1:4 Scale Model Viper Engine

Discussion

Here's a bit more info on the 1/4 scale Viper Engine and the fire:

Conley Engineering said:

in 1996 two Chrysler representatives approached me. Since I was already making a V-8 engine there question was would I not consider building a ¼ scale Viper V-10 engine? At that time I was contemplating building a ¼ scale V-12 and after some serious thoughts, the V-10 seamed to be the logical choice. After going through and receiving a licensing agreement from Chrysler the next step was to get a full sized engine for the purpose of “reverse engineering”. One day I get a knock on the door and a truck unloaded a complete Viper V-10 engine in my driveway. At that point in time, I wondered what I had gotten myself into? Since this engine was mainly a façade, with limited internals, it was totally dismantled and each piece was then analyzed and evaluated to see if the engine could actually be reduced to ¼ scale. Little did I know that this was only the beginning of my very long “uphill battle”? Some of the molds I made myself, but a great friend of mine, Ken Bennett from Topaz Engineering, made one of the most complicated. It was the mold for the head and runners for the intake and exhaust ports. The problems that were encounter are too numerous to list. Two of the major problem areas, which had not been considered, were the ignition system and the oiling system. Keep in mind voltage cannot be scaled down. The alternator housing became my distributor. It had ten electronic sensors and one rotating magnet. The signal created was then sent to another circuit with told each coil when it needed to fire. After numerous failures it was discovered that the RF interference was burning out some of the sensitive components. The solution was “magnetic suppression wire”. This does not exist in small size. I contacted Delphi Packard and two months later I had 10,000 feet of small diameter magnetic suppression wire. This eliminated the problem. The other problem was oil control. There was always plenty of oil; it was almost impossible to scrape the oil from the walls of the cylinders. This alone took me over nine months of twelve hour days to solve. Remember, oil control rings for this size engine are not commercially available. The entire project should have only taken one to one and a half years. In actuality it took almost 5 years. Only one V-10 engine was ever completed and is now in the possession of an avid engine collector in Kentucky.

Almost five years later, I receive possible the most devastating phone call of my life. The foundry that was doing all of my castings was consumed in a catastrophic fire that destroyed everything. All of the V-10 molds melted down to large puddles of aluminum. Even the molds for the V-8 were destroyed. Over $350,000.00 in molds and five years of hard labor were gone and there was no insurance to cover any of my loses! For the next three days I sat in my office and cried. There was nothing left for me to do. If that were not bad enough, all of the deposits for every engine had to be returned. It would have been very easy to declare Bankruptcy. For me this was not an option. I had built a company on honesty and integrity and could not do that to my customers. There did not seam to be any definite answer. About that same time the company that was making the model carbs that were used on my engines was being sold. With some very strong “soul searching” and lengthy conversations with my wife, I decided to purchase the entire line of Perry products from Varsane Manufacturing. This included not only the model carburetor line but also the model engine pumps and fuel control valves. This purchase proved to be my “saving grace”. Slowly, all of the deposits were returned and I started to see a little light at the end of the tunnel. Things have continued to improve and after exhausting my entire existing V-8 inventory, in the fall of 2005 I decided to build another V-8 engine. The one thing that I had retained from the fire was all of the masters from the V-10 engine. Instead of trying to revive the V-10 engine, the decision was made to modify and shorten the V-10 engine into an all-new V-8 engine. There is something that is called “transferable knowledge”, which became very evident when I decided to build the new engine. Remember almost five years was spent on its design and construction. Some of the internal components did not change and since I had a lot of parts in stock I put them to good use on the new Stinger 609 engine. Surprising, the only molds that survive the fire were the mold for the head and the mold for the intake and exhaust runners. With a lot of measuring and careful machining the mold for the V-10 head was shortened to make a great V-8 head. The runners did not change. Someway, somehow all of the masters were modified for the new Stinger 609 engine. The rest, as they say is “history”. Thanks to my many customers who stood by me in good times and in bad.

Almost five years later, I receive possible the most devastating phone call of my life. The foundry that was doing all of my castings was consumed in a catastrophic fire that destroyed everything. All of the V-10 molds melted down to large puddles of aluminum. Even the molds for the V-8 were destroyed. Over $350,000.00 in molds and five years of hard labor were gone and there was no insurance to cover any of my loses! For the next three days I sat in my office and cried. There was nothing left for me to do. If that were not bad enough, all of the deposits for every engine had to be returned. It would have been very easy to declare Bankruptcy. For me this was not an option. I had built a company on honesty and integrity and could not do that to my customers. There did not seam to be any definite answer. About that same time the company that was making the model carbs that were used on my engines was being sold. With some very strong “soul searching” and lengthy conversations with my wife, I decided to purchase the entire line of Perry products from Varsane Manufacturing. This included not only the model carburetor line but also the model engine pumps and fuel control valves. This purchase proved to be my “saving grace”. Slowly, all of the deposits were returned and I started to see a little light at the end of the tunnel. Things have continued to improve and after exhausting my entire existing V-8 inventory, in the fall of 2005 I decided to build another V-8 engine. The one thing that I had retained from the fire was all of the masters from the V-10 engine. Instead of trying to revive the V-10 engine, the decision was made to modify and shorten the V-10 engine into an all-new V-8 engine. There is something that is called “transferable knowledge”, which became very evident when I decided to build the new engine. Remember almost five years was spent on its design and construction. Some of the internal components did not change and since I had a lot of parts in stock I put them to good use on the new Stinger 609 engine. Surprising, the only molds that survive the fire were the mold for the head and the mold for the intake and exhaust runners. With a lot of measuring and careful machining the mold for the V-10 head was shortened to make a great V-8 head. The runners did not change. Someway, somehow all of the masters were modified for the new Stinger 609 engine. The rest, as they say is “history”. Thanks to my many customers who stood by me in good times and in bad.

