205 1.6 - 205 gti6 engine swap

Discussion

Hi all.

Below are the details of my on going engine conversion...

The car itself is a 1.6 gti, with 309 beam, wishbones and driveshafts. It also has Gaz dampers all round along with Eibach springs on the front, along with gti6 brakes...so really the engine was the only weak link in the chain!!!

First of all, start with one Xsara VTS engine, with new cambelt, waterpump and clutch.

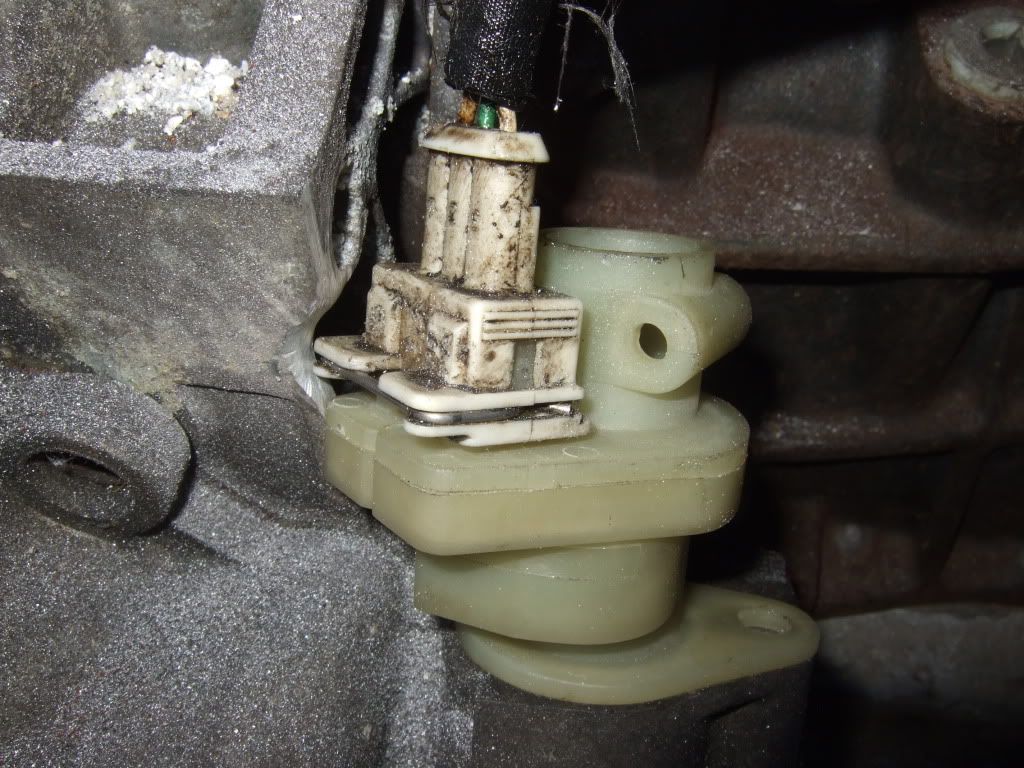

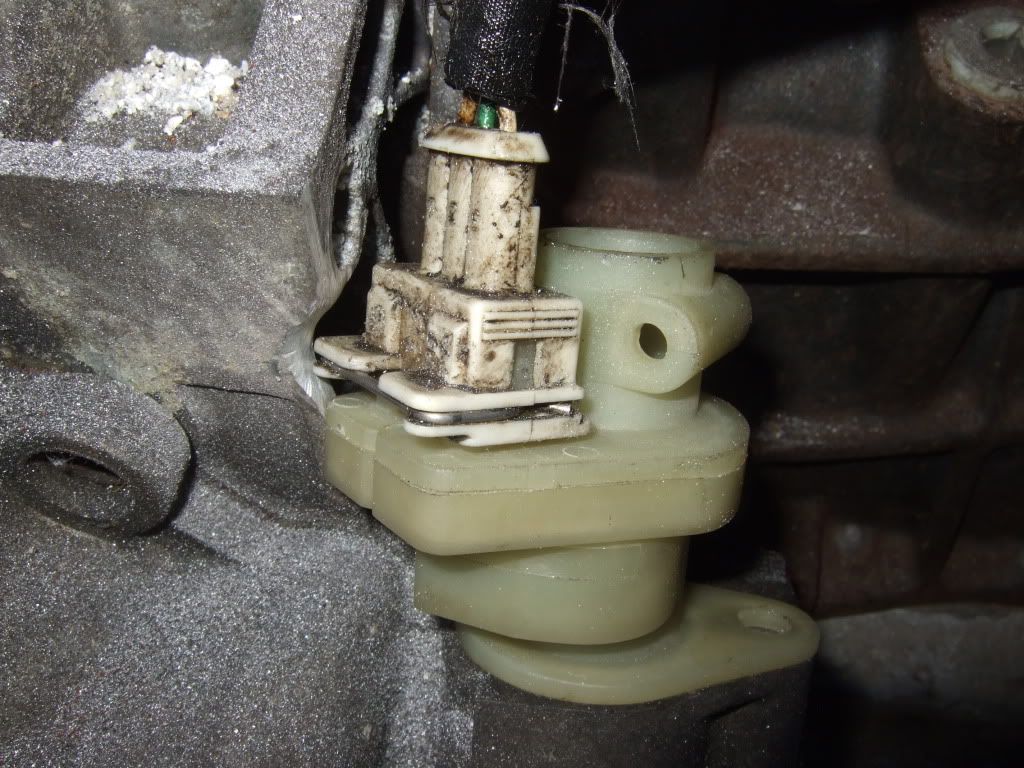

The VTS/GTI6 engine needs a digital speed sensor, but the gti clocks need an analog one...what to do? fit a speed sensor from a s16, available from ebay...

Original digital speed sensor

Compare the original sensor to the new digital and analog sensor...

Sadly the new plug doesn't fit straight on, so some modification is necessary.

So some material needs to be removed from the gearbox. hardly any, just a bit of work with a dremmel required.

all fitting perfectly.

