What is an electric supercharger? PH Explains

If you need to improve a turbocharged engine's power delivery, an electric supercharger might just do the trick

How does an electric supercharger work?

Electric superchargers function like conventional superchargers, in that they are designed to pump air into an engine. This increases the density of air in the engine's intake, meaning more oxygen is present in each cylinder after the intake stroke. This, among other things, allows more fuel to be burned and more power to be produced.

Electric superchargers, however, have so far primarily been used to improve the response of turbocharged engines by combatting turbocharger lag. This has been achieved by using compact set-ups that generate a small amount of boost almost immediately, helping get the car moving and more exhaust gas flowing - which helps spool the turbocharger, or turbochargers, quickening the engine's responses.

How do they differ from conventional superchargers?

A conventional supercharger is driven by mechanical means. In most automotive applications, the supercharger is typically driven by the engine via a belt. Older superchargers may feature shaft or gear-drive set-ups, while some racing applications feature a standalone powerplant - a gas turbine, for example - to power the supercharger.

An electric supercharger, on the other hand, is driven by a powerful electric motor. This allows the supercharger to be shut down entirely, or spun up in fractions of a second when required, as well as permitting its output to be varied to best suit the engine load and conditions.

A mechanical supercharger, unless fitted with a multi-speed gearbox, is otherwise restricted by the speed of the engine that is driving it. Similarly, unless a clutch is fitted, a mechanical supercharger will consume energy and reduce efficiency when not needed.

Electric supercharger set-ups are complicated, however. Besides requiring dedicated control systems and additional intake piping, they require heavy-duty power supplies that can keep up with their high demands.

Common types of electric supercharger

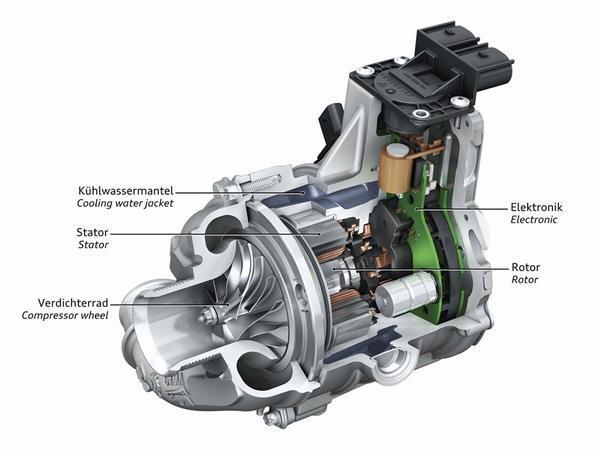

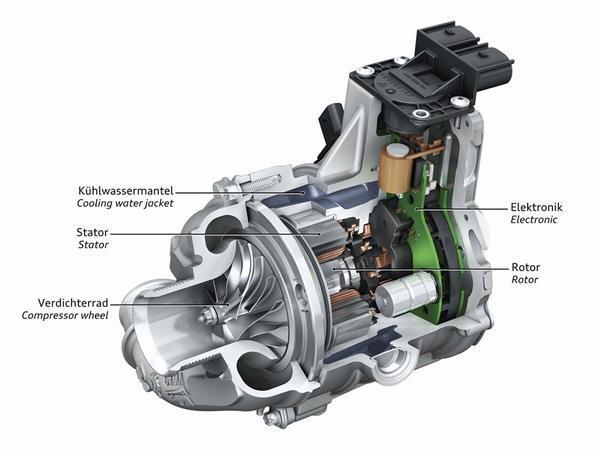

Electrically driven centrifugal superchargers: These resemble a turbocharger at a glance but, instead of an exhaust-driven turbine, they have a compact and powerful electric motor assembly driving the compressor wheel. This is the type used in the Audi SQ7 and, so far, it appears to be the preferable design.

Electrically driven Roots-style superchargers: Many early efforts involved converting conventional engine-driven Roots blowers to electric superchargers. They were often heavy, complicated and inefficient, and their appeal was limited as a result. That said, electrically assisted units - which retain an engine-driven pulley - have been developed. These offer improved response, reduced losses and other useful features. Some compact units have also been developed for fuel cells, where a compressor is needed to pump air through the fuel cell stack.

Are these the same as electric turbochargers?

Turbochargers, by their nature, are driven by exhaust gases - so a compressor that is driven by mechanical or electrical means cannot be anything other than a type of supercharger.

Consequently, the term 'electric turbocharger' is incorrect. It is routinely the case that the method of forced induction being referred to is actually an electrically driven centrifugal supercharger which can resemble a turbocharger.

That said, electrically assisted turbochargers do exist. These feature an inbuilt electric motor that can be used to spool the turbocharger, or to recover energy to improve efficiency.

Recent examples of electric supercharging

Audi's SQ7 was the first production car to feature an electrically powered compressor. The small compressor unit, which operates from idle to around 1,500rpm, helps get the SQ7 off the line and gets the turbocharging system up to speed quicker. The same system is used in the Bentley Bentayga.

Several other companies, including specialists Federal-Mogul Controlled Power and Aeristech, have also developed electric superchargers for commercial applications - the aim being to supply 'on-demand' supercharging that can reduce fuel consumption and emissions while improving performance.

[/quote]

Go on then, what exactly does this look like?

It fires air through the impeller right?

Two seconds on Google found this:

https://jalopnik.com/this-is-the-difference-betwee...

Looks like an electric motor is placed between the turbine (hot side) and the compressor (cold side) to get the compressor spinning before the exhaust pressure is high enough to spin the turbine in order to reduce turbo lag.

An electric supercharger may in a "dual-charged" system assist a conventional turbocharger by "firing compressed air" into the compressor..

I'm just not confident the article is really clear.

I believe that all turbo-hybrid era F1 engines and the late Porsche 919 use the electrically assisted turbocharger format.

The motor/generator doesn't always have to be located between compressor and turbine and I believe one of Merc's advantages was locating their motor outside.

Also due to packaging I think all teams mount the turbocharger within the v of the engine, adding to heat issues.

Gassing Station | General Gassing | Top of Page | What's New | My Stuff