long term reliability is also a consideration for me, I'd like it to be 'turn key' for years to come. The car won't be used for any kind of launches or sprinting, but I do like flat out high speed driving, so I'd like it to be able to withstand that. I hadn't added anything regads engine response, rev band etc as I doubt this is much of a consideration in something so light as a Fiesta!

Most important to me would be low speed tractability and good manners (I suspect this is down to the map) - I'd like to be able to take the car away for a weekend and use it for 'normal' activities and around town if I wanted.""

Dropped off the engine today, spec is:

[list]

[*]Ported exhaust side (being a Black Top the inlet flows 20% more than a Sliver Top as standard)

[*]Ians exhaust cam and vernier pulleys on both cams

[*]Focus RS Pistons

[*]Ians rods to suit the 22mm pin pistons

[*]GT2871R and I'm going for a bigger exhaust housing to reduce back pressure - this will raise boost threshold by 250rpm but keep under bonnet temps lower

[*]TiAL stainless steel exhaust housing

[*]Pulsar inlet manifold

[*]Couple of thou honed from the standard bores to allow more expansion room for the pistons, because I want the engine to withstand my high speed driving (props to Ian for this as I wouldn't have known this tip!)

[*]WRC Inconel exhaust manifold[/list]

That's about it - there's really not much work involved to get 400, especially when starting with a brand new Black Top! I'm having it mapped on the Dyno with Pectel T2; I thought T2 was prehistoric but Ian assured me that the processor in it is still better than Autronic. I asked for 400 and Ian said I'll get a good 400 - so we'll have to wait and see what that means :lol:

I'm working on the car today and tomorrow. I hope to get the side skirts on, and the mk5 pedal box in.

I fabricated some brackets to hold the edge of the RS skirts firmly against the sill - I rolled a step into some 1mm sheet which will trap the return lip on the inside edge of the skirts. No they're not perfectly straight, I rough cut them with an angle grinder :lol:

Mk8 Fiesta front panel clips for the bottom of the skirts (up into the sill) - these weren't long enough in the end, I think they were over £1 each and I over ordered in a big way :lol:

I will try something like this:

Drilling holes for the brackets and trim clips - I pumped a load more wax into each hole until it was dripping out of the sill join. I then painted each sill with semi-set Waxoyl.

Brackets fitted and a skirt fitted to show the good fit

Windows are in, new side mouldings, new weather seals etc (had to wait an age for the Mk5 aperture seals as they were on back order!) and new genuine lights all round - although I have changed my mind about the lights and will fit some smoked side repeaters and my UK RS accessory rear lamps. Here's the car with the skirts and new brakes fitted. I'm going for silver calipers with blue AP Racing decals.

I'm still waiting for a Mk5 aerial which is on back order, when it arrives the car will be water tight and I can give it a good clean. I will take some pics with a decent camera when that's done!

£370 gets you this - i.e. not a lot, mainly fixtures and fittings!

Arch spats back on:

Genuine Ford Stainless scuff plates and the correct Mk5 strikers:

New deadlocks and full spec door looms fitted, new door lock & handle rods, new check straps, and new bungs for the a pillars :

New screws for sunroof brackets, and new foam gaskets behind:

The orange indicators really didn't suit Aubergine, smoked looks much better

Just ordered a set of Team Dynamics Pro Race 1.2 in Gloss Anthracite, 7x16 ET38 and with 195/45/16 F1 GSD3.

I'm now focusing on the engine bay so I can get it painted.

Pulsar inlet stripped down ready for modification.

Throttle plates removed.

Here's a 10mm alloy Zetec inlet flange laid over the top to show the port work involved:

Next up is my Mk2 Focus TC/ABS module (right) compared with the Mk5 Fiesta ABS module (left). Physically they very similar which means the Mk5 mounting bracket can be swapped to the Focus module for relatively easy mounting to the Mk3 bay. The only major difference is the wiring plug, and the fact the Focus module uses a different type of ABS sensor.

Hydraluic clutch conversion. I was going to use the Mk5 pedal box as I wanted the improved brake link bar setup from that model, but I remembered I had a nearly new Sport Ka pedal box which had the same upgrade, and after some examination it's a near enough bolt on part (the Ka is much more closely aligned with the Mk3 than the Mk4/5 are).

Mk5 (left) Ka (centre), Mk3 (right)

Mk3 (left) Ka (centre), Mk5 (right). You can see the entirely different dimensions of the mk5 box:

I've just given Ian H the go-ahead for a big valve head, double valve springs and 500+ capability. Ian hasn't used a GTX yet so I've been looking in to them to see what they offer. The unit in my kind of power range would be the GTX3071R, which would see 550.

It's been mainly the Subaru guys testing these so far and there is some good data out there if you can find it.The GTX3071R has a similar 60mm Turbine to the GT3076R and dyno tests have shown that the GT3071R (60mm) and GT3076R spooled up pretty much the same on the Dyno, so I'd expect the GTX3071R to be very similar.

""We always tell customers, buy the turbo that fits your needs and nothing bigger as it will be slower responding for no reason. In the case of the GTX3071r, I see no reason to sell these as it should spool the same and will make less power than the GTX3076. What I would say is this customer should consider buying the GT3076r as it flows about the same and costs much less. Keep in mind I am guessing that the GTX3071 spools just like a GT3071 because of my results I found with the GT3076/GTX3076 comparison, and my GT3071/GT3076 comparison all using the same turbine wheel.

If you want more response than the GT3076r then you need to look at the GT3071r with the smaller 56.5mm turbine wheel. Garrett doesn't offer this with a GTx wheel which is too bad.""

The 56.5mm wheel is missing for me at the moment! The one thing that does attract me to the GTX is the noise, or lack of it from the new 11 vane turbine.

The best of the links I found:

http://forums.nasioc.com/forums/showthread.php?t=2...

http://bbs.scoobynet.com/799025-scoobyclinics-turb...