Another pic:

The Viper V-10 Engine Project

The Viper V-10--a project cut down after years of work by an unfortunate fire at the foundry where all the patterns were stored. Here is the prototype ready to run.

A finished Viper V-10 engine and its engine stand with gauges to measure RPM and other vital engine temperature and pressure functions. At the left end is a pencil sharpener driven by the transmission. Probably the most expensive and powerful one in existence, in first gear it can grind an entire #2 pencil into sawdust in a matter of seconds.

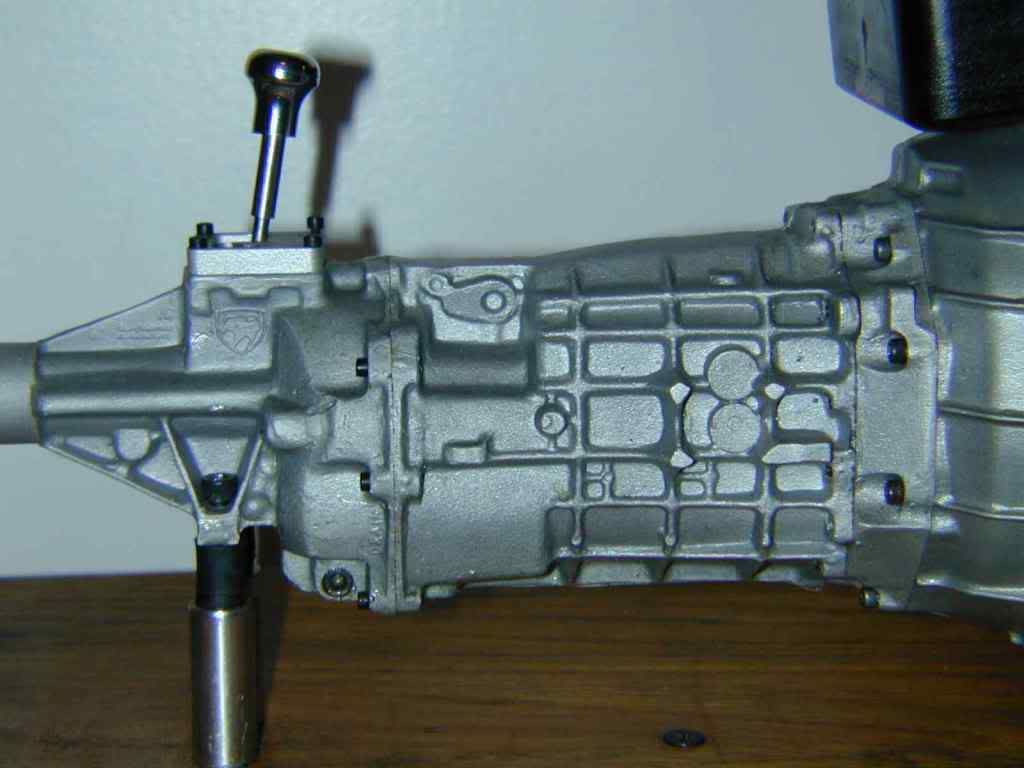

The transmission case for the Viper has two speeds forward and a reverse..

A V-10 block, head, exhaust and valve train plus a camshaft and gaskets is laid out before assembly.

The Viper V-10 Engine Project

The Viper V-10--a project cut down after years of work by an unfortunate fire at the foundry where all the patterns were stored. Here is the prototype ready to run.

A finished Viper V-10 engine and its engine stand with gauges to measure RPM and other vital engine temperature and pressure functions. At the left end is a pencil sharpener driven by the transmission. Probably the most expensive and powerful one in existence, in first gear it can grind an entire #2 pencil into sawdust in a matter of seconds.

The transmission case for the Viper has two speeds forward and a reverse..

A V-10 block, head, exhaust and valve train plus a camshaft and gaskets is laid out before assembly.

Edited by RT/10Dave on Monday 24th November 09:41

Gassing Station | Vipers | Top of Page | What's New | My Stuff