While the engine is out of the car, remove the carbon cannister, not required in the 205 as emissions are not a concern in this pre cat model.

Don't forget to block the outlet on the throttle body!

The exhaust manifold from the VTS/GTI6 is a work of art, but needs to be modified slightly to miss the bulkhead on the 205, Miles will be able to modify your manifold for a very reasonable sum!!!

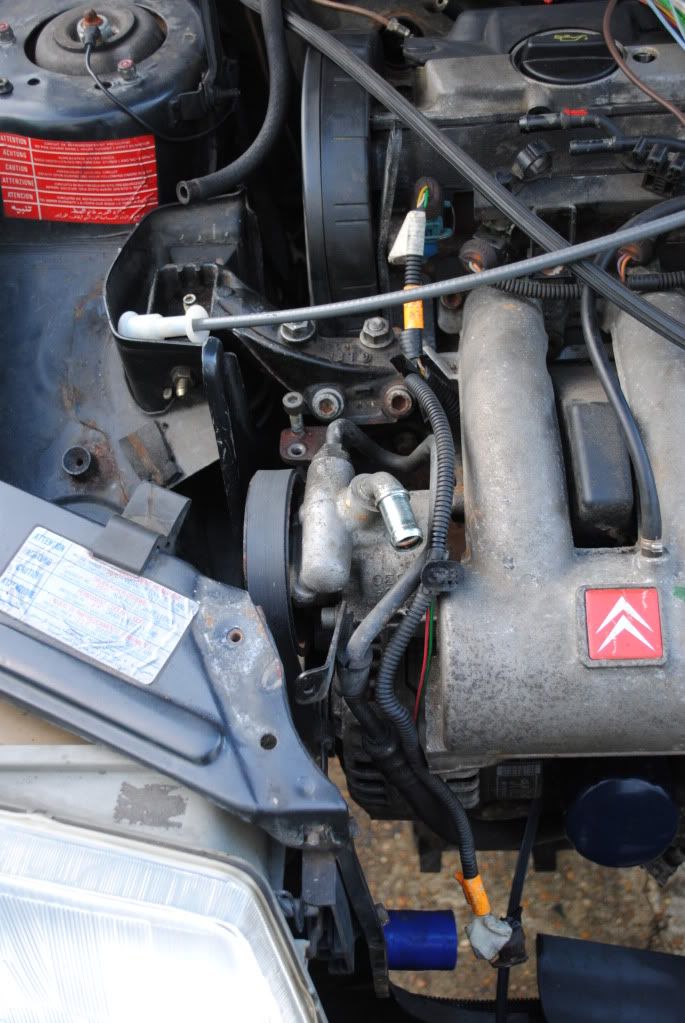

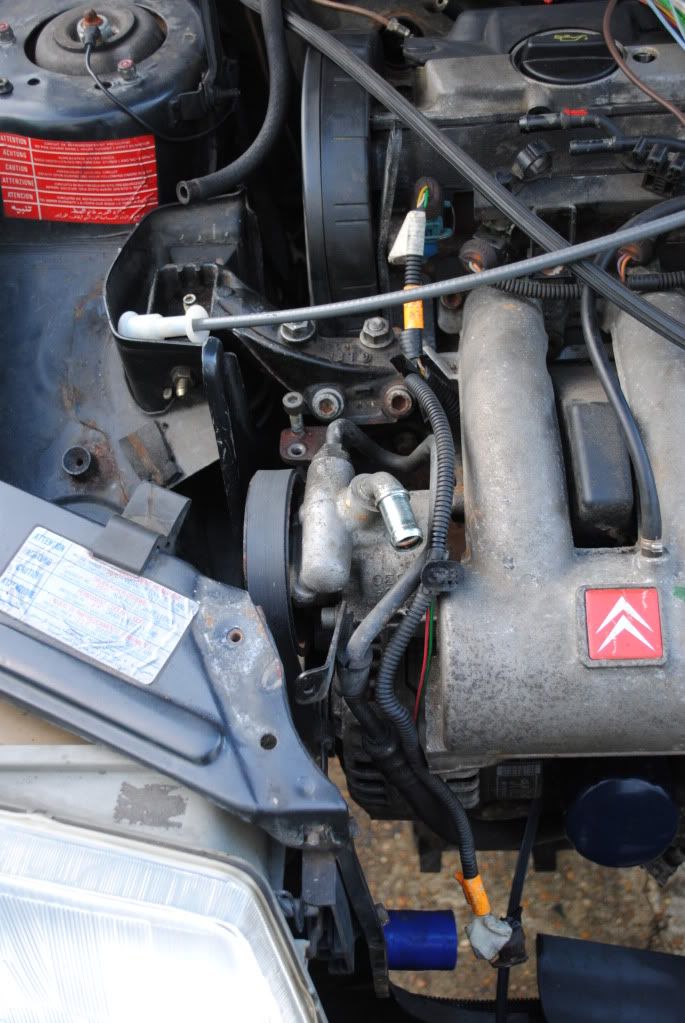

Finally the top hose connection on the GTI6/VTS is a bespoke connector, so you need to bolt on a adaptor, allowing you to use the 205 thermostat piece in the conversion, available from Baker BM, HERE

Once this has all been done, the engine can come out...

While this is out, you need to swap the differential out of the 205 gti gearbox, and put it into to VTS box. This allows the 205 driveshafts to be used with the VTS box. Then carefully seal the whole lot back up again.

Finally, after much sweating and swearing the engine is back in the car! It really is very tight indeed and a load leveller would be a very useful device to use when fitting...sadly not present when we were fitting the engine!

Thanks go out to Jake GTI and his buddy who were very helpful indeed and without whom I would have had a very tricky time indeed!!!!

Wooop!

I was extremely concerned about how easy it would be to unite the power steering between the car and engine, but it turns out this is probably the easiest part of the project. Using the high pressure hose from the VTS engine means that the whole lot bolts straight up, the only issues seemed to be the low pressure side, and that simply involved finding the right hoses and deciding how to route them. not completed yet, but more than happy with the progress.

