Finally a new home

Discussion

Having moved earlier in the year, the house didn't have a garage, but a bit of land and rear access to build one for my 2006 vantage. Finally got the aston in yesterday and now embarking on those 'winter' type jobs. Main one is rear sub frame, but also big brake upgrade, v12 switchable exhaust and refurbishing alloys. Should keep me busy for a while. For info, garage is just a 5x6m wooden build, thick reinforced concrete base, automech 2 post lift.

Edited by leerandle on Sunday 22 December 12:14

Excellent. All looking good.

Your road wheels must be from a later Aston Martin, not sure which car.

You mention V12 switchable exhaust. I expect you know, that with your age Vantage there is a way (with your obvious mechanical ability) to get perfect extra sound at virtually no cost (not fuse 22, but a cat 'adjustment' and a 3 way exhaust valve switch).

Ask if you want more detailed info.

Enjoy your new car.

Dewi 2 said:

Excellent. All looking good.

Your road wheels must be from a later Aston Martin, not sure which car.

You mention V12 switchable exhaust. I expect you know, that with your age Vantage there is a way (with your obvious mechanical ability) to get perfect extra sound at virtually no cost (not fuse 22, but a cat 'adjustment' and a 3 way exhaust valve switch).

Ask if you want more detailed info.

Enjoy your new car.

This no-cost procedure is only on V12?

I know it's a long discussion but I wouldn't want to open a post unnecessarily

Thank you

Buzzi77 said:

Hi, I'm interested in your speech. I have a Vantage v8 manual 2006 without fuse 22 sounds good, but I would like more saund!

This no-cost procedure is only on V12?

I know it's a long discussion but I wouldn't want to open a post unnecessarily

Thank you

This no-cost procedure is only on V12?

I know it's a long discussion but I wouldn't want to open a post unnecessarily

Thank you

Hello Buzzi,

I will abbreviate this, because it was discussed recently on another topic.

4.3 and 4.7 up to about 2010 have the same exhaust system.

Only one pair of cats each containing two 'bricks', a 400 cell and 900 cell.

My work was done by Bamford Rose, but presumably a mechanically minded owner could do the work without cost.

The two 900 cell 'bricks' are removed, therefore leaving a pair of 400 catalytic converters.

The external cat appearance remains unchanged.

Not sure whether the ECU needs recoding to avoid error messages. The sensor is between the two 'bricks'.

BR also at the same time, fit a wired 3-way exhaust valve switch, hidden out of sight near the gear lever (manual), so the valves can be kept completely closed if required on occasions, which cannot be done using fuse 22, or associated remote control.

No MoT problems for me, in fact some figures have been improvements.

Not noticeably noisier (from Coupe cabin) during steady use, but floor the throttle and Wow!

After about 2010, manifold cats were fitted together with different secondary cats, so increasing the exhaust sound would then involve buying sports cats.

I did the rear subframe on my DB9 a few years ago before I got the same 2 post lift in my garage as yours.

https://www.pistonheads.com/gassing/topic.asp?h=0&...

https://www.pistonheads.com/gassing/topic.asp?h=0&...

Dewi 2 said:

Buzzi77 said:

Hi, I'm interested in your speech. I have a Vantage v8 manual 2006 without fuse 22 sounds good, but I would like more saund!

This no-cost procedure is only on V12?

I know it's a long discussion but I wouldn't want to open a post unnecessarily

Thank you

This no-cost procedure is only on V12?

I know it's a long discussion but I wouldn't want to open a post unnecessarily

Thank you

Hello Buzzi,

I will abbreviate this, because it was discussed recently on another topic.

4.3 and 4.7 up to about 2010 have the same exhaust system.

Only one pair of cats each containing two 'bricks', a 400 cell and 900 cell.

My work was done by Bamford Rose, but presumably a mechanically minded owner could do the work without cost.

The two 900 cell 'bricks' are removed, therefore leaving a pair of 400 catalytic converters.

The external cat appearance remains unchanged.

Not sure whether the ECU needs recoding to avoid error messages. The sensor is between the two 'bricks'.

BR also at the same time, fit a wired 3-way exhaust valve switch, hidden out of sight near the gear lever (manual), so the valves can be kept completely closed if required on occasions, which cannot be done using fuse 22, or associated remote control.

No MoT problems for me, in fact some figures have been improvements.

Not noticeably noisier (from Coupe cabin) during steady use, but floor the throttle and Wow!

After about 2010, manifold cats were fitted together with different secondary cats, so increasing the exhaust sound would then involve buying sports cats.

I knew that to give a good noise I would have to put the 200 cats as many videos explain.

A video on removal I was looking for the 400 and I didn't know it. Yet I read a lot in the forum.