This is the low pressure pump feed, yet to be connected...

The Vacuum hose from the engine to the brake servo fitted straight on with a little trim to make it a little shorter.

The clutch cable required some minor modification. I have used a 1.9 cable, with the original VTS clutch completely unmodified. All seems to be working beautifully, nice light clutch compared to the original BE3 box!!!

I've also disconnected the oil-water cooler, as I don't have the right hoses, hopefully this shouldn't be a problem, if i start to see high oil temps I'll get an air-oil Mocal cooler or something.

Also, no pics but the accelerator cable is out of a 405 and clips straight on.

This angle shows the famous master cylinder issue, you can see there's not much space. I've ordered a 406 master cylinder to compliment my gti6 brakes (although I was reasonably happy with the performance with the 205 M/C) it seems worthwhile to replace it while it's out. The pedal box will be tilted, and some material removed from both the master cylinder, and the cambelt cover.

Finally, onto the tricky bits...

I'm going to use the 106 gti inline fuel filter, so I need to remove the bespoke connectors on the 205 and replace with standard lines. However, I'm finding it hard to remove the fuel lines from the solid lines on the engine bulkhead - has anyone else had this problem and are there any tips, other than poke it with a screwdriver until it rips off?

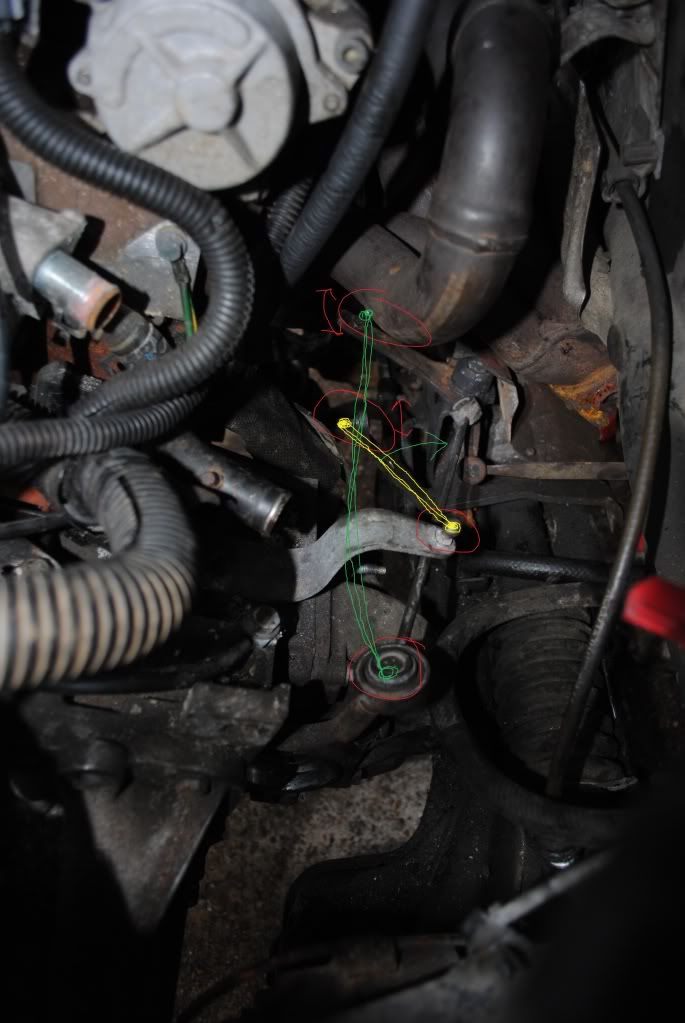

And the real biggy, I'm having a lot of trouble with the gearbox linkages.

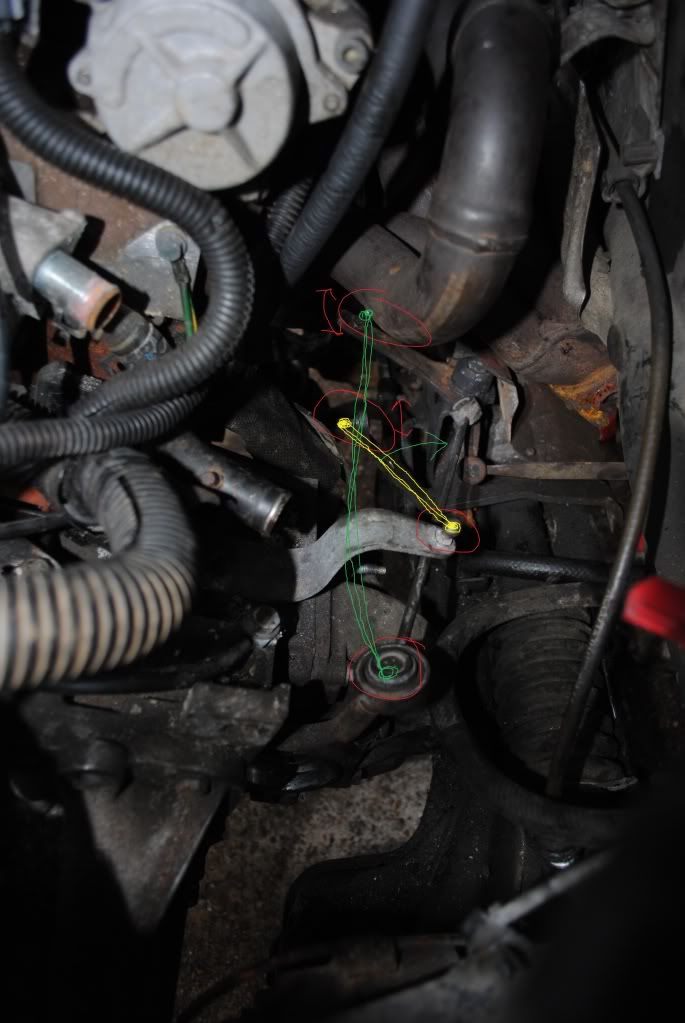

There are two levers for the gearbox, which can be seen below.

and a diagram here...

The long linkage (drawn in green above) won't be a problem. However the yellow linkage is proving to be a bit of a ball ache. It's at an angle which doesn't make for a very pleasant gearshift, so I'm toying with bending the gearstick-end linkage backwards as demonstrated by the green arrow. This seems to be an obvious move, but feels like a bit of a bodge so if I can replace any components with OEM parts I'd rather do that... additionally it is a bloody thick bit of steel and would require a hell of a lot of bending which would be a lot of effort.

Other than those two issues things are going relatively smoothly at the moment, but if anyone has any top tips then please let me know!!!!

Below are the details of my on going engine conversion...

The car itself is a 1.6 gti, with 309 beam, wishbones and driveshafts. It also has Gaz dampers all round along with Eibach springs on the front, along with gti6 brakes...so really the engine was the only weak link in the chain!!!

First of all, start with one Xsara VTS engine, with new cambelt, waterpump and clutch.

The VTS/GTI6 engine needs a digital speed sensor, but the gti clocks need an analog one...what to do? fit a speed sensor from a s16, available from ebay...

Original digital speed sensor

Compare the original sensor to the new digital and analog sensor...

Sadly the new plug doesn't fit straight on, so some modification is necessary.

So some material needs to be removed from the gearbox. hardly any, just a bit of work with a dremmel required.

all fitting perfectly.

While the engine is out of the car, remove the carbon cannister, not required in the 205 as emissions are not a concern in this pre cat model.

Don't forget to block the outlet on the throttle body!

The exhaust manifold from the VTS/GTI6 is a work of art, but needs to be modified slightly to miss the bulkhead on the 205, Miles will be able to modify your manifold for a very reasonable sum!!!

Finally the top hose connection on the GTI6/VTS is a bespoke connector, so you need to bolt on a adaptor, allowing you to use the 205 thermostat piece in the conversion, available from Baker BM, HERE

Once this has all been done, the engine can come out...

While this is out, you need to swap the differential out of the 205 gti gearbox, and put it into to VTS box. This allows the 205 driveshafts to be used with the VTS box. Then carefully seal the whole lot back up again.

Finally, after much sweating and swearing the engine is back in the car! It really is very tight indeed and a load leveller would be a very useful device to use when fitting...sadly not present when we were fitting the engine!

Thanks go out to Jake GTI and his buddy who were very helpful indeed and without whom I would have had a very tricky time indeed!!!!

Wooop!

I was extremely concerned about how easy it would be to unite the power steering between the car and engine, but it turns out this is probably the easiest part of the project. Using the high pressure hose from the VTS engine means that the whole lot bolts straight up, the only issues seemed to be the low pressure side, and that simply involved finding the right hoses and deciding how to route them. not completed yet, but more than happy with the progress.

This is the low pressure pump feed, yet to be connected...

The Vacuum hose from the engine to the brake servo fitted straight on with a little trim to make it a little shorter.

The clutch cable required some minor modification. I have used a 1.9 cable, with the original VTS clutch completely unmodified. All seems to be working beautifully, nice light clutch compared to the original BE3 box!!!

I've also disconnected the oil-water cooler, as I don't have the right hoses, hopefully this shouldn't be a problem, if i start to see high oil temps I'll get an air-oil Mocal cooler or something.

Also, no pics but the accelerator cable is out of a 405 and clips straight on.

This angle shows the famous master cylinder issue, you can see there's not much space. I've ordered a 406 master cylinder to compliment my gti6 brakes (although I was reasonably happy with the performance with the 205 M/C) it seems worthwhile to replace it while it's out. The pedal box will be tilted, and some material removed from both the master cylinder, and the cambelt cover.

Finally, onto the tricky bits...

I'm going to use the 106 gti inline fuel filter, so I need to remove the bespoke connectors on the 205 and replace with standard lines. However, I'm finding it hard to remove the fuel lines from the solid lines on the engine bulkhead - has anyone else had this problem and are there any tips, other than poke it with a screwdriver until it rips off?

And the real biggy, I'm having a lot of trouble with the gearbox linkages.

There are two levers for the gearbox, which can be seen below.

and a diagram here...

The long linkage (drawn in green above) won't be a problem. However the yellow linkage is proving to be a bit of a ball ache. It's at an angle which doesn't make for a very pleasant gearshift, so I'm toying with bending the gearstick-end linkage backwards as demonstrated by the green arrow. This seems to be an obvious move, but feels like a bit of a bodge so if I can replace any components with OEM parts I'd rather do that... additionally it is a bloody thick bit of steel and would require a hell of a lot of bending which would be a lot of effort.

Other than those two issues things are going relatively smoothly at the moment, but if anyone has any top tips then please let me know!!!!

If u buy this kit: http://cgi.ebay.co.uk/Peugeot-205-GTi-Mi16-Turbo-G...

You will be able to alter the angle at which the linkages connect to the levers. I have done an mi16, 2.0 8v turbo and gti6 conversions with this kit and never run into any problems. Plus they have securing pins so your linkages will never pop off 9something worn, standard items are common for doing)

Good work with the conversion, its the best engine for the car.

You will be able to alter the angle at which the linkages connect to the levers. I have done an mi16, 2.0 8v turbo and gti6 conversions with this kit and never run into any problems. Plus they have securing pins so your linkages will never pop off 9something worn, standard items are common for doing)

Good work with the conversion, its the best engine for the car.

DiscoStu said:

If u buy this kit: http://cgi.ebay.co.uk/Peugeot-205-GTi-Mi16-Turbo-G...

You will be able to alter the angle at which the linkages connect to the levers. I have done an mi16, 2.0 8v turbo and gti6 conversions with this kit and never run into any problems. Plus they have securing pins so your linkages will never pop off 9something worn, standard items are common for doing)

Good work with the conversion, its the best engine for the car.