I own the 4.3 2006. I will have my trusted mechanic do this job

Thank you again

Now I read more topics on the forum!

👍👍👍

For info, wheels are officially 'winter' ? dbs alloys. I love them and just dropped them off to be refurbished. The exhaust is a modified v12 exhaust so it should fit my v8 vantage (managed to get it second hand from the great james/lenny at aston installations) . I've already had the power pack upgrade from DAE combined with a non switchable exhaust (loud tubi exhaust) and occasionally want it to be little less noisy. Thanks for the link, exactly what I need to help me.

paulrog1 said:

I did the rear subframe on my DB9 a few years ago before I got the same 2 post lift in my garage as yours.

https://www.pistonheads.com/gassing/topic.asp?h=0&...

Paul, its been the best 'tool' buy so far !!https://www.pistonheads.com/gassing/topic.asp?h=0&...

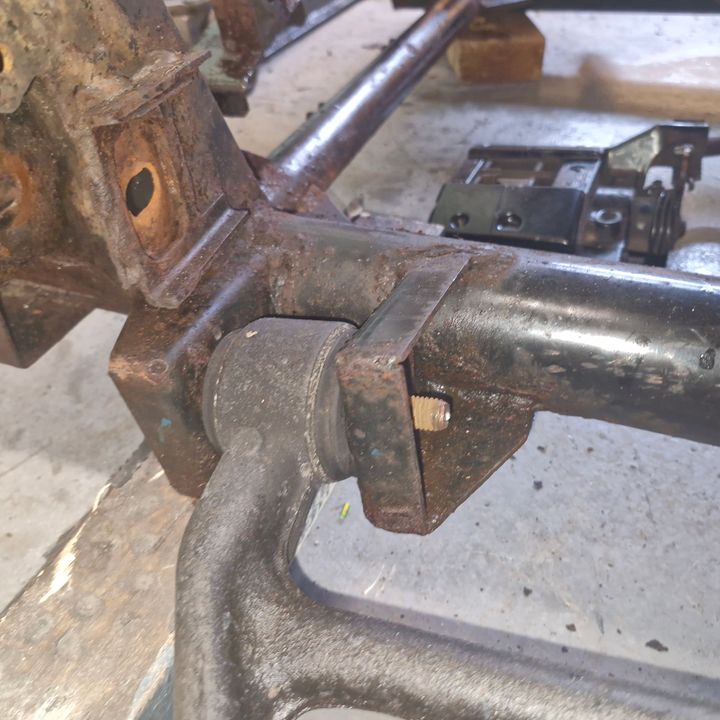

For info, latest status is that I am now down to sawing off a toe arm from one side and lower control arm on the other. Both are completely stuck and tried all the methods to free them (loads of penetrating fluid, mallet, rotating, sds drill, heat etc). Its now a case of sawing off the bolt and trying to potential press the corroded bolt out afterwards (if I can cut the bolt without damaging the metal bush as they are close fit inside the rear subframe brackets).

Today I am planning to try and:

1) Disconnect the hard brake lines (I've already done the flexi's between the frame and calipers)

2) Undo exhaust clamps (I've already removed back box/finishers)

3) Oil cooler pipes (Not looking forward to this)

4) Hand brake cable (Not sure if you need to disconnect from lever under the seat or that's only required if its 'seized' or corroded in the subframe.

leerandle said:

Paul, its been the best 'tool' buy so far !!

For info, latest status is that I am now down to sawing off a toe arm from one side and lower control arm on the other. Both are completely stuck and tried all the methods to free them (loads of penetrating fluid, mallet, rotating, sds drill, heat etc). Its now a case of sawing off the bolt and trying to potential press the corroded bolt out afterwards (if I can cut the bolt without damaging the metal bush as they are close fit inside the rear subframe brackets).

Today I am planning to try and:

1) Disconnect the hard brake lines (I've already done the flexi's between the frame and calipers)

2) Undo exhaust clamps (I've already removed back box/finishers)

3) Oil cooler pipes (Not looking forward to this)

4) Hand brake cable (Not sure if you need to disconnect from lever under the seat or that's only required if its 'seized' or corroded in the subframe.

Your doing well, For info, latest status is that I am now down to sawing off a toe arm from one side and lower control arm on the other. Both are completely stuck and tried all the methods to free them (loads of penetrating fluid, mallet, rotating, sds drill, heat etc). Its now a case of sawing off the bolt and trying to potential press the corroded bolt out afterwards (if I can cut the bolt without damaging the metal bush as they are close fit inside the rear subframe brackets).

Today I am planning to try and:

1) Disconnect the hard brake lines (I've already done the flexi's between the frame and calipers)

2) Undo exhaust clamps (I've already removed back box/finishers)

3) Oil cooler pipes (Not looking forward to this)

4) Hand brake cable (Not sure if you need to disconnect from lever under the seat or that's only required if its 'seized' or corroded in the subframe.