I've actually got a set of those waiting to go on...some of the guys on the 205 forum seem to think that I need to be swapping the lever on the gearbox over, so I'm going to give that a go.You will be able to alter the angle at which the linkages connect to the levers. I have done an mi16, 2.0 8v turbo and gti6 conversions with this kit and never run into any problems. Plus they have securing pins so your linkages will never pop off 9something worn, standard items are common for doing)

Good work with the conversion, its the best engine for the car.

Not many people seem to use the VTS box, but it seems to be an excellent choice for the 205 - nicer cruising ratios than the 1.6 box, slightly shorter bottom end than the 1.9 box and none of the issues with steering lock that you get with the 6 speed box.

i beleve that a combonation of standard gear links will do the job. std 205 ones did the job fine on my s16 engined one.

what gearbox are you using std gti gearbox's 1.6 and 1.9 will both fit on that engine fine they are stronger than the 6 speed box ( you cant get out of junctions with out a 3 point turn with a 6 speed.

they also dont have the speed pick up issue.

the gear change is always crap in pugs if your not happy or need parts give ben or daz at spoox a ring 0116 2751414 they will have all the linkages in stock and make a in house quick shift kit with is very good. or if you want to get very serious you they can make you some custom rose jointed links.

ps i have no involvement with spoox but used them on a few of my projects they specialise in pug and no there stuff.

what gearbox are you using std gti gearbox's 1.6 and 1.9 will both fit on that engine fine they are stronger than the 6 speed box ( you cant get out of junctions with out a 3 point turn with a 6 speed.

they also dont have the speed pick up issue.

the gear change is always crap in pugs if your not happy or need parts give ben or daz at spoox a ring 0116 2751414 they will have all the linkages in stock and make a in house quick shift kit with is very good. or if you want to get very serious you they can make you some custom rose jointed links.

ps i have no involvement with spoox but used them on a few of my projects they specialise in pug and no there stuff.

The VTS uses a 5-speed box, not a 6-speed like the 306.

Have a read here for info on VTS box in 205:

http://forum.205gtidrivers.com/index.php?s=bc74a19...

Have a read here for info on VTS box in 205:

http://forum.205gtidrivers.com/index.php?s=bc74a19...

Update now that the weather is a bit nicer!!! Please note this is copied over from 205 gtidrivers so might not all make sense! Obviously questions welcome!

After have discovered that the crown wheels need to be swapped on the differentials (see here...http://forum.205gtidrivers.com/index.php?showtopic=127792&st=0&p=1153146&#entry1153146)

I needed to remove the 205 differential i had installed in the VTS gearbox.

To clarify: You need the 205 differential, with the VTS crown wheel. The VTS crown wheel is noticeably bigger than the 205 one, I should have noticed at the time, really. This allows you to use 205 driveshafts, which engage properly with the 205 diff, while maintaining proper contact with the VTS drive gear.

This is the Xsara diff

notice the numbers - 65 teeth to engage with the VTS gearbox

you need to use the crown wheel and place on the 205 diff...

Here.

different numbers indicating different tooth pitch and number of teeth

removing crown wheel

This needs to be bolted onto the 205 diff.

bolts come out nice and easily with a big ol' breaker bar. need to be torqued up to 65nm according to peugeot.

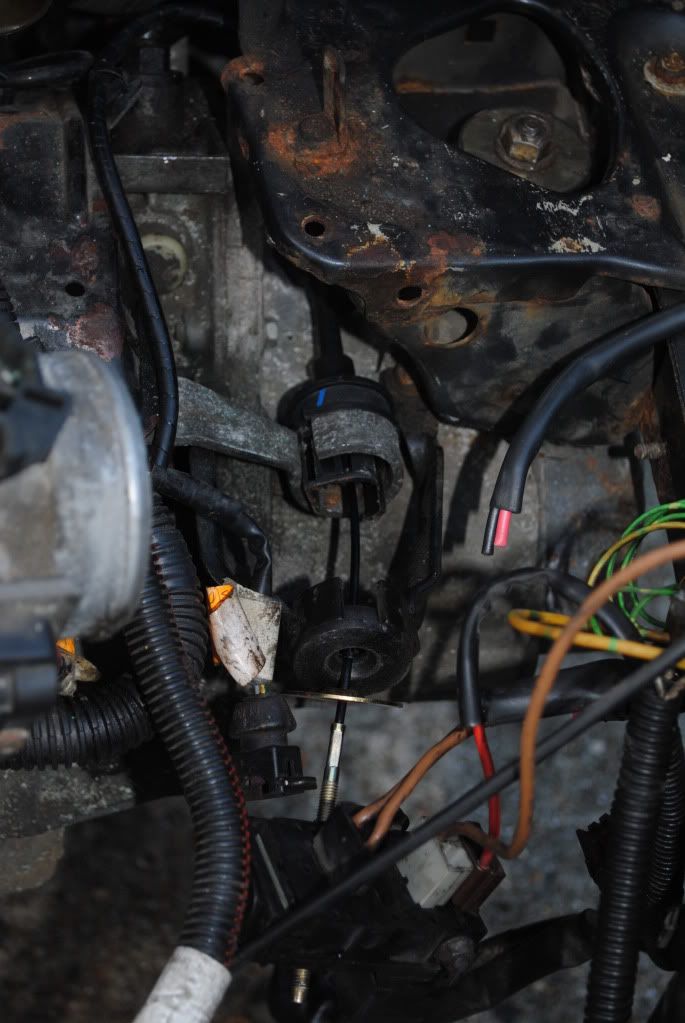

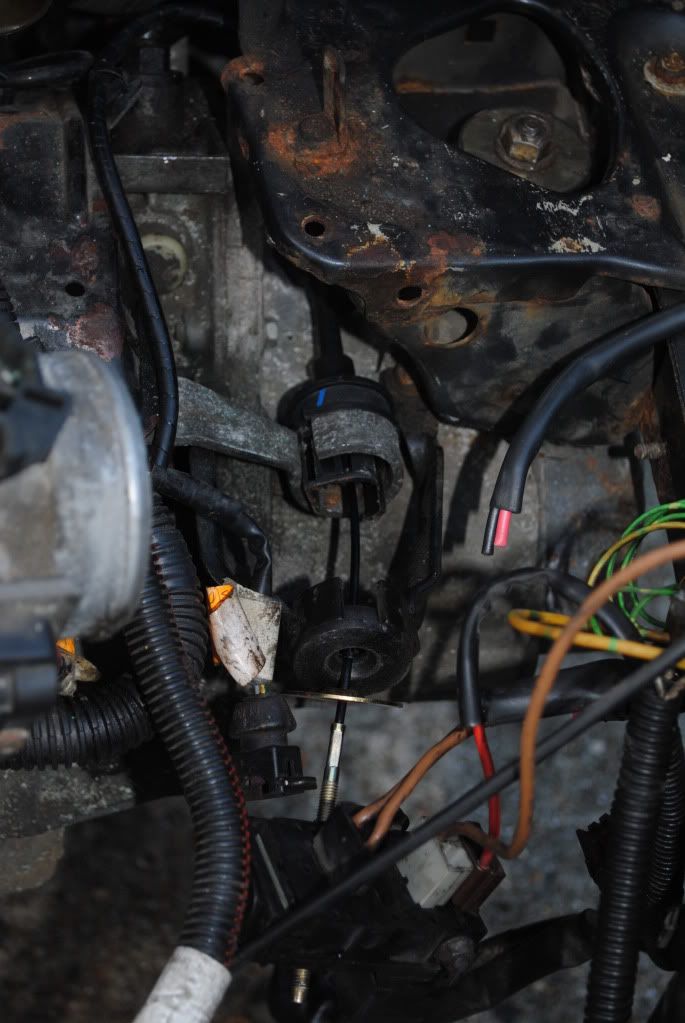

In other news, fitted new oil temp sensor...

not very exciting.