Get some brass brake blanks to avoid alot of fluid loss, you'll be glad because you'll be getting air out the brake for ages.

If you intend to replace the handbrake cable you will need to remove the driver's seat to get to the handbrake cable inside the handle.

A couple of exhaust clamps on mine were cracked so you can easily get replacements.

Good luck, post some photos of your progress.

Before you disconnect the battery make sure the boot is not closed, you will need access to some bolts.

Edited by paulrog1 on Friday 3rd January 12:54

So, brake lines oil cooler pipes and exhaust disconnected. Hand brake cable looks ok, so shouldn't need to replace (will be able to see a little better once subframe down).

So next big question, dropping the gearbox taking out the subframe.....

Do you undo the top nuts off the x2 hydromounts, which would allow the transaxle to drop with the subframe, then support underneath the gearbox to allow getting the subframe over the transaxle? Hope that makes sense. I've got a gearbox support and some bungees to help hold the subframe when removing.

Just don't want to start dropping transaxle/subframe and realise something is still hard connected.

I'll post some pictures later.

So next big question, dropping the gearbox taking out the subframe.....

Do you undo the top nuts off the x2 hydromounts, which would allow the transaxle to drop with the subframe, then support underneath the gearbox to allow getting the subframe over the transaxle? Hope that makes sense. I've got a gearbox support and some bungees to help hold the subframe when removing.

Just don't want to start dropping transaxle/subframe and realise something is still hard connected.

I'll post some pictures later.

Subframe finally removed this morning. I used a few jack stands, trolley jack and diff stand to support the transaxle and subframe when removing.

Dropped the transaxle by about 2 inches (50mm for some) and placed some card on top to help slide the subframe over it.

I've still got to try and remove the toe arm, lower control arm, but easier once subframe off the car. I've ordered a bearing kit which might work by pressing the bolt out. Final method before I start cutting bolts or arms. Also the middle bolt between subframe to fuel filter bracket still needs to come out, the captive nut broke off the bracket when trying to remove (will need to weld back on)

Handbrake was a bit of a pain and might need a new one or as a minimum some parts to rebuild it.

Dropped the transaxle by about 2 inches (50mm for some) and placed some card on top to help slide the subframe over it.

I've still got to try and remove the toe arm, lower control arm, but easier once subframe off the car. I've ordered a bearing kit which might work by pressing the bolt out. Final method before I start cutting bolts or arms. Also the middle bolt between subframe to fuel filter bracket still needs to come out, the captive nut broke off the bracket when trying to remove (will need to weld back on)

Handbrake was a bit of a pain and might need a new one or as a minimum some parts to rebuild it.

leerandle said:

Having moved earlier in the year, the house didn't have a garage, but a bit of land and rear access to build one for my 2006 vantage. Finally got the aston in yesterday and now embarking on those 'winter' type jobs. Main one is rear sub frame, but also big brake upgrade, v12 switchable exhaust and refurbishing alloys. Should keep me busy for a while. For info, garage is just a 5x6m wooden build, thick reinforced concrete base, automech 2 post lift.

I've just bought my first AM, a 4.7 V8V, I have a two post lift in the garage but I'm struggling to find definitive lifting instructions for the car. I haven't taken delivery yet, so I'm just surfing... If you can send me details of where you lift and any adapter pads necessary, it would be much appreciated...Edited by leerandle on Sunday 22 December 12:14

There's lots on trolley jacks and axel stands, but I haven't found lift pad details as yet.

I’ve literally just bought some Jack pads for my V8V as it’s having alloys refurbed this weekend and want to make sure they don’t damage it jacking to remove wheels. There’s different pads that can work depending on year, bodykit or if it’s a roadster etc.

https://www.astonmartinjackpads.co.uk/products

I can’t recommend Steve Cavanagh enough, he confirmed the correct pad style needed for my car from photos I sent, then items were boxed and delivered within 3 days from payment.

Here’s photos as examples of the jacking points under the vehicle.

https://www.astonmartinjackpads.co.uk/products

I can’t recommend Steve Cavanagh enough, he confirmed the correct pad style needed for my car from photos I sent, then items were boxed and delivered within 3 days from payment.

Here’s photos as examples of the jacking points under the vehicle.

leerandle said:

I'll get you some photos. There's not much room to jack, but you'll see the holes in the chassis where you can jack up. Just don't use the long aluminum crash structure parts as these are not designed to jack it up. I've got a bit of wood between the arms and jacking points.

Ah, I can see the wood now I’ve zoomed in. I thought they were jack pads… Gassing Station | Aston Martin | Top of Page | What's New | My Stuff