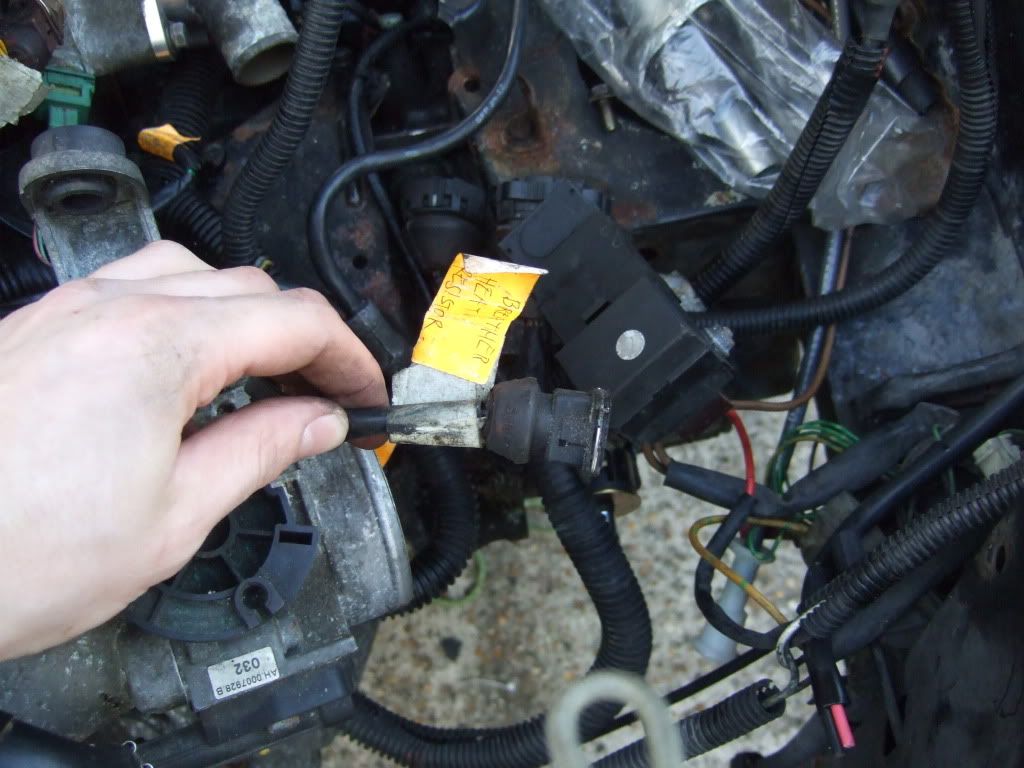

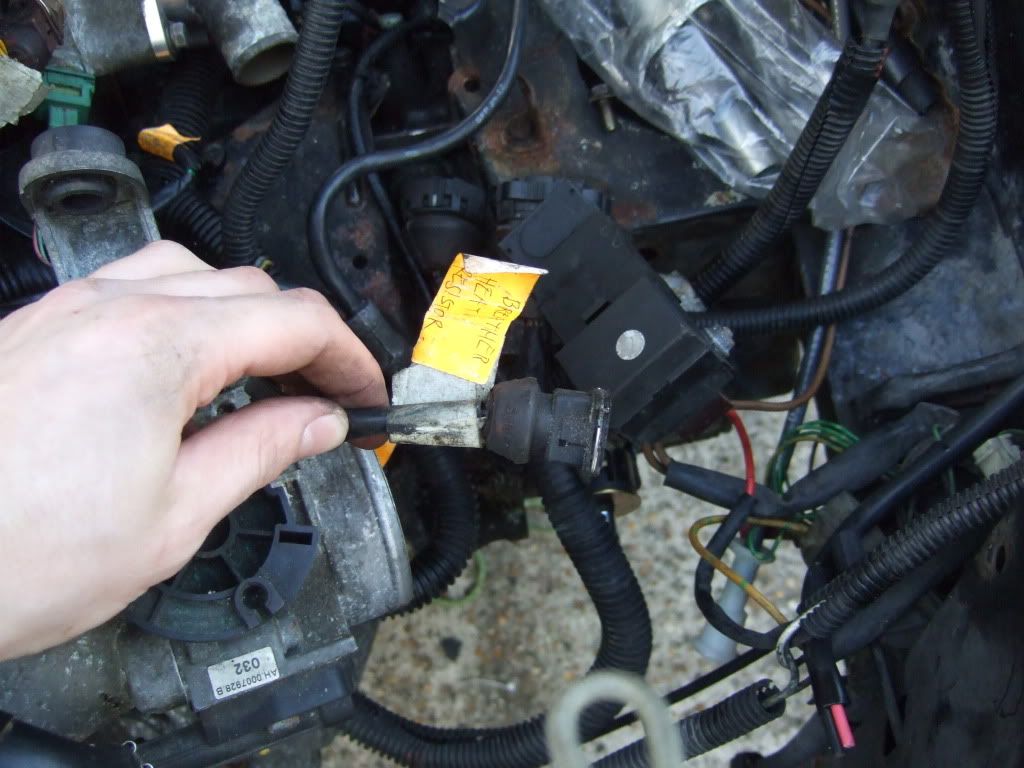

starting to connect up the electronics...

This is the live side, for some reason the Xsara has two positive cables, both going to the same place...redundancy I guess...

Gearbox earth bolted up...

all the gear linkages are all fitted together, gearshift is lovely with the BBM linkages and BBM brass bush.

To confirm, you need the 205 BE3 flat linkage, which needs to replace the bent linkage which comes with the Xsara box

very happy with this ATM.

still need to solder the inertia switch together.

Thought I'd check the timing before I mash the valves to bits...

All looking good.

I've gotta say I think the tensioning system on the GTI6 engine is a pile of gash, I can't believe that the tension simply comes from clamping the tensioner to the block, doesn't surprise me so many of these munch their valvetrain given that all it takes is for the tensioner to work loose.

made sure mine is nice and tight with a blob of threadlock.

Still need to remove some material here, no biggie.

Cannot bend this b d THING to the right angle. really don't want to snap the f***er off. This is the only major stumbling block really!!!!

d THING to the right angle. really don't want to snap the f***er off. This is the only major stumbling block really!!!!

Some electrical questions...

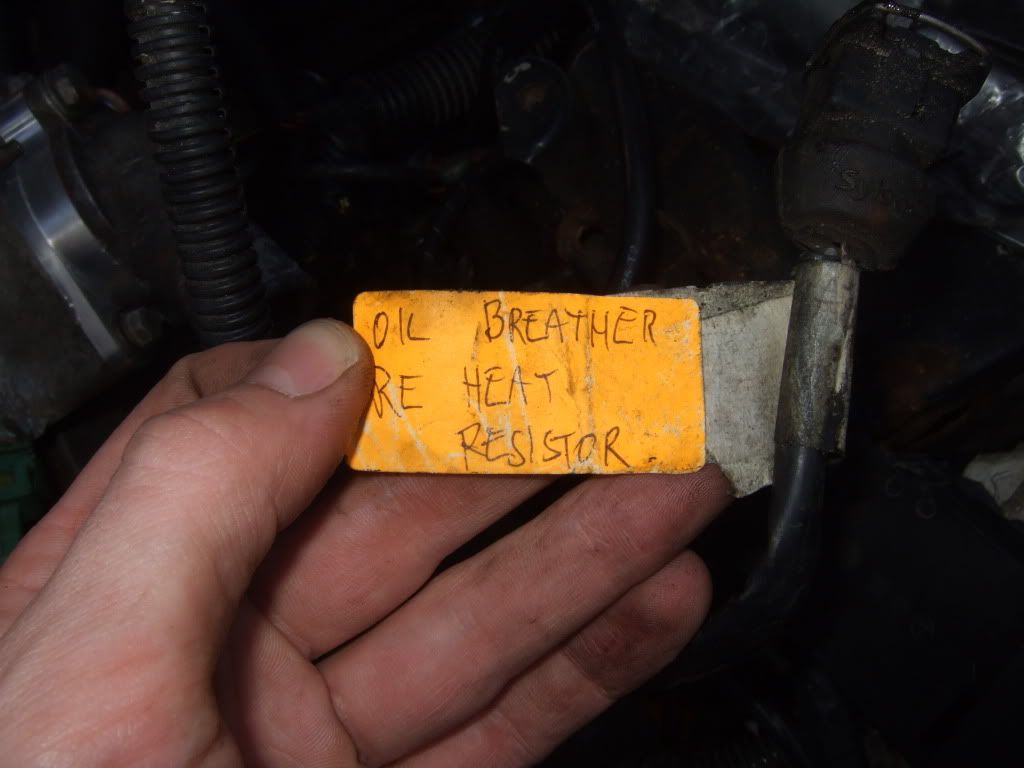

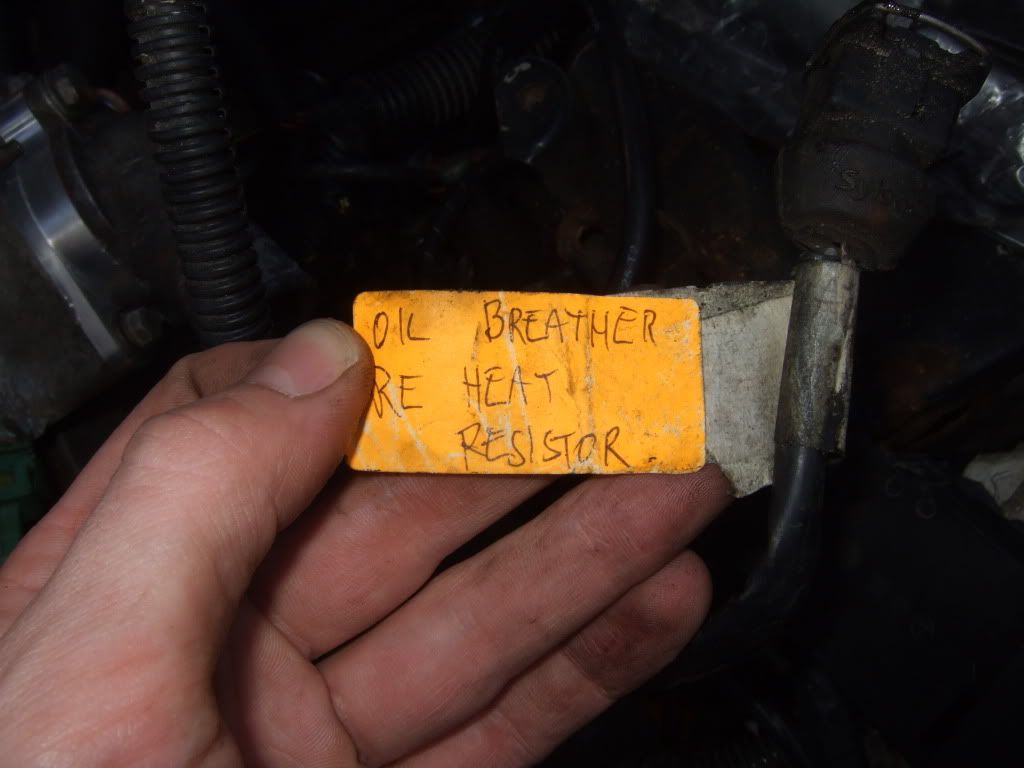

What to do with this?

Think it's for the carbon purge valve. Can I just short it out or leave it dangling around? don't want any ECU errors really!

And the air compressor widget -

same again, obvs. no AC on this, short it out or leave it unconnected?

Cheers guys, hopefully been useful to someone!

After have discovered that the crown wheels need to be swapped on the differentials (see here...http://forum.205gtidrivers.com/index.php?showtopic=127792&st=0&p=1153146&#entry1153146)

I needed to remove the 205 differential i had installed in the VTS gearbox.

To clarify: You need the 205 differential, with the VTS crown wheel. The VTS crown wheel is noticeably bigger than the 205 one, I should have noticed at the time, really. This allows you to use 205 driveshafts, which engage properly with the 205 diff, while maintaining proper contact with the VTS drive gear.

This is the Xsara diff

notice the numbers - 65 teeth to engage with the VTS gearbox

you need to use the crown wheel and place on the 205 diff...

Here.

different numbers indicating different tooth pitch and number of teeth

removing crown wheel

This needs to be bolted onto the 205 diff.

bolts come out nice and easily with a big ol' breaker bar. need to be torqued up to 65nm according to peugeot.

In other news, fitted new oil temp sensor...

not very exciting.

starting to connect up the electronics...

This is the live side, for some reason the Xsara has two positive cables, both going to the same place...redundancy I guess...

Gearbox earth bolted up...

all the gear linkages are all fitted together, gearshift is lovely with the BBM linkages and BBM brass bush.

To confirm, you need the 205 BE3 flat linkage, which needs to replace the bent linkage which comes with the Xsara box

very happy with this ATM.

still need to solder the inertia switch together.

Thought I'd check the timing before I mash the valves to bits...

All looking good.

I've gotta say I think the tensioning system on the GTI6 engine is a pile of gash, I can't believe that the tension simply comes from clamping the tensioner to the block, doesn't surprise me so many of these munch their valvetrain given that all it takes is for the tensioner to work loose.

made sure mine is nice and tight with a blob of threadlock.

Still need to remove some material here, no biggie.

Cannot bend this b

d THING to the right angle. really don't want to snap the f***er off. This is the only major stumbling block really!!!!

d THING to the right angle. really don't want to snap the f***er off. This is the only major stumbling block really!!!!Some electrical questions...

What to do with this?

Think it's for the carbon purge valve. Can I just short it out or leave it dangling around? don't want any ECU errors really!

And the air compressor widget -

same again, obvs. no AC on this, short it out or leave it unconnected?

Cheers guys, hopefully been useful to someone!

With regards to you mentioning earlier that you have done away with the carbon canister as the 205 does not require one for the emissions; it's actually the engine that is emission tested, not the car. So if you fit a newer engine to an old car, the engine has to meet the emission levels as per the year of it's production.

Fitting a 2002 engine to a 1985 car will mean that it will need to meet 2002 emission standards.

Make sure you find yourself a friendly MoT station

Fitting a 2002 engine to a 1985 car will mean that it will need to meet 2002 emission standards.

Make sure you find yourself a friendly MoT station

TEKNOPUG said:

With regards to you mentioning earlier that you have done away with the carbon canister as the 205 does not require one for the emissions; it's actually the engine that is emission tested, not the car. So if you fit a newer engine to an old car, the engine has to meet the emission levels as per the year of it's production.

Fitting a 2002 engine to a 1985 car will mean that it will need to meet 2002 emission standards.

Make sure you find yourself a friendly MoT station

That's not entirely true. As detailed here: Fitting a 2002 engine to a 1985 car will mean that it will need to meet 2002 emission standards.

Make sure you find yourself a friendly MoT station

http://www.motuk.co.uk/manual_730.htm

Edited by Bosshogg76 on Monday 7th March 12:59

Bosshogg76 said:

TEKNOPUG said:

With regards to you mentioning earlier that you have done away with the carbon canister as the 205 does not require one for the emissions; it's actually the engine that is emission tested, not the car. So if you fit a newer engine to an old car, the engine has to meet the emission levels as per the year of it's production.

Fitting a 2002 engine to a 1985 car will mean that it will need to meet 2002 emission standards.

Make sure you find yourself a friendly MoT station

That's not entirely true. As detailed here: Fitting a 2002 engine to a 1985 car will mean that it will need to meet 2002 emission standards.

Make sure you find yourself a friendly MoT station

http://www.motuk.co.uk/manual_730.htm

Edited by Bosshogg76 on Monday 7th March 12:59